Evaluation of Different Compatibilization Strategies to Improve the Performance of Injection-Molded Green Composite Pieces Made of Polylactide Reinforced with Short Flaxseed Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

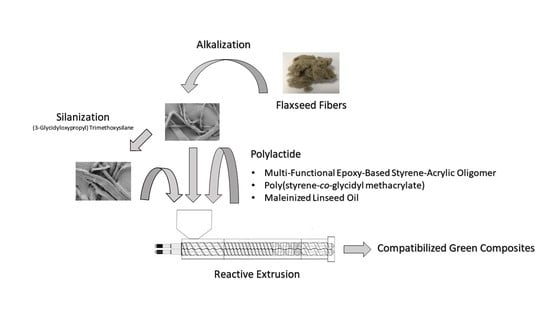

2.2. Pretreatment of the Flaxseed Fibers

2.3. Reactive Extrusion of the Green Composites

2.4. Injection Molding of the Green Composites

2.5. Characterization of the Green Composite Pieces

2.5.1. Microscopy

2.5.2. Mechanical Tests

2.5.3. Thermal Tests

2.5.4. Thermomechanical Tests

3. Results and Discussion

3.1. Morphology of the Flaxseed Fibers

3.2. Mechanical Properties of the Green Composite Pieces

3.3. Morphology of the Green Composite Pieces

3.4. Thermal Properties of the Green Composite Pieces

3.5. Thermomechanical Properties of the Green Composite Pieces

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Garkhail, S.K.; Heijenrath, R.W.H.; Peijs, T. Mechanical properties of natural-fibre-mat-reinforced thermoplastics based on flax fibres and polypropylene. Appl. Compos. Mater. 2000, 7, 351–372. [Google Scholar] [CrossRef]

- Khandelwal, V.; Sahoo, S.K.; Kumar, A.; Manik, G. Electrically conductive green composites based on epoxidized linseed oil and polyaniline: An insight into electrical, thermal and mechanical properties. Compos. Part B Eng. 2018, 136, 149–157. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Jha, K.; Kataria, R.; Verma, J.; Pradhan, S. Potential biodegradable matrices and fiber treatment for green composites: A review. AIMS Mater. Sci. 2019, 6, 119–138. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Wibowo, A.; Misra, M.; Drzal, L.T. Effect of process engineering on the performance of natural fiber reinforced cellulose acetate biocomposites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 363–370. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Almasi, H. Biodegradable polymers. In Biodegradation-Life of Science; InTech Publications: Rijeka, Croatia, 2013; pp. 141–186. [Google Scholar]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Corrado, A.; Polini, W. Measurement of high flexibility components in composite material by touch probe and force sensing resistors. J. Manuf. Process. 2019, 45, 520–531. [Google Scholar] [CrossRef]

- Chen, J.; Gao, X. Directional dependence of electrical and thermal properties in graphene-nanoplatelet-based composite materials. Results Phys. 2019, 15, 102608. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng. Sci. Technol. Int. J. 2016, 19, 717–736. [Google Scholar] [CrossRef] [Green Version]

- Eichhorn, S.J.; Baillie, C.A.; Zafeiropoulos, N.; Mwaikambo, L.Y.; Ansell, M.P.; Dufresne, A.; Entwistle, K.M.; Herrera-Franco, P.J.; Escamilla, G.C.; Groom, L.; et al. Review: Current international research into cellulosic fibres and composites. J. Mater. Sci. 2001, 36, 2107–2131. [Google Scholar] [CrossRef]

- Harada, J.; de Souza, A.G.; de Macedo, J.R.; Rosa, D.S. Soil culture: Influence of different natural fillers incorporated in biodegradable mulching film. J. Mol. Liq. 2019, 273, 33–36. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Liu, W.; Misra, M.; Askeland, P.; Drzal, L.T.; Mohanty, A.K. ‘Green’ composites from soy based plastic and pineapple leaf fiber: Fabrication and properties evaluation. Polymer 2005, 46, 2710–2721. [Google Scholar] [CrossRef]

- Hoffmann, R.; Morais, D.; Braz, C.; Haag, K.; Wellen, R.; Canedo, E.; de Carvalho, L.; Koschek, K. Impact of the natural filler babassu on the processing and properties of PBAT/PHB films. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105472. [Google Scholar] [CrossRef]

