Hydrothermal Modification of Wood: A Review

Abstract

:1. Introduction

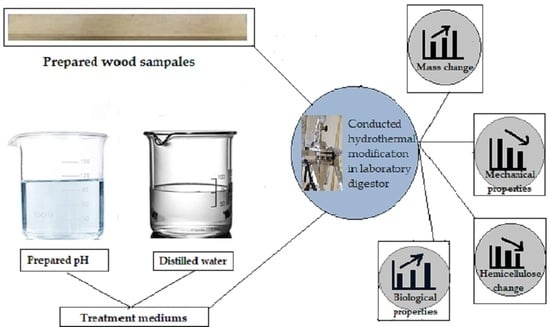

2. Wood Modification

3. Hydrothermal Modification of Wood

4. Variables Determining Hydrothermal Modification Performance

4.1. Medium

4.2. Wood Species

5. Effects of Hydrothermal Modification on Wood Properties

5.1. Morphology

5.2. Physical Properties

5.3. Mechanical Properties

5.4. Chemical Properties

5.5. Biological Properties

6. Comparison of Hydrothermal Modification and Other Thermal Treatment Methods

7. Potential Applications of Hydrothermally Treated Wood

8. Technoeconomic Challenges

9. Environmental Impact

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Global Forest Products Facts and Figures 2018; Food and Agriculture Organization of the United Nations: Quebec City, QC, Canada. Available online: http://www.fao.org/publications/card/en/c/CA7415EN/ (accessed on 7 May 2021).

- Stirling, R.; Sturrock, R.N.; Braybrooks, A. Fungal decay of western redcedar wood products—A review. Int. Biodeterior. Biodegrad. 2017, 125, 105–115. [Google Scholar] [CrossRef]

- Gradeci, K.; Labonnote, N.; Time, B.; Köhler, J. Mould growth criteria and design avoidance approaches in wood-based materials—A systematic review. Constr. Build. Mater. 2017, 150, 77–88. [Google Scholar] [CrossRef]

- Mazela, B.; Zakrzewski, R.; Grześkowiak, W.; Cofta, G.; Bartkowiak, M. Resistance of thermally modified wood to basidiomycetes. Electron. J. Polish Agric. Univ. 2004, 7, 253–262. [Google Scholar]

- Hill, C.A.S. Wood modification: Chemical, thermal and other processes. BioResources 2006, 6, 918–919. [Google Scholar] [CrossRef]

- Kocaefe, D.; Poncsak, S.; Boluk, Y. Effect of thermal treatment on the chemical composition and mechanical properties of birch and aspen. BioResources 2008, 3, 517–537. [Google Scholar] [CrossRef]

- Nikolov, S.; Encev, E. Effect of heat treatment on the sorption dynamics of beech wood. Nauc. Trud. Lesoteh. Inst. Sofija 1967, 14, 71–77. [Google Scholar]

- Kollmann, F.; Schneider, A. On the sorption behaviour of heat stabilized wood. Holz Roh Werkst. 1963, 21, 77–85. [Google Scholar] [CrossRef]

- Kollmann, F.; Fengel, D. Changes in the chemical composition of wood due to thermal treatment. Wood Raw Mater. 1965, 23, 461. [Google Scholar]

- Tiemann, H.D. The effect of different methods of drying on the strength of wood. Lumber World Rev. 1915, 28, 19–20. [Google Scholar]

- Manninen, A.M.; Pasanen, P.; Holopainen, J.K. Comparing the VOC emissions between air-dried and heat-treated scots pine wood. Atmos. Environ. 2002, 36, 1763–1768. [Google Scholar] [CrossRef]

- Dwianto, W.; Morooka, T.; Norimoto, M.; Kitajima, T. Stress relaxation of sugi (Cryptomeria Japonica d.Don) wood in radial compression under high temperature steam. Holzforschung 1999, 53, 541–546. [Google Scholar] [CrossRef]

- Kamdem, D.P.; Pizzi, A.; Jermannaud, A. Durability of heat-treated wood. Holz Roh Werkst. 2002, 60, 1–6. [Google Scholar] [CrossRef]

- Talaei, A.; Karimi, A. Chemical analysis of hydrothermally treated beech wood in buffered mediums. In Proceedings of the IRG43 Conference, Kuala Lumpur, Malaysia, 6–10 May 2012. [Google Scholar]

- Jimenez, J.P.; Acda, M.N.; Razal, R.A. Physico-mechanical properties and durability of thermally modified malapapaya [Polyscias Nodosa (Blume) Seem]. Wood 2011, 140, 13–23. [Google Scholar]

