Wood Composites and Their Polymer Binders

Abstract

:1. Introduction

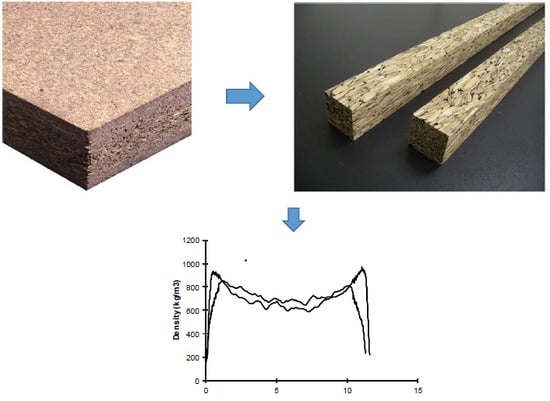

2. Wood, Wood Plasticization and Wood Panels

3. Types of Wood Composites

4. Current Wood Composite Adhesives

4.1. Urea–formaldehyde Adhesives

4.2. Melamine-Formaldehyde and Melamine–Urea–Formaldehyde Adhesives

4.3. Phenol–Formaldehyde Adhesives

4.4. Phenol-Resorcinol-Formaldehyde (PRF) Adhesives

4.5. Polymeric Isocyanates

4.6. One-Component Polyurethanes (PURs)

5. New, Biobased, Renewable and Synthetic Wood Polymeric Adhesives

5.1. Biobased Wood Composite Adhesives

5.2. Other Bioadhesives for Wood Composites

6. New Approaches to Synthetic Adhesives

7. Thermoplastics as Binders for Wood Composites

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pizzi, A. Wood and Fiber Panels Technology. In Lignocellulosic Fibers and Wood Handbook: Renewable Materials for to-Day’s Environment; Belgacem, M.N., A.Pizzi, A., Eds.; Scrivener-Wiley: Beverley, MA, USA, 2017; Chapter 15; pp. 385–406. [Google Scholar]

- Geimer, R.L.; Mahoney, R.J.; Loehnertz, S.P.; Meyer, R.W. Influence of Processing Induced Damage on the Strength of Flakes and Flakeboards; Research Paper FPL 463; USDA Forest Products Laboratory: Madison, WI, USA, 1985. [Google Scholar]

- Maloney, T.M. Modern Particleboard & Dry-Process Fiberboard Manufacturing; Backbeat Books; Rowman & Littlefield: Lanham, MD, USA, 1993. [Google Scholar]

- Mantanis, G.; Athanassiadou, E.; Barbu, M.; Wijnendaele, K. Adhesive systems used in the European particleboard, MDF and OSB industries. Wood Mater. Sci. Eng. 2018, 13, 104–116. [Google Scholar] [CrossRef]

- Pizzi, A. Wood Adhesives Chemistry and Technology; Marcel Dekker: New York, NY, USA, 1983. [Google Scholar]

- Pizzi, A. Urea-formaldehyde adhesives. In Handbook of Adhesive Technology, 2nd ed.; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 2003; Chapter 31; pp. 635–652. [Google Scholar]

- Pizzi, A. Urea and melamine aminoresin adhesives. In Handbook of Adhesive Technology, 3rd ed.; Pizzi, A., Mittal, K.L., Eds.; Taylor and Francis: New York, NY, USA, 2017; Chapter 10; pp. 283–320. [Google Scholar]

- Pizzi, A. Advanced Wood Adhesives Technology; Marcel Dekker: New York, NY, USA, 1994. [Google Scholar]

- Pizzi, A. Melamine-formaldehyde adhesives. In Handbook of Adhesive Technology, 2nd ed.; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 2003; Chapter 32; pp. 653–680. [Google Scholar]

- Pizzi, A. Phenolic resin adhesives. In Handbook of Adhesive Technology, 3rd ed.; Pizzi, A., Mittal, K.L., Eds.; Taylor and Francis: New York, NY, USA, 2017; Chapter 8; pp. 223–262. [Google Scholar]

- Pizzi, A. Phenolic resin adhesives. In Handbook of Adhesive Technology, 2nd ed.; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 2003; Chapter 26; pp. 541–572. [Google Scholar]

- Pizzi, A. Resorcinol adhesives. In Handbook of Adhesive Technology, 2nd ed.; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 2003; Chapter 29; pp. 599–614. [Google Scholar]

- Frazier, C.E. Isocyanate wood binders. In Handbook of Adhesive Technology, 2nd ed.; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 2003; Chapter 33; pp. 681–694. [Google Scholar]

- Lay, D.G.; Cranley, P.; Pizzi, A. Polyurethane adhesives. In Handbook of Adhesive Technology, 3rd ed.; Pizzi, A., Mittal, K.L., Eds.; Taylor and Francis: New York, NY, USA, 2017; Chapter 11; pp. 321–348. [Google Scholar]

- Pizzi, A. Tannin-based wood adhesives. In Wood Adhesives Chemistry and Technology; Pizzi, A., Ed.; Marcel Dekker: New York, NY, USA, 1983; Volume 1, pp. 178–246. [Google Scholar]

- Pizzi, A. Wattle-based adhesives for exterior grade particleboard. For. Prod. J. 1978, 28, 42–47. [Google Scholar]

- Pizzi, A.; Scharfetter, H. The chemistry and development of tannin-based wood adhesives for exterior plywood. J. Appl. Polym. Sci. 1978, 22, 1745–1761. [Google Scholar] [CrossRef]

- Valenzuela, J.; von Leyser, E.; Pizzi, A.; Westermeyer, C.; Gorrini, B. Industrial production of pine tannin-bonded particleboard and MDF. Eur. J. Wood Prod. 2012, 70, 735–740. [Google Scholar] [CrossRef]

- Pizzi, A. Glue blenders effect on particleboard using wattle tannin adhesives. Holzforsch. Holzverwert. 1979, 31, 85–86. [Google Scholar]

- Pizzi, A. Hot-setting tannin-urea-formaldehyde exterior wood adhesives. Adhes. Age 1977, 20, 27–32. [Google Scholar]

- Custers, P.A.J.L.; Rushbrook, R.; Pizzi, A.; Knauff, C.J. Industrial applications of wattle-tannin/urea-formaldehyde fortified starch adhesives for damp-proof corrugated cardboard. Holzforsch. Holzverwert. 1979, 31, 131–132. [Google Scholar]

- Pizzi, A.; Roux, D.G. The chemistry and development of tannin-based weather- and boil-proof cold-setting and fast-setting adhesives for wood. J. Appl. Polym. Sci. 1978, 22, 1945–1954. [Google Scholar] [CrossRef]

