Influence of Polyethylene Terephthalate Powder on Hydration of Portland Cement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Test Methods

3. Results and Discussion

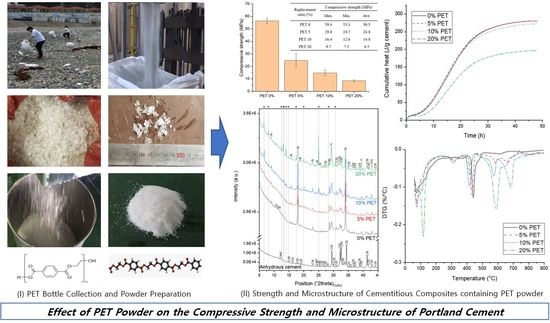

3.1. Compressive Strength

3.2. Isothermal Calorimetry Results of Cement Paste Samples Incorporating PET Powder

3.3. X-ray Diffraction Patterns of Cement Pastes with PET Powder

3.4. Results from Thermogravimetric Analysis

3.5. Results from Fourier–Transform Infrared Spectroscopy

3.6. Results from Raman Spectroscopy

4. Conclusions

- The hydration degree of PC can be influenced by a high PET fraction (e.g., 20%), as observed by the reduced heat released during the calorimetry, which can be associated with an interaction between water molecules and polar groups of PET.

- Calcium aluminate hydrates such as katoite or hydrogarnets were formed in the samples containing PET powder (5–20%).

- No clear microstructural and chemical changes were observed in the PET-incorporated PC samples exposed to different curing conditions, and the PET incorporated in cementitious material may not be affected by harsh environmental conditions.

- Based on these observations, the PET-incorporated PC paste sample exhibited physical changes that might occur during the mixing rather than the hydration process.

- The PET powder showed similar properties to rubrene, based on the XRD results, while the Raman spectrum showed different trends in the absence of C=O stretching vibration.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Brooks, A.L.; Wang, S.; Jambeck, J.R. The Chinese import ban and its impact on global plastic waste trade. Sci. Adv. 2018, 4, eaat0131. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adyel, T.M. Accumulation of plastic waste during COVID-19. Science 2020, 369, 1314–1315. [Google Scholar] [PubMed]

- Rillig, M.C.; Lehmann, A. Microplastic in terrestrial ecosystems. Science 2020, 368, 1430–1431. [Google Scholar] [CrossRef]

- Narancic, T.; O’Connor, K.E. Plastic waste as a global challenge: Are biodegradable plastics the answer to the plastic waste problem? Microbiology 2019, 165, 129–137. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics—The Facts 2017; Association of Plastics Manufacturers: Brussels, Belgium, 2017. [Google Scholar]

- Welle, F. Twenty years of PET bottle to bottle recycling—An overview. Resour. Conserv. Recycl. 2011, 55, 865–875. [Google Scholar] [CrossRef]

- Lonca, G.; Lesage, P.; Majeau-Bettez, G.; Bernard, S.; Margni, M. Assessing scaling effects of circular economy strategies: A case study on plastic bottle closed-loop recycling in the USA PET market. Resour. Conserv. Recycl. 2020, 162, 105013. [Google Scholar] [CrossRef]

- Cruz, S.; Zanin, M. PET recycling: Evaluation of the solid state polymerization process. J. Appl. Polym. Sci. 2006, 99, 2117–2123. [Google Scholar] [CrossRef]

- Welle, F. Is PET bottle-to-bottle recycling safe? Evaluation of post-consumer recycling processes according to the EFSA guidelines. Resour. Conserv. Recycl. 2013, 73, 41–45. [Google Scholar] [CrossRef]

- Behera, P.; Noman, M.T.; Petrů, M. Enhanced Mechanical Properties of Eucalyptus-Basalt-Based Hybrid-Reinforced Cement Composites. Polymers 2020, 12, 2837. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef]