- Ilanidis, D.; Stagge, S.; Jönsson, L.J.; Martín, C. Hydrothermal Pretreatment of Wheat Straw: Effects of Temperature and Acidity on Byproduct Formation and Inhibition of Enzymatic Hydrolysis and Ethanolic Fermentation. Agronomy 2021, 11, 487. [Google Scholar] [CrossRef]

- Endo, K.; Obataya, E.; Zeniya, N.; Matsuo, M. Effects of heating humidity on the physical properties of hydrothermally treated spruce wood. Wood Sci. Technol. 2016, 50, 1161–1179. [Google Scholar] [CrossRef] [Green Version]

- Song, B.; Lin, R.; Lam, C.H.; Wu, H.; Tsui, T.H.; Yu, Y. Recent advances and challenges of inter-disciplinary biomass valorization by integrating hydrothermal and biological techniques. Renew. Sustain. Energy Rev. 2021, 135, 110370. [Google Scholar] [CrossRef]

- Jamsa, P.; Jämsä, S.; Viitaniemi, P. Heat treatment of wood better durability without chemicals. In Special Seminar: Environmental Optimization of Wood Protection; Rapp, A.O., Ed.; COST: Bruseless, Belgium; Antibes, France, 2001; pp. 17–22. [Google Scholar]

- Borrega, M.; Kärenlampi, P.P. Hygroscopicity of heat-treated norway spruce (Picea Abies) wood. Eur. J. Wood Wood Prod. 2010, 68, 233–235. [Google Scholar] [CrossRef] [Green Version]

- Saliman, M.A.R.; Ashaari, Z.; Bakar, E.S.; Hua, L.S.; Tahir, P.M.; Halip, J.A.; Leemon, N.F. Hydrothermal treatment of oil palm wood: Effect of treatment variables on dimensional stability using response surface methodology. J. Oil Palm Res. 2017, 29, 130–135. [Google Scholar] [CrossRef] [Green Version]

- Talaei, A.; Karimi, A. Compression Strength, hardness and shear strength of heat treated beech (Fagus Orientalis) wood in buffered mediums. Int. J. Mech. Prod. Eng. 2015, 3, 6–9. [Google Scholar]

- Ebadi, S.E.; Ashaari, Z.; Late Masoumi, H.R.F.; Soltani, M.; Naji, H.R.; Vaysi, R. Evaluation of bending strength of hydrothermally treated oil palm wood in various buffered media using response surface methodology. J. Trop. For. Sci. 2019, 31, 151–161. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Pelaez-Samaniego, M.R.; Yadama, V.; Lowell, E.; Espinoza-Herrera, R. A review of wood thermal pretreatments to improve wood composite properties. Wood Sci. Technol. 2013, 47, 1285–1319. [Google Scholar] [CrossRef]

- Lee, S.H.; Ashaari, Z.; Lum, W.C.; Abdul Halip, J.; Ang, A.F.; Tan, L.P.; Chin, K.L.; Md Tahir, P. Thermal treatment of wood using vegetable oils: A review. Constr. Build. Mater. 2018, 181, 408–419. [Google Scholar] [CrossRef]

- Militz, H.; Altgen, M. Processes and properties of thermally modified wood manufactured in Europe. ACS Symp. Ser. 2014, 1158, 269–285. [Google Scholar] [CrossRef]

- Xie, Y.; Fu, Q.; Wang, Q.; Xiao, Z.; Militz, H. Effects of chemical modification on the mechanical properties of wood. Eur. J. Wood Wood Prod. 2013, 71, 401–416. [Google Scholar] [CrossRef]

- Kocaefe, D.; Huang, X.; Kocaefe, Y. Dimensional stabilization of wood. Curr. For. Rep. 2015, 1, 151–161. [Google Scholar] [CrossRef]

- Norimoto, M.; Gril, J. Recent Research on Wood and Wood-Based Materials; Elsevier: Amsterdam, The Netherlands, 1993. [Google Scholar]

- Sundqvist, B.; Karlsson, O.; Westermark, U. Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness and hardness. Wood Sci. Technol. 2006, 40, 549–561. [Google Scholar] [CrossRef]

- Rezayati Charani, P.; Mohammadi Rovshandeh, J.; Mohebby, B.; Ramezani, O. Influence of hydrothermal treatment on the dimensional stability of beech wood. Casp. J. Environ. Sci. 2007, 05, 125–131. [Google Scholar]

