Mechanical and Thermal Characterization of Natural Intralaminar Hybrid Composites Based on Sisal

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials

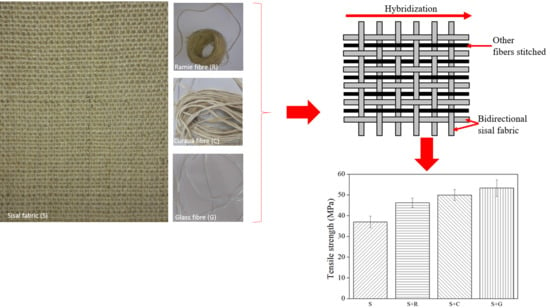

2.2. Hybrid Fabric Production

2.3. Composite Manufacture

2.4. Test Methods

2.4.1. Tensile Test

2.4.2. Flexural Test

2.4.3. Impact Test

2.4.4. Scanning Electron Microscopy (SEM) Analysis

2.4.5. Thermogravimetric Analysis (TGA)

2.4.6. Differential Scanning Calorimetry (DSC)

3. Experimental Results and Discussion

3.1. Mechanical Characterization

3.1.1. Tensile Test

3.1.2. Flexural Test

3.1.3. Impact Test

3.1.4. SEM Analysis

3.2. Thermal Analysis

3.2.1. Thermogravimetric Analysis (TGA)

3.2.2. DSC

4. Conclusions

- The hybridization process improved the tensile properties of the non-hybrid sisal fiber based composites. For S+C and S+G composites, the increase in tensile strength was by 34.98% and 43.99%, respectively, compared to non-hybrid sisal composites, while for S+R composite the improvement in strength was by approximately 24.83%. The Young’s modulus increased for S+R (by approximately 14.01%), S+C (by approximately 32.14%) and S+G (by approximately 50.00%) composites when compared to the non-hybrid sisal composites.

- The flexural strength and modulus of the hybrid composites were also affected by the incorporation of fibers. S+C and S+G composites had a flexural strength increase of approximately 51.63% and 58.54%, respectively, compared to non-hybrid sisal composites, while for S+R composite the increase in flexural strength was by approximately 37.81%. The best flexural modulus was found for the S+G composite (an increase by approximately 63.31% compared to non-hybrid sisal composites).

- The hybridization improved the impact properties for S+C (an increase of approximately 47.28%) and S+G composites (an increase of approximately 50.90%), while the impact resistance of S+R had an insignificant increase (approximately 2.59%) when compared to non-hybrid sisal composites.

- The SEM analysis showed a brittle fracture of the epoxy matrix and fibers breakage near the matrix.

- The DTG curves showed two main stages of decomposition: a first stage with a slight mass loss in the range of 30–150 °C due to the removal of the moisture from the composites and a second stage, which occurs between 240 and 420 °C due to the pyrolysis process. The major degradation peak appears from the DTG plots to occur at around 337 °C for all composites. This shows that the hybridization did not affected the thermal stability of the composites.

- The DSC analysis showed that the S+R and S+C composites presented a slightly lower endothermic peak value compared to non-hybrid S.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- de Queiroz, H.; Banea, M.D.; Cavalcanti, D. Experimental analysis of adhesively bonded joints in synthetic-and natural fibre-reinforced polymer composites. J. Compos. Mater. 2020, 54, 1245–1255. [Google Scholar] [CrossRef]

- Dong, C. Review of natural fibre-reinforced hybrid composites. J. Reinf. Plast. Compos. 2018, 37, 331–348. [Google Scholar] [CrossRef] [Green Version]

- Sahu, P.; Gupta, M. Sisal (Agave sisalana) fibre and its polymer-based composites: A review on current developments. J. Reinf. Plast. Compos. 2017, 36, 1759–1780. [Google Scholar] [CrossRef]

