Visualization of Activated Area on Polymers for Evaluation of Atmospheric Pressure Plasma Jets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Atmospheric Pressure Plasma Sources

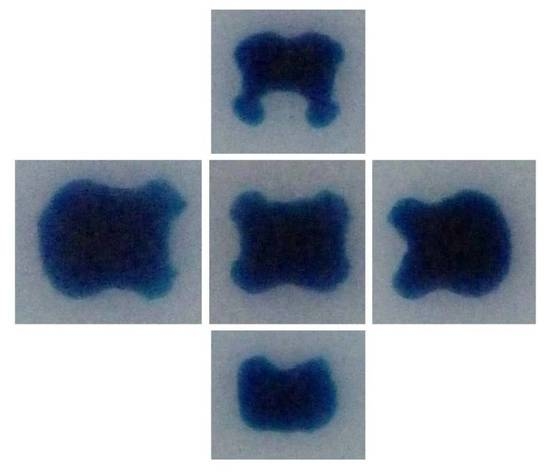

2.2. Visualization of the Activation Area

2.3. Activation Image Recording

2.4. Test Inks

2.4.1. Formamide Based Test Inks

2.4.2. SFE Radial Distribution

2.4.3. Aging of Test Ink

2.4.4. Environmental Influences

2.5. Substrates

3. Results and Discussion

3.1. Activation Area Determination

3.1.1. Shrinkage of the Test Ink Patch

3.1.2. Selection of Substrate Material

3.1.3. Ink Patch Shrinkage Mechanism

3.1.4. Influence of Ink SFE Value on Shrinkage Characteristics

3.1.5. Renewed Ink Application

3.1.6. Hydrophobic Recovery

3.2. Characterization of Plasma Sources

3.2.1. Dependence on Treatment Time

3.2.2. Influence of the Substrate Distance

4. Conclusions and Outlook

- The AIR results are valid only for intensive discharges, when 72 mN/m saturation on a large part of the activation area on HDPE is reached;

- the treatment time should not exceed the limit for the thermal damage of the HDPE surface;

- only a fresh test ink should be used, and the test ink vial should be opened only for a short time of ink application;

- the amount of the test ink should be adjusted to the size of the activation area; and

- the AIR measurements should be conducted at room temperature and medium humidity.

- determination of the optimum operating conditions for the maximum surface activation speed;

- investigation of the influence of the constructional changes on the APPJ performance;

- determination of equivalent working point for plasma tool replacing a different one;

- the investigation of the performance changes of the APPJ in course of an endurance test; and

- the analysis of the influence of the type of discharge on the hydrophobic recovery.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Becker, K.H.; Kogelschatz, U.; Schoenbach, K.H.; Barker, R.J. (Eds.) Non-Equilibrium Air Plasmas at Atmospheric Pressure; IoP—Institute of Physics Publishing: Bristol, UK; Philadelphia, PA, USA, 2005; Chapter 9; pp. 597–686. [Google Scholar]

- Choi, J.H.; Lee, E.S.; Baik, H.K.; Lee, S.J.; Song, K.M.; Lim, Y.S. Analysis of polymer surface treated by dielectric barrier discharge. Plasma Sources Sci. Technol. 2005, 14, 363–367. [Google Scholar] [CrossRef]

- Primc, G. Surface modification of polyamides by gaseous plasma—Review and scientific challenges. Polymers 2020, 12, 3020. [Google Scholar] [CrossRef]

- Wertheimer, M.; Martinu, L.; Klemberg-Sapieha, J.; Czeremuszkin, G. Plasma treatment of polymers to improve adhesion. In Adhesion Promotion Techniques: Technological Applications; Mittal, K., Pizzi, A., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 2002; Chapter 5; pp. 139–173. [Google Scholar]

- Yáñez-Pacios, A.J.; Martín-Martínez, J.M. Comparative adhesion, ageing resistance, and surface properties of wood plastic composite treated with low pressure plasma and atmospheric pressure plasma jet. Polymers 2018, 10, 643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sasmazel, H.; Alazzawi, M.; Alsahib, N. Atmospheric pressure plasma surface treatment of polymers and influence on cell cultivation. Molecules 2021, 26, 1665. [Google Scholar] [CrossRef] [PubMed]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Man, J.U.; Prasad, S.D. Surface treatment of high density polyethylene (HDPE) film by 50 Hz dielectric barrier discharge produced in air and argon/air mixture at atmospheric pressure. Int. J. Eng. Res. Appl. 2015, 5, 1–9. [Google Scholar]