- Ashaari, Z. Low Density Wood from Poor to Excellent; Penerbit Universiti Putra Malaysia: Serdang, Malaysia, 2017. [Google Scholar]

- Mohebby, B.; Ilbeighi, F.; Kazemi-Najafi, S. Influence of hydrothermal modification of fibers on some physical and mechanical properties of Medium Density Fiberboard (MDF). Holz Roh Werkst. 2008, 66, 213–218. [Google Scholar] [CrossRef]

- Talaei, A. Effects of Hydrothermal Treatment in Buffered Medium on Natural Durability and Mechanical Properties of Beech Wood. Ph.D. Thesis, University of Tehran, Iran, 2010. [Google Scholar]

- Boonstra, M.J.; Tjeerdsma, B. Chemical analysis of heat-treated softwoods. Holz Roh Werkst. 2006, 64, 204–211. [Google Scholar] [CrossRef]

- Ebadi, S.E.; Karimi, A.; Choo, A.C.Y.; Ashari, Z.; Naji, H.R.; Soltani, M.; Ridzuan, S.M.A. Physical behavior of hydro-thermally treated oil palm wood in different buffered PH media. BioResources 2015, 10, 5317–5329. [Google Scholar] [CrossRef] [Green Version]

- Ebadi, S.E.; Ashaari, Z.; Naji, H.R.; Jawaid, M.; Soltani, M.; San, H.P. Mechanical behavior of hydrothermally treated oil palm wood in different buffered Ph media. Wood Fiber Sci. 2016, 48, 193–201. [Google Scholar]

- Saliman, M.A.R.; Zaidon, A.; Bakar, E.S.; Lee, S.H.; Tahir, P.M.; Leemon, N.F.; Kaipin, M.F.; Juliana, A.H. Response surface methodology model of hydrothermall treatment parameters on decay resistance of oil palm wood. J. Trop. For. Sci. 2017, 29, 318–324. [Google Scholar]

- Wongprot, T.; Matan, N.; Matan, N.; Preechatiwong, W.; Kyokong, B. Response surface modeling of hydrothermal treatment conditions on color changes, strength, and durability properties of rubberwood. BioResources 2013, 8, 302–312. [Google Scholar] [CrossRef] [Green Version]

- Tarmian, A.; Remond, R.; Dashti, H.; Perre’, P. Moisture diffusion coefficient of reaction woods: Compression wood of Picea abies, L. and Tension wood of Fagus sylvatica, L. Wood Sci. Technol. 2012, 46, 405–417. [Google Scholar] [CrossRef]

- Varga, D.; Van Der Zee, M.E. Einfluss der dämpfung auf verschiedene eigenschaften von vier laubholzarten. Holz Roh Werkst. 2008, 66, 11–18. [Google Scholar] [CrossRef]

- de Freitas, F.P.; Carvalho, A.M.M.L.; Carneiro, A.d.C.O.; Vital, B.R.; de Magalhães, M.A.; Xisto, M.F. Hydrothermal treatment of eucalyptus grandis wood. Floresta 2019, 49, 247–256. [Google Scholar] [CrossRef] [Green Version]

- Rasdianah, D.; Zaidon, A.; Hidayah, A.; Lee, S.H. Effects of superheated steam treatment on the physical and mechanical properties of light red meranti and kedondong wood. J. Trop. For. Sci. 2018, 30, 384–392. [Google Scholar] [CrossRef]

- Rahimi, S.; Singh, K.; DeVallance, D. Effect of different hydrothermal treatments (steam and hot compressed water) on physical properties and drying behavior of yellow-poplar (Liriodendron Tulipifera). For. Prod. J. 2019, 69, 42–52. [Google Scholar] [CrossRef]

- Dündar, T.; Büyüksari, Ü.; Avci, E.; Akkiliç, H. Effect of heat treament on the physical and mechanical properties of compression and opposite wood of black pine. BioResources 2012, 7, 5009–5018. [Google Scholar] [CrossRef] [Green Version]

- Jiang, F.; Heng, W.; ChuanGui, W. Effects of high temperature treatment on the color and visual psychology of rattan. J. For. Eng. 2017, 2, 25–29. [Google Scholar]

- Reinprecht, L.; Pánek, M.; Dǎková, J.; Murínová, T.; Pavel, M.E.C.; Plevová, L. Performance of methyl-tripotassiumsilanol treated wood against swelling in water, decay fungi and moulds. Wood Res. 2013, 58, 511–520. [Google Scholar]

- Skyba, O.; Schwarze, F.W.M.R.; Niemz, P. Physical and mechanical properties of Thermo-Hygro-Mechanically (THM)-densified wood. Wood Res. 2009, 54, 1–18. [Google Scholar]

