Rheology of Polymer Processing in Spain (1995–2020)

Abstract

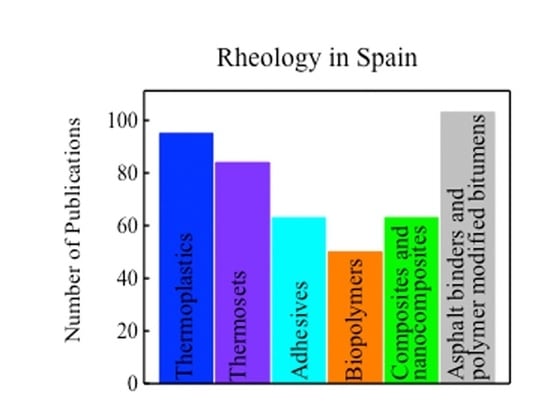

:1. Introduction and Some Remarks on the Rheology in Spain

2. Thermoplastic Polymers

2.1. Extrusion Moulding

2.2. Injection Moulding

2.3. Additive Manufacturing

2.4. Film Blowing and Foaming

3. Thermoset Polymers

4. Adhesives

5. Biopolymers

6. Polymer Composites and Nanocomposites

7. Asphalt Binders and Polymer Modified Bitumens

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Flores, V. In Memoriam: Dr. D. Carlos Gómez Herrera. Boletín Grupo Reol. Español. 2016, 17, 1–3. [Google Scholar]

- Guzman, G.M.; Fatou, J.M.G. Comportamiento reológico de las disoluciones diluidas de poli(metacrilato de metilo). An. Real Soc. Española Física Química Ser. B-Química 1962, B58, 745. [Google Scholar]

- Guerrero, A. Evolución de la investigación sobre Reología en los últimos años. Boletín Grupo Reol. Español 2018, 23, 1–3. [Google Scholar]

- Izu, P.; Muñoz, M.E.; Peña, J.J.; Santamaria, A. Capillary and slit-die flow of 2 liquid-crystalline polymers-The effect of pressure on viscosity. J. Polym. Sci. Part B Polym. Phys. 1993, 31, 347–356. [Google Scholar] [CrossRef]

- De Abajo, J.; De La Campa, J.G.; Izu, P.; Santamaria, A.; Tormes, M. Rheological features of thermotropic and isotropic poly(ester imide)s. Polymer 1995, 36, 1683–1687. [Google Scholar] [CrossRef]

- Zaldua, A.M.; Muñoz, M.E.; Peña, J.J.; Santamaria, A. The effect of mixing time on the morphology and physical properties of liquid crystalline polymer based blends. Macromol. Rapid Commun. 1995, 16, 417–424. [Google Scholar] [CrossRef]

- Vega, J.F.; Muñoz-Escalona, A.; Santamaria, A.; Muñoz, M.E.; Lafuente, P. Comparison of the Rheological Properties of Metallocene-Catalyzed and Conventional high- Density Polyethylenes. Macromolecules 1996, 29, 960–965. [Google Scholar] [CrossRef]

- Izu, P.; Muñoz, M.E.; Peña, J.J.; Santamaria, A. Competition between Textural Transitions and Pressure Effects on the Viscosity of Thermotropic Liquid-Crystalline Polymers. Polym. Eng. Sci. 1996, 36, 721–730. [Google Scholar] [CrossRef]

- Vega, J.F.; Muñoz Escalona, A.; Santamaria, A.; Muñoz, M.E.; Lafuente, P. Rheological behavior of metallocene catalyzed high density polyethylene blends. Polymer 1997, 38, 589–594. [Google Scholar]

- Tormes, M.; Muñoz, M.E.; Santamaria, A. Deorientation effects on extrusion rheometry of a thermotropic copolyester. Macromol. Rapid Commun. 1997, 18, 591–599. [Google Scholar] [CrossRef]

- Santamaria, A.; Vega, J.F.; Muñoz-Escalona, A.; Lafuente, P. Rheology of metallocene catalysed polyethylenes: Energy consumption perspective. Macromol. Symp. 2000, 152, 15–27. [Google Scholar] [CrossRef]

- Muñoz Escalona, A.; Lafuente, P.; Fernández, M.; Santamaría, A.; Muñoz-Escalona, P. Melt-flow instabilities in metallocene based polyethyelenes. Spe Antec Proc. 2000, 1, 1016–1020. [Google Scholar]

- Fernández, M.; Vega, J.F.; Santamaria, A.; Muñoz Escalona, A.; Lafuente, P. The effect of chain architecture on “sharkskin” of metallocene polyethylenes. Macromol. Rapid Commun. 2000, 21, 973–978. [Google Scholar] [CrossRef]

- Hernandez, R.; Peña, J.J.; Irusta, L.; Santamaria, A. The effects of a miscible and a immiscible polymeric modifier on the mechanical and rheological properties of PVC. Eur. Polym. J. 2000, 36, 1011–1025. [Google Scholar] [CrossRef]

- Zarraga, A.; Muñoz, M.E.; Peña, J.J.; Santamaria, A. Rheological effects of the incorporation of CPE compatibilizers to a HDPE/PVC blend. Polym. Eng. Sci. 2001, 41, 1893–1902. [Google Scholar] [CrossRef]

- Aguilar, M.; Vega, J.F.; Muñoz Escalona, A.; Martínez-Salazar, J. Temperature and branching dependence of surface extrusion instabilities in metallocene catalysed polyethylene. J. Mater. Sci. 2002, 16, 3415–3421. [Google Scholar] [CrossRef]

- Santamaria, A.; Fernandez, M.; Sanz, E.; Lafuente, P.; Muñoz Escalona, A. Postponing sharkskin of metallocene polyethylenes at low temperatures: The effect of molecular parameters. Polymer 2003, 44, 2473–2480. [Google Scholar] [CrossRef]

- Aguilar, M.; Expósito, M.T.; Vega, J.F.; Muñoz-Escalona, A.; Martínez-Salazar, J. Elimination of extrudate distortions in metallocene-catalyzed polyethylene. Macromolecules 2004, 37, 681–683. [Google Scholar] [CrossRef]

- Zarraga, A.; Villanueva, S.; Muñoz, M.E.; Obeso, R.; Peña, J.J.; Pascual, B.; Santamaria, A. Ternary blends to improve heat distortion temperature and rheological properties of PVC. Macromol. Mater. Eng. 2004, 289, 648–652. [Google Scholar] [CrossRef]

- Flores, M.A.; Alicante, R.; Perez, R.; Rojo, E.; Fernandez, M.; Santamaria, A. Binary and Ternary mLLDPE Blends. Tailoring their properties using complex viscosity measurements. Macromol. Mater. Eng. 2005, 290, 705–709. [Google Scholar] [CrossRef]

- Perez, R.; Rojo, E.; Fernandez, M.; Leal, V.; Lafuente, P.; Santamaria, A. Basic and applied rheology of m-LLDPE/LDPE blends: Miscibility and Processing features. Polymer 2005, 46, 8045–8053. [Google Scholar] [CrossRef]