- Kapatel, P.M. Investigation of green composite: Preparation and characterization of alkali-treated jute fabric-reinforced polymer matrix composites. J. Nat. Fibers 2019. [Google Scholar] [CrossRef]

- Srivastava, K.R.; Singh, M.K.; Mishra, P.K.; Srivastava, P. Pretreatment of banana pseudostem fibre for green composite packaging film preparation with polyvinyl alcohol. J. Polym. Res. 2019, 26, 95. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Lagaron, J.M.; Balart, R.; Torres-Giner, S. On the use of acrylated epoxidized soybean oil as a reactive compatibilizer in injection-molded compostable pieces consisting of polylactide filled with orange peel flour. Polym. Int. 2018, 67, 1341–1351. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Hilliou, L.; Melendez-Rodriguez, B.; Figueroa-Lopez, K.J.; Madalena, D.; Cabedo, L.; Covas, J.A.; Vicente, A.A.; Lagaron, J.M. Melt processability, characterization, and antibacterial activity of compression-molded green composite sheets made of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) reinforced with coconut fibers impregnated with oregano essential oil. Food Packag. Shelf Life 2018, 17, 39–49. [Google Scholar] [CrossRef] [Green Version]

- Melendez-Rodriguez, B.; Torres-Giner, S.; Aldureid, A.; Cabedo, L.; Lagaron, J.M. Reactive melt mixing of poly(3-hydroxybutyrate)/rice husk flour composites with purified biosustainably produced poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Materials 2019, 12, 2152. [Google Scholar] [CrossRef] [Green Version]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crops Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Montava-Jordà, S.; Quiles-Carrillo, L.; Richart, N.; Torres-Giner, S.; Montanes, N. Enhanced interfacial adhesion of polylactide/poly(ε-caprolactone)/walnut shell flour composites by reactive extrusion with maleinized linseed oil. Polymers 2019, 11, 758. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brett, C.T.; Waldron, K.W. Physiology and Biochemistry of Plant Cell Walls; Chapman & Hall: London, UK, 1996; Volume 2. [Google Scholar]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 6, 1437–1447. [Google Scholar] [CrossRef]

- Bos, H.L.; Donald, A.M. In situ ESEM study of the deformation of elementary flax fibres. J. Mater. Sci. 1999, 34, 3029–3034. [Google Scholar] [CrossRef]

- Wang, H.H.; Drummond, J.G.; Reath, S.M.; Hunt, K.; Watson, P.A. An improved fibril angle measurement method for wood fibers. Wood Sci. Technol. 2001, 34, 493–503. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Lopresti, F. Physical properties of green composites based on poly-lactic acid or Mater-Bi® filled with Posidonia Oceanica leaves. Compos. Part A Appl. Sci. Manuf. 2018, 112, 315–327. [Google Scholar] [CrossRef]

- Hughes, M.; Carpenter, J.; Hill, C. Deformation and fracture behaviour of flax fibre reinforced thermosetting polymer matrix composites. J. Mater. Sci. 2007, 42, 2499–2511. [Google Scholar] [CrossRef]

- Garkhail, S.K.; Heijenrath, R.W.H.; Peijs, T. Natural-fibre-mat-reinforced thermoplastic composites based on flax fibres and polypropylene. Appl. Compos. Mater. 1996, 7, 351–372. [Google Scholar] [CrossRef]

- Diederichsen, A.; Raney, J.P. Seed colour, seed weight and seed oil content in Linum usitatissimum accessions held by Plant Gene Resources of Canada. Plant Breed. 2006, 125, 372–377. [Google Scholar] [CrossRef]

- FAOSTAT. Flax and Linseed Crops; FAOSTAT: Roma, Italy, 2017. [Google Scholar]

- Sharma, H.S.S.; Faughey, G.; Lyons, G. Comparison of physical, chemical, and thermal characteristics of water-, dew-, and enzyme-retted flax fibers. J. Appl. Polym. Sci. 1999, 74, 139–143. [Google Scholar] [CrossRef]

- Charlet, K.; Jernot, J.P.; Gomina, M.; Bréard, J.; Morvan, C.; Baley, C. Influence of an Agatha flax fibre location in a stem on its mechanical, chemical and morphological properties. Compos. Sci. Technol. 2009, 69, 1399–1403. [Google Scholar] [CrossRef]

- Maity, S.; Gon, D.P.; Paul, P. A review of flax nonwovens: Manufacturing, properties, and applications. J. Nat. Fibers 2014, 11, 365–390. [Google Scholar] [CrossRef]