- Noman, M.T.; Amor, N.; Petru, M.; Mahmood, A.; Kejzlar, P. Photocatalytic Behaviour of Zinc Oxide Nanostructures on Surface Activation of Polymeric Fibres. Polymers 2021, 13, 1227. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.-H.J.; Song, Y.-C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Alani, A.H.; Bunnori, N.M.; Noaman, A.T.; Majid, T. Durability performance of a novel ultra-high-performance PET green concrete (UHPPGC). Constr. Build. Mater. 2019, 209, 395–405. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.; Queneudec, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- Mohammed, A.A. Flexural behavior and analysis of reinforced concrete beams made of recycled PET waste concrete. Constr. Build. Mater. 2017, 155, 593–604. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Shahmansouri, A.A.; Fakoor, M. Post-fire compressive strength of recycled PET aggregate concrete reinforced with steel fibers: Optimization and prediction via RSM and GEP. Constr. Build. Mater. 2020, 252, 119057. [Google Scholar] [CrossRef]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Maalouf, C.; Ingrao, C.; Scrucca, F.; Moussa, T.; Bourdot, A.; Tricase, C.; Presciutti, A.; Asdrubali, F. An energy and carbon footprint assessment upon the usage of hemp-lime concrete and recycled-PET façades for office facilities in France and Italy. J. Clean. Prod. 2018, 170, 1640–1653. [Google Scholar] [CrossRef]

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Pekmezci, B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Font, J.; Muntasell, J.; Cesari, E. Poly (butylene terephthalate) poly (ethylene terephthalate) mixtures formed by ball milling. Mater. Res. Bull. 1999, 34, 157–165. [Google Scholar] [CrossRef]

- Deschner, F.; Lothenbach, B.; Winnefeld, F.; Neubauer, J. Effect of temperature on the hydration of Portland cement blended with siliceous fly ash. Cem. Concr. Res. 2013, 52, 169–181. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Soroushian, P.; Plasencia, J.; Ravanbakhsh, S. Assessment of reinforcing effects of recycled plastic and paper in concrete. Mater. J. 2003, 100, 203–207. [Google Scholar]

- Silva, R.V.; de Brito, J.; Saikia, N. Influence of curing conditions on the durability-related performance of concrete made with selected plastic waste aggregates. Cem. Concr. Compos. 2013, 35, 23–31. [Google Scholar] [CrossRef]

- Panyakapo, P.; Panyakapo, M. Reuse of thermosetting plastic waste for lightweight concrete. Waste Manag. 2008, 28, 1581–1588. [Google Scholar] [CrossRef]

- Merdas, I.; Thominette, F.; Tcharkhtchi, A.; Verdu, J. Factors governing water absorption by composite matrices. Compos. Sci. Technol. 2002, 62, 487–492. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Jurchescu, O.D.; Meetsma, A.; Palstra, T.T. Low-temperature structure of rubrene single crystals grown by vapor transport. Acta Crystallogr. Sect. B Struct. Sci. 2006, 62, 330–334. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silva, D.; Betioli, A.; Gleize, P.; Roman, H.; Gomez, L.; Ribeiro, J. Degradation of recycled PET fibers in Portland cement-based materials. Cem. Concr. Res. 2005, 35, 1741–1746. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Nardinocchi, A. Influence of type of fibers on the properties of high performance cement-based composites. Constr. Build. Mater. 2016, 107, 321–331. [Google Scholar] [CrossRef]

- Das, J.; Halgeri, A.; Sahu, V.; Parikh, P. Alkaline hydrolysis of poly (ethylene terephthalate) in presence of a phase transfer catalyst. Indian J. Chem. Technol. 2007, 14, 173–177. [Google Scholar]

- Lothenbach, B.; Durdzinski, P.; De Weerdt, K. Thermogravimetric analysis. In A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016; pp. 177–212. [Google Scholar]

- Taylor, H.F. Cement Chemistry; Thomas Telford: London, UK, 1997. [Google Scholar]

- Samperi, F.; Puglisi, C.; Alicata, R.; Montaudo, G. Thermal degradation of poly (ethylene terephthalate) at the processing temperature. Polym. Degrad. Stab. 2004, 83, 3–10. [Google Scholar] [CrossRef]

- dos Santos Pereira, A.P.; da Silva, M.H.P.; Lima Júnior, É.P.; dos Santos Paula, A.; Tommasini, F.J. Processing and characterization of PET composites reinforced with geopolymer concrete waste. Mater. Res. 2017, 20, 411–420. [Google Scholar] [CrossRef] [Green Version]

