The Integral Utilization of Date Palm Waste to Produce Plastic Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Date Palm Waste Characterization

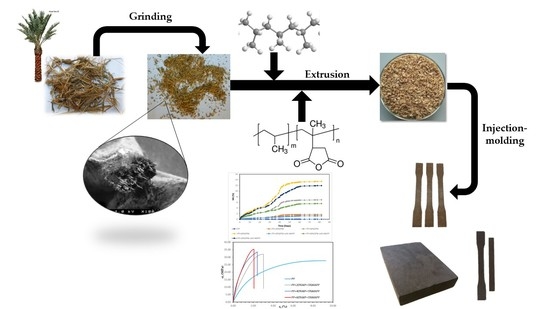

2.2.2. Date Palm Waste Plastic Composite Preparation

2.2.3. Composite’s Characterization

3. Results and Discussion

3.1. Date Palm Characterization

3.1.1. Chemical Composition

3.1.2. Morphological Characterization

3.2. Tensile Properties of Date Palm Waste Plastic Composites without Coupling Agent

3.3. Tensile Properties of Date Palm Waste Composites with the Coupling Agent

3.4. Flexural and Impact Properties of Date Palm Waste Composites with the Coupling Agent

3.5. Thermal Properties and Stability of Date Palm Waste Composites

3.6. Water Uptake and Wood Composite Behavior at Wet Conditions

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Kumar, V.; Pathak, P.; Bhardwaj, N.K. Micro-nanofibrillated cellulose preparation from bleached softwood pulp using chemo-refining approach and its evaluation as strength enhancer for paper properties. Appl. Nanosci. 2021, 11, 101–115. [Google Scholar] [CrossRef]

- Vedrtnam, A.; Kumar, S.; Chaturvedi, S. Experimental study on mechanical behavior, biodegradability, and resistance to natural weathering and ultraviolet radiation of wood-plastic composites. Compos. Part B Eng. 2019, 176, 107282. [Google Scholar] [CrossRef]

- Ashori, A. Wood-plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Keskisaari, A.; Kärki, T. The use of waste materials in wood-plastic composites and their impact on the profitability of the product. Resour. Conserv. Recycl. 2018, 134, 257–261. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Preparation and properties of wood plastic composites made of recycled high-density polyethylene. J. Compos. Mater. 2009, 43, 877–883. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Mutjé, P.; Boufi, S. Olive stones flour as reinforcement in polypropylene composites: A step forward in the valorization of the solid waste from the olive oil industry. Ind. Crops Prod. 2015, 72, 183–191. [Google Scholar] [CrossRef]

- Tarrés, Q.; Oliver-Ortega, H.; Alcalà, M.; Espinach, X.X.; Mutjé, P.; Delgado-Aguilar, M. Research on the strengthening advantages on using cellulose nanofibers as polyvinyl alcohol reinforcement. Polymers 2020, 12, 974. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neagu, R.C.; Gamstedt, E.K.; Berthold, F. Stiffness contribution of various wood fibers to composite materials. J. Compos. Mater. 2006, 40, 663–699. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Tarrés, Q.; Espinach, F.X.; Vilaseca, F.; Mutjé, P.; Delgado-Aguilar, M. Influence of lignin content on the intrinsic modulus of natural fibers and on the stiffness of composite materials. Int. J. Biol. Macromol. 2020, 155, 81–90. [Google Scholar] [CrossRef]

- Vilaseca, F.; Serra-Parareda, F.; Espinosa, E.; Rodríguez, A.; Mutjé, P.; Delgado-Aguilar, M. Valorization of Hemp Core Residues: Impact of NaOH Treatment on the Flexural Strength of PP Composites and Intrinsic Flexural Strength of Hemp Core Fibers. Biomolecules 2020, 10, 823. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A. Effects of fiber characteristics on the physical and mechanical properties of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1975–1981. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K.; Verma, S.K.; Tripathy, S.S. Effect of MAPP as a Coupling Agent on the Performance of Jute-PP Composites. J. Reinf. Plast. Compos. 2004, 23, 625–637. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. Part B 2017, 114, 15–22. [Google Scholar] [CrossRef] [Green Version]

- Carus, M.; Eder, A.; Dammer, L.; Korte, H.; Scholz, L.; Essel, R.; Breitmayer, E.; Barth, M. WPC/NFC Market Study 2014–10 (Update 2015–06): Wood-Plastic Composites (WPC) and Natural Fibre Composites (NFC): European and Global Markets 2012 and Future Trends in Automotive and Construction. Mark. study by Nov. Inst. GmbH, Hürth, DE. 2015. Available online: www.biobased.eu/markets (accessed on 27 June 2021).