- Hearle, J.W.; Morton, W.E. Physical Properties of Textile Fibres; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-González, A. Mechanical properties of continuous natural fibre-reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 339–345. [Google Scholar] [CrossRef]

- Muñoz-Vélez, M.F.; Hidalgo-Salazar, M.A.; Mina-Hernández, J.H. Fique fiber an alternative for reinforced plastics. Influence of sorface modification. Biotecnol. Sect. Agropecu. Agroind. 2014, 12, 60–70. [Google Scholar]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites. Compos. Sci. Technol. 1999, 30, 309–320. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, F.; Guo, H.; Yang, Y.; Du, Y.; Liang, J.; Zhang, F. Effect of coupling agent on surface free energy of organic modified attapulgite (OAT) powders and tensile strength of OAT/ethylene-propylene-diene monomer rubber nanocomposites. Powder Technol. 2015, 270, 92–97. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, F.; Liu, X.; Tang, M.; Zeng, Z.; Liang, J.; Guan, X.; Wang, J.; Mu, X. Surface modified palygorskite nanofibers and their applications as reinforcement phase in cis-polybutadiene rubber nanocomposites. Appl. Clay Sci. 2016, 132, 175–181. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Montanes, N.; Fenollar, O.; García-Sanoguera, D.; Balart, R. Development and optimization of renewable vinyl plastisol/wood flour composites exposed to ultraviolet radiation. Mater. Des. 2016, 108, 648–658. [Google Scholar] [CrossRef]

- Pothan, L.A.; Thomas, S. Polarity parameters and dynamic mechanical behaviour of chemically modified banana fiber reinforced polyester composites. Compos. Sci. Technol. 2003, 63, 1231–1240. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Chemical modification of henequén fibers with an organosilane coupling agent. Compos. Part B Eng. 1998, 30, 321–331. [Google Scholar] [CrossRef]

- España, J.M.; Samper, M.D.; Fages, E.; Sánchez-Nácher, L.; Balart, R. Investigation of the effect of different silane coupling agents on mechanical performance of basalt fiber composite laminates with biobased epoxy matrices. Polym. Compos. 2013, 34, 376–381. [Google Scholar] [CrossRef]

- García-García, D.; Carbonell, A.; Samper, M.D.; García-Sanoguera, D.; Balart, R. Green composites based on polypropylene matrix and hydrophobized spend coffee ground (SCG) powder. Compos. Part B Eng. 2015, 78, 256–265. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Effect of maleated compatibilizer on performance of PLA/Wheat straw-based green composites. Macromol. Mater. Eng. 2011, 296, 710–718. [Google Scholar] [CrossRef]

- Jorda, M.; Montava-Jorda, S.; Balart, R.; Lascano, D.; Montanes, N.; Quiles-Carrillo, L. Functionalization of Partially Bio-Based Poly(Ethylene Terephthalate) by Blending with Fully Bio-Based Poly(Amide) 10,10 and a Glycidyl Methacrylate-Based Compatibilizer. Polymers 2019, 11, 1331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jaszkiewicz, A.; Meljon, A.; Bledzki, A. Bledzki. mechanical and thermomechanical properties of PLA/man-made cellulose green composites modified with functional chain extenders—A comprehensive study. Polym. Compos. 2018, 39, 1716–1723. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Bernardi, L.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Balart, R. Development of environmentally friendly composite matrices from epoxidized cottonseed oil. Eur. Polym. J. 2015, 63, 1–10. [Google Scholar] [CrossRef]

- Agüero, Á.; Lascano, D.; Garcia-Sanoguera, D.; Fenollar, O.; Torres-Giner, S. Valorization of linen processing by-products for the development of injection-molded green composite pieces of polylactide with improved performance. Sustainability 2020, 12, 652. [Google Scholar] [CrossRef] [Green Version]

- Quiles-Carrillo, L.; Montanes, N.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Balart, R.; Torres-Giner, S. Effect of different compatibilizers on injection-molded green composite pieces based on polylactide filled with almond shell flour. Compos. Part B Eng. 2018, 147, 76–85. [Google Scholar] [CrossRef]

- Sever, K.; Sarikanat, M.; Seki, Y.; Erkan, G.; Erdoğan, Ü.H. The mechanical properties of γ-methacryloxypropyltrimethoxy silane-treated jute/polyester composites. J. Compos. Mater. 2010, 44, 1913–1924. [Google Scholar] [CrossRef]