- Unsal, O.; Candan, Z.; Buyuksari, U.; Korkut, S.; Babiak, M. Effects of thermal modification on surface characteristics of Osb panels. Wood Res. 2010, 55, 51–58. [Google Scholar]

- Biziks, V.; Andersons, B.; Beȩkova, Ļ.; Kapača, E.; Militz, H. Changes in the microstructure of birch wood after hydrothermal treatment. Wood Sci. Technol. 2013, 47, 717–735. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, L. Effects of steam explosion on wood appearance and structure of sub-alpine fir. Wood Sci. Technol. 2006, 40, 427–436. [Google Scholar] [CrossRef]

- José-Vicente, O.V.; Enrique, G.A.; Patricia, G.G. Analysis of durability and dimensional stability of hydrothermal carbonized wooden pellets. Wood Res. 2016, 61, 321–330. [Google Scholar]

- Percin, O.; Peker, H.; Atilgan, A. The effect of heat treatment on the some physical and mechanical properties of beech (Fagus Orientalis Lipsky) wood. Wood Res. 2016, 61, 443–456. [Google Scholar]

- Wang, C.; Li, R.; Liu, C.; Wang, X. Effects of medium-low temperature hydrothermal treatment on microstructure and dimensional stability of Chinese sweetgum wood. Wood Res. 2019, 64, 97–104. [Google Scholar]

- Tjeerdsma, B.F.; Boostra, M.; Pizzi, A.; Tekely, P.; Militz, H. Characterisation of thermally modified wood: Molecular reasons for wood performance improvement. Holz RohWerkst. 1998, 56, 149–153. [Google Scholar] [CrossRef]

- Scheiding, W.; Direske, M.; Zauer, M. Water absorption of untreated and thermally modified sapwood and heartwood of Pinus Sylvestris, L. Eur. J. Wood Wood Prod. 2016, 74, 585–589. [Google Scholar] [CrossRef]

- Bhuiyan, M.T.R.; Hirai, N. Study of Crystalline behavior of heat-treated wood cellulose during treatments in water. J. Wood Sci. 2005, 51, 42–47. [Google Scholar] [CrossRef]

- Kartal, S.N.; Hwang, W.J.; Imamura, Y. Water absorption of boron-treated and heat-modifi ed wood. J. Wood Sci. 2007, 53, 454–457. [Google Scholar] [CrossRef]

- Salim, N.; Hashim, R.; Sulaiman, O.; Nordin, N.A.; Ibrahim, M.; Akil, H.M.; Sato, M.; Sugimoto, T.; Hiziroglu, S. Effect of steaming on some properties of compressed oil palm trunk lumber. BioResources 2013, 8, 2310–2324. [Google Scholar] [CrossRef] [Green Version]

- Garrote, G.; Domínguez, H.; Parajó, J.C. Hydrothermal processing of lignocellulosic materials. Holz Roh Werkst. 1999, 57, 191–202. [Google Scholar] [CrossRef]

- Theander, O.; Nelson, D.A. Aqueous, high-temperature transformation of carbohydrates relative to utilization of biomass. Adv. Carbohydr. Chem. Biochem. 1988, 46, 273–326. [Google Scholar] [CrossRef]

- Kubojima, Y.; Okano, T.; Ohta, M. Bending strength and toughness of heat-treated wood. J. Wood Sci. 2000, 46, 8–15. [Google Scholar] [CrossRef]

- Sulaiman, O.; Awalludin, M.F.; Hashim, R.; Ibrahim, H.; Mondal, M.D. The effect of relative humidity on the physical and mechanical properties of oil palm trunk and rubberwood. Cellul. Chem. Technol. 2012, 46, 401–407. [Google Scholar]

- Kim, G.H.; Yun, K.E.; Kim, J.J. Effect of heat treatment on the decay resistance and the bending properties of radiata pine sapwood. Mater. Org. 1998, 32, 102–108. [Google Scholar]

- Poncsák, S.; Kocaefe, D.; Bouazara, M.; Pichette, A. Effect of high temperature treatment on the mechanical properties of birch (Betula Papyrifera). Wood Sci. Technol. 2006, 40, 647–663. [Google Scholar] [CrossRef]

- Mirzaei, G.; Mohebby, B.; Tasooji, M. The effect of hydrothermal treatment on bond shear strength of beech wood. Eur. J. Wood Wood Prod. 2012, 70, 705–709. [Google Scholar] [CrossRef]