- Battegazzore, D.; Noori, A.; Frache, A. Hemp hurd and alfalfa as particle filler to improve the thermo-mechanical and fire retardant properties of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate). Polym. Compos. 2019, 40, 3429–3437. [Google Scholar] [CrossRef]

- Anastas, P.; Warner, J. Green Chemistry: Theory and Practice; Oxford University Press: New York, NY, USA, 1998. [Google Scholar]

- Chandrasekaran, M.; Bahkali, A.H. Valorization of date palm (Phoenix dactylifera) fruit processing by-products and wastes using bioprocess technology—Review. Saudi J. Biol. Sci. 2013, 20, 105–120. [Google Scholar] [CrossRef] [Green Version]

- Liang, M.; Fu, C.; Xiao, B.; Luo, L.; Wang, Z. A fractal study for the effective electrolyte diffusion through charged porous media. Int. J. Heat Mass Transf. 2019, 137, 365–371. [Google Scholar] [CrossRef]

- Liang, M.; Liu, Y.; Xiao, B.; Yang, S.; Wang, Z.; Han, H. An analytical model for the transverse permeability of gas diffusion layer with electrical double layer effects in proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2018, 43, 17880–17888. [Google Scholar] [CrossRef]

- Bauza, E.; Botto, J.; Marchand, T.; Roux, E.; Breissier, G.; Dal Farra, C.; Domloge, N. Date palm kernel extract: An anti-aging active ingredient that exhibits significant antioxidative stress-defense properties. J. Investig. Dermatol. 2005, 124, A61. [Google Scholar]

- ALrajhi, M.; AL-Rasheedi, M.; Eltom, S.E.M.; Alhazmi, Y.; Mustafa, M.M.; Ali, A.M. Antibacterial activity of date palm cake extracts (Phoenix dactylifera). Cogent Food Agric. 2019, 5, 1625479. [Google Scholar] [CrossRef]

- Elseify, L.A.; Midani, M.; Shihata, L.A.; El-Mously, H. Review on cellulosic fibers extracted from date palms (Phoenix Dactylifera L.) and their applications. Cellulose 2019, 26, 2209–2232. [Google Scholar] [CrossRef]

- Abu-Sharkh, B.F.; Hamid, H. Degradation study of date palm fibre/polypropylene composites in natural and artificial weathering: Mechanical and thermal analysis. Polym. Degrad. Stab. 2004, 85, 967–973. [Google Scholar] [CrossRef]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part. B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.; Nógellová, Z.; Mičušík, M.; Novák, I.; Krupa, I. Mechanical, sorption and adhesive properties of composites based on low density polyethylene filled with date palm wood powder. Mater. Des. 2014, 53, 29–37. [Google Scholar] [CrossRef]

- Sbiai, A.; Maazouz, A.; Fleury, E.; Sautereau, H.; Kaddami, H. Short Date Palm Tree Fibers / Polyepoxy Composites Prepared Using Rtm Process: Effect Of Tempo Mediated Oxydation Of The Fibers. BioResources 2010, 5, 672–689. [Google Scholar]

- Oushabi, A.; Sair, S.; Oudrhiri Hassani, F.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF–Polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Ibrahim, H.; Farag, M.; Megahed, H.; Mehanny, S. Characteristics of starch-based biodegradable composites reinforced with date palm and flax fibers. Carbohydr. Polym. 2014, 101, 11–19. [Google Scholar] [CrossRef]

- Dhakal, H.; Bourmaud, A.; Berzin, F.; Almansour, F.; Zhang, Z.; Shah, D.U.; Beaugrand, J. Mechanical properties of leaf sheath date palm fibre waste biomass reinforced polycaprolactone (PCL) biocomposites. Ind. Crops Prod. 2018, 126, 394–402. [Google Scholar] [CrossRef] [Green Version]

- Mirmehdi, S.M.; Zeinaly, F.; Dabbagh, F. Date palm wood flour as filler of linear low-density polyethylene. Compos. Part. B Eng. 2014, 56, 137–141. [Google Scholar] [CrossRef]

- Bendahou, A.; Kaddami, H.; Sautereau, H.; Raihane, M.; Erchiqui, F.; Dufresne, A. Short palm tree fibers poly olefin composites: Effect of filler content and coupling agent on physical properties. Macromol. Mater. Eng. 2008, 293, 140–148. [Google Scholar] [CrossRef]