- Aguero, A.; Quiles-Carrillo, L.; Jorda-Vilaplana, A.; Fenollar, O.; Montanes, N. Effect of different compatibilizers on environmentally friendly composites from poly(lactic acid) and diatomaceous earth. Polym. Int. 2019, 68, 893–903. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Boronat, T.; Montanes, N.; Balart, R.; Torres-Giner, S. Injection-molded parts of fully bio-based polyamide 1010 strengthened with waste derived slate fibers pretreated with glycidyl- and amino-silane coupling agents. Polym. Test. 2019, 77, 105875. [Google Scholar] [CrossRef]

- Samper, M.D.; Petrucci, R.; Sánchez-Nacher, L.; Balart, R.; Kenny, J.M. Effect of silane coupling agents on basalt fiber-epoxidized vegetable oil matrix composite materials analyzed by the single fiber fragmentation technique. Polym. Compos. 2015, 36, 1205–1212. [Google Scholar] [CrossRef] [Green Version]

- Torres-Giner, S.; Montanes, N.; Boronat, T.; Quiles-Carrillo, L.; Balart, R. Melt grafting of sepiolite nanoclay onto poly(3-hydroxybutyrate-co-4-hydroxybutyrate) by reactive extrusion with multi-functional epoxy-based styrene-acrylic oligomer. Eur. Polym. J. 2016, 84, 693–707. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Montanes, N.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil as biobased plasticizer in poly(lactic acid)-based formulations. Polym. Int. 2017, 66, 882–891. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Gimeno-Alcañiz, J.V.; Ocio, M.J.; Lagaron, J.M. Optimization of electrospun polylactide-based ultrathin fibers for osteoconductive bone scaffolds. J. Appl. Polym. Sci. 2011, 122, 914–925. [Google Scholar] [CrossRef]

- Foulk, J.A.; Akin, D.E.; Dodd, R.B. Harvesting and processing of flax in the USA. In Recent Progress in Medicinal Plants; Studium Press, LLC: Houston, TX, USA, 2006; p. 15. [Google Scholar]

- Foulk, J.; Akin, D.; Dodd, R.; Ulven, C. Production of Flax Fibers for Biocomposites. In Cellulose Fibers: Bio- and Nano-Polymers Composites; Springer-Verlag Berlin Heidelberg: Heidelberg, Germany, 2011; pp. 61–95. [Google Scholar]

- Bos, H.L.; Müssig, J.; van den Oever, M.J.A. Mechanical properties of short-flax-fibre reinforced compounds. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1591–1604. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K. Characterization of alkali-treated jute fibers for physical and mechanical properties. J. Appl. Polym. Sci. 2000, 80, 1013–2001. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated coupling agents for natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, Q.; McNabb, H.S. Chemical coupling in wood fiber and polymer composites: A review of coupling agents and treatments. Wood Fiber Sci. 2000, 32, 88–104. [Google Scholar]

- Lu, J.Z.; Wu, Q.; Negulescu, I.I. The influence of maleation on polymer adsorption and fixation, wood surface wettability, and interfacial bonding strength in wood-PVC composites. Wood Fiber Sci. 2002, 34, 434–459. [Google Scholar]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.R. Effect of Alkali and silane treatments on mechanical and fibre-matrix bond strength of kenaf and pineapple leaf fibres. J. Bionic Eng. 2016, 13, 426–435. [Google Scholar] [CrossRef]

- Lopattananon, N.; Panawarangkul, K.; Sahakaro, K.; Ellis, B. Performance of pineapple leaf fiber–natural rubber composites: The effect of fiber surface treatments. J. Appl. Polym. Sci. 2006, 102, 1974–1984. [Google Scholar] [CrossRef]

- Puglia, D.; Monti, M.; Santulli, C.; Sarasini, F.; De Rosa, I.M.; Kenny, J.M. Effect of alkali and silane treatments on mechanical and thermal behavior of Phormium tenax fibers. Fibers Polym. 2013, 14, 423–427. [Google Scholar] [CrossRef]

- Jaszkiewicz, A.; Bledzki, A.K.; van der Meer, R.; Franciszczak, P.; Meljon, A. How does a chain-extended polylactide behave?: A comprehensive analysis of the material, structural and mechanical properties. Polym. Bull. 2014, 71, 1675–1690. [Google Scholar] [CrossRef] [Green Version]