- Ibrahim, M.M.; Agblevor, F.A.; El-Zawawy, W.K. Isolation and characterization of cellulose and lignin from steam-exploded lignocellulosic biomass. BioResources 2010, 5, 397–418. [Google Scholar] [CrossRef]

- Shebani, A.N.; van Reenen, A.J.; Meincken, M. The effect of wood extractives on the thermal stability of different wood species. Thermochim. Acta 2008, 471, 43–50. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Militz, H. Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz Roh Werkst. 2005, 63, 102–111. [Google Scholar] [CrossRef]

- Sik, H.S.; Choo, K.T.; Zakaria, S.; Ahmad, S.; Yusoff, M.; Chia, C.H. The influence of drying temperature on the hygroscopicity of rubberwood (Hevea Brasiliensis). J. Agric. Sci. 2010, 2, 48–58. [Google Scholar] [CrossRef] [Green Version]

- Talaei, A.; Karimi, A.; Thevenon, M.F. Influence of heat treatment medium on fungal resistance of beech wood. In International Research Group on Wood Preservation, IRG/WP 13-40643 Stockholm, Sweden; FAO: Rome, Italy, 2013. [Google Scholar]

- Yildiz, S.; Gümüşkaya, E. The effects of thermal modification on crystalline structure of cellulose in soft and hardwood. Build. Environ. 2007, 42, 62–67. [Google Scholar] [CrossRef]

- Mitsui, K.; Inagaki, T.; Tsuchikawa, S. Monitoring of hydroxyl groups in wood during heat treatment using NIR spectroscopy. Biomacromolecules 2008, 9, 286–288. [Google Scholar] [CrossRef]

- Inagaki, T.; Siesler, H.W.; Mitsui, K.; Tsuchikawa, S. Difference of the crystal structure of cellulose in wood after hydrothermal and aging degradation: A NIR spectroscopy and XRD study. Biomacromolecules 2010, 11, 2300–2305. [Google Scholar] [CrossRef]

- Cai, S.; Zhang, N.; Li, K.; Li, Y.; Wang, X.; Cai, S. Effect of pressurized hot water treatment on the mechanical properties, surface color, chemical composition and crystallinity of pine wood. Wood Res. 2019, 64, 389–400. [Google Scholar]

- Lee, S.H.; Ashaari, Z. Durability of phenolic-resin-treated sesenduk (Endospermum Diadenum) and jelutong (Dyera Costulata) wood against white rot fungus. Eur. J. Wood Wood Prod. 2015, 73, 553–555. [Google Scholar] [CrossRef]

- Kamdem, D.P.; Pizzi, A.; Guyonnet, R.; Jermannaud, A. Durability of Heat-Treated Wood; Springer: Berlin, Germany, 1999. [Google Scholar]

- Nabil, F.L.; Zaidon, A.; Anwar, U.M.K.; Bakar, E.S.; Lee, S.H.; Paridah, M.T. Impregnation of sesenduk (Endospermum Diadenum) wood with phenol formaldehyde and nanoclay admixture: Effect on fungal decay and termites attack. Sains Malays. 2016, 45, 255–262. [Google Scholar]

- Doi, S.; Aoyama, M.; Yamauchi, S.; Kurimoto, Y. Changes of decay and termite durabilities of Japanese larch (Larix Leptolepis) wood due to high-temperature kiln drying processes. J. Wood Sci. 2005, 51, 526–530. [Google Scholar] [CrossRef]

- Hakkou, M.; Pétrissans, M.; Gérardin, P.; Zoulalian, A. Investigations of the reasons for fungal durability of heat-treated beech wood. Polym. Degrad. Stab. 2006, 91, 393–397. [Google Scholar] [CrossRef]

- Sailer, M.; Rapp, A.O.; Leithoff, H. Improved Resistance of Scots Pine and Spruce by Application of an Oil-Heat Treatment. Holz Roh Werkst. 2000, 58, 15–22. [Google Scholar] [CrossRef]

- Cheng, D.; Jiang, S.; Zhang, Q. Effect of hydrothermal treatment with different aqueous solutions on the mold resistance of moso bamboo with chemical and FTIR analysis. BioResources 2013, 8, 371–382. [Google Scholar] [CrossRef] [Green Version]

- Militz, H. Thermal Treatment of Wood: European Processes and Their Background. In Proceedings of the 33rd Annual Meeting of the International Research Group on Wood Preservation, Cardiff, Wales, UK, 12–17 May 2002; IRG Secretary: Stockholm, Sweden, 2002. [Google Scholar]