- Rojo, E.; Muñoz, M.E.; Mateos, A.; Santamaria, A. Flow instabilities in linear and branched syndiotactic poly(propylene)s. Macromol. Mater. Eng. 2007, 292, 1210–1217. [Google Scholar] [CrossRef]

- Vega, J.F.; Hristova, D.; Peters, G. Flow-induced crystallization regimes and rheology of isotactic polypropylene: Effects of molecular architecture. J. Therm. Anal. Calorim. 2009, 98, 655–666. [Google Scholar] [CrossRef]

- Arevalillo, A.; Fernández, M.; Muñoz, M.E.; Santamaria, A. Linear viscoelasticity, probe tack, and extrusion flow results of SEBS copolymers. Polym. Eng. Sci. 2010, 50, 1449–1456. [Google Scholar] [CrossRef]

- Vega, J.F.; Exposito, M.T.; Otegui, J.; Martinez-Salazar, J. Eliminating sharkskin distortion in polyethylene extrusion via molecular route. J. Rheol. 2011, 55, 855–873. [Google Scholar] [CrossRef] [Green Version]

- Quintana, R.; de Ilarduya, A.M.; Alla, A.; Muñoz-Guerra, S. Polyterephthalates made from ethylene glycol, 1,4-cyclohexanedimethanol, and isosorbide. J. Polym. Sci. Part A: Polym. Chem. 2011, 49, 2252–2260. [Google Scholar] [CrossRef]

- Vega, J.F.; Ramos, J.; Martínez-Salazar, J. Effect of short chain branching in molecular dimensions and Newtonian viscosity of ethylene/1-hexene copolymers: Matching conformational and rheological experimental properties and atomistic simulations. Rheol. Acta 2014, 53, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Lopez, M.D.C.; Pernas, A.I.A.; Lopez, M.J.A.; Latorre, A.L.; Vilarino, J.M.L.; Rodriguez, M.V.G. Assessing changes on poly(ethylene terephthalate) properties after recycling: Mechanical recycling in laboratory versus postconsumer recycled material. Mater. Chem. Phys. 2014, 147, 884–894. [Google Scholar] [CrossRef]

- Peinado, V.; Castell, P.; García, L.; Fernández, A. Effect of extrusion on the mechanical and rheological properties of a reinforced Poly(lactic acid): Reprocessing and recycling of biobased materials. Materials 2015, 8, 7106–7117. [Google Scholar] [CrossRef]

- Rodriguez, E.; Fernandez, M.; Muñoz, M.E.; Santamaria, A. The effect of pressure on the viscosity of two different nanocomposites based on a PS matrix: A case of piezorheological complexity. J. Rheol. 2016, 60, 1199–1210. [Google Scholar] [CrossRef]

- Calafel, I.; Muñoz, M.E.; Santamaria, A.; Boix, M.; Conde, J.I. Pascual, B. The effect of crystallites on the rheological properties of microphase-separated PVC-PBS-PVC triblock copolymers obtained by single electron transfer-degenerative chain transfer living radical polymerization. J. Vinyl Addit. Technol. 2015, 21, 24–31. [Google Scholar] [CrossRef]

- Calafel, I.; Aguirresarobe, R.H.; Sadaba, N.; Boix, M.; Conde, J.I.; Pascual, B.; Santamaria, A. Tuning the viscoelastic features required for 3D printing of PVC-acrylate copolymers obtained by single electron transfer-degenerative chain transfer living radical polymerization (SET-DTLRP). Express Polym. Lett. 2018, 12, 824–835. [Google Scholar] [CrossRef]

- Calafel, I.; Fernandez, M.; Santamaria, A.; Boix, M.; Conde, J.I.; Pascual, B. PVC/PBA random copolymers obtained by STE-DTLRP: Pressure effect on glass transition, rheology and processing. J. Vinyl Addit. Technol. 2019, 25, 76–84. [Google Scholar] [CrossRef]

- Peñas, M.I.; Calafel, I.; Aguirresarobe, R.H.; Tierno, M.; Conde, J.I.; Pascual, B.; Santamaria, A. How is Rheology involved in 3D printing of phase-separated PVC-Acrylate copolymers obtained by free radical polymerization. Polymers 2020, 12, 2070. [Google Scholar] [CrossRef]

- Calafel, I.; Aguirresarobe, R.H.; Peñas, M.I.; Santamaria, A.; Tierno, M.; Conde, J.I.; Pascual, B. Searching for rheological conditions for FFF 3D printing with PVC based flexible compounds. Materials 2020, 13, 178. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sangroniz, L.; Van Drongelen, M.; Cardinaels, R.; Santamaria, A.; Gerrit, W.M.; Müller, A.J. Effect of shear rate and pressure on the crystallization of PP nanocomposites and PP/PET polymer blend nanocomposites. Polymer 2020, 186, 121950. [Google Scholar] [CrossRef]

- Fernandez, M.; Muñoz, M.E.; Santamaria, A.; Syrjäla, S.; Aho, J. Determining the pressure dependency of the viscosity using PVT data: A practical alternative for thermoplastics. Polym. Test. 2009, 28, 109–113. [Google Scholar] [CrossRef]

- Fernandez, A.; Mercado, D.; Javierre, C.; Muniesa, M. Large thermoplastic parts quality improvements using monitorized nozzle. J. Mech. Eng. 2008, 54, 258–265. [Google Scholar]

- Fernandez, A.; Muniesa, M.; Javierre, C. In-line rheological rheological testing of thermoplastic and a monitored device for an injection moulding machine: Application to raw and recycled polypropylene. Polym. Test. 2014, 33, 107–115. [Google Scholar] [CrossRef]

- Navarro, R.; Lopez, J.; Parres, F.; Ferrandiz, S. Process behavior of compatible polymer blends. J. Appl. Polym. Sci. 2012, 124, 2485–2493. [Google Scholar] [CrossRef]

- Asensio, M.; Nunez, K.; Guerrero, J.; Herrero, M.; Merino, J.C.; Pastor, J.M. Rheological modification of recycled poly(ethylene terephthale): Blending and reactive extrusion. Polym. Degrad. Stab. 2020, 179, 109258. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Boronat, T.; Segui, V.J.; Peydro, M.A.; Reig, M.J. Influence of temperature and shear rate on the rheology and processability of reprocessed ABS in injection molding process. J. Mater. Process. Tech. 2008, 209, 2735–2745. [Google Scholar] [CrossRef]

- Seppala, J.; Hoon Han, S.; Hillgartner, K.; Davis, C.; Migler, K. Weld formation during material extrusion additive manufacturing. Soft Matter 2017, 13, 6761–6769. [Google Scholar] [CrossRef] [PubMed]

- McIlroy, C.; Olmsted, P.D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef] [Green Version]

- Cobos, C.M.; Garzon, L.; Lopez-Martinez, J.; Fenollar, O.; Ferrandiz, S. Study of thermal and rheological properties of PLA loaded with carbon and halloysite nanotubes for additive manufacturing. Rapid Prototyp. J. 2019, 25, 738–743. [Google Scholar] [CrossRef]