- Pizzi, A.; Rossouw, D.D.T.; Knuffel, W.; Singmin, M. “Honeymoon” phenolic and tannin-based fast setting adhesive systems for exterior grade fingerjoints. Holzforsch. Holzverwert. 1980, 32, 140–151. [Google Scholar]

- Pizzi, A.; Cameron, F.A. Fast-set adhesives for glulam. For. Prod. J. 1984, 34, 61–65. [Google Scholar]

- Mansouri, H.R.; Pizzi, A.; Fredon, E. Honeymoon fast-set adhesives for glulam/fingerjoints of higher natural materials content. Eur. J. Wood. Prod. 2009, 67, 207–210. [Google Scholar] [CrossRef]

- Pizzi, A. Phenolic resins by reactions of coordinated metal ligands. J. Polym. Sci. Polym. Lett. 1979, 17, 489–492. [Google Scholar] [CrossRef]

- Pizzi, A. Phenol and tannin-based adhesive resins by reactions of coordinated metal ligands, Part 1: Phenolic chelates. J. Appl. Polym. Sci. 1979, 24, 1247–1255. [Google Scholar] [CrossRef]

- Pizzi, A. Phenol and tannin-based adhesive resins by reactions of coordinated metal ligands, Part II: Tannin adhesives preparation, characteristics and application. J. Appl. Polym. Sci. 1979, 24, 1257–1268. [Google Scholar] [CrossRef]

- von Leyser, E.; Pizzi, A. The formulation and commercialization of glulam pine tannin adhesives in Chile. Holz Roh-und Werkst. 1990, 48, 25–29. [Google Scholar] [CrossRef]

- Pizzi, A.; Walton, T. Non-emulsifiable, water-based diisocyanate adhesives for exterior plywood, Part 1: Novel reaction mechanisms and their chemical evidence. Holzforschung 1992, 46, 541–547. [Google Scholar] [CrossRef]

- Pizzi, A.; Valenzuela, J.; Westermeyer, C. Non-emulsifiables, water-based, diisocyanate adhesives for exterior plywood, Part 2: Industrial application. Holzforschung 1993, 47, 69–72. [Google Scholar] [CrossRef]

- Böhm, R.; Hauptmann, M.; Pizzi, A.; Friederich, C.; Laborie, M.-P. The chemical, kinetic and mechanical characterization of Tannin-based adhesives with different crosslinking systems. Int. J. Adhes. Adhes. 2016, 68, 1–8. [Google Scholar] [CrossRef]

- Santiago-Medina, F.J.; Foyer, G.; Pizzi, A.; Calliol, S.; Delmotte, L. lignin-derived non-toxic aldehydes for ecofriendly tannin adhesives for wood panels. Int. J. Adhes. Adhes. 2016, 70, 239–248. [Google Scholar] [CrossRef]

- Ndiwe, B.; Pizzi, A.; Tibi, B.; Danwe, R.; Konai, N.; Amirou, S. African tree bark exudate extracts as biohardeners of fully biosourced thermoset tannin adhesives for wood panels. Ind. Crops Prod. 2019, 132, 253–268. [Google Scholar] [CrossRef]

- Pizzi, A.; Meikleham, N.; Dombo, B.; Roll, W. Autocondensation-based, zero-emission, tannin adhesives for particleboard. Holz Roh-und Werkst. 1995, 53, 201–204. [Google Scholar] [CrossRef]

- Meikleham, N.; Pizzi, A.; Stephanou, A. Induced accelerated autocondensation of polyflavonoid tannins for phenolic polycondensates, Part 1: 13C NMR, 29Si NMR, X-ray and polarimetry studies and mechanism. J. Appl. Polym. Sci. 1994, 54, 1827–1845. [Google Scholar] [CrossRef]

- Pizzi, A.; Meikleham, N.; Stephanou, N. Induced accelerated autocondensation of polyflavonoid tannins for phenolic polycondensates—Part II: Cellulose effect and application. J. Appl. Polym. Sci. 1995, 55, 929–933. [Google Scholar] [CrossRef]

- Garcia, R.; Pizzi, A.; Merlin, A. Ionic polycondensation effects on the radical autocondensation of polyflavonoid tannins-An ESR study. J. Appl. Polym. Sci. 1997, 65, 2623–2632. [Google Scholar] [CrossRef]

- Garcia, R.; Pizzi, A. Polycondensation and autocondensation networks in polyflavonoid tannins, Part 1: Final networks. J. Appl. Polym. Sci. 1998, 70, 1083–1091. [Google Scholar] [CrossRef]

- Garcia, R.; Pizzi, A. Polycondensation and autocondensation networks in polyflavonoid tannins, Part 2: Polycondensation vs. autocondensation. J. Appl. Polym. Sci. 1998, 70, 1093–1110. [Google Scholar] [CrossRef]

- Garcia, R.; Pizzi, A. Cross-linked and entanglement networks in thermomechanical analysis of polycondensation resins. J. Appl. Polym. Sci. 1998, 70, 1111–1116. [Google Scholar] [CrossRef]

- Pichelin, F.; Nakatani, M.; Pizzi, A.; Wieland, S.; Despres, A.; Rigolet, S. Structural beams from thick wood panels bonded industrially with formaldehyde free tannin adhesives. For. Prod. J. 2006, 56, 31–36. [Google Scholar]

- Kamoun, C.; Pizzi, A. Mechanism of hexamine as a non-aldehyde polycondensation hardener, Part 1: Hexamine decomposition and reactive intermediates. Holzforsch. Holzverwert. 2000, 52, 16–19. [Google Scholar]

- Kamoun, C.; Pizzi, A. Mechanism of hexamine as a non-aldehyde polycondensation hardener, Part 2: Recomposition of intermediate reactive compound. Holzforsch. Holzverwert. 2000, 52, 66–67. [Google Scholar]

- Kamoun, C.; Pizzi, A.; Zanetti, M. Upgrading of MUF resins by buffering additives—Part 1: Hexamine sulphate effect and its limits. J. Appl. Polym. Sci. 2003, 90, 203–214. [Google Scholar] [CrossRef]

- Navarrete, P.; Mansouri, H.R.; Pizzi, A.; Tapin-Lingua, S.; Benjelloun-Mlayah, B.; Rigolet, S. Synthetic-resin-free wood panel adhesives from low molecular mass lignin and tannin. J. Adhes. Sci. Technol. 2010, 24, 1597–1610. [Google Scholar] [CrossRef]