- Hadi, S.; Hosseinihashemi, S.K.; Latibari, A.J.; Salem, M.Z.M. Effects of acid copper chromate preservative and hydrothermal treatment on the dimensional stability, hardness, and decay resistance of poplar wood. BioResources 2016, 11, 4850–4864. [Google Scholar] [CrossRef]

- Bakar, B.F.A.; Tahir, P.M.; Karimi, A.; Bakar, E.S.; Uyup, M.K.A.; Yong Choo, A.C. Evaluations of some physical properties for oil palm as alternative biomass resources. Wood Mater. Sci. Eng. 2013, 8, 119–128. [Google Scholar] [CrossRef] [Green Version]

- Sandberg, D.; Navi, P. Introduction to Thermo-Hydro-Mechanical (THM) Wood Processing; Växjö Universitet Skog & Trä: Växjö, Sweden, 2007. [Google Scholar]

- Ashaari, Z.; Hua, L.S.; Halip, J.A.; Al Edrus, S.S.; Chen, L.W.; Hao, L.C. Application of response surface methodology models for dimensional stability of hydrothermally treated semantan bamboo. Int. J. Recent Technol. Eng. 2019, 8, 460–463. [Google Scholar] [CrossRef]

- Vivian, M.A.; Modes, K.S.; Beltrame, R.; Souza, J.T.; Stangerlin, D.M.; Morais, W.W.C.; Santini, E.J. Influência do tratamento térmico nos defeitos de secagem da madeira de hovenia dulcis thunb. Rev. Ciência Madeira RCM 2011, 2, 15–38. [Google Scholar] [CrossRef]

- Saari, N.; Hashim, R.; Sulaiman, O.; Hiziroglu, S.; Sato, M.; Sugimoto, T. Properties of steam treated binderless particleboard made from oil palm trunks. Compos. Part B Eng. 2014, 56, 344–349. [Google Scholar] [CrossRef]

- Gunduz, G.; Aydemir, D. The influence of mass loss on the mechanical properties of heat-treated black pine wood. Wood Res. 2009, 54, 33–42. [Google Scholar]

- Chen, Y.; Fan, Y.; Gao, J.; Stark, N.M. The effect of heat treatment on the chemical and color change of black locust (Robinia Pseudoacacia) wood flour. BioResources 2012, 7, 1157–1170. [Google Scholar] [CrossRef]

- Yang, T.H.; Chang, F.R.; Lin, C.J.; Chang, F.C. Effects of temperature and duration of heat treatment on the physical, surface, and mechanical properties of Japanese cedar wood. BioResources 2016, 11, 3947–3963. [Google Scholar] [CrossRef]

- Umar, I.; Zaidon, A.; Lee, S.H.; Halis, R. Oil-heat treatment of rubberwood for optimum changes in chemical constituents and decay resistance. J. Trop. For. Sci. 2016, 28, 88–96. [Google Scholar]

- Sik, H.S.; Choo, K.T.; Sarani, Z.; Sahrim, A.; How, S.S.; Omar, M.K.O. Influence of drying temperature on the physical and mechanical properties of rubberwood. J. Trop. For. Sci. 2009, 21, 181–189. [Google Scholar]

- Kačíková, D.; Kačík, F.; Čabalová, I.; Ďurkovič, J. Effects of thermal treatment on chemical, mechanical and colour traits in norway spruce wood. Bioresour. Technol. 2013, 144, 669–674. [Google Scholar] [CrossRef] [PubMed]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H. Heat-induced colour changes of pine (Pinus Pinaster) and eucalypt (Eucalyptus Globulus) Wood. Wood Sci. Technol. 2008, 42, 369–384. [Google Scholar] [CrossRef] [Green Version]

- Esteves, B.; Domingos, I.; Pereira, H. Improvement of technological quality of eucalypt wood by heat treatment in air at 170-200 °C. For. Prof. J. 2007, 57, 47–52. [Google Scholar]

- Nuopponen, M.; Vuorinen, T.; Jámsä, S.; Viitaniemi, P. Thermal modifications in softwood studied by FT-IR and UV resonance raman spectroscopies. J. Wood Chem. Technol. 2004, 24, 13–26. [Google Scholar] [CrossRef]

- Taghiyari, H.R. Study on the effect of nano-silver impregnation on mechanical properties of heat-treated populus nigra. Wood Sci. Technol. 2011, 45, 399–404. [Google Scholar] [CrossRef]

- Tolvaj, L.; Sopron, S.M.; Richter, H.G.; Riehl, T. Hydrothermal Treatment (Steaming) under Atmospheric and Pressure Conditions. Available online: http://real.mtak.hu/24598/1/hydrothermal_treatment_u.pdf (accessed on 3 May 2021).