- Cobos, C.M.; Fenollar, O.; Lopez Martinez, J. Effect of maleinized linseed oil (MLO) on thermal and rheological properties of PLA/MWCNT and PLA/HNT nanocomposites for additive manufacturing. Rapid Prototyp. J. 2020, 26, 1027–1033. [Google Scholar] [CrossRef]

- Ortega, Z.; Alemán, M.E.; Benítez, A.N.; Monzón, M.D. Theoretical–experimental evaluation of different biomaterials for parts obtaining by fused deposition modeling. Measurement 2016, 89, 137–144. [Google Scholar] [CrossRef]

- Candal, M.V.; Calafel, I.; Aranburu, N.; Fernández, M.; Gerrica-Echeverria, G.; Santamaria, A.; Müller, A.J. Thermo-rheological effects on successful 3D printing of biodegradable polyesters. Addit. Manuf. 2020, 36, 101408. [Google Scholar] [CrossRef]

- Kovalcik, A.; Sangroniz, L.; Kalina, M.; Skopalova, K.; Humpolicek, P.; Omastova, M.; Mundigler, N.; Müller, A.J. Properties of scaffolds prepared by fused deposition modeling of poly(hydroxyalkanoates). Int. J. Biol. Macromol. 2020, 161, 364–376. [Google Scholar] [CrossRef]

- Leal, V.; Lafuente, P.; Alicante, R.; Pérez, R.; Santamaria, A. New Results on the Correlation Molecular Architecture-Melt Elasticity-Blowing Process-Film Properties for Conventional and Metallocene-Catalyzed Polyethylenes. Macromol. Mater. Eng. 2006, 291, 670–676. [Google Scholar] [CrossRef]

- Robledo, N.; Vega, J.F.; Nieto, J.; Martínez-Salazar, J. Role of the interface in the melt-rheology properties of linear low-density polyethylene/low-density polyethylene blends: Effect of the molecular architecture of the dispersed phase. J. Appl. Polym. Sci. 2011, 119, 3217–3226. [Google Scholar] [CrossRef] [Green Version]

- Lopez-Gonzalez, E.; Salmazo, L.O.; Lopez-Gil, A.; Laguna-Gutierrez, E.; Rodriguez-Perez, M.A. Analysis of the foaming mechanisms of materials based on high-density polyethylene (HDPE) crosslinked with different irradiation doses. J. Appl. Polym. Sci. 2018, 135, 46276. [Google Scholar] [CrossRef]

- Laguna-Gutierrez, E.; Lopez-Gil, A.; Saiz-Arroyo, C.; Van Hooghten, R.; Moldenaers, P.; Rodriguez-Perez, M.A. Extensional rheology, cellular structure, mechanical behavior relationships in HMS PP/montmorillonite foams with similar densities. J. Polym. Res. 2016, 23, 251. [Google Scholar] [CrossRef] [Green Version]

- Laguna-Gutierrez, E.; Van Hooghten, R.; Moldenaers, P.; Rodriguez-Perez, M.A. Understanding the foamability and mechanical properties of foamed polypropylene blends by using extensional rheology. J. Appl. Polym. Sci. 2015, 132, 42430. [Google Scholar] [CrossRef]

- Macosko, C.W. Rheological changes during crosslinkinging. Br. Polym. J. 1985, 17, 239–245. [Google Scholar] [CrossRef]

- Vidil, T.; Tournilhac, F.; Musso, S.; Robisson, A.; Leibler, L. Control of reactions and network structures of epoxy thermosets. Prog. Polym. Sci. 2016, 62, 126–179. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q. Thermosets: Structure, Properties, and Applications; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Halley, P.J.; Mackay, M.E. Chemorheology of thermosets—An overview. Polym. Eng. Sci. 1996, 36, 593–609. [Google Scholar] [CrossRef]

- Halley, P.J.; Mackay, M.E.; George, G.A. Determining the gel point of an epoxy resin by various rheological methods. High Perform. Polym. 1994, 6, 405–414. [Google Scholar] [CrossRef]

- Mussatti, F.G.; Macosko, C.W. Rheology of network forming systems. Polym. Eng. Sci. 1973, 13, 236–240. [Google Scholar] [CrossRef]

- Arasa, M.; Ramis, X.; Salla, J.M.; Mantecon, A.; Serra, A. FTIR/ATR study of the copolymerization of diglycidyl ether of bisphenol a with methyl-substituted gamma-lactones catalyzed by rare earth triflate initiators. J. Polym. Sci. Part A Polym. Chem. 2007, 45, 2129–2141. [Google Scholar] [CrossRef]

- Castell, P.; Galia, M.; Serra, A.; Salla, J.M.; Ramis, X. Study of lanthanide triflates as new curing initiators for DGEBA. Polymer 2000, 41, 8465–8474. [Google Scholar] [CrossRef]

- Flores, M.; Tomuta, A.M.; Fernández-Francos, X.; Ramis, X.; Sangermano, M.; Serra, A. A new two-stage curing system. Thiol-ene/epoxy homopolymerization using an allyl terminated hyperbranched polyester as reactive modifier. Polymer 2013, 54, 5473–5481. [Google Scholar] [CrossRef]

- Konuray, O.; Fernández-Francos, X.; Ramis, X.; Serra, A. State of the art in dual-curing acrylate systems. Polymers 2018, 10, 178. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morell, M.; Ramis, X.; Ferrando, F.; Serra, A. Effect of polymer topology on the curing process and mechanical characteristics of epoxy thermosets modified with linear or multiarm star poly(e-caprolactone). Polymer 2011, 52, 4694–4702. [Google Scholar] [CrossRef]

- Mas, C.; Ramis, X.; Salla, J.M.; Mantecón, A.; Serra, A. Copolymerization of diglycidyl ether of bisphenol a with gamma-butyrolactone catalyzed by ytterbium triflate: Shrinkage during curing. J. Polym. Sci. A Polym. Chem. 2003, 41, 2794–2808. [Google Scholar] [CrossRef]

- Acebo, C.; Picardi, A.; Fernández-Francos, X.; De la Flor, S.; Ramis, X.; Serra, A. Effect of hydroxyl ended and end-capped multiarm star polymers on the curing process and mechanical characteristics of epoxy/anhydride thermosets. Prog. Org. Coat. 2014, 77, 1288–1298. [Google Scholar] [CrossRef]

- Giménez, R.; Fernández-Francos, X.; Salla, J.M.; Serra, A.; Mantecón, A.; Ramis, X. New degradable thermosets obtained by cationic copolymerization of DGEBA with an s(g-butyrolactone). Polymer 2005, 46, 10637–10647. [Google Scholar] [CrossRef]

- Larrañaga, M.; Gabilondo, N.; Kortaberria, G.; Serrano, E.; Remiro, P.; Riccardi, C.C.; Mondragon, I. Micro or nanoseparated phases in thermoset blends of an epoxy resin and PEO-PPO-PEO triblock copolymer. Polymer 2005, 46, 7082–7093. [Google Scholar] [CrossRef]