- Ghahri, S.; Pizzi, A.; Mohebby, B.; Mirshoktaie, A.; Mansouri, H.R. Soy-based, tannin-modified plywood adhesives. J. Adhes. 2018, 94, 218–237. [Google Scholar] [CrossRef]

- Abdullah, U.H.B.; Pizzi, A. Tannin-Furfuryl alcohol wood panel adhesives without formaldehyde. Eur. J. Wood Prod. 2013, 71, 131–132. [Google Scholar] [CrossRef]

- Ballerini, A.; Despres, A.; Pizzi, A. Non-toxic, zero-emission tannin-glyoxal adhesives for wood panel. Holz Roh-und Werkst. 2005, 63, 477–478. [Google Scholar] [CrossRef]

- Trosa, A.; Pizzi, A. A no-aldehyde emission hardener for tannin-based wood adhesives. Holz Roh-und Werkst. 2001, 59, 266–271. [Google Scholar] [CrossRef]

- Grigsby, W.J.; McIntosh, C.D.; Warnes, J.M.; Suckling, I.D.; Anderson, C.R. Adhesives. U.S. Patent 7,319,115 B2, 2008. [Google Scholar]

- Trosa, A.; Pizzi, A. Industrial hardboard and other panels binder from tannin/furfuryl alcohol in absence of formaldehyde. Holz Roh-und Werkst. 1998, 56, 213–214. [Google Scholar] [CrossRef]

- Frihart, C.R.; Lorenz, L. Specific oxidants improve the wood bonding strength of soy and other plant flours. J. Polym. Sci. A Polym. Chem. 2019, 57, 1017–1023. [Google Scholar] [CrossRef]

- Frihart, C.R.; Pizzi, A.; Xi, X.; Lorenz, L. Reactions of Soy flour and Soy protein by non-volatile aldehydes generation by specific oxidation. Polymers 2019, 11, 1478. [Google Scholar] [CrossRef] [Green Version]

- Xi, X.; Pizzi, A.; Frihart, C.R.; Lorenz, L.; Gerardin, C. Tannin plywood adhesives by non-volatile aldehydes generation from specific oxidation of mono- and disaccharides. Int. J. Adhes. Adhes. 2020, 98, 102499. [Google Scholar] [CrossRef]

- Nimz, H.H. Lignin-based adhesives. In Wood Adhesives Chemistry and Technology; Pizzi, A., Ed.; Marcel Dekker: New York, NY, USA, 1983; Chapter 5; Volume 1, pp. 247–288. [Google Scholar]

- Blanchet, P.; Cloutier, A.; Riedl, B. Particleboard made from hammer milled black spruce bark residues. Wood Sci. Technol. 2000, 34, 11–19. [Google Scholar] [CrossRef]

- Lopez-Suevos, F.; Riedl, B. Effects of Pinus pinaster bark extracts content on the cure properties of tannin-modified adhesives and on bonding of exterior grade MDF. J. Adhes. Sci. Technol. 2003, 17, 1507–1522. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.-J. Curing behaviour and viscoelastic properties of pine and wattle tannin-based adhesives studied by dynamic mechanical thermal analysis and FT-IR-ATR spectroscopy. J. Adhes. Sci. Technol. 2003, 17, 1369–1384. [Google Scholar] [CrossRef]

- Calvé, L.R. Fast cure and pre-cure resistant cross-linked phenol-formaldehyde adhesives and methods of making same. Canada Patent 2042476, 1999. [Google Scholar]

- Shimatani, K.; Sono, Y.; Sasaya, T. Preparation of moderate-temperature setting adhesives from softwood kraft lignin. Part 2. Effect of some factors on strength properties and characteristics of lignin-based adhesives. Holzforschung 1994, 48, 337–342. [Google Scholar] [CrossRef]

- Gardner, D.; Sellers, T., Jr. Formulation of a lignin-based plywood adhesive from steam-exploded mixed hardwood lignin. For. Prod. J. 1986, 36, 61–67. [Google Scholar]

- Newman, W.H.; Glasser, W.G. Engineering plastics from lignin-XII. Synthesis and performance of lignin adhesives with isocyanate and melamine. Holzforschung 1985, 39, 345–353. [Google Scholar] [CrossRef]

- Azarov, V.I.; Koverniskii, N.N.; Zaitseva, G.V. Izvestjia Vysshikh Uchnykh Zavedenii. Lesnai Zhurna 1985, 5, 81–83. [Google Scholar]

- Viikari, L.; Hase, A.; Quintus-Leina, P.; Kirsi, K.; Tuominen, S.; Gaedda, L. Lignin Based Adhesives and a Process for the Preparation Thereof. European Patent EP 0953029 A1, 1999. [Google Scholar]

- Kharazipour, A.; Haars, A.; Shekholeslami, M.; Hüttermann, A. Enzymgebundene holzwerkstoffe auf der basis von lignin und phenoloxidasen. Adhäsion 1991, 35, 30–36. [Google Scholar]

- Kharazipour, A.; Mai, C.; Hüttermann, A. Polyphenols for compounded materials. Polym. Degrad. Stabil. 1998, 59, 237–243. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Mantanis, G.I.; Neykov, N. Medium-density fibreboards bonded with phenol-formaldehyde resin and calcium lignosulfonate as an eco-friendly additive. Wood Mat. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Calvé, L.R. Phenolic-lignin wood adhesives for plywood. In Proceedings of the 19th IUFRO World Congress, Montreal, QC, Canada, 6–10 August 1990. [Google Scholar]

- Calvé, L.R. Fast Cure and Pre-Cure Resistant Cross-Linked Phenol-Formaldehyde Adhesives and Methods of Making Same. US Patent 5,173,527, 1992. [Google Scholar]

- Valkonen, S. Lignin-based binders: An industrial reality, latest developments. In Proceedings of the International Conference on Wood Adhesives, Atlanta, GA, USA, 25–27 October 2017. [Google Scholar]

- Younesi-Kordkheili, H.; Pizzi, A. Some Properties of Particleboard Panels Bonded with Phenol- Lignin- Glyoxal Resin. J. Adhes. 2019. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Pizzi, A. Properties of plywood panels bonded with ionic liquid-modified lignin–phenol–formaldehyde resin. J. Adhes. 2018, 94, 143–154. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Pizzi, A.; Hornabakhsh-Raouf, A.; Nemati, F. The Effect of Modified Soda Bagasse Lignin by Ionic Liquid on Properties of Urea-Formaldehyde Resin as Wood Adhesive. J. Adhes. 2017, 93, 914–925. [Google Scholar] [CrossRef]