- Feng, Y.; Shen, H.; Qu, J.; Liu, B.; He, H.; Han, L. Preparation and properties of PBS/sisal-fiber composites. Polym. Eng. Sci. 2011, 51, 474–481. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Ramzy, A.; Beermann, D.; Steuernagel, L.; Meiners, D.; Ziegmann, G. Developing a new generation of sisal composite fibres for use in industrial applications. Compos. Part B Eng. 2014, 66, 287–298. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.-W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Zah, R.; Hischier, R.; Leão, A.L.; Braun, I. Curauá fibers in the automobile industry–a sustainability assessment. J. Clean. Prod. 2007, 15, 1032–1040. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Yu, H.N.; Kim, S.S.; Hwang, I.U. Application of natural fiber reinforced composites to trenchless rehabilitation of underground pipes. Compos. Struct. 2008, 86, 285–290. [Google Scholar] [CrossRef]

- Almeida, J.H.S., Jr.; Amico, S.C.; Botelho, E.C.; Amado, F.D.R. Hybridization effect on the mechanical properties of curaua/glass fiber composites. Compos. Part B Eng. 2013, 55, 492–497. [Google Scholar] [CrossRef]

- Ferreira, B.T.; da Silva, L.J.; Panzera, T.H.; Santos, J.C.; Freire, R.T.S.; Scarpa, F. Sisal-glass hybrid composites reinforced with silica microparticles. Polym. Test. 2019, 74, 57–62. [Google Scholar] [CrossRef] [Green Version]

- Zin, M.H.; Abdan, K.; Norizan, M.N. The effect of different fiber loading on flexural and thermal properties of banana/pineapple leaf (PALF)/glass hybrid composite. In Structural Health Monitoring of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–17. [Google Scholar]

- Cavalcanti, D.; Banea, M.D.; Neto, J.; Lima, R.; da Silva, L.F.M.; Carbas, R. Mechanical characterization of intralaminar natural fibre-reinforced hybrid composites. Compos. Part B Eng. 2019, 175, 107149. [Google Scholar] [CrossRef]

- Boopalan, M.; Niranjanaa, M.; Umapathy, M. Study on the mechanical properties and thermal properties of jute and banana fiber reinforced epoxy hybrid composites. Compos. Part B Eng. 2013, 51, 54–57. [Google Scholar] [CrossRef]

- Prasanna Venkatesh, R.; Ramanathan, K.; Srinivasa Raman, V. Tensile, flexual, impact and water absorption properties of natural fibre reinforced polyester hybrid composites. Fibres Text. East. Eur. 2016, 24, 90–94. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Lima, R.; Cavalcanti, D.K.; da Costa, H.M.; Banea, M.D. Effect of surface treatments on interfacial properties of natural intralaminar hybrid composites. Polym. Compos. 2020, 41, 314–325. [Google Scholar] [CrossRef]

- Budhe, S.; de Barros, S.; Banea, M.D. Theoretical assessment of the elastic modulus of natural fiber-based intra-ply hybrid composites. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 263. [Google Scholar] [CrossRef]

- Braga, R.; Magalhaes, P., Jr. Analysis of the mechanical and thermal properties of jute and glass fiber as reinforcement epoxy hybrid composites. Mater. Sci. Eng. C 2015, 56, 269–273. [Google Scholar] [CrossRef] [PubMed]

- Radzi, A.; Sapuan, S.; Jawaid, M.; Mansor, M. Water absorption, thickness swelling and thermal properties of roselle/sugar palm fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 3988–3994. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.; Ishak, M.; Alothman, O.Y. Thermal properties of sugar palm/glass fiber reinforced thermoplastic polyurethane hybrid composites. Compos. Struct. 2018, 202, 954–958. [Google Scholar] [CrossRef]

- Giridharan, R. Preparation and property evaluation of Glass/Ramie fibers reinforced epoxy hybrid composites. Compos. Part B Eng. 2019, 167, 342–345. [Google Scholar] [CrossRef]

- Chen, J.; Zou, Y.; Ge, H.; Cui, Z.; Liu, S. Mechanical and water absorption behaviors of corn stalk/sisal fiber-reinforced hybrid composites. J. Appl. Polym. Sci. 2018, 135, 46405. [Google Scholar] [CrossRef]