- Tercjak, A.; Gutierrez, J.; Peponi, L.; Rueda, L.; Mondragon, I. Arrangement of conductive TiO2 nanoparticles in hybrid inorganic/organic thermosetting materials using liquid crystal. Macromolecules 2009, 42, 3386–3390. [Google Scholar] [CrossRef]

- Tercjak, A.; Serrano, E.; Garcia, I.; Mondragon, I. Thermoresponsive meso/nanostructured thermosetting materials based on PS-b-PEO block copolymer-dispersed liquid crystal: Curing behavior ad morphological variation. Acta Mater. 2008, 56, 5112–5122. [Google Scholar] [CrossRef]

- Chapartegui, M.; Markaide, N.; Florez, S.; Elizetxea, C.; Fernandez, M.; Santamaria, A. Specific rheological and electrical features of carbon nanotube dispersions in an epoxy matrix. Compos. Sci. Technol. 2010, 70, 879–884. [Google Scholar] [CrossRef]

- Chapartegui, M.; Barcena, J.; Irastorza, X.; Elizetxea, C.; Fernandez, M.; Santamaria, A. Analysis of the conditions to the manufacture a MWCNT buckypaper/benzoxazine nanocomposite. Compos. Sci. Technol. 2012, 72, 489–497. [Google Scholar] [CrossRef]

- Chapartegui, M.; Markaide, N.; Florez, S.; Elizetxea, C.; Fernandez, M.; Santamaria, A. Curing of epoxy/carbon nanotubes physical networks. Polym. Eng. Sci. 2012, 52, 663–670. [Google Scholar] [CrossRef]

- Castro-Cabado, M.; Casado, A.L.; San Román, J. Bio-based thermosets: Effect of the structure of polycarboxylic acids on the thermal crosslinkinging of maltodextrins. Eur. Polym. J. 2016, 78, 91–105. [Google Scholar] [CrossRef]

- Lakrout, H.; Sergot, P.; Creton, C. Direct observation of cavitation and fibrillation in a probe tack experiment on model acrylic pressure-sensitive adhesive. J. Adhes. 1999, 69, 307–359. [Google Scholar] [CrossRef]

- Verdier, C.; Piau, J.M. Effect of non linear viscoelastic properties on tack. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 3139–3149. [Google Scholar] [CrossRef] [Green Version]

- Torró-Palau, A.; Fernández-García, J.C.; Orgilés-Barcelo, A.C.; Pastor-Blas, M.M.; Martín-Martínez, J.M. Comparison of the properties of polyurethane adhesives containing fumed silica or sepiolite as filler. J. Adhes. 1997, 61, 195–211. [Google Scholar] [CrossRef]

- Torró-Palau, A.M.; Fernández-García, J.C.; Orgilés, B.; Martín-Martínez, J.M. Characterization of polyurethanes containing different silicas. Int. J. Adhes. Adhes. 2001, 21, 1–9. [Google Scholar] [CrossRef]

- Vega-Baudrit, J.; Navarro-Bañon, V.; Vázquez, P.; Martín-Martínez, J.M. Addition of nanosilicas with different silanol content to thermoplastic polyurethane adhesives. Int. J. Adhes. Adhes. 2006, 26, 378–387. [Google Scholar] [CrossRef]

- Álvarez-García, S.; Martín-Martínez, J.M. Effect of the carbon black content on the thermal, rheological and mechanical properties of thermoplastic polyurethanes. J. Adhes. Sci. Technol. 2015, 29, 1136–1154. [Google Scholar] [CrossRef]

- Arán-Aís, F.; Torró-Palau, A.M.; Orgilés-Barceló, A.C.; Martín-Martínez, J.M. Synthesis and characterization of new thermoplastic polyurethane adhesives containing rosin resin as an internal tackifier. J. Adhes. Sci. Technol. 2000, 14, 1557–1573. [Google Scholar] [CrossRef]

- Orgilés-Calpena, E.; Francisca, A.A.; Torró-Palau, A.M.; Orgilés, B.; Martín-Martínez, J.M. Influence of the Chemical Structure of Urethane-Based Thickeners on the Properties of Waterborne Polyurethane Adhesives. J. Adhes. 2009, 85, 665–689. [Google Scholar] [CrossRef]

- Orgilés-Calpena, E.; Arán-Aís, F.; Torró-Palau, A.M.; Orgilés-Barceló, C.; Martín-Martínez, J.M. Addition of different amounts of a urethane-based thickener to waterborne polyurethane adhesive. Int. J. Adhes. Adhes. 2009, 29, 309–318. [Google Scholar] [CrossRef]

- Moyano, M.A.; Paríz, R.; Martín-Martínez, J.M. Assessment of the compatibility in hot melts by using different thermoanalytical methods. Ethylene/n-butyl acrylate (EBA) hot melts containing tackifiers of different nature. J. Therm. Anal. Calorim. 2017, 129, 1495–1503. [Google Scholar] [CrossRef]

- Pérez-Limiñana, M.A.; Arán-Aís, F.; Torró-Palau, A.M.; Orgilés-Barcel, C.; Martín-Martínez, J.M. Influence of the hard-to-soft segment ratio on the adhesion of water-borne polyurethane adhesive. J. Adhes. Sci. Technol. 2007, 21, 755–773. [Google Scholar] [CrossRef]

- García-Pacios, V.; Costa, V.; Colera, M.; Martín-Martínez, J.M. Waterborne polyurethane dispersions obtained with polycarbonate of hexanediol intended for use as coatings. Prog. Org. Coat. 2011, 71, 136–146. [Google Scholar] [CrossRef]

- Pérez-Limañana, M.A.; Arán-Aís, F.; Torró-Palau, A.M.; Orgilés-Barceló, A.C.; Martín-Martínez, J.M. Characterization of waterborne polyurethane adhesives containing different amounts of ionic groups. Int. J. Adhes. Adhes. 2005, 25, 507–517. [Google Scholar] [CrossRef]

- Fuensanta, M.; Martín-Martínez, J.M. Thermoplastic polyurethane coatings made with mixtures of polyethers of different molecular weights with pressure sensitive adhesion property. Prog. Org. Coat. 2018, 118, 148–156. [Google Scholar] [CrossRef] [Green Version]

- Sancho-Querol, S.; Yáñez-Pacios, A.J.; Martín-Martínez, J.M. New Binary Blends of Ethylene-co-n-butyl Acrylate (EBA) Copolymer and Low Molecular Weight Rosin Ester Resin with Potential as Pressure Sensitive Adhesives. Materials 2018, 11, 2037. [Google Scholar] [CrossRef] [Green Version]

- Bahattab, M.A.; Donate-Robles, J.; García-Pacios, V.; Martín-Martínez, J.M. Characterization of polyurethane adhesives containing nanosilicas of different particle size. Int. J. Adhes. Adhes. 2011, 31, 97–103. [Google Scholar] [CrossRef]

- Vega-Baudrit, J.; Sibaja-Ballestero, M.; Vázquez, P.; Torregrosa-Maciá, R.; Martín-Martínez, J.M. Properties of thermoplastic polyurethane adhesives containing nanosilicas with different specific surface area and silanol content. Int. J. Adhes. Adhes. 2007, 27, 469–479. [Google Scholar] [CrossRef]