- Heräjärvi, H.; Pirhonen, I.; Saukkola, P. Recycling of modified wood products. In Proceedings of the Fifth European Conference on Wood Modification ECWM5, Riga, Latvia, 20–21 September 2010; Hill, C.A.S., Militz, H., Andersons, B., Eds.; Latvia State University of Wood Chemistry: Riga, Latvia, 2010; pp. 285–290. [Google Scholar]

- Heräjärvi, H.; Kunttu, J.; Hurmekoski, E.; Hujala, T. Outlook for modified wood use and regulations in circular economy. Holzforschung 2020, 74, 334–343. [Google Scholar] [CrossRef]

- Tavassoli, F.; Razzaghi-Kashani, M.; Mohebby, B. Hydrothermally treated wood as reinforcing filler for natural rubber bio-composites. J. Polym. Res. 2018, 25, 2018. [Google Scholar] [CrossRef]

- Militz, H.; Lande, S. Challenges in wood modification technology on the way to practical applications. Wood Mater. Sci. Eng. 2009, 4, 23–29. [Google Scholar] [CrossRef]

- Sandberg, D.; Haller, P.; Navi, P. Thermo-hydro and thermo-hydro-mechanical wood processing: An Opportunity for future environmentally friendly wood products. Wood Mater. Sci. Eng. 2013, 8, 64–88. [Google Scholar] [CrossRef] [Green Version]

- Rapp, A.O. Review on Heat Treatments of Wood; BFH The Federal Research Centre for Forestry and Forest Products: Hamburg, Germany, 2001; ISBN 3-926301–02–3. [Google Scholar]

- Rétfalvi, T.; Hofmann, T.; Albert, L.; Niemz, P. The environmental chemical features of the waste water originated from the thermal treatment of wood. Wood Res. 2009, 54, 13–22. [Google Scholar]

- Candelier, K.; Dibdiakova, J. A review on life cycle assessments of thermally modified wood. Holzforschung 2021, 75, 199–224. [Google Scholar] [CrossRef]

- Candelier, K.; Thevenon, M.F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef] [Green Version]

| Division | Types of Modification | Class | Illustration |

|---|---|---|---|

| Active | Chemical | Cell wall | (e) and (f) |

| Surface | - | ||

| Thermal | Cell wall | - | |

| Enzymatic | Surface | - | |

| Passive | Impregnation | Cell-wall fill | (b) and (d) |

| Lumen fill | (c) | ||

| Untreated | (a) |

| Advantages | Disadvantages |

|---|---|

|

|

| Wood Species | Treatment Condition | Modulus of Rupture (MOR; MPa) | Modulus of Elasticity (MOE; MPa) | Compression Parallel to Grain PCII (MPa) | Specific Gravity | References |

|---|---|---|---|---|---|---|

| Yellow poplar | Hydrothermal modification at 100 and 40 °C | - | Untreated: 1290.0 Treated at 100 °C: 1170.0 140 °C: 1570.0 | Untreated: 42.95 Treated at 100 °C: 38.50 140 °C: 42.27 | Untreated: 0.50 Treated at 100 °C: 0.50 140 °C: 0.49 | [45] |

| Light red meranti | Superheated steam at several temperature levels and du- rations | Untreated: 57.0 Treated at 172 °C for 180 min: 54.47 | Untreated: 7482.11 Treated at 172 °C for 180 min: 6699.6 | - | Untreated: 0.39 After treatment: Loss of 4.41% to 10.37% | [44] |

| Kedondong | Untreated: 105.88 Treated at 172 °C for 180 min: 101.58 | Untreated: 11690.4 Treated at 172 °C for 180 min: 9874.8 | - | Untreated: 0.62 After treatment: Loss of 4.01% to 16.23% | ||

| Eucalyptus grandis | Hydrothermal process at 140 °C for 5 to 25 min | Untreated: 89.0 After treatment: 76.0 | Untreated: 6988.0 After treatment: 6830.0 | Untreated: 53.0 After treatment: 54.0 | Untreated: 0.52 After treatment: 0.54 | [43] |

| Oil palm wood | Hydrothermal modification at 140 °C for 120 min | Untreated: 39.84 After treatment: 25.15 | Untreated: 5907.0 After treatment: 4866.0 | Untreated: 31.87 After treatment: 8.75 | Untreated: 0.57 After treatment: 0.56 | [38] |