- Neto, J.F.D.M.; Alves de Souza, I.; Feitor, M.C.; Targino, T.G.; Diniz, G.F.; Libório, M.S.; Sousa, R.R.M.; Costa, T.H.D.C. Study of high-density polyethylene (HDPE) kinetics modification treated by dielectric barrier discharge (DBD) plasma. Polymers 2020, 12, 2422. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Zhang, C.; Hwang, Y.; Bures, B.; McCord, M. The effect of atmospheric pressure helium plasma treatment on the surface and mechanical properties of ultrahigh-modulus polyethylene fibers. J. Adhes. Sci. Technol. 2002, 16, 99–107. [Google Scholar] [CrossRef]

- Laroussi, M.; Akan, T. Arc-free atmospheric pressure cold plasma jets: A review. Plasma Proces. Polym. 2007, 4, 777–778. [Google Scholar] [CrossRef]

- Winter, J.; Brandenburg, R.; Weltmann, K.D. Atmospheric pressure plasma jets: An overview of devices and new directions. Plasma Sources Sci. Technol. 2015, 24, 064001-19. [Google Scholar] [CrossRef]

- Fanelli, F.; Fracassi, F. Atmospheric pressure non-equilibrium plasma jet technology: General features, specificities and applications in surface processing of materials. Surf. Coat. Technol. 2017, 322, 174–201. [Google Scholar] [CrossRef]

- Noeske, M.; Degenhardt, J.; Strudthoff, S.; Lommatzsch, U. Plasma jet treatment of five polymers at atmospheric pressure: Surface modifications and the relevance for adhesion. Int. J. Adhes. Adhes. 2004, 24, 171–177. [Google Scholar] [CrossRef]

- Choi, J.; Matsuo, K.; Yoshida, H.; Namihira, T.; Katsuki, S.; Akiyama, H. Double-layered atmospheric pressure plasma jet. Jpn. J. Appl. Phys. 2009, 48, 086003. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Y.; Han, E.; Ge, Y. Atmospheric pressure DBD gun and its application in ink printability. Plasma Sources Sci. Technol. 2005, 14, 670–675. [Google Scholar] [CrossRef]

- Laroussi, M. Low temperature plasma jets: Characterization and biomedical applications. Plasma 2020, 3, 54–58. [Google Scholar] [CrossRef] [Green Version]

- Zaplotnik, R.; Vesel, A. Effect of VUV radiation on surface modification of polystyrene exposed to atmospheric pressure plasma jet. Polymers 2020, 12, 1136. [Google Scholar] [CrossRef]

- Sangnal Matt Durandhara Murthy, V.; Vaidya, U. Improving the adhesion of glass/polypropylene (glass-PP) and high-density polyethylene (HDPE) surfaces by open air plasma treatment. Int. J. Adhes. Adhes. 2019, 95, 102435. [Google Scholar] [CrossRef]

- Fei, X.; Kuroda, S.-i.; Mori, T.; Hosoi, K. High-density polyethylene (HDPE) surface treatment using an RF capacitive atmospheric pressure cold Ar plasma jet. Plasma Sci. Technol. 2013, 15, 577–581. [Google Scholar] [CrossRef]

- Van Deynse, A.; Cools, P.; Leys, C.; Morent, R.; De Geyter, N. Surface modification of polyethylene in an argon atmospheric pressure plasma jet. Surf. Coat. Technol. 2015, 276, 384–390. [Google Scholar] [CrossRef] [Green Version]

- Korzec, D.; Hoppenthaler, F.; Burger, D.; Andres, T.; Nettesheim, S. Atmospheric pressure plasma jet powered by piezoelectric direct discharge. Plasma Process. Polym. 2020, 17, 2000053. [Google Scholar] [CrossRef]

- Kostov, K.; Nishime, T.; Castro, A.; Toth, A.; Hein, L. Surface modification of polymeric materials by cold atmospheric plasma jet. Appl. Surf. Sci. 2014, 314, 367–375. [Google Scholar] [CrossRef] [Green Version]

- Van Deynse, A.; Cools, P.; Leys, C.; De Geyter, N.; Morent, R. Surface activation of polyethylene with an argon atmospheric pressure plasma jet: Influence of applied power and flow rate. Appl. Surf. Sci. 2015, 328, 269–278. [Google Scholar] [CrossRef]