- ISO. ISO 2144:2019: Determination of Residue (Ash Content) on Ignition at 900 °C; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- TAPPI. T204cm-07: Solvent Extractives of Wood and Pulp; TAPPI: Peachtree Corners, GA, USA, 2007. [Google Scholar]

- ISO. ISO/DIS 21436: Determination of Lignin Content; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- Tarrés, Q.; Ehman, N.V.; Vallejos, M.E.; Area, M.C.; Delgado-Aguilar, M.; Mutjé, P. Lignocellulosic nanofibers from triticale straw: The influence of hemicelluloses and lignin in their production and properties. Carbohydr. Polym. 2017, 163, 20–27. [Google Scholar] [CrossRef] [PubMed]

- Alotaibi, M.D.; Alshammari, B.A.; Saba, N.; Alothman, O.Y.; Sanjay, M.R.; Almutairi, Z.; Jawaid, M. Characterization of natural fiber obtained from different parts of date palm tree (Phoenix dactylifera L.). Int. J. Biol. Macromol. 2019, 135, 69–76. [Google Scholar] [CrossRef]

- Mahdi, E.; Ochoa, D.R.H.; Vaziri, A.; Dean, A.; Kucukvar, M. Khalasa date palm leaf fiber as a potential reinforcement for polymeric composite materials. Compos. Struct. 2021, 265, 113501. [Google Scholar] [CrossRef]

- Ghori, W.; Saba, N.; Jawaid, M.; Asim, M. A review on date palm (phoenix dactylifera) fibers and its polymer composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012009. [Google Scholar] [CrossRef] [Green Version]

- Chokshi, S.; Parmar, V.; Gohil, P.; Chaudhary, V. Chemical Composition and Mechanical Properties of Natural Fibers. J. Nat. Fibers 2020. [Google Scholar] [CrossRef]

- Radoor, S.; Karayil, J.; Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J. A review on the extraction of pineapple, sisal and abaca fibers and their use as reinforcement in polymer matrix. Express Polym. Lett. 2020, 14, 309–335. [Google Scholar] [CrossRef]

- Tarrés, Q.; Vilaseca, F.; Herrera-Franco, P.J.; Espinach, F.X.; Delgado-Aguilar, M.; Mutjé, P. Interface and micromechanical characterization of tensile strength of bio-based composites from polypropylene and henequen strands. Ind. Crops Prod. 2019, 132, 319–326. [Google Scholar] [CrossRef]

- Torres, F.G.; Cubillas, M.L. Study of the interfacial properties of natural fibre reinforced polyethylene. Polym. Test. 2005, 24, 694–698. [Google Scholar] [CrossRef]

- Mulinari, D.R.; Voorwald, H.J.C.; Cioffi, M.O.H.; da Silva, M.L.C.P.; da Cruz, T.G.; Saron, C. Sugarcane bagasse cellulose/HDPE composites obtained by extrusion. Compos. Sci. Technol. 2009, 69, 214–219. [Google Scholar] [CrossRef]

- Serra, A.; Tarrés, Q.; Claramunt, J.; Mutjé, P.; Ardanuy, M.; Espinach, F.X. Behavior of the interphase of dyed cotton residue flocks reinforced polypropylene composites. Compos. Part. B Eng. 2017, 128, 200–207. [Google Scholar] [CrossRef] [Green Version]

- Jaszkiewicz, A.; Meljon, A.; Bledzki, A.K.; Radwanski, M. Gaining knowledge on the processability of PLA-based short-fibre compounds—A comprehensive comparison with their PP counterparts. Compos. Part. A Appl. Sci. Manuf. 2016, 83, 140–151. [Google Scholar] [CrossRef]

- Rodriguez, M.; Rodriguez, A.R.J.B.; Vilaseca, F.; Girones, J.; Mutje, P. Determination of corn stalk fibers’ strength through modeling of the mechanical properties of its composites. BioResources 2010, 5, 2535–2546. [Google Scholar]

- Zarges, J.C.; Sälzer, P.; Heim, H.P. Correlation of fiber orientation and fiber-matrix-interaction of injection-molded polypropylene cellulose fiber composites. Compos. Part. A Appl. Sci. Manuf. 2020, 139, 106112. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the tensile strength of natural fibre reinforced thermoplastics. Compos. Sci. Technol. 2007, 67, 2454–2466. [Google Scholar] [CrossRef]