- Del Bosque, I.S.; Martínez-Ramírez, S.; Blanco-Varela, M.T. FTIR study of the effect of temperature and nanosilica on the nano structure of C–S–H gel formed by hydrating tricalcium silicate. Constr. Build. Mater. 2014, 52, 314–323. [Google Scholar] [CrossRef] [Green Version]

- Bensted, J.; Varma, S.P. Some applications of infrared and Raman spectroscopy in cement chemistry. Part 3-hydration of Portland cement and its constituents. Cem. Technol. 1974, 5, 440–445. [Google Scholar]

- Edge, M.; Wiles, R.; Allen, N.; McDonald, W.; Mortlock, S. Characterisation of the species responsible for yellowing in melt degraded aromatic polyesters—I: Yellowing of poly (ethylene terephthalate). Polym. Degrad. Stab. 1996, 53, 141–151. [Google Scholar] [CrossRef]

- Silverstein, R.M.; Bassler, G.C. Spectrometric identification of organic compounds. J. Chem. Educ. 1962, 39, 546. [Google Scholar] [CrossRef]

- Miyake, A. The infrared spectrum of polyethylene terephthalate. I The effect of crystallization. J. Polym. Sci. 1959, 38, 479–495. [Google Scholar] [CrossRef]

- Schmidt, P. Polyethylene terephthalate structural studies. J. Polym. Sci. Part A Gen. Pap. 1963, 1, 1271–1292. [Google Scholar] [CrossRef]

- Vijayakumar, S.; Rajakumar, P. Infrared spectral analysis of waste pet samples. Int. Lett. Chem. Phys. Astron. 2012, 4, 58–65. [Google Scholar] [CrossRef]

- Bensted, J. Uses of Raman spectroscopy in cement chemistry. J. Am. Ceram. Soc. 1976, 59, 140–143. [Google Scholar] [CrossRef]

- Boerio, F.; Bahl, S.; McGraw, G. Vibrational analysis of polyethylene terephthalate and its deuterated derivatives. J. Polym. Sci. Polym. Phys. Ed. 1976, 14, 1029–1046. [Google Scholar] [CrossRef]

- Rebollar, E.; Pérez, S.; Hernández, M.; Domingo, C.; Martín, M.; Ezquerra, T.A.; García-Ruiz, J.P.; Castillejo, M. Physicochemical modifications accompanying UV laser induced surface structures on poly (ethylene terephthalate) and their effect on adhesion of mesenchymal cells. Phys. Chem. Chem. Phys. 2014, 16, 17551–17559. [Google Scholar] [CrossRef] [PubMed]

| CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | K2O | TiO2 | F | Na2O | ZnO | LOI * |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 64.50 | 17.30 | 4.36 | 3.70 | 3.25 | 2.51 | 1.07 | 0.30 | 0.17 | 0.16 | 0.13 | 2.16 |

| Types of Ions | Cl− | Br− | SO42− | Na+ | K+ | Ca2+ | Mg2+ |

|---|---|---|---|---|---|---|---|

| Concentration (mg/L) | 21,075 | 51 | 2258 | 17,075 | 549 | 364 | 973 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.O.; Park, J.K.; Han, T.H.; Seo, J.; Park, S. Influence of Polyethylene Terephthalate Powder on Hydration of Portland Cement. Polymers 2021, 13, 2551. https://doi.org/10.3390/polym13152551

Kim MO, Park JK, Han TH, Seo J, Park S. Influence of Polyethylene Terephthalate Powder on Hydration of Portland Cement. Polymers. 2021; 13(15):2551. https://doi.org/10.3390/polym13152551

Chicago/Turabian StyleKim, Min Ook, Jun Kil Park, Taek Hee Han, Joonho Seo, and Solmoi Park. 2021. "Influence of Polyethylene Terephthalate Powder on Hydration of Portland Cement" Polymers 13, no. 15: 2551. https://doi.org/10.3390/polym13152551

APA StyleKim, M. O., Park, J. K., Han, T. H., Seo, J., & Park, S. (2021). Influence of Polyethylene Terephthalate Powder on Hydration of Portland Cement. Polymers, 13(15), 2551. https://doi.org/10.3390/polym13152551