- Alavi, S.; Lotz, O.; Akhavan, B.; Yeo, G.; Walia, R.; McKenzie, D.; Bilek, M. Atmospheric pressure plasma jet treatment of polymers enables reagent-free covalent attachment of biomolecules for bioprinting. ACS Appl. Mater. Interfaces 2020, 12, 38730–38743. [Google Scholar] [CrossRef] [PubMed]

- Van Vrekhem, S.; Vloebergh, K.; Asadian, M.; Vercruysse, C.; Declercq, H.; Van Tongel, A.; De Wilde, L.; De Geyter, N.; Morent, R. Improving the surface properties of an UHMWPE shoulder implant with an atmospheric pressure plasma jet. Sci. Rep. 2018, 8, 4720. [Google Scholar] [CrossRef]

- Brewis, D.; Mathieson, I. Flame treatment of polymers to improve adhesion. In Adhesion Promotion Techniques: Technological Applications; Mittal, K., Pizzi, A., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 2002; Chapter 6; pp. 175–190. [Google Scholar]

- Farris, S.; Pozzoli, S.; Biagioni, P.; Duó, L.; Mancinelli, S. The fundamentals of flame treatment for the surface activation of polyolefin polymers—A review. Polymer 2010, 51, 3591–3605. [Google Scholar] [CrossRef] [Green Version]

- Goldman, M.; Goldman, A. Corona discharges. In Gasous Electronics, Vol. I: Electrical Discharges; Hirsh, M.N., Oskam, H.J., Eds.; Academic Press: New York, NY, USA, 1978; Chapter 4; pp. 219–290. [Google Scholar]

- Chang, J.S.; Lawless, P.A.; Yamamoto, T. Corona discharge processes. IEEE Trans. Plasma Sci. 1991, 19, 1152–1166. [Google Scholar] [CrossRef] [Green Version]

- Sutherland, I.; Popat, R.; Brewis, D.; Calder, R. Corona discharge treatment of polyolefins. J. Adhes. 1994, 46, 79–88. [Google Scholar] [CrossRef]

- Pascual, M.; Calvo, O.; Sanchez-Nácher, L.; Bonet, M.; Garcia-Sanoguera, D.; Balart, R. Optimization of adhesive joints of low density polyethylene (LDPE) composite laminates with polyolefin foam using corona discharge plasma. J. Appl. Polym. Sci. 2009, 114, 2971–2977. [Google Scholar] [CrossRef]

- Popelka, A.; Novák, I.; Al-Maadeed, M.A.S.; Ouederni, M.; Krupa, I. Effect of corona treatment on adhesion enhancement of LLDPE. Surf. Coat. Technol. 2017, 335, 118–125. [Google Scholar] [CrossRef]

- Prevosto, L.; Kelly, H.; Mancinelli, B.R. Langmuir probe diagnostics of an atmospheric pressure, vortex–stabilized nitrogen plasma jet. J. Appl. Phys. 2012, 112, 063302. [Google Scholar] [CrossRef] [Green Version]

- Begum, A.; Laroussi, M.; Pervez, M. Dielectric probe: A new electrical diagnostic tool for atmospheric pressure non-thermal plasma jet. Int. J. Eng. Technol.-Ijet-Ijens 2011, 11, 209–215. [Google Scholar]

- Laux, C.O.; Spence, T.G.; Krugr, C.H.; Zare, R.N. Optical diagnostics of atmospheric pressure air plasmas. Plasma Sources Sci. Technol. 2003, 12, 125–138. [Google Scholar] [CrossRef]

- Milosavljević, V.; Donegan, M.; Cullen, P.J.; Dowling, D.P. Diagnostics of an O2–He RF atmospheric plasma discharge by spectral emission. J. Phys. Soc. Jpn. 2014, 83, 014501. [Google Scholar] [CrossRef] [Green Version]

- Reuter, S.; Sousa, J.; Stancu, G.D.; van Helden, J.P.H. Review on VUV to MIR absorption spectroscopy of atmospheric pressure plasma jets. Plasma Sources Sci. Technol. 2015, 24, 054001. [Google Scholar] [CrossRef]

- Lu, X.P.; Laroussi, M. Electron density and temperature measurement of an atmospheric pressure plasma by millimeter wave interferometer. Appl. Phys. Lett. 2008, 92, 051501. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Laroussi, M. Dynamics of an atmospheric pressure plasma plume generated by submicrosecond voltage pulses. J. Appl. Phys. 2006, 100, 063302-1–063302-6. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Laroussi, M.; Puech, V. On atmospheric-pressure non-equilibrium plasma jets and plasma bullets. Plasma Sources Sci. Technol. 2012, 21, 034005. [Google Scholar] [CrossRef]