- Paul, S.A.; Joseph, K.; Mathew, G.D.G.; Pothen, L.A.; Thomas, S. Influence of polarity parameters on the mechanical properties of composites from polypropylene fiber and short banana fiber. Compos. Part. A Appl. Sci. Manuf. 2010, 41, 1380–1387. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial hemp fibers: An overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef] [Green Version]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanen, M.; Nousiainen, P. Novel aligned hemp fibre reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part. A Appl. Sci. Manuf. 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Joffre, T.; Miettinen, A.; Berthold, F.; Gamstedt, E.K. X-ray micro-computed tomography investigation of fibre length degradation during the processing steps of short-fibre composites. Compos. Sci. Technol. 2014, 105, 127–133. [Google Scholar] [CrossRef]

- Sangeetha, V.H.; Deka, H.; Varghese, T.O.; Nayak, S.K. State of the art and future prospectives of poly(lactic acid) based blends and composites. Polym. Compos. 2018, 39, 81–101. [Google Scholar] [CrossRef]

- Trigui, A.; Karkri, M.; Pena, L.; Boudaya, C.; Candau, Y.; Bouffi, S.; Vilaseca, F. Thermal and mechanical properties of maize fibres-high density polyethylene biocomposites. J. Compos. Mater. 2013, 47, 1387–1397. [Google Scholar] [CrossRef]

- Várdai, R.; Lummerstorfer, T.; Pretschuh, C.; Jerabek, M.; Gahleitner, M.; Faludi, G.; Móczó, J.; Pukánszky, B. Comparative study of fiber reinforced PP composites: Effect of fiber type, coupling and failure mechanisms. Compos. Part. A Appl. Sci. Manuf. 2020, 133, 105895. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part. A Appl. Sci. Manuf. 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L. Mechanical performance of Kraft fibre reinforced polypropylene composites: Influence of fibre length, fibre beating and hygrothermal ageing. Compos. Part. A Appl. Sci. Manuf. 2008, 39, 1748–1755. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated Coupling Agents for Natural Fibre Composites. In Composites Part A: Applied Science and Manufacturing; Elsevier: Amsterdam, The Netherlands, 2004; Volume 35, pp. 357–362. [Google Scholar]

- Sanadi, A.R.; Caulfield, D.F.; Jacobson, R.E.; Rowell, R.M. Renewable agricultural fibers as reinforcing fillers in plastics: Prediction of thermal properties. J. Therm. Anal. Calorim. 2009, 96, 85–90. [Google Scholar]

- Doan, T.T.L.; Gao, S.L.; Mäder, E. Jute/polypropylene composites I. Effect of matrix modification. Compos. Sci. Technol. 2006, 66, 952–963. [Google Scholar] [CrossRef]

- Teramoto, Y. Recent Advances in Multi-Scale Experimental Analysis to Assess the Role of Compatibilizers in Cellulosic Filler-Reinforced Plastic Composites. J. Compos. Sci. 2021, 5, 138. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and PP composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. Part. A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Faruk, O. Abaca fibre reinforced PP composites and comparison with jute and flax fibre PP composites. Express Polym. Lett. 2007, 1, 755–762. [Google Scholar] [CrossRef]

- Halpin, J.C.; Pagano, N.J. The Laminate Approximation for Randomly Oriented Fibrous Composites. J. Compos. Mater. 1969, 3, 720–724. [Google Scholar] [CrossRef]

- Espinach, F.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.; Vilaseca, F.; Mutje, P. Analysis of tensile and flexural modulus in hemp strands/polypropylene composites. Compos. Part. B Eng. 2013, 47, 339–343. [Google Scholar] [CrossRef]

- Kakou, C.A.; Arrakhiz, F.Z.; Trokourey, A.; Bouhfid, R.; Qaiss, A.; Rodrigue, D. Influence of coupling agent content on the properties of high density polyethylene composites reinforced with oil palm fibers. Mater. Des. 2014, 63, 641–649. [Google Scholar] [CrossRef]

- Shah Mohammadi, M.; Ahmed, I.; Muja, N.; Rudd, C.D.; Bureau, M.N.; Nazhat, S.N. Effect of phosphate-based glass fibre surface properties on thermally produced poly(lactic acid) matrix composites. J. Mater. Sci. Mater. Med. 2011, 22, 2659–2672. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mohanty, S. Sisal Glass Fiber Reinforced PP Hybrid Composites: Effect of MAPP on the Dynamic Mechanical and Thermal Properties. J. Reinf. Plast. Compos. 2010, 29, 1551–1568. [Google Scholar] [CrossRef]