- El Mansouri, N.E.; Pizzi, A.; Salvado, J. Lignin-based polycondensation resins for wood adhesives. J. Appl. Polym. Sci. 2007, 103, 1690–1699. [Google Scholar] [CrossRef]

- El Mansouri, N.E.; Pizzi, A.; Salvado, J. Lignin-based wood panel adhesives without formaldehyde. Holz Roh-und Werkst. 2007, 65, 65–70. [Google Scholar] [CrossRef]

- Pizzi, A.; Kueny, R.; Lecoanet, F.; Massetau, B.; Carpentier, D.; Krebs, A.; Loiseau, F.; Molina, S.; Ragoubi, M. High resin content natural matrix-natural fibre biocomposites. Ind. Crops Prod. 2009, 30, 235–240. [Google Scholar] [CrossRef]

- Mansouri, H.R.; Navarrete, P.; Pizzi, A.; Tapin-Lingua, S.; Benjelloun-Mlayah, B.; Rigolet, S. Synthetic-resin-free wood panel adhesives from low molecular mass lignin and tannin. Eur. J. Wood Prod. 2011, 69, 221–229. [Google Scholar] [CrossRef] [Green Version]

- Navarrete, P.; Mansouri, H.R.; Pizzi, A.; Tapin-Lingua, S.; Benjelloun-Mlayah, B.; Pasch, H.; Rode, K.; Delmotte, L.; Rigolet, S. Low formaldehyde emitting biobased wood adhesives manufactured from mixtures of tannin and glyoxalated lignin. J. Adh. Sci. Technol. 2012, 26, 1667–1684. [Google Scholar] [CrossRef]

- Bertaud, F.; Tapin-Lingua, S.; Pizzi, A.; Navarrete, P.; Petit-Conil, M. Development of green adhesives for fibreboards manufacturing, using tannins and lignin from pulp mill residues. Cellul. Chem. Technol. 2012, 46, 449–455. [Google Scholar]

- Sauget, A.; Nicollin, A.; Pizzi, A. Fabrication and mechanical analysis of mimosa tannin and commercial flax fibers biocomposites. J. Adhes. Sci. Technol. 2013, 27, 2204–2218. [Google Scholar] [CrossRef]

- Zhu, J.; Abhyanker, H.; Njuguna, J.; Perreux, D.; Thiebaud, F.; Chapelle, D.; Pizzi, A.; Sauget, A.; Nicollin, A. Tannin-based flax fibre-reinforced bio-composites for structural application in Superlight Electric Vehicles. Ind. Crops Prod. 2013, 50, 68–76. [Google Scholar] [CrossRef]

- Nicollin, A.; Li, X.; Girods, P.; Pizzi, A.; Rogaume, Y. Fast pressing composite using tannin-furfuryl alcohol resin and vegetal fibers reinforcement. J. Renew. Mater. 2013, 1, 311–316. [Google Scholar] [CrossRef]

- Chen, X.; Xi, X.; Pizzi, A.; Fredon, E.; Du, G.; Gerardin, C. Oxidized Demethylated Lignin as a Bio-Based Adhesive for Wood Bonding. J. Adhes. 2020. [Google Scholar] [CrossRef]

- Wescott, J.M.; Frihart, C.R.; Lorenz, L. Durable soy-based adhesives. In Proceedings Wood Adhesives 2005; Forest Products Society: Madison, WI, USA, 2006. [Google Scholar]

- Lorenz, L.; Frihart, C.R.; Wescott, J.M. Analysis of soy flour/phenol-formaldehyde adhesives for bonding wood. In Wood Adhesives 2005: November 2–4, 2005... San Diego, California; Forest Products Society: Madison, WI, USA, 2006. [Google Scholar]

- Amaral-Labat, G.A.; Pizzi, A.; Goncalves, A.R.; Celzard, A.; Rigolet, S. Environment-friendly soy flour-based resins without formaldehyde. J. Appl. Polym. Sci. 2008, 108, 624–632. [Google Scholar] [CrossRef]

- Lei, H.; Pizzi, A.; Navarrete, P.; Rigolet, S.; Redl, A.; Wagner, A. Gluten protein adhesives for wood panels. J. Adhesion Sci. Technol. 2010, 24, 1583–1596. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K. Chemical modification of soy protein for wood adhesives. Macromol. Rapid Comm. 2002, 23, 739–742. [Google Scholar] [CrossRef]

- Liu, K.; Li, K. Development and characterization of adhesives from soy protein for bonding wood. Int. J. Adhes. Adhes. 2007, 27, 59–67. [Google Scholar] [CrossRef]

- Xi, X.; Pizzi, A.; Gerardin, C.; Liao, J.; Amirou, S.; Abdalla, S. Glutaradehyde-wheat protein-based adhesives for plywood. J. Adhes. 2019. [Google Scholar] [CrossRef]

- Lagel, M.C.; Pizzi, A.; Redl, A. Phenol-wheat protein-formaldehyde adhesives for wood-based panels. ProLigno 2014, 10, 3–17. [Google Scholar]

- Ghahri, S.; Pizzi, A.; Mohebby, B.; Mirshoktaie, A.; Mansouri, H.R. Improving Water Resistance of Soy-Based Adhesive by Vegetable Tannin. J. Polym. Environ. 2018, 26, 1881–1890. [Google Scholar] [CrossRef]

- Ghahri, S.; Pizzi, A. Improving Soy-Based Adhesives for Wood Particleboard by Tannins Addition. Wood Sci. Technol. 2018, 52, 261–279. [Google Scholar] [CrossRef]

- Xi, X.; Pizzi, A.; Gerardin, C.; Chen, X.; Amirou, S. Soy Protein Isolate based Polyamides as Wood Adhesives. Wood Sci. Technol. 2020, 54, 89–102. [Google Scholar] [CrossRef]

- Conner, A.H.; River, B.H.; Lorenz, L.F. Carbohydrates-modified PF resins for wood panels. J. Wood Chem. Technol. 1986, 6, 591–596. [Google Scholar] [CrossRef]

- Conner, A.H.; Lorenz, L.F.; River, B.H. Carbohydrate-modified PF resins formulated at neutral conditions. ACS Symp. Ser. 1989, 385, 355–369. [Google Scholar]

- Moubarik, A.; Pizzi, A.; Charrier, F.; Allal, A.; Badia, M.-A.; Mansouri, H.R.; Charrier, B. Mechanical characterization of industrial particleboard panels glued with cornstarch- mimosa tannin- urea formaldehyde resins. J. Adhes. Sci. Technol. 2013, 27, 423–429. [Google Scholar] [CrossRef]