- Kewitz, T.; Fröhlich, M.; von Frieling, J.; Kersten, H. Investigation of a commercial atmospheric pressure plasma jet by a newly designed calorimetric probe. IEEE Trans. Plasma Sci. 2015, 43, 1769–1773. [Google Scholar] [CrossRef]

- Korzec, D.; Nettesheim, S. Application of a pulsed atmospheric arc plasma jet for low-density polyethylene coating. Plasma Process. Polym. 2020, 17, 1900098. [Google Scholar] [CrossRef]

- TDK Electronics. Cold Plasma from a Single Component. Applications & Cases. 2014. Available online: https://www.tdk-electronics.tdk.com/en/373562/tech-library/articles/applications— cases/applications—cases/cold-plasma-from-a-single-component/1109546 (accessed on 11 August 2021).

- EPCOS AG. CeraPlas® HF Series. Piezoelectric Based Plasma Generator. Data Sheet. 2018. Available online: https://www.mouser.de/datasheet/2/400/ceraplas-db-1487530.pdf (accessed on 11 August 2021).

- Wang, C.; Chen, X.; Ouyang, J.; Li, T.; Fu, J. Pulse current of multi-needle negative corona discharge and its electromagnetic radiation characteristics. Energies 2018, 11, 3120. [Google Scholar] [CrossRef] [Green Version]

- Korzec, D.; Hoppenthaler, F.; Nettesheim, S. Piezoelectric direct discharge: Devices and applications. Plasma 2021, 4, 1–41. [Google Scholar] [CrossRef]

- Stoffels, E.; Flikweert, A.; Stoffels, W.; Kroesen, G. Plasma needle: A non-destructive atmospheric plasma source for fine surface treatment of (bio)materials. Plasma Sources Sci. Technol. 2002, 11, 383–388. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Wetting Tension of Polyethylene and Polypropylene Films. 2004. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/D2578-04.htm (accessed on 11 August 2021).

- Open Chemistry Database. CID 713. 2019. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/formamide#section=Computed-Properties (accessed on 11 August 2021).

- Wu, J.; Farouk, T.; Ward, C. Pressure dependence of the contact angle. J. Phys. Chem. B 2007, 111, 6189–6197. [Google Scholar] [CrossRef]

- Pérez-Díaz, J.L.; Álvarez-Valenzuela, M.A.; García-Prada, J.C. The effect of the partial pressure of water vapor on the surface tension of the liquid water–air interface. J. Colloid Interface Sci. 2012, 381, 180–182. [Google Scholar] [CrossRef]

- Pérez-Díaz, J.L.; Álvarez-Valenzuela, M.A.; Valiente-Blanco, I.; Jimenez-Lopez, S.; Palacios-Cuesta, M.; Garcia, O.; Diez-Jimenez, E.; Sanchez-Garcia-Casarrubios, J.; Cristache, C. On the influence of relative humidity on the contact angle of a water droplet on a silicon wafer. In Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition. Vlume 7A: Fluids Engineering Systems and Technologies, San Diego, CA, USA, 15–21 November 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, D.; Wadsworth, L. Corona treatment of polyolefin films—A review. Adv. Polym. Technol. 1999, 18, 171–180. [Google Scholar]

- Jin, M.; Thomsen, F.; Skrivanek, T.; Willers, T. Why test inks cannot tell the whole truth about surface free energy of solids. In Advances in Contact Angle, Wettability and Adhesion; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; Chapter 17; pp. 419–438. [Google Scholar]

- Morra, M.; Occhiello, E.; Marola, R.; Garbassi, F.; Humphrey, P.; Johnson, D. On the aging of oxygen plasma-treated polydimethylsiloxane surfaces. J. Colloid Interface Sci. 1990, 137, 11–24. [Google Scholar] [CrossRef]

- Kim, J.; Chaudhury, M.K.; Owen, M.J. Modeling hydrophobic recovery and electrically discharged polydimethylsiloxane elastomers. J. Colloid Interface Sci. 2006, 293, 364–375. [Google Scholar] [CrossRef]

- Alves, P.; Pinto, S.; de Souse, H.; Gil, M. Surface modification of a thermoplastic polyurethane by low-pressure plasma treatment to improve hydrophilicity. J. Appl. Polym. Sci. 2011, 122, 2302–2308. [Google Scholar] [CrossRef]