- Gironès, J.; Lopez, J.P.; Vilaseca, F.; Bayer, R.; Herrera-Franco, P.J.; Mutjé, P. Biocomposites from Musa textilis and polypropylene: Evaluation of flexural properties and impact strength. Compos. Sci. Technol. 2011, 71, 122–128. [Google Scholar] [CrossRef]

- Girones, J.; Mendez, J.A.; Boufi, S.; Vilaseca, F.; Mutjé, P. Effect of silane coupling agents on the properties of pine fibers/polyropylene composites. J. Appl. Polym. Sci. 2007, 103, 3706–3717. [Google Scholar] [CrossRef]

- Wang, W.; Sain, M.; Cooper, P.A. Study of moisture absorption in natural fiber plastic composites. Compos. Sci. Technol. 2006, 66, 379–386. [Google Scholar] [CrossRef]

- Daramola, O.O.; Akintayo, O.S. Water Absorption Characteristics of Epoxy Matrix Composites Reinforced with Green Silica Particles. Leonardo Electron. J. Pract. Technol. 2018, 2018, 215–232. [Google Scholar]

- Balogun, O.P.; Adediran, A.A.; Omotoyinbo, J.A.; Alaneme, K.K.; Oladele, I.O. Evaluation of Water Diffusion Mechanism on Mechanical Properties of Polypropylene Composites. Int. J. Polym. Sci. 2020, 2020, 8865748. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, J.; Li, H. Water diffusion in carbon fiber reinforced polyamide 6 composites: Experimental, theoretical, and numerical approaches. J. Reinf. Plast. Compos. 2019, 38, 578–587. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Ramos, J.A.; Retegi, A.; Llano-Ponte, R.; Mondragon, I. Mechanical properties of short flax fibre bundle/polypropylene composites: Influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos. Sci. Technol. 2005, 65, 1582–1592. [Google Scholar] [CrossRef]

- Orue, A.; Eceiza, A.; Peña-Rodriguez, C.; Arbelaiz, A. Water uptake behavior and young modulus prediction of composites based on treated sisal fibers and poly(lactic acid). Materials 2016, 9, 400. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Component | Content (wt.%) |

|---|---|

| Ashes | 8.12 ± 0.17 |

| Extractives | 3.11 ± 0.09 |

| Klason lignin | 27.81 ± 0.28 |

| Hemicellulose | 22.95 ± 0.33 |

| Cellulose | 39.34 ± 0.27 |

| Date Palm Content (wt.%) | Vf | σt (MPa) | Et (GPa) | ɛt (%) | (MPa) | Toughness (kJ/m3) | Yield Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 0 | 0 | 27.62 ± 0.65 | 1.74 ± 0.07 | 9.3 ± 0.3 | 27.62 | 2566.3 | 13.39 |

| 20 | 0.150 | 28.41 ± 0.81 | 3.07 ± 0.05 | 2.8 ± 0.2 | 21.58 | 562.4 | 16.17 |

| 40 | 0.320 | 26.17 ± 0.86 | 3.30 ± 0.03 | 2.1 ± 0.2 | 17.23 | 420.9 | 16.31 |

| 60 | 0.514 | 18.21 ± 0.54 | 4.35 ± 0.05 | 1.1 ± 0.3 | 10.76 | 137.9 | 14.83 |

| Date Palm Content (wt.%). | Vf | σt (MPa) | Et (GPa) | ɛt (%) | (MPa) | Toughness (kJ/m3) | Yield Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 0 | 0 | 27.62 ± 0.65 | 1.74 ± 0.07 | 9.3 ± 0.3 | 27.62 | 2566.3 | 13.39 |

| 20 | 0.150 | 31.93 ± 0.73 | 3.25 ± 0.06 | 3.0 ± 0.1 | 20.58 | 770.2 | 10.53 |

| 40 | 0.320 | 33.55 ± 0.91 | 4.04 ± 0.04 | 2.4 ± 0.4 | 18.49 | 630.5 | 10.66 |

| 60 | 0.514 | 35.35 ± 0.47 | 4.99 ± 0.05 | 2.0 ± 0.3 | 16.65 | 549.2 | 18.39 |

| Date Palm content (wt.%) | Vf | σf (MPa) | Ef (GPa) | ɛf (%) | (kJ/m2) | (kJ/m2) |