- Moubarik, A.; Mansouri, H.R.; Pizzi, A.; Charrier, F.; Allal, A.; Charrier, B. Corn flour-mimosa tannin-based adhesives without formaldehyde for interior particleboard production. Wood Sci. Technol. 2013, 47, 1–9. [Google Scholar] [CrossRef]

- Moubarik, A.; Allal, A.; Pizzi, A.; Charrier, F.; Charrier, B. Characterization of a formaldehyde-free cornstarch-tannin wood adhesives for interior plywood. Eur. J. Wood Prod. 2010, 68, 427–433. [Google Scholar] [CrossRef] [Green Version]

- Moubarik, A.; Charrier, B.; Allal, A.; Charrier, F.; Pizzi, A. Development and optimisation of a new formaldehyde-free cornstarch and tannin adhesive. Eur. J. Wood Prod. 2010, 68, 167–177. [Google Scholar] [CrossRef] [Green Version]

- Moubarik, A.; Pizzi, A.; Allal, A.; Charrier, F.; Charrier, B. Cornstarch and tannin in phenol-formaldehyde resins for plywood production. Ind. Crops Prod. 2009, 30, 188–193. [Google Scholar] [CrossRef]

- Belgacem, M.N.; Gandini, A. Furan-based adhesives. In Handbook of Adhesive Technology, 2nd ed.; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 2003; Chapter 30; pp. 615–634. [Google Scholar]

- Xi, X.; Wu, Z.; Pizzi, A.; Gerardin, C.; Lei, H.; Du, G. Furfuryl alcohol-aldehyde plywood adhesive resins. J. Adhes. 2018. [Google Scholar] [CrossRef]

- Alma, M.H.; Yoshioka, M.; Yao, Y.; Shiraishi, N. Preparation of sulfuric acid-catalyzed phenolated wood resin. Wood Sci. Technol. 1998, 32, 297–308. [Google Scholar] [CrossRef]

- Alma, M.H.; Yoshioka, M.; Yao, Y.; Shiraishi, N. The preparation and flow properties of HC1 catalyzed phenolated wood and its blends with commercial novolak resin. Holzforschung 1996, 50, 85–90. [Google Scholar] [CrossRef]

- Bobbitt, J.M. Periodate oxidation of carbohydrates. Adv. Carbohydr. Chem. 1956, 11, 1–41. [Google Scholar]

- Guigo, N.; Mazeau, K.; Putaux, J.L.; Heux, L. Surface modification of cellulose microfibrils by periodate oxidation and subsequent reductive amination with benzylamine: A topochemical study. Cellulose 2014, 21, 4119–4133. [Google Scholar] [CrossRef]

- Codou, A.; Guigo, N.; Heux, L.; Sbirrazzuoli, N. Partial periodate oxidation and thermal cross-linking for the processing of thermoset all-cellulose composites. Compos. Sci. Technol. 2015, 117, 54–61. [Google Scholar] [CrossRef]

- Xi, X.; Pizzi, A.; Delmotte, L. Isocyanate-free Polyurethane Coatings and Adhesives from Mono- and Di-Saccharides. Polymers 2018, 10, 402. [Google Scholar] [CrossRef] [Green Version]

- Xi, X.; Wu, Z.; Pizzi, A.; Gerardin, C.; Lei, H.; Zhang, B.; Du, G. Non-Isocyanate Polyurethane Adhesive from sucrose used for particleboard. Wood Sci. Technol. 2019, 53, 393–405. [Google Scholar] [CrossRef]

- Umemura, K.; Ueda, T.; Munawar, S.; Kawai, S. Application of citric acid as natural adhesive for wood. J. Appl. Polym. Sci. 2012, 123, 1991–1996. [Google Scholar] [CrossRef]

- Umemura, K.; Kawai, S. Development of Wood-Based Materials Bonded with Citric Acid. For. Prod. J. 2015, 65, 38–42. [Google Scholar] [CrossRef]

- Amirou, S.; Pizzi, A.; Delmotte, L. Citric acid as waterproofing additive in butt joints linear wood welding. Eur. J. Wood Prod. 2017, 75, 651–654. [Google Scholar] [CrossRef]

- Del Menezzi, C.; Amirou, S.; Pizzi, A.; Xi, X.; Delmotte, L. Reactions with Wood Carbohydrates and Lignin of Citric Acid as a Bond Promoter of Wood Veneer Panels. Polymers 2018, 10, 833. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Umemura, K.; Sugihara, O.; Kawai, S. Investigation of a new natural adhesive composed of citric acid and sucrose for particleboard. J. Wood Sci. 2013, 59, 203–208. [Google Scholar] [CrossRef] [Green Version]

- Widyorini, R.; Nugraha, P.; Rahman, M.; Prayitno, T. Bonding ability of a new adhesive composed of citric acid-sucrose for particleboard. BioResources 2016, 11, 4526–4535. [Google Scholar] [CrossRef]

- Zhao, Z.; Sakai, S.; Chen, Z.; Zhu, N.; Huang, C.; Sun, S.; Zhang, M.; Umemura, K.; Yong, X. Further Exploration of Sucrose–Citric Acid Adhesive: Investigation of Optimal Hot-Pressing Conditions for Plywood and Curing Behavior. Polymers 2019, 11, 1996. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Zhao, Z.; Umemura, K. Further Exploration of Sucrose-Citric Acid Adhesive: Synthesis and Application on Plywood. Polymers 2019, 11, 1875. [Google Scholar] [CrossRef] [Green Version]

- Tomkinson, J. Adhesives based on natural resources. In Wood Adhesion and Glued Products: Wood Adhesives; Dunky, M., Pizzi, A., Van Leemput, M., Eds.; European Commission, Directorate General for Research: Brussels, Belgium, 2002; pp. 46–65. [Google Scholar]

- Jial, P.; Song, F.; Li, Q.; Xia, H.; Shu, X.; Zhou, Y. Recent Development of Cardanol Based Polymer Materials: A Review. J. Renew. Mat. 2019, 7, 601–619. [Google Scholar]

- Tasooji, M.; Tabarsa, T.; Khazaeian, A.; Wool, R.P. Acrylated epoxidised soy oil as an alternative to urea-formaldehyde in making wheat sraw particleboard. J. Adhes. Sci. Technol. 2010, 24, 1717–1727. [Google Scholar] [CrossRef]

- Wool, R.P. Proceedings of the second European Panel Products Symposium; Academic Press: Bangor, UK, 1998. [Google Scholar]

- Miller, R.; Shonfeld, U. Company Literature; Esbacher Weg 15; Preform Raumgliederungssysteme GmBH: Feuchtwangen, Germany, 2002. [Google Scholar]