- Kim, J.; Chaudhury, M.K.; Owen, M.J.; Orbeck, T. The mechanisms of hydrophobic recovery of polydimethylsiloxane elastomers exposed to partial electrical discharges. J. Colloid Interface Sci. 2001, 244, 200–207. [Google Scholar] [CrossRef] [Green Version]

- Jokinen, V.; Suvanto, P.; Franssila, S. Oxygen and nitrogen plasma hydrophilization and hydrophobic recovery of polymers. Biomicrofluidics 2012, 6, 016501. [Google Scholar] [CrossRef] [Green Version]

- Guckenberger, D.; Berthier, E.; Young, E.; Beebe, D. Induced hydrophobic recovery of oxygen plasma-treated surfaces. Lab Chip 2012, 12, 2317–2321. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Behnisch, J.; Holländer, A.; Zimmermann, H. Factors influencing the hydrophobic recovery of oxygen-plasma-treated polyethylene. Surf. Coat. Technol. 1993, 59, 356–358. [Google Scholar] [CrossRef]

- Pascual, M.; Balart, R.; Sánchez, L.; Fenollar, O.; Calvo, O. Study of the aging process of corona discharge plasma effects on low density polyethylene film surface. J. Mater. Sci. 2008, 43, 4901–4909. [Google Scholar] [CrossRef]

- Fricke, K.; Tresp, H.; Bussiahn, R.; Schröder, K.; von Woedtke, T.; Weltmann, K.D. On the use of atmospheric pressure plasma for the bio-decontamination of polymers and its impact on their chemical and morphological surface properties. Plasma Chem. Plasma Process. 2012, 32, 801–816. [Google Scholar] [CrossRef]

- Fricke, K.; Steffen, H.; von Woedtke, T.; Schröder, K.; Weltmann, K.D. High rate etching of polymers by means of an atmospheric pressure plasma jet. Plasma Process. Polym. 2011, 8, 51–58. [Google Scholar] [CrossRef]

- Deynse, A.V.; Cools, P.; Leys, C.; Morent, R.; de Geyter, N. Optimising the surface activation of polyethylene using different argon plasmas. In Proceedings of the 22nd International Symposium on Plasma Chemistry, Antwerp, Belgium, 5–10 July 2015. [Google Scholar]

| Case | Device | Nozzle | Power [W] | Frequency [kHz] | Distance [mm] | Gas | Gas Flow [SLM] |

|---|---|---|---|---|---|---|---|

| A | plasmabrush® PB3 | A450 | 700 | 54 | 25 | CDA | 35–80 |

| B | piezobrush® PZ2 | CeraPlas™F | 8.0 | 50 | 6 | air | ∼20 |

| C | piezobrush® PZ3 | CeraPlas™F | 8.0 | 50 | 6 | air | ∼10 |

| D | CeraPlas™package | CeraPlas™HF | 4.5 | 82 | 5 | CDA | |

| E | piezobrush® PZ3 | needle corona | 8.0 | 50 | 3–20 | air | |

| F | piezobrush® PZ3 | plasma needle | 8.0 | 50 | 3–25 | Ar | 3 |

| G | piezobrush® PZ3 | DBD | 8.0 | 50 | 1.0 | air |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korzec, D.; Andres, T.; Brandes, E.; Nettesheim, S. Visualization of Activated Area on Polymers for Evaluation of Atmospheric Pressure Plasma Jets. Polymers 2021, 13, 2711. https://doi.org/10.3390/polym13162711

Korzec D, Andres T, Brandes E, Nettesheim S. Visualization of Activated Area on Polymers for Evaluation of Atmospheric Pressure Plasma Jets. Polymers. 2021; 13(16):2711. https://doi.org/10.3390/polym13162711

Chicago/Turabian StyleKorzec, Dariusz, Thomas Andres, Eva Brandes, and Stefan Nettesheim. 2021. "Visualization of Activated Area on Polymers for Evaluation of Atmospheric Pressure Plasma Jets" Polymers 13, no. 16: 2711. https://doi.org/10.3390/polym13162711

APA StyleKorzec, D., Andres, T., Brandes, E., & Nettesheim, S. (2021). Visualization of Activated Area on Polymers for Evaluation of Atmospheric Pressure Plasma Jets. Polymers, 13(16), 2711. https://doi.org/10.3390/polym13162711