| Black pine | Hydrothermal modification at 180 and 210 °C | Untreated: 61.4 Treated at 180 °C: 43.0 | Untreated: 5606.8 Treated at 180 °C: 4783.5 | - | - | [46] |

| Wood Species | Treatment Type | Treatment Condition | Findings | References |

|---|---|---|---|---|

| Beech | Hydrothermal treatment | pH 5 to 8 and temperature 160 and 180 °C for 45 min | Hydrothermal modification with pH 7 or 8 prevents the strength loss | [22] |

| Black locust | Heat treatment | 120 °C for 24 h | Discoloration of wood due to heat treatment | [92] |

| Oil palm wood | Hydrothermal treatment | pH (5 and 8) and temp. 140 °C for 120 min | Enhanced physical properties | [37] |

| Beech wood | Heat treatment | 20 to 280 °C | Improved durability of wood | [81] |

| Malapapaya Wood | Heat treatment | 160 to 220 °C for 30 to 120 min | Decreased strength properties and increased decay resistance | [15] |

| Birch and aspen | Heat treatment | 120 °C for 30 min | Decreased strength properties | [6] |

| Japanese cedar wood | Heat treatment | Temperature 170, 190, and 210 °C for 60, 120, and 240 min | Untreated MOR and MOE, 70.7 and 8100 MPa, and treated at 210 °C for 4 h, 36.0 and 6200 MPa | [93] |

| Rubberwood | Oil-heat treat- ment | Temp. 172 to 228 °C for 95 to 265 min | Enhanced decay resistance against P. sanguineus | [94] |

| Beech and Scots pine | Hydrothermal treatment | Temperature 165 and 185 °C | Accessible acetyl groups are cleaved | [70] |

| Rubber wood | Heat treatment | Temperature 100 to 150 °C | MOR and MOE values treated at 60 °C, 117.01 and 12,187 MPa, and 150 °C, 107.05 and 11,909 MPa | [95] |

| Norway spruce wood | Heat treatment | Temperature 113 to 271 °C | Increased cellulose crystallinity | [96] |

| Pine and Eucalyptus globulus | Heat treatment | hot air in an oven for 2–24 h at 170–200 °C and by steam in an autoclave for 2–12 h at 190–210 °C. | Both woods became darker in color | [97] |

| Eucalyptus globulus | Heat treatment | 2–24 h and temperatures of 170–200 °C | Attained better dimensional sta- bility | [98] |

| Spruce and Beech | Heat treatment | 150, 180, and 200 °C for 6 and 10 h | Changed cellulose crystallinity | [73] |

| Scots pine Populus nigra Birch Black pine wood | Hydrothermal treatment Heat treatment Heat treatment Heat treatment | 100 to 240 °C 24 h at 45 °C, 24 h at 145 °C, and 4 h at 185 °C 120 to 230 °C 160 to 200 °C for 2 and 6 h | Lignin content increased MOR decreased from 529 to 461 kg/cm2 MOR decreased increased tem- perature Bending-strength values de- creased 3.2% when treated at 160 ° C for 2 h and 47.2% at 200 °C for 6 h | [99] [100] [66] [91] |

| Pine wood | Hydrothermal treatment | 140 to 200 °C for 1 to 5 h | Relative content of lignin (%): Untreated: 28.401 Treated at 160 °C for 5 h, 31.795 Treated at 180 °C for 5 h, 33.916 Treated at 200 °C for 5 h, 40.473 | [76] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.R.; Abdullah, U.H.; Ashaari, Z.; Hamid, N.H.; Hua, L.S. Hydrothermal Modification of Wood: A Review. Polymers 2021, 13, 2612. https://doi.org/10.3390/polym13162612

Ali MR, Abdullah UH, Ashaari Z, Hamid NH, Hua LS. Hydrothermal Modification of Wood: A Review. Polymers. 2021; 13(16):2612. https://doi.org/10.3390/polym13162612

Chicago/Turabian StyleAli, Md. Rowson, Ummi Hani Abdullah, Zaidon Ashaari, Norul Hisham Hamid, and Lee Seng Hua. 2021. "Hydrothermal Modification of Wood: A Review" Polymers 13, no. 16: 2612. https://doi.org/10.3390/polym13162612

APA StyleAli, M. R., Abdullah, U. H., Ashaari, Z., Hamid, N. H., & Hua, L. S. (2021). Hydrothermal Modification of Wood: A Review. Polymers, 13(16), 2612. https://doi.org/10.3390/polym13162612