- Pérez-Limiñana, M.A.; Arán-Aís, F.; Torró-Palau, A.M.; Orgilés-Barceló, C.; Martín-Martínez, J.M. Structure and properties of waterborne polyurethane adhesives obtained by different methods. J. Adhes. Sci. Technol. 2006, 20, 519–536. [Google Scholar] [CrossRef]

- Barrueso-Martínez, M.L.; Ferrándiz-Gómez, T.P.; Romero-Sánchez, M.D.; Martín-Martínez, J.M. Characterization of EVA-based adhesives containing different amounts of rosin ester or polyterpene tackifier. J. Adhes. 2003, 79, 805–824. [Google Scholar] [CrossRef]

- Torró-Palau, A.M.; Fernández-García, J.C.; Orgilés-Barceló, A.C.; Ferrándiz-Gómez, T.P.; Martín-Martínez, J.M. Rheological properties of polyurethane adhesives containing silica as filler: Influence of the nature and surface chemistry of silica. Macromol. Symp. 2001, 169, 191–196. [Google Scholar] [CrossRef]

- Barrueso-Martínez, M.L.; Ferrándiz-Gómez, T.P.; Cepeda-Jiménez, C.M.; Sepulcre-Guilabert, J.; Martín-Martínez, J.M. Influence of the vinyl acetate content and the tackifier nature on the rheological, thermal, and adhesion properties of EVA adhesives. J. Adhes. Sci. Technol. 2001, 15, 243–263. [Google Scholar] [CrossRef]

- Martínez-Ruiz, A.; Torró-Palau, A.M.; Orgilés-Barceló, A.C.; Martín-Martínez, J.M. Effect of using sepiolite silicate + fumed silica mixtures as fillers on the characteristics of solvent-based polyurethane adhesives. J. Adhes. Sci. Technol. 2000, 14, 833–849. [Google Scholar] [CrossRef]

- Torró-Palau, A.; Fernández-García, J.C.; Orgilés-Barceló, A.C.; Pérez-Lozano, V.M.; Martín-Martínez, J.M. Attapulgite as a filler for solvent-based polyurethane adhesives. J. Adhes. Sci. Technol. 1998, 12, 479–495. [Google Scholar] [CrossRef]

- Chang, E.P. Viscoelastic windows of pressure-sensitive adhesives. J. Adhes. 1991, 34, 189–200. [Google Scholar] [CrossRef]

- Pascual-Sánchez, V.; Mahíques-Bujanda, M.M.; Martín-Martínez, J.M.; Alió-Sanz, J.L.; Mulet-Homs, E. Synthesis and characterization of a new acrylic adhesive mixture for use in ocular strabismus surgery. J. Adhes. 2003, 79, 1067–1089. [Google Scholar] [CrossRef]

- Landa, M.; Fernández, M.; Muñoz, M.E.; Santamaria, A. The effect of flow on the physical properties of polyurethane/carbon nanotubes nanocomposites: Repercussions on their use as electrically conductive Hot-Melt adhesives. Polym. Compos. 2014, 36, 704–712. [Google Scholar] [CrossRef]

- Fernández, M.; Landa, M.; Muñoz, M.E.; Santamaria, A. Thermal and Viscoelastic Features of New Nanocomposites Based on a Hot-Melt Adhesive Polyurethane and Multi-Walled Carbon Nanotubes. Macromol. Mater. Eng. 2010, 295, 1031–1041. [Google Scholar] [CrossRef]

- Fernández, M.; Landa, M.; Muñoz, M.E.; Santamaria, A. Tackiness of an electrically conducting polyurethane–nanotube nanocomposite. Int. J. Adhes. Adhes. 2010, 30, 609–614. [Google Scholar] [CrossRef]

- Florez, S.; Santamaria, S.M. A Novel Dynamic Viscoelastic Measurements of Polyurethane Copolymer Melts and Their Implication to Tack Results. Macromol. Mater. Eng. 2006, 291, 1194–1200. [Google Scholar] [CrossRef]

- Tenorio-Alfonso, A.; Sánchez, M.C.; Franco, J.M. Synthesis and mechanical properties of bio-sourced polyurethane adhesives obtained from castor oil and MDI-modified cellulose acetate: Influence of cellulose acetate modification. Int. J. Adhes. Adhes. 2019, 95, 102404. [Google Scholar] [CrossRef]

- Tenorio-Alfonso, A.; Sánchez, M.C.; Franco, J.M. Preparation, Characterization and Mechanical Properties of Bio-Based Polyurethane Adhesives from Isocyanate-Functionalized Cellulose Acetate and Castor Oil for Bonding Wood. Polymers 2017, 9, 132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Santan, H.D.; James, C.; Fratini, E.; Martínez, I.; Valencia, C.; Sánchez, M.C.; Franco, J.M. Structure-property relationships in solvent free adhesives derived from castor oil. Ind. Crop. Prod. 2018, 121, 90–98. [Google Scholar] [CrossRef]

- Tenorio-Alfonso, A.; Pizarro, M.L.; Sánchez, M.C.; Franco, J.M. Assessing the rheological properties and adhesion performance on different substrates of a novel green polyurethane based on castor oil and cellulose acetate: A comparison with commercial adhesives. Int. J. Adhes. Adhes. 2018, 82, 21–26. [Google Scholar] [CrossRef]

- Núñez, L.; Gómez-Barreiro, S.; Gracia-Fernández, C.A. Study of the influence of isomerism on the curing properties of the epoxy system DGEBA (n = 0)/1,2-DCH by rheology. Rheol. Acta 2005, 45, 184–191. [Google Scholar] [CrossRef]

- Núñez-Regueira, L.; Gracia-Fernández, C.A.; Gómez-Barreiro, S. Use of rheology, dielectric analysis and differential scanning calorimetry for gel time determination of a thermoset. Polymer 2005, 46, 5979–5985. [Google Scholar] [CrossRef]

- Sánchez-Silva, B.; Díaz-Díaz, A.; Tarrío-Saavedra, J.; López-Beceiro, J.; Gracia-Fernández, C.A.; Artiaga, R. Thermal and rheological comparison of adhesives. J. Therm. Anal. Calorim. 2019, 138, 3357–3366. [Google Scholar] [CrossRef]

- Gómez-Barreiro, S.; Gracia-Fernández, C.; López-Beceiro, J.; Artiaga, R. Rheological testing of a curing process controlled by Joule heating. Polym. Test. 2016, 55, 97–100. [Google Scholar] [CrossRef]

- Rodríguez, R.; Pérez, B.; Flórez, S. Effect of Different Nanoparticles on Mechanical Properties and Curing Behavior of Thermoset Polyurethane Adhesives. J. Adhes. 2014, 90, 848–859. [Google Scholar] [CrossRef]

- Gandini, A. Polymers from renewable resources: A challenge for the future of macromolecular materials. Macromolecules 2008, 41, 9491–9504. [Google Scholar] [CrossRef]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef]

- Schneiderman, D.K.; Hillmyer, M.A. 50th Anniversary Perspective: There is a great future in sustainable polymers. Macromolecules 2017, 50, 3733–3749. [Google Scholar] [CrossRef]