- Gupta, M.; Srivastava, R. Tribological and dynamic mechanical analysis of epoxy based hybrid sisal/jute composite. Indian J. Eng. Mater. Sci. 2016, 23, 17–44. [Google Scholar]

- Gupta, M. Thermal and dynamic mechanical analysis of hybrid jute/sisal fibre reinforced epoxy composite. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2018, 232, 743–748. [Google Scholar] [CrossRef]

- Jarukumjorn, K.; Suppakarn, N. Effect of glass fiber hybridization on properties of sisal fiber–polypropylene composites. Compos. Part B Eng. 2009, 40, 623–627. [Google Scholar] [CrossRef]

- Neto, J.; Lima, R.; Cavalcanti, D.; Souza, J.; Aguiar, R.; Banea, M.D. Effect of chemical treatment on the thermal properties of hybrid natural fiber-reinforced composites. J. Appl. Polym. Sci. 2019, 136, 47154. [Google Scholar] [CrossRef]

- ASTM D638: Standard Test Method for Tensile Properties of Plastics; ASTM Int.: West Conshohocken, PA, USA, 2002.

- Sharpe, W.N. Springer Handbook of Experimental Solid Mechanics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- ASTM D790-07: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM Int.: West Conshohocken, PA, USA, 2007.

- ASTM D6110-04: Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics; ASTM Int.: West Conshohocken, PA, USA, 2004.

- ISO 179-1: Plastics―Determination of Charpy Impact Properties; ISO: Geneva, Switzerland, 2010.

- ASTM E1131: Standard Test Method for Compositional Analysis by Thermogravimetry; ASTM Int.: West Conshohocken, PA, USA, 2003.

- ASTM D3418: Standard Test Method for Transition Temperatures of Polymers by Differential Scanning Calorimetry; ASTM Int.: West Conshohocken, PA, USA, 2015.

- Mishra, S.; Mohanty, A.; Drzal, L.; Misra, M.; Parija, S.; Nayak, S.; Tripathy, S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Tomczak, F.; Satyanarayana, K.G.; Sydenstricker, T.H.D. Studies on lignocellulosic fibers of Brazil: Part III–Morphology and properties of Brazilian curauá fibers. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2227–2236. [Google Scholar] [CrossRef]

- Ornaghi, H.L., Jr.; da Silva, H.S.P.; Zattera, A.J.; Amico, S.C. Hybridization effect on the mechanical and dynamic mechanical properties of curaua composites. Mater. Sci. Eng. A 2011, 528, 7285–7289. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Hemachandra Reddy, K. Impact behaviour analysis of Sisal/Jute and Glass fiber reinforced hybrid composites. Adv. Mater. Res. 2014, 984, 266–272. [Google Scholar] [CrossRef]

- Papa, I.; Ricciardi, M.; Antonucci, V.; Pagliarulo, V.; Lopresto, V. Impact behaviour of hybrid basalt/flax twill laminates. Compos. Part B Eng. 2018, 153, 17–25. [Google Scholar] [CrossRef]

- Gañán, P.; Garbizu, S.; Llano-Ponte, R.; Mondragon, I. Surface modification of sisal fibers: Effects on the mechanical and thermal properties of their epoxy composites. Polym. Compos. 2005, 26, 121–124. [Google Scholar] [CrossRef]

- Saw, S.K.; Datta, C. Thermo mechanical properties of jute/bagasse hybrid fibre reinforced epoxy thermoset composites. BioResources 2009, 4, 1455–1475. [Google Scholar]

- Aji, I.; Zainudin, E.; Khalina, A.; Sapuan, S.; Khairul, M. Thermal property determination of hybridized kenaf/PALF reinforced HDPE composite by thermogravimetric analysis. J. Therm. Anal. Calorim. 2011, 109, 893–900. [Google Scholar] [CrossRef]