- Zimele, Z.; Irbe, I.; Grinins, J.; Bikovens, O.; Verovkins, A.; Bajare, D. Novel Mycelium-based Biocomposites (MBB) as Building Materials. J. Renew. Mat. 2020, in press. [Google Scholar]

- Gfeller, B.; Zanetti, M.; Properzi, M.; Pizzi, A.; Pichelin, F.; Lehmann, M.; Delmotte, L. Wood bonding by vibrational welding. J. Adhes. Sci. Technol. 2003, 17, 1425–1590. [Google Scholar]

- Pizzi, A.; Leban, J.-M.; Kanazawa, F.; Properzi, M.; Pichelin, F. Wood dowels bonding by high speed rotation welding. J. Adhes. Sci. Technol. 2004, 18, 1263–1278. [Google Scholar] [CrossRef]

- Kanazawa, F.; Pizzi, A.; Properzi, M.; Delmotte, L.; Pichelin, F. Influence parameters in wood dowels welding by high speed rotation. J. Adhes. Sci. Technol. 2005, 19, 1025–1038. [Google Scholar] [CrossRef]

- Mansouri, M.; Leban, J.-M.; Pizzi, A. End-grain butt joints obtained by friction welding of high density eucalyptus wood. Wood Sci. Technol. 2010, 44, 399–406. [Google Scholar] [CrossRef]

- Leban, J.M.; Pizzi, A.; Properzi, M.; Pichelin, F.; Gelhaye, P.; Rose, C. Wood Welding. A challenging alternative to conventional wood gluing. Scand. J. For. Res. 2005, 20, 534–538. [Google Scholar] [CrossRef]

- Pizzi, A.; Mansouri, H.R.; Leban, J.M.; Delmotte, L.; Omrani, P.; Pichelin, F. Enhancing the exterior performance of wood linear and rotational welding. J. Adhes. Sci. Technol. 2011, 25, 2717–2730. [Google Scholar] [CrossRef]

- Pizzi, A.; Zhou, X.; Navarrete, P.; Segovia, C.; Mansouri, H.R.; Placentia Pena, M.I.; Pichelin, F. Enhancing water resistance of welded dowel wood joints by acetylated lignin. J. Adhes. Sci. Technol. 2013, 27, 252–262. [Google Scholar] [CrossRef]

- Bocquet, J.-F.; Pizzi, A.; Resch, L. Full-scale (Industrial) wood floor assembly and structures by welded through dowels. Holz Roh-und Werkst. 2007, 65, 149–156. [Google Scholar] [CrossRef]

- Bocquet, J.F.; Pizzi, A.; Despres, A.; Mansouri, H.R.; Resch, L.; Michel, D.; Letort, F. Wood joints and laminated wood beams assembled by mechanically welded wood dowels. J. Adhes. Sci. Technol. 2007, 21, 301–317. [Google Scholar] [CrossRef]

- Segovia, C.; Pizzi, A. Performance of dowel-welded wood furniture linear joints. J. Adhes. Sci. Technol. 2009, 23, 1293–1301. [Google Scholar] [CrossRef]

- Segovia, C.; Pizzi, A. Performance of dowel-welded T-joints for wood furniture. J. Adhes. Sci. Technol. 2009, 23, 2073–2084. [Google Scholar] [CrossRef]

- Oudjene, M.; Khalifa, M.; Segovia, C.; Pizzi, A. Application of numerical modelling to dowel-welded wood joints. J. Adhes. Sci. Technol. 2010, 24, 359–370. [Google Scholar] [CrossRef]

- Segovia, C.; Renaud, A.; Pizzi, A. Performance of dowel-welded L-joints for wood furniture. J. Adhes. Sci. Technol. 2010, 25, 1829–1837. [Google Scholar] [CrossRef]

- Renaud, A. Minimalist Z-chair assembly by rotational dowel welding. Eur. J. Wood Prod. 2009, 67, 111–112. [Google Scholar] [CrossRef]

- O’Loising, C.; Oudjene, M.; Shotton, E.; Pizzi, A.; Fanning, P. Mechanical behaviour and 3D stress analysis of multilayered wooden beams made with welded-through wood dowels. Compos. Struct. 2012, 94, 313–321. [Google Scholar]

- O’Loising, C.; Oudjene, M.; Ait-Adler, H.; Fanning, P.; Pizzi, A.; Shotton, E.; Meghlat, E.-M. Experimental study of timber-to-timber composite beam using welded-through wood dowels. Constr. Build. Mater. 2012, 36, 245–250. [Google Scholar]

- Segovia, C.; Zhou, X.; Pizzi, A. Wood blockboards for construction by wood welding with pre-oiled dowels. J. Adhes. Sci. Technol. 2013, 27, 577–585. [Google Scholar] [CrossRef]

- Mansouri, M.; Leban, J.-M.; Pizzi, A. High density panels by wood veneers welding without any adhesives. J. Adhes. Sci. Technol. 2010, 24, 1529–1534. [Google Scholar] [CrossRef]

- Cristescu, C.; Karlsson, O. Changes in content of furfurals and phenols in self-bonded laminated boards. BioResources 2013, 8, 4056–4071. [Google Scholar] [CrossRef]

- Je, H.; Won, J. Natural urushiol as a novel under-water adhesive. Chem. Eng. J. 2020, in press. [Google Scholar]

- Bobade, S.K.; Paluvai, N.R.; Mohanty, S.; Nayaka, S.K. Bio-Based Thermosetting Resins for Future Generation: A Review. Polym. -Plast. Technol. Eng. 2016, 55, 1863–1896. [Google Scholar] [CrossRef]

- Sangregorio, A.; Guigo, N.; van der Waal, J.C.; Sbirrazzuoli, N. All ‘green’ composites comprising flax fibres and humins resins. Compos. Sci. Technol. 2019, 171, 70–77. [Google Scholar] [CrossRef]

- Sangregorio, A.; Muralidhara, A.; Guigo, N.; Marlair, G.; Angelici, C.; Thygesen, G.; de Jong, E.; Sbirrazzuoli, N. Humins based resin for wood modification and property improvement. Green Chem. 2020. [Google Scholar] [CrossRef] [Green Version]

- Hammami, N.; Jarroux, N.; Robitzer, M.; Majdoub, M.; Habas, J.-P. Optimized Synthesis According to One-Step Process of a Biobased Thermoplastic Polyacetal Derived from Isosorbide. Polymers 2016, 8, 294. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Higuchi, M.; Morita, M.; Hse, C.-Y. Synthetic conditions and chemical structure of urea-formaldehyde resins. I: Properties of the resins synthesized by three different procedures. Mokuzai Gakkaishi 1995, 41, 1115–1121. [Google Scholar]