- Guerrero, A. Grupo de Tecnología y Diseño de Productos Multicomponentes (ReoTech). Boletín Trimest. Inf. Grupo Español de Reol. 2016, 18, 1–2. [Google Scholar]

- Bengoechea, C.; Arrachid, A.; Guerrero, A.; Hill, A.E.; Mitchell, J.R. Relationship between the glass transition temperature and the melt flow behavior for gluten, casein and soya. J. Cereal Sci. 2007, 45, 275–284. [Google Scholar] [CrossRef]

- Jerez, A.; Partal, P.; Martínez, I.; Gallegos, C.; Guerrero, A. Rheology and processing of gluten based bioplastics. Biochem. Eng. J. 2005, 26, 131–138. [Google Scholar] [CrossRef]

- Jerez, A.; Partal, P.; Martinez, I.; Gallegos, C.; Guerrero, A. Egg whitebased bioplastics developed by thermomechanical processing. J. Food Eng. 2007, 82, 608–617. [Google Scholar] [CrossRef]

- Jerez, A.; Partal, P.; Martinez, I.; Gallegos, C.; Guerrero, A. Protein-based bioplastics: Effect of thermo-mechanical processing. Rheol. Acta 2007, 46, 711–720. [Google Scholar] [CrossRef]

- Perez-Puyana, V.; Romero, A.; Guerrero, A. Influence of collagen concentration and glutaraldehyde on collagen-based scaffold properties. J. Biomed. Mater. Res. 2016, 104, 1462–1468. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Heincke, D.; Martínez, I.; Partal, P.; Guerrero, A.; Gallegos, C. Development of antimicrobial active packaging materials based on gluten proteins. J. Sci. Food Agric. 2015, 96, 3432–3438. [Google Scholar] [CrossRef] [PubMed]

- Cuadri, A.A.; Romero, A.; Bengoechea, C.; Guerrero, A. The effect of carboxyl group content on water uptake capacity and tensile properties of functionalized soy protein based superabsorbent plastics. J. Polym. Environ. 2018, 26, 2934–2944. [Google Scholar] [CrossRef]

- Gennadios, A. Protein Based Films and Coatings; CRC Press: New York, NY, USA, 2002; pp. 66–115. [Google Scholar]

- González-Gutiérrez, J.; Partal, P.; García-Morales, M.; Gallegos, C. Effect of processing on the viscoelastic, tensile and optical properties of albumen/starch based bioplastic. Carbohydr. Polym. 2011, 84, 308–315. [Google Scholar] [CrossRef]

- Félix, M.; Martín-Alfonso, J.E.; Romero, A.; Guerrero, A. Development of albumen/soy biobased plastic materials processed by injection molding. J. Food Eng. 2014, 125, 7–16. [Google Scholar] [CrossRef]

- Mortier, R.M.; Fox, M.F.; Orszulik, S. Chemistry and Technology of Lubricants; Springer: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Mas, R.; Magnin, A. Rheology of colloidal suspensions: Case of lubricating greases. J. Rheol. 1994, 38, 889–908. [Google Scholar] [CrossRef]

- Sanchez, R.; Valencia, C.; Franco, J.M. Rheological and tribological characterization of new acylated chitosan-based biodegradable lubricating grease: A comparative study with transitional lithium and calcium greases. Tribol. Trans. 2014, 57, 445–454. [Google Scholar] [CrossRef]

- Sánchez, R.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Development of new green lubricating grease formulations based on cellulosic derivatives and castor oil. Green Chem. 2009, 11, 686–693. [Google Scholar] [CrossRef]

- Sánchez, R.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Thermal and mechanical characterization of cellulosic derivatives-based oleogels potentially applicable as bio-lubricating greases: Influence of ethyl cellulose molecular weight. Carbohydr. Polym. 2011, 83, 151–158. [Google Scholar] [CrossRef]

- Nuñez, N.; Martin-Alfonso, J.E.; Eugenio, M.E.; Valencia, C.; Diaz, M.J.; Franco, J.M. Preparation and Characterization of Gel-like Dispersions Based on Cellulosic Pulps and Castor Oil for Lubricant Applications. Ind. Eng. Chem. Res. 2011, 50, 5618–5627. [Google Scholar] [CrossRef]

- Gallego, R.; Arteaga, J.F.; Valencia, C.; Diaz, M.J.; Franco, J.M. Gel-Like Dispersions of HMDI-Cross-Linked Lignocellulosic Materials in Castor Oil: Toward Completely Renewable Lubricating Grease Formulations. ACS Sustain. Chem. Eng. 2015, 3, 2130–2141. [Google Scholar] [CrossRef]

- Cailloux, J.; Santana, O.O.; Franco-Urquiza, E.; Bou, J.J.; Carrasco, F.; Gámez-Pérez, J.; Maspoch, M.L. Sheets of branched poly(lactic acid) obtained by one step reactive extrusion calendaring process: Melt rheology analysis. Express Polym. Lett. 2013, 7, 304–318. [Google Scholar] [CrossRef]

- Cailloux, J.; Santana, O.O.; Maspoch, M.L. Using viscoelastic properties to quantitatively estimate the amount of modified poly(lactic acid) chains through reactive extrusion. J. Rheol. 2015, 59, 1191–1227. [Google Scholar] [CrossRef] [Green Version]

- Mavridis, H.; Shroff, R.N. Temperature dependence of polyolefin melt rheology. Polym. Eng. Sci. 1992, 32, 1778–1791. [Google Scholar] [CrossRef]

- Booij, H.C.; Palmen, J.H.M. Some aspects of linear and nonlinear viscoelastic behavior of polymer melts in shear. Rheol. Acta 1982, 21, 376–387. [Google Scholar] [CrossRef]

- Booij, H.C.; Palmen, J.H.M. Linear viscoelastic properties of miscible polymer blend system. In Theoretical and Applied Rheology, Proceedings of the XIth International Congress on Rheology; Moldenaers, P., Keunings, R., Eds.; Elsevier: Brussels, Belguim, 1992; pp. 321–323. [Google Scholar]

- Moniruzzaman, M.; Winey, K.I. Polymer Nanocomposites Containing Carbon Nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Winey, K.I.; Vaia, R.A. Polymer Nanocomposites. MRS Bull. 2007, 32, 314–322. [Google Scholar] [CrossRef] [Green Version]

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/Polymer Nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Huegun, A.; Fernández, M.; Muñoz, M.E.; Santamaria, A. Rheological properties and electrical conductivity of irradiated MWCNT/PP nanocomposites. Compos. Sci. Technol. 2012, 72, 1602–1607. [Google Scholar] [CrossRef]

- Huegun, A.; Fernández, M.; Peña, J.; Muñoz, M.E.; Santamaria, A. Liquid-State and Solid-State Properties of Nanotube/Polypropylene Nanocomposites Elaborated via a Simple Procedure. Nanomaterials 2013, 3, 173–191. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Canales, J.; Muñoz, M.E.; Fernández, M.; Santamaria, A. Rheology, electrical conductivity and crystallinity of a polyurethane/graphene composite: Implications for its use as a hot-melt adhesive. Compos. Part A Appl. Sci. Manuf. 2016, 84, 9–16. [Google Scholar] [CrossRef]