- Anakabe, J.; Zaldua Huici, A.M.; Eceiza, A.; Arbelaiz, A. The effect of the addition of poly(styrene-co-glycidyl methacrylate) copolymer on the properties of polylactide/poly(methyl methacrylate) blend. J. Appl. Polym. Sci. 2016, 133, 43935. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, M.; Zhang, H.; Zhang, X. Polylactide toughening with epoxy-functionalized grafted acrylonitrile-butadiene-styrene particles. J. Appl. Polym. Sci. 2011, 122, 2992–2999. [Google Scholar] [CrossRef]

- Battegazzore, D.; Abt, T.; Maspoch, M.L.; Frache, A. Multilayer cotton fabric bio-composites based on PLA and PHB copolymer for industrial load carrying applications. Compos. Part B Eng. 2019, 163, 761–768. [Google Scholar] [CrossRef]

- Battegazzore, D.; Frache, A.; Abt, T.; Maspoch, M.L. Epoxy coupling agent for PLA and PHB copolymer-based cotton fabric bio-composites. Compos. Part B Eng. 2018, 148, 188–197. [Google Scholar] [CrossRef]

- Bocqué, M.; Voirin, C.; Lapinte, V.; Caillol, S.; Robin, J.-J. Petro-based and bio-based plasticizers: Chemical structures to plasticizing properties. J. Polym. Sci. Part A Polym. Chem. 2016, 54, 11–33. [Google Scholar] [CrossRef]

- Nor Azowa, I.; Kamarul Arifin, H.; Abdan, K. Effect of fiber treatment on mechanical properties of kenaf fiber-ecoflex composites. J. Reinf. Plast. Compos. 2009, 29, 2192–2198. [Google Scholar] [CrossRef]

- Móczó, J.; Pukánszky, B. Polymer micro and nanocomposites: Structure, interactions, properties. J. Ind. Eng. Chem. 2008, 14, 535–563. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Fatigue behavior and modeling of short fiber reinforced polymer composites: A literature review. Int. J. Fatigue 2015, 70, 297–321. [Google Scholar] [CrossRef]

- Lourdin, D.; Bizot, H.; Colonna, P. ‘‘Antiplasticization’’ in starch-glycerol films? J. Appl. Polym. Sci. 1997, 63, 1047–1053. [Google Scholar] [CrossRef]

- Rizzuto, M.; Mugica, A.; Zubitur, M.; Caretti, D.; Müller, A.J. Plasticization and anti-plasticization effects caused by poly(lactide-ran-caprolactone) addition to double crystalline poly(l-lactide)/poly(ε-caprolactone) blends. CrystEngComm 2016, 18, 2014–2023. [Google Scholar] [CrossRef]

- Sanyang, M.; Sapuan, S.; Jawaid, M.; Ishak, M.; Sahari, J. Effect of plasticizer type and concentration on tensile, thermal and barrier properties of biodegradable films based on sugar palm (Arenga pinnata) Starch. Polymers 2015, 7, 1106–1124. [Google Scholar] [CrossRef]

- Cacciotti, I.; Mori, S.; Cherubini, V.; Nanni, F. Eco-sustainable systems based on poly(lactic acid), diatomite and coffee grounds extract for food packaging. Int. J. Biol. Macromol. 2018, 112, 567–575. [Google Scholar] [CrossRef] [Green Version]

- Perinović, S.; Andričić, B.; Erceg, M. Thermal properties of poly(l-lactide)/olive stone flour composites. Thermochim. Acta 2010, 510, 97–102. [Google Scholar] [CrossRef]

- Pilla, S.; Gong, S.; O’Neill, E.; Rowell, R.M.; Krzysik, A.M. Polylactide-pine wood flour composites. Polym. Eng. Sci. 2008, 48, 578–587. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Y.; Zhao, C. Morphology and properties of PET/PA-6/E-44 blends. J. Appl. Polym. Sci. 1998, 69, 1505–1515. [Google Scholar] [CrossRef]

- Corre, Y.-M.; Duchet, J.; Reignier, J.; Maazouz, A. Melt strengthening of poly(lactic acid) through reactive extrusion with epoxy-functionalized chains. Rheol. Acta 2011, 50, 613–629. [Google Scholar] [CrossRef]

- Ojijo, V.; Ray, S.S. Super toughened biodegradable polylactide blends with non-linear copolymer interfacial architecture obtained via facile in-situ reactive compatibilization. Polymer 2015, 80, 1–17. [Google Scholar] [CrossRef]