- Sen, A.; Kumar, S. Coir-fiber-based fire retardant nano filler for epoxy composites. J. Therm. Anal. Calorim. 2010, 101, 265–271. [Google Scholar] [CrossRef]

- Albano, C.; Gonzalez, J.; Ichazo, M.; Kaiser, D. Thermal stability of blends of polyolefins and sisal fiber. Polym. Degrad. Stabil. 1999, 66, 179–190. [Google Scholar] [CrossRef]

- Lee, S.-H.; Wang, S. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. A Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

| Properties | Sisal | Ramie | Curauá |

|---|---|---|---|

| Density (g/cm³) | 1.30 | 1.20 | 1.33 |

| Diameter (µm) | 150 ± 1 | 95 ± 5 | 46 ± 13 |

| Tensile strength (MPa) | 398.48 ± 83.70 | 212.32 ± 7.28 | 1929.8 ± 249.5 |

| Young’s modulus (GPa) | 61.99 ± 25.30 | 30.39 ± 10.80 | 87.23 ± 15.40 |

| Elongation at break (%) | 2.74 ± 0.70 | 2.62 ± 0.20 | 3.94 ± 0.60 |

| Cellulose (wt %) | 67–78 | 68.6–91 | 70.7–73.60 |

| Hemicellulose (wt %) | 10–14 | 5–16.60 | 9.9 |

| Lignin (wt %) | 8–11 | 0.6–0.70 | 7.5–11.10 |

| Composites | Tensile Strength (MPa) | Young’s Modulus (GPa) | Strain (%) |

|---|---|---|---|

| S | 37.05 ± 2.78 | 4.20 ± 0.61 | 2.17 ± 0.27 |

| S+R | 46.25 ± 2.27 | 4.79 ± 0.60 | 2.10 ± 0.29 |

| S+C | 50.01 ± 2.62 | 5.55 ± 1.01 | 2.39 ± 0.14 |

| S+G | 53.35 ± 4.04 | 6.30 ± 1.41 | 2.20 ± 0.36 |

| Composites | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|

| S | 52.1 ± 6.44 | 2.78 ± 0.49 |

| S+R | 71.8 ± 9.80 | 3.91 ± 0.43 |

| S+C | 79.0 ± 0.74 | 4.39 ± 0.71 |

| S+G | 82.6 ± 4.77 | 4.54 ± 0.23 |

| Composites | Impact Resistance (J/m) |

|---|---|

| S | 506.1 ± 69.40 |

| S+R | 519.2 ± 50.26 |

| S+C | 745.4 ± 37.54 |

| S+G | 763.7 ± 46.81 |

| Composite | Endothermic Peak (°C) | Exothermic Peak (°C) |

|---|---|---|

| S | 140.5 | 362.9 |

| S+R | 136.5 | 364.2 |

| S+C | 137.8 | 367.6 |

| S+G | 144.2 | 365.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, A.L.; Banea, M.D.; Neto, J.S.S.; Cavalcanti, D.K.K. Mechanical and Thermal Characterization of Natural Intralaminar Hybrid Composites Based on Sisal. Polymers 2020, 12, 866. https://doi.org/10.3390/polym12040866

Pereira AL, Banea MD, Neto JSS, Cavalcanti DKK. Mechanical and Thermal Characterization of Natural Intralaminar Hybrid Composites Based on Sisal. Polymers. 2020; 12(4):866. https://doi.org/10.3390/polym12040866

Chicago/Turabian StylePereira, Alexandre L., Mariana D. Banea, Jorge S.S. Neto, and Daniel K.K. Cavalcanti. 2020. "Mechanical and Thermal Characterization of Natural Intralaminar Hybrid Composites Based on Sisal" Polymers 12, no. 4: 866. https://doi.org/10.3390/polym12040866

APA StylePereira, A. L., Banea, M. D., Neto, J. S. S., & Cavalcanti, D. K. K. (2020). Mechanical and Thermal Characterization of Natural Intralaminar Hybrid Composites Based on Sisal. Polymers, 12(4), 866. https://doi.org/10.3390/polym12040866