- Soulard, C.; Kamoun, C.; Pizzi, A. Uron and Uron-Urea-formaldehyde resins. J. Appl. Polym. Sci. 1999, 72, 277–289. [Google Scholar] [CrossRef]

- Gonçalves, C.; Pereira, J.; Almeida, M.; Carvalho, L.H. Impact of alkaline–acid and strongly acid process on the synthesis of urea–formaldehyde resins and derived composites: A comparison study. Eur. J. Wood Prod. 2019, 77, 1177–1187. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.-D. Enhancing the Performance of Low Molar Ratio Urea–Formaldehyde Resin Adhesives via in-situ Modification with Intercalated Nanoclay. J. Adhes. 2020, in press. [Google Scholar] [CrossRef]

- Hatam, A.; The role of TiO2 on the catalysis of reaction and cure of urea-formaldehyde resins. Personal communication, 2020.

- Dorieh, A.; Mahmoodi, N.; Mamaghani, M.; Pizzi, A.; Zeydi, M.M.; Moslemi, A. New insight into the use of latent catalysts for the synthesis of urea formaldehyde adhesives and the mechanical properties of medium density fiberboards bonded with them. Eur. Polym. J. 2019, 112, 195–205. [Google Scholar] [CrossRef]

- Dorieh, A.; Mahmoodi, N.; Mamaghani, M.; Pizzi, A.; Zeydi, M.M. Comparison of the properties of urea-formaldehyde resins by the use of formalin or urea formaldehyde condensates. J. Adhes. Sci. Technol. 2018, 32, 2537–2551. [Google Scholar] [CrossRef]

- Pizzi, A.; Lipschitz, L.; Valenzuela, J. Theory and practice of the preparation of low formaldehyde emission UF adhesives for particleboard. Holzforschung 1994, 48, 254–261. [Google Scholar] [CrossRef]

- Dunker, A.K.; Johns, W.E.; Rammon, R.; Farmer, B.; Johns, S.Y. Slightly Bizarre Protein Chemistry: Urea-Formaldehyde Resin from a Biochemical Perspective. J. Adhes. 1986, 19, 153–176. [Google Scholar] [CrossRef]

- Levendis, D.; Pizzi, A.; Ferg, E.E. The correlation of strength and formaldehyde emission with the crystalline/amorphous structure of UF resins. Holzforschung 1992, 45, 260–267. [Google Scholar] [CrossRef]

- Ferg, E.E.; Pizzi, A.; Levendis, D. A 13C NMR analysis method for urea-formaldehyde resin strength and formaldehyde emission. J. Appl. Polym. Sci. 1993, 50, 907–915. [Google Scholar] [CrossRef]

- Zanetti, M.; Pizzi, A.; Kamoun, C. Upgrading of MUF particleboard adhesives and decrease of melamine content by buffer and additives. Holz Roh-und Werkst. 2003, 61, 55–65. [Google Scholar] [CrossRef]

- Zanetti, M.; Pizzi, A. Upgrading of MUF resins by buffering additives – Part 2: Hexamine sulphate mechanisms and alternate buffers. J. Appl. Polym. Sci. 2003, 90, 215–226. [Google Scholar] [CrossRef]

- Despres, A.; Pizzi, A.; Delmotte, L. 13C NMR investigation of the reaction in water of UF resins with blocked emulsified isocyanates. J. Appl. Polym. Sci. 2006, 99, 589–596. [Google Scholar] [CrossRef]

- Wieland, S.; Pizzi, A.; Hill, S.; Grigsby, W.; Pichelin, F. The reaction in water of UF resins with isocyanates at short curing times: A 13C NMR investigation. J. Appl. Polym. Sci. 2006, 100, 1624–1632. [Google Scholar] [CrossRef]

- Wieland, S.; Pizzi, A.; Grigsby, W.; Warnes, J.; Pichelin, F. Microcristallinity and colloidal peculiarities of UF/isocyanates hybrid resins. J. Appl. Polym. Sci. 2007, 104, 2633–2636. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.D.; Lee, S.M. Microencapsulation of polymeric isocyanate for the modification of urea-formaldehyde resins. Int. J. Adhes. Adhes. 2020, in press. [Google Scholar] [CrossRef]

- Martin, A.E.; Calvin, M. Chemistry of Metal Chelate Compounds; Prentice-Hall: New York, NY, USA, 1952. [Google Scholar]

- Lemon, P.H.R.B. An improved sand binder for steel castings. Int. J. Mater. Prod. Technol. 1990, 5, 25–35. [Google Scholar]

- Pizzi, A.; Stephanou, A. On the chemistry, behaviour and cure acceleration of phenol-formaldehyde resins under very alkaline conditions. J. Appl. Polym. Sci. 1993, 49, 2157–2160. [Google Scholar] [CrossRef]

- Stephanou, A.; Pizzi, A. Rapid curing lignins-based exterior wood adhesives, Part 2: Acceleration mechanisms and application to panel products. Holzforschung 1993, 47, 501–506. [Google Scholar] [CrossRef]

- Pizzi, A.; Stephanou, A. Phenol-formaldehyde wood adhesives under very alkaline conditions, Part 2: Acceleration mechanism and applied results. Holzforschung 1994, 48, 150–156. [Google Scholar] [CrossRef]

- Pizzi, A.; Stephanou, A. Completion of alkaline cure acceleration of phenol-formaldehyde resins: Acceleration by organic anhydrides. J. Appl. Polym. Sci. 1994, 51, 1351–1352. [Google Scholar] [CrossRef]

- Pizzi, A.; Garcia, R.; Wang, S. On the networking mechanisms of additives accelerated PF polycondensates. J. Appl. Polym. Sci. 1997, 66, 255–266. [Google Scholar] [CrossRef]

- Higuchi, M.; Tohmura, S.; Sakata, I. Acceleration of the cure of phenolic resin adhesives 5. Catalytic actions of carbonates and formamide. Mokuzai Gakkaishi 1994, 40, 604–611. [Google Scholar]

- Conner, A.H.; Lorenz, L.F.; Hirth, K.C. Accelerated cure of phenol–formaldehyde resins: Studies with model compounds. J. Appl. Polym. Sci. 2002, 86, 3256–3263. [Google Scholar] [CrossRef]

- Kamo, N.; Okamura, H.; Higuchi, M.; Morita, M. Condensation reactions of phenolic resins V: Cure-acceleration effects of propylene carbonate. J. Wood Sci. 2004, 50, 236–241. [Google Scholar] [CrossRef]