- Mansaray, K.G.; Ghaly, A.E. Thermogravimetric analysis of rice husks in an air atmosphere. Energy Sources 2007, 20, 653–663. [Google Scholar] [CrossRef]

- Wielage, B.; Lampke, T.; Marx, G.; Nestler, K.; Starke, D. Thermogravimetric and differential scanning calorimetric analysis of natural fibres and polypropylene. Thermochim. Acta 1999, 337, 169–177. [Google Scholar] [CrossRef]

- Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A.; Perejón, A.; Criado, J.A. Generalized kinetic master plots for the thermal degradation of polymers following a random scission mechanism. J. Phys. Chem. A 2010, 114, 7868–7876. [Google Scholar] [CrossRef] [Green Version]

- Zhan, J.; Song, L.; Nie, S.; Hu, Y. Combustion properties and thermal degradation behavior of polylactide with an effective intumescent flame retardant. Polym. Degrad. Stabil. 2009, 94, 291–296. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Parija, S.; Nayak, S.K.; Tripathy, S.S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

| Sample | PLA (wt %) | FF (wt %) | Fiber Pretreatment | Compatibilizer (phr) |

|---|---|---|---|---|

| PLA | 100 | 0 | - | - |

| PLA/FF | 80 | 20 | Alkalization | - |

| PLA/FF + GPTMS | 80 | 20 | Alkalization + Silanization | - |

| PLA/FF + ESAO | 80 | 20 | Alkalization | 1 |

| PLA/FF + PS-co-GMA | 80 | 20 | Alkalization | 1 |

| PLA/FF + MLO | 80 | 20 | Alkalization | 5 |

| Piece | Tensile Test | Impact Strength (kJ/m2) | Shore D Hardness | ||

|---|---|---|---|---|---|

| E (MPa) | σy (MPa) | εb (%) | |||

| PLA | 1194.2 ± 27.4 | 64.7 ± 1.2 | 8.1 ± 0.5 | 34.5 ± 2.7 | 75.8 ± 0.9 |

| PLA/FF | 1749.9 ± 32.9 | 39.1 ± 5.8 | 3.4 ± 0.2 | 5.8 ± 0.4 | 79.5 ± 1.4 |

| PLA/FF + GPTMS | 1676.9 ± 45.7 | 57.9 ± 4.9 | 5.7 ± 0.9 | 21.9 ± 2.1 | 83.1 ± 0.7 |

| PLA/FF + ESAO | 1685.1 ± 27.6 | 65.2 ± 4.1 | 6.8 ± 1.1 | 24.1 ± 2.7 | 83.2 ± 0.7 |

| PLA/FF + PS-co-GMA | 1719.7 ± 33.8 | 61.8 ± 5.2 | 5.8 ± 0.8 | 21.3 ± 3.7 | 78.8 ± 0.8 |

| PLA/FF + MLO | 1192.7 ± 41.4 | 24.8 ± 5.5 | 10.7 ± 1.1 | 20.4 ± 3.8 | 76.2 ± 0.9 |

| Piece | (°C) | (°C) | (°C) | |||

|---|---|---|---|---|---|---|

| PLA | 67.3 ± 0.1 | 114.7 ± 0.5 | 167.7 ± 0.6/174.1 ± 0.4 | 28.61 ± 0.2 | 33.13 ± 0.2 | 4.86 ± 0.4 |

| PLA/FF | 67.0 ± 0.3 | 109.0 ± 0.4 | 154.3 ± 0.5/ 164.9 ± 0.4 | 19.50 ± 0.4 | 22.47 ± 0.2 | 3.99 ± 0.2 |

| PLA/FF + GPTMS | 64.7 ± 0.4 | 110.3 ± 0.4 | 151.3 ± 0.6 | 15.55 ± 0.5 | 19.88 ± 0.4 | 5.81 ± 0.5 |

| PLA/FF + ESAO | 64.0 ± 0.4 | 111.7 ± 0.6 | 151.0 ± 0.7 | 13.88 ± 0.6 | 17.48 ± 0.6 | 4.89 ± 0.3 |

| PLA/FF + PS-co-GMA | 64.3 ± 0.6 | 118.3 ± 0.2 | 153.2 ± 0.4 | 13.47 ± 0.4 | 18.32 ± 0.5 | 6.58 ± 0.4 |

| PLA/FF + MLO | 61.7 ± 0.2 | 124.5 ± 0.4 | 152.3 ± 0.4 | 10.48 ± 0.6 | 13.97 ± 0.4 | 4.92 ± 0.4 |