- Sangroniz, L.; Palacios, J.K.; Fernández, M.; Eguiazabal, J.I.; Santamaria, A.; Müller, A.J. Linear and non-linear rheological behavior of polypropylene/polyamide blends modified with a compatibilizer agent and nanosilica and its relationship with the morphology. Eur. Polym. J. 2016, 83, 10–21. [Google Scholar] [CrossRef]

- Sangroniz, L.; Moncerrate, M.A.; De Amicis, V.A.; Palacios, J.K.; Fernández, M.; Santamaria, A.; Sánchez, J.J.; Laoutid, F.; Dubois, P.; Müller, A.J. The outstanding ability of nanosilica to stabilize dispersions of nylon 6 droplets in a polypropylene matrix. J. Polym. Sci. B Polym. Phys. 2015, 53, 1567–1579. [Google Scholar] [CrossRef]

- Sangroniz, L.; Santamaria, A.; Muller, A.J. Rheology of Polymer Blend Nanocomposites. In Rheology of Polymer Blends and Nanocomposites; Thomas, S., Chandrasekharakurup, S., Chandran, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Sangroniz, L.; Ruiz, J.L.; Sangroniz, A.; Fernández, M.; Etxeberria, A.; Müller, A.J.; Santamaria, A. Polyethylene terephthalate/Low Density Polyethylene/Titanium dioxide blend nanocomposites: Morphology, crystallinity, rheology and transport properties. J. Appl. Polym. Sci. 2019, 136, 46986. [Google Scholar] [CrossRef]

- Cidade, M.T.; Fernández, M.; Filipe, S.; Santamaria, A. PVT and oscillatory tests to analyze pressure effects on polypropylene/Rodrun LC3000 blends: Determination of the pressure dependency of the viscosity. Polym. Test. 2012, 31, 290–296. [Google Scholar] [CrossRef]

- Ares, A.; Bouza, R.; Pardo, S.G.; Abad, M.J.; Barral, L. Rheological, Mechanical and Thermal Behaviour of Wood Polymer Composites Based on Recycled Polypropylene. J. Polym. Environ. 2010, 18, 318–325. [Google Scholar] [CrossRef]

- Pardo, S.G.; Arboleda, L.; Ares, A.; García, X.; Dopico, S.; Abad, M.J. Toughening strategies of carbon nanotube/polycarbonate composites with electromagnetic interference shielding properties. Polym. Compos. 2013, 34, 1938–1949. [Google Scholar] [CrossRef]

- Ares, A.; Abad, M.J.; Noguerol, R.; Dopico, S.; Cerecedo, C.; Valcarcel, V.; Caamano, J.M.; Guitian, F. Alumina Whisker Selection to Design Fiber-Reinforced Polyethylene Composites. Polym. Plast. Technol. Eng. 2014, 53, 1119–1130. [Google Scholar] [CrossRef]

- Dopico-García, M.S.; Ares, A.; Lasagabáster-Latorre, A.; García, X.; Arboleda, L.; Abad, M.J. Extruded polyaniline/EVA blends: Enhancing electrical conductivity using gallate compatibilizers. Synth. Met. 2014, 189, 193–202. [Google Scholar] [CrossRef]

- Arboleda-Clemente, L.; Ares-Pernas, A.; Garcia, X.; Dopico, S.; Abad, M.J. Segregated conductive network of MWCNT in PA12/PA6 composites: Electrical and rheological behavior. Polym. Compos. 2017, 38, 2679–2686. [Google Scholar] [CrossRef]

- Vega, J.F.; Martínez-Salazar, J.; Trujillo, M.; Arnal, M.L.; Müller, A.J.; Bredeau, S.; Dubois, P.H. Rheology, processing, tensile properties and crystallization of polyethylene/carbon nanotube nanocomposites. Macromolecules 2009, 42, 4719–4727. [Google Scholar] [CrossRef]

- Hay, G.; Mackay, M.E. Pressure and temperature effects in slit rheometry. J. Rheol. 1999, 43, 1099–1116. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Gupta, M.; Tarannum, H. Evaluation of TDI production waste as a modifier for bituminous waterproofing. Constr. Build. Mater. 2004, 18, 591–601. [Google Scholar] [CrossRef]

- Ait-Kadi, A.; Brahimi, H.; Bousmina, M. Polymer blends for enhanced asphalt binders. Polym. Eng. Sci. 1996, 36, 1724–1733. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological properties of styrene-butadiene-styrene polymer modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Fawcett, A.H.; McNally, T. Blends of bitumen with polymers having a styrene component. Polym. Eng. Sci. 2001, 41, 1251–1264. [Google Scholar] [CrossRef]

- Garcia-Morales, M.; Partal, P.; Navarro, F.J.; Martinez-Boza, F.; Gallegos, C.; Gonzalez, N.; Gonzalez, O.; Munoz, M.E. Viscous properties and microstructure of recycled EVA modified bitumen. Fuel 2004, 83, 31–38. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martinez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- Gallegos, C.; Garcia-Morales, M. Rheology of polymer-modified bitumens. In Polymer Modified Bitumen: Properties and Characterisation; McNally, T., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 197–237. [Google Scholar]

- Partal, P.; Martinez-Boza, F.; Conde, B.; Gallegos, C. Rheological characterisation of synthetic binders and unmodified bitumens. Fuel 1999, 78, 1–10. [Google Scholar] [CrossRef]

- Martin-Alfonso, M.J.; Partal, P.; Navarro, F.J.; Garcia-Morales, M.; Gallegos, C. Use of a MDI-functionalized reactive polymer for the manufacture of modified bitumen with enhanced properties for roofing applications. Eur. Polym. J. 2008, 44, 1451–1461. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Garcia-Morales, M.; Martinez-Boza, F.J.; Gallegos, C. Bitumen modification with a low-molecular-weight reactive isocyanate-terminated polymer. Fuel 2007, 86, 2291–2299. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Garcia-Morales, M.; Martin-Alfonso, M.J.; Martinez-Boza, F.; Gallegos, C.; Bordado, J.C.M.; Diogo, A.C. Bitumen modification with reactive and non-reactive (virgin and recycled) polymers: A comparative analysis. J. Ind. Eng. Chem. 2009, 15, 458–464. [Google Scholar] [CrossRef]

- Garcia-Morales, M.; Partal, P.; Navarro, F.J.; Gallegos, C. Effect of waste polymer addition on the rheology of modified bitumen. Fuel 2006, 85, 936–943. [Google Scholar] [CrossRef]

- Gonzalez, O.; Munoz, M.E.; Santamaria, A. Bitumen/polyethylene blends: Using m-LLDPEs to improve stability and viscoelastic properties. Rheol. Acta 2006, 45, 603–610. [Google Scholar] [CrossRef]