|---|---|---|---|---|---|---|

| 0 | 0 | 40.0 ± 0.6 | 1.50 ± 0.10 | 9.05 ± 0.11 | 68.0 ± 0.2 | 3.5 ± 0.2 |

| 20 | 0.150 | 55.6 ± 0,4 | 2.39 ± 0.07 | 4.37 ± 0.08 | 11.5 ± 0.1 | 2.9 ± 0.1 |

| 40 | 0.320 | 61.0 ± 0.5 | 3.29 ± 0.09 | 3.24 ± 0.16 | 10.5 ± 0.3 | 2.8 ± 0.1 |

| 60 | 0.514 | 62.3 ± 0.2 | 4.99 ± 0.06 | 1.29 ± 0.09 | 8.7 ± 0.1 | 2.5 ± 0.1 |

| ΔHm or ΔHc (J/g) | Tm or Tc (°C) | Xc % Crystallinity | (Tm–Tc) (°C) | ||

|---|---|---|---|---|---|

| PP | Heating | 91.4 | 169.2 | 55.95 | 44.7 |

| Cooling | 106.3 | 124.5 | |||

| PP–DPW Without MAPP | Heating | 100.6 | 170.5 | 45.80 | 46.2 |

| Cooling | 87.0 | 124.3 | |||

| PP–DPW With MAPP | Heating | 111.9 | 169.4 | 52.05 | 46.7 |

| Cooling | 98.9 | 122.7 |

| Date Palm Content (wt.%) | Slpoe (n) | Intercept (k) | R2 | |

|---|---|---|---|---|

| Without MAPP | 20 | 0.907 | 0.023 | 0.982 |

| 40 | 0.744 | 0.044 | 0.970 | |

| 60 | 0.786 | 0.037 | 0.973 | |

| With MAPP | 20 | 0.640 | 0.065 | 0.988 |

| 40 | 0.666 | 0.059 | 0.989 | |

| 60 | 0.777 | 0.036 | 0.980 |

| Date Palm Content (wt.%) | σt (MPa) | Decrease on σt (%) | Et (GPa) | Decrease on Et (%) | ɛt (%) | Decrease on ɛt (%) | |

|---|---|---|---|---|---|---|---|

| PP | 0 | 27.50 ± 0.41 | 0.4 | 1.58 ± 0.09 | 10.0 | 9.0 ± 0.3 | 3.3 |

| Without MAPP | 20 | 27.42 ± 0.37 | 3.6 | 2.81 ± 0.07 | 9.3 | 2.7 ± 0.1 | 3.7 |

| 40 | 24.13 ± 0.29 | 8.4 | 3.04 ± 0.04 | 8.6 | 1.8 ± 0.4 | 16.7 | |

| 60 | 16.23 ± 0.17 | 12.2 | 3.92 ± 0.10 | 10.9 | 1.0 ± 0.3 | 10.0 | |

| With MAPP | 20 | 31.21 ± 0.38 | 2.3 | 3.12 ± 0.08 | 4.2 | 2.9 ± 0.2 | 3.4 |

| 40 | 31.67 ± 0.16 | 5.9 | 3.75 ± 0.05 | 7.7 | 2.2 ± 0.2 | 9.1 | |

| 60 | 32.16 ± 0.19 | 9.9 | 4.53 ± 0.08 | 10.1 | 2.1 ± 0.1 | 0.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belgacem, C.; Serra-Parareda, F.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M.; Boufi, S. The Integral Utilization of Date Palm Waste to Produce Plastic Composites. Polymers 2021, 13, 2335. https://doi.org/10.3390/polym13142335

Belgacem C, Serra-Parareda F, Tarrés Q, Mutjé P, Delgado-Aguilar M, Boufi S. The Integral Utilization of Date Palm Waste to Produce Plastic Composites. Polymers. 2021; 13(14):2335. https://doi.org/10.3390/polym13142335

Chicago/Turabian StyleBelgacem, Chihaoui, Ferran Serra-Parareda, Quim Tarrés, Pere Mutjé, Marc Delgado-Aguilar, and Sami Boufi. 2021. "The Integral Utilization of Date Palm Waste to Produce Plastic Composites" Polymers 13, no. 14: 2335. https://doi.org/10.3390/polym13142335

APA StyleBelgacem, C., Serra-Parareda, F., Tarrés, Q., Mutjé, P., Delgado-Aguilar, M., & Boufi, S. (2021). The Integral Utilization of Date Palm Waste to Produce Plastic Composites. Polymers, 13(14), 2335. https://doi.org/10.3390/polym13142335