| Piece | T5% (°C) | Tdeg1 (°C) | Tdeg2 (°C) | Residual Mass (%) |

|---|---|---|---|---|

| FF | 255.3 ± 0.4 | 316.6 ± 0.4 | 419.8 ± 0.9 | 20.6 ± 0.2 |

| PLA | 334.2 ± 0.7 | 373.3 ± 0.4 | 410.3 ± 1.1 | 1.5 ± 0.3 |

| PLA/FF | 279.1 ± 0.6 | 340.6 ± 0.7 | 368.4 ± 1.1 | 3.4 ± 0.3 |

| PLA/FF + GPTMS | 337.7 ± 0.4 | 375.8 ± 1.1 | 411.6 ± 0.8 | 4.2 ± 0.4 |

| PLA/FF + ESAO | 332.2 ± 0.3 | 381.2 ± 0.9 | 412.7 ± 0.9 | 4.1 ± 0.3 |

| PLA/FF + PS-co-GMA | 331.6 ± 0.9 | 383.9 ± 1.2 | 411.2 ± 1.3 | 4.4 ± 0.2 |

| PLA/FF + MLO | 337.6 ± 0.5 | 381.7 ± 0.8 | 409.6 ± 1.2 | 3.6 ± 0.5 |

| Piece | Tg (°C) | G′ (MPa) | ||

|---|---|---|---|---|

| 40 °C | 75 °C | 110 °C | ||

| PLA | 68.4 ± 1.3 | 566.5 ± 8.2 | 2.2 ± 0.7 | 47.7 ± 0.5 |

| PLA/FF | 63.8 ± 0.8 | 1080.3 ± 9.5 | 13.1 ± 0.5 | 154.6 ± 0.5 |

| PLA/FF + GPTMS | 63.1 ± 1.1 | 2908.8 ± 7.8 | 26.7 ± 0.7 | 293.8 ± 0.7 |

| PLA/FF + ESAO | 64.2 ± 1.2 | 1683.7 ± 7.3 | 11.9 ± 0.8 | 141.7 ± 0.5 |

| PLA/FF + PS-co-GMA | 63.4 ± 0.6 | 2293.4 ± 6.4 | 13.9 ± 0.8 | 214.2 ± 0.6 |

| PLA/FF + MLO | 60.8 ± 0.9 | 1437.6 ± 9.1 | 11.2 ± 0.7 | 63.6 ± 0.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agüero, Á.; Garcia-Sanoguera, D.; Lascano, D.; Rojas-Lema, S.; Ivorra-Martinez, J.; Fenollar, O.; Torres-Giner, S. Evaluation of Different Compatibilization Strategies to Improve the Performance of Injection-Molded Green Composite Pieces Made of Polylactide Reinforced with Short Flaxseed Fibers. Polymers 2020, 12, 821. https://doi.org/10.3390/polym12040821

Agüero Á, Garcia-Sanoguera D, Lascano D, Rojas-Lema S, Ivorra-Martinez J, Fenollar O, Torres-Giner S. Evaluation of Different Compatibilization Strategies to Improve the Performance of Injection-Molded Green Composite Pieces Made of Polylactide Reinforced with Short Flaxseed Fibers. Polymers. 2020; 12(4):821. https://doi.org/10.3390/polym12040821

Chicago/Turabian StyleAgüero, Ángel, David Garcia-Sanoguera, Diego Lascano, Sandra Rojas-Lema, Juan Ivorra-Martinez, Octavio Fenollar, and Sergio Torres-Giner. 2020. "Evaluation of Different Compatibilization Strategies to Improve the Performance of Injection-Molded Green Composite Pieces Made of Polylactide Reinforced with Short Flaxseed Fibers" Polymers 12, no. 4: 821. https://doi.org/10.3390/polym12040821

APA StyleAgüero, Á., Garcia-Sanoguera, D., Lascano, D., Rojas-Lema, S., Ivorra-Martinez, J., Fenollar, O., & Torres-Giner, S. (2020). Evaluation of Different Compatibilization Strategies to Improve the Performance of Injection-Molded Green Composite Pieces Made of Polylactide Reinforced with Short Flaxseed Fibers. Polymers, 12(4), 821. https://doi.org/10.3390/polym12040821