- Park, B.-D.; Riedl, B.; Hsu, E.W.; Shields, J.A. Differential scanning calorimetry of phenol–formaldehyde resins cure-accelerated by carbonates. Polymer 1999, 40, 1689–1699. [Google Scholar] [CrossRef]

- Park, B.-D.; Riedl, B. 13C-NMR study on cure-accelerated phenol–formaldehyde resins with carbonates. J. Appl. Polym. Sci. 2000, 77, 841–851. [Google Scholar] [CrossRef]

- Park, B.-D.; Riedl, B.; Hsu, E.W.; Shields, J.A. Application of cure-accelerated phenol-formaldehyde (PF) adhesives for three-layer medium density fiberboard (MDF) manufacture. Wood Sci. Technol. 2001, 35, 311–323. [Google Scholar] [CrossRef]

- Lei, H.; Pizzi, A.; Despres, A.; Pasch, H.; Du, G. Esters acceleration mechanisms in phenol-formaldehyde resin adhesives. J. Appl. Polym. Sci. 2006, 100, 3075–3093. [Google Scholar] [CrossRef]

- Zhao, C.; Pizzi, A.; Garnier, S. Fast advancement and hardening acceleration of low condensation alkaline PF resins by esters and copolymerized urea. J. Appl. Polym. Sci. 1999, 74, 359–378. [Google Scholar] [CrossRef]

- Zhao, C.; Pizzi, A.; Kuhn, A.; Garnier, S. Fast advancement and hardening acceleration of low condensation alkaline PF resins by esters and copolymerized urea. Part 2: Esters during resin reaction and effect of guanidine salts. J. Appl. Polym. Sci. 2000, 77, 249–259. [Google Scholar] [CrossRef]

- Deng, S.; Du, G.; Li, X.; Zhang, J.; Pizzi, A. Performance and reaction mechanism of zero formaldehyde-emission urea-glyoxal (UG) resin. J. Taiwan Inst. Chem. Eng. 2014, 45, 2029–2038. [Google Scholar] [CrossRef]

- Deng, S.; Pizzi, A.; Du, G.; Zhang, J.; Zhang, J. Synthesis, structure, and characterization of Glyoxal-Urea-Formaldehyde cocondensed resins. J. Appl. Polym. Sci. 2014, 131, 41009–41019. [Google Scholar] [CrossRef]

- Deng, S.; Pizzi, A.; Du, G.; Lagel, M.C.; Delmotte, L.; Abdalla, S. Synthesis, structure characterization and application of melamine-glyoxal adhesive resins. Eur. J. Wood Prod. 2018, 76, 283–296. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Pizzi, A. Acid Ionic Liquids as a New Hardener in Urea-Glyoxal Adhesive Resins. Polymers 2016, 8, 57. [Google Scholar] [CrossRef] [Green Version]

- Xi, X.; Pizzi, A.; Amirou, S. Melamine-Glyoxal-Glutaraldehyde Wood Panel Adhesives without Formaldehyde. Polymers 2018, 10, 22. [Google Scholar] [CrossRef] [Green Version]

- Novotny, E.E.; Johnson, W.W. Urea-Furfural Resins and Process of Making Them. U.S. Patent 1,827,824, 1931. [Google Scholar]

- Stierli, R.F.; Newton, N.Y. Urea-Formaldehyde-Furfuryl Alcohol Resins. U.S. Patent 2,487,394, 1949. [Google Scholar]

- Lagel, M.C.; Berner Fachhochschule, Biel, Switzerland. personal communication, 2016.

- Xu, C.; Zhang, Y.; Yuan, Z. Formaldehyde-Free Phenolic Resins, Downstream Products, Their Synthesis and Use. U.S. patent 10,266,633, 2019. [Google Scholar]

- Santiago-Medina, F.J.; Pizzi, A.; Abdalla, S. Hydroxymethylfurfural hardening of pine tannin wood adhesives. J. Renew. Mat. 2018, 5, 435–447. [Google Scholar] [CrossRef]

- Xi, X.; Pizzi, A. No-Aldehydes Glucose/Sucrose-Triacetin-Diamine Wood Adhesives for Particleboard. J. Renew. Mat. 2020, in press. [Google Scholar]

- Bekhta, P.; Sedliačik, J. Environmentally-Friendly High-Density Polyethylene-Bonded Plywood Panels. Polymers 2019, 11, 1166. [Google Scholar] [CrossRef] [Green Version]

- Berthevas, P.; Santoro, G.; Wevers, R.; Gruenbauer, H.; Pizzi, A. Recycled polyurethane foam powder can be used in conjunction with PMDI in particleboards to obtain the required properties while reducing costs. In Proceedings of the Ninth European Panel Products Symposium, Llandudno, UK, 5–7 October 2005; pp. 40–47. [Google Scholar]

- Mansouri, H.R.; Pizzi, A. Recycled polyurethane micronized powders as active extenders of UF and PF wood panel adhesives. Holz Roh-und Werkst. 2007, 65, 293–299. [Google Scholar] [CrossRef]

- Ashori, A. Wood–plastic composites as promising green-composites for automotive industries: A review. Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef]

- Clemons, C. Wood plastic composites in the United States. The interfacing of two industries. For. Prod. J. 2002, 52, 10–18. [Google Scholar]

- Klyosov, A.A. Wood Plastic Composites; Wiley Interscience: New York, NY, USA, 2007; pp. 1–726. [Google Scholar]

- Schwarzkopf, M.J.; Burnard, M.D. Wood-Plastic Composites—Performance and Environmental Impacts. In Environmental Impacts of Traditional and Innovative Forest-based Bioproducts; Kutnar, A., Muthu, S., Eds.; Springer: Singapore, 2016. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pizzi, A.; Papadopoulos, A.N.; Policardi, F. Wood Composites and Their Polymer Binders. Polymers 2020, 12, 1115. https://doi.org/10.3390/polym12051115

Pizzi A, Papadopoulos AN, Policardi F. Wood Composites and Their Polymer Binders. Polymers. 2020; 12(5):1115. https://doi.org/10.3390/polym12051115

Chicago/Turabian StylePizzi, Antonio, Antonios N. Papadopoulos, and Franco Policardi. 2020. "Wood Composites and Their Polymer Binders" Polymers 12, no. 5: 1115. https://doi.org/10.3390/polym12051115

APA StylePizzi, A., Papadopoulos, A. N., & Policardi, F. (2020). Wood Composites and Their Polymer Binders. Polymers, 12(5), 1115. https://doi.org/10.3390/polym12051115