- Rojo, E.; Fernandez, M.; Peña, J.J.; Peña, B.; Muñoz, M.E.; Santamaria, A. Rheological aspects of blends of metallocene-catalyzed atactic polypropylenes with bitumen. Polym. Eng. Sci. 2004, 44, 1792–1799. [Google Scholar] [CrossRef]

- Yuliestyan, A.; Cuadri, A.A.; Garcia-Morales, M.; Partal, P. Influence of polymer melting point and Melt Flow Index on the performance of ethylene-vinyl-acetate modified bitumen for reduced-temperature application. Mater. Des. 2016, 96, 180–188. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez, O.; Muñoz, M.E.; Santamaria, A.; Garcia-Morales, M.; Navarro, F.J.; Partal, P. Rheology and stability of bitumen/EVA blends. Eur. Polym. J. 2004, 40, 2365–2372. [Google Scholar] [CrossRef]

- Perez-Lepe, A.; Martinez-Boza, F.J.; Gallegos, C.; Gonzalez, O.; Muñoz, M.E.; Santamaria, A. Influence of the processing conditions on the rheological behaviour of polymer-modified bitumen. Fuel 2003, 82, 1339–1348. [Google Scholar] [CrossRef]

- Lagos-Varas, M.; Movilla-Quesada, D.; Raposeiras, A.C.; Arenas, J.P.; Calzada-Perez, M.A.; Vega-Zamanillo, A.; Lastra-Gonzalez, P. Influence of limestone filler on the rheological properties of bituminous mastics through susceptibility master curves. Constr. Build. Mater. 2020, 231, 117126. [Google Scholar] [CrossRef]

- Roman, C.; Cuadri, A.A.; Liashenko, I.; Garcia-Morales, M.; Partal, P. Linear and non-linear viscoelastic behavior of SBS and LDPE modified bituminous mastics. Constr. Build. Mater. 2016, 123, 464–472. [Google Scholar] [CrossRef]

- Barral, M.; Garmendia, P.; Muñoz, M.E.; Palmillas, Z.; Romera, R.; Santamaria, A.; Villanueva, S. Novel bituminous mastics for pavements with improved fire performance. Constr. Build. Mater. 2012, 30, 650–656. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Iglesias, G.R.; Rubio-Gamez, M.C. Mechanical performance of mechanomutable asphalt binders under cyclic creep and recovery loads. Constr. Build. Mater. 2016, 113, 506–512. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sanchez, M.; Gamiz, F.; Rubio-Gamez, M.C. Mechanical and thermal properties of graphene modified asphalt binders. Constr. Build. Mater. 2018, 180, 265–274. [Google Scholar] [CrossRef]

- Miro, R.; Martinez, A.H.; Moreno-Navarro, F.; Rubio-Gamez, M.C. Effect of ageing and temperature on the fatigue behaviour of bitumens. Mater. Des. 2015, 86, 129–137. [Google Scholar] [CrossRef] [Green Version]

- Romera, R.; Santamaria, A.; Pena, J.J.; Munoz, M.E.; Barral, M.; Garcia, E.; Janez, V. Rheological aspects of the rejuvenation of aged bitumen. Rheol. Acta 2006, 45, 474–478. [Google Scholar] [CrossRef]

| Method | Shear Rates Range (s−1) |

|---|---|

| Compression moulding | 1–10 |

| Calendaring | 10–100 |

| Extrusion moulding | 100–1000 |

| Additive Manufacturing | 10–2000 |

| Injection moulding | 1000–100,000 |

| Institution | 1995–1999 | 2000–2004 | 2005–2009 | 2010–2014 | 2015–2020 |

|---|---|---|---|---|---|

| University of the Basque Country | 8 | 8 | 9 | 4 | 10 |

| Institute for the Structure of Matter CSIC (Madrid) | 1 | 4 | 5 | 3 | 3 |

| REPSOL and ERCROS | 4 | 6 | 2 | 2 | 4 |

| Others | 1 | 1 | 3 | 5 | 12 |

| In Total: 95 | 14 | 19 | 19 | 14 | 29 |

| Institution | 1995–1999 | 2000–2004 | 2005–2009 | 2010–2014 | 2015–2020 |

|---|---|---|---|---|---|

| Rovira i Virgili University | 8 | 17 | 14 | ||

| University of the Basque Country | 2 | 2 | 7 | 5 | |

| Complutense University of Madrid | 4 | ||||

| National Institute of Aerospace Technology | 3 | ||||

| Others | 1 | 5 | 7 | 9 | |

| In total: 84 | 2 | 3 | 20 | 36 | 23 |

| Institution | 1995–1999 | 2000–2004 | 2005–2009 | 2010–2014 | 2015–2020 |

|---|---|---|---|---|---|

| Prof. Martin-Martínez | 5 | 16 | 7 | 6 | 9 |

| INESCOP | 1 | 2 | 1 | ||

| University of the Basque Country | 1 | 3 | 1 | ||

| University of Huelva | 1 | 4 | |||

| TECNALIA | 1 | ||||

| TA Instruments Spain | 2 | 3 | |||

| In total: 63 | 5 | 17 | 11 | 12 | 18 |

| Institution | 1995–1999 | 2000–2004 | 2005–2009 | 2010–2014 | 2015–2020 |

|---|---|---|---|---|---|

| University of the Basque Country | 1 | 5 | 3 | ||

| University of Alicante | 1 | 3 | 1 | ||

| Institute of Polymer Science and Technology, CSIC | 1 | 1 | 4 | ||

| Coruña University | 2 | ||||

| Materials Technology Institute, Polytechnic University of València | 2 | ||||

| University of Zaragoza, Centro Politécnico Superior | 2 | 1 | |||

| University of Seville | 3 | ||||

| Others | 2 | 8 | 9 | 14 | |

| In total: 63 | 4 | 10 | 27 | 22 |

| Institution | 1995–1999 | 2000–2004 | 2005–2009 | 2010–2014 | 2015–2020 |

|---|---|---|---|---|---|

| University of Huelva | 1 | 8 | 18 | 21 | 22 |

| University of Basque Country | 4 | 5 | 2 | ||

| University of Granada | 9 | ||||

| Others | 4 | 9 | |||

| In total: 103 | 1 | 12 | 23 | 27 | 40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sangroniz, L.; Fernández, M.; Partal, P.; Santamaria, A. Rheology of Polymer Processing in Spain (1995–2020). Polymers 2021, 13, 2314. https://doi.org/10.3390/polym13142314

Sangroniz L, Fernández M, Partal P, Santamaria A. Rheology of Polymer Processing in Spain (1995–2020). Polymers. 2021; 13(14):2314. https://doi.org/10.3390/polym13142314

Chicago/Turabian StyleSangroniz, Leire, Mercedes Fernández, Pedro Partal, and Antxon Santamaria. 2021. "Rheology of Polymer Processing in Spain (1995–2020)" Polymers 13, no. 14: 2314. https://doi.org/10.3390/polym13142314

APA StyleSangroniz, L., Fernández, M., Partal, P., & Santamaria, A. (2021). Rheology of Polymer Processing in Spain (1995–2020). Polymers, 13(14), 2314. https://doi.org/10.3390/polym13142314