Energy Absorption and Limit Velocity of Epoxy Composites Incorporated with Fique Fabric as Ballistic Armor—A Brief Report

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Fabrication

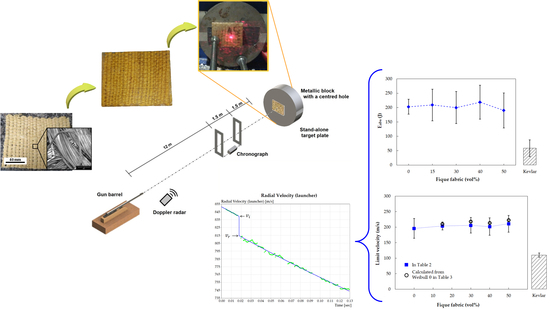

2.3. Stand-Alone Ballistic Tests

2.4. Ballistic Parameters

2.5. Weibull Statistical Analysis

2.6. Analysis of Variance (ANOVA)

2.7. Scanning Electron Microscopy (SEM)

3. Results and Discussion

3.1. Stand-Alone Ballistic Tests

3.2. Analysis of Variance (ANOVA) for Absorbed Energy

3.3. Limit Velocity Discussion

3.4. Composites Integrity and Failure Analyses

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, Y.S.; Wetzel, E.D.; Wagner, N.J. The Ballistic Impact Characteristic of kevlar woven fabrics impregnated with a colloidal shear thickening fluid. J. Mater. Sci. 2003, 38, 2825–2833. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lima, E.P., Jr.; Louro, L.H.L.; Silva, L.C.; Drelich, J.W. Unlocking function of aramid fibers in multilayered ballistic armor. Mettal. Mat. Trans. A 2014, 46, 37–40. [Google Scholar] [CrossRef]

- Luz, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Nascimento, L.F.C.; Monteiro, S.N. Composites with natural fibers and conventional materials applied in a hard armor: A comparison. Polymers 2020, 12, 1920. [Google Scholar] [CrossRef]

- Benzait, Z.; Trabzon, L. A review of recent research on materials used in polymer–matrix composites for body armor application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Sultan, M.T.H.; Shenoy, S.B.; Kini, C.R.; Samant, R.; Shah, A.U.M.; Amuthakkannan, P. Potential of natural fibers in composites for ballistic applications–A review. J. Nat. Fibers 2021, 44, 1–11. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, A.; et al. A review on natural fiber reinforced polymer composite for bullet proof and ballistic applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Odesanya, K.O.; Ahmad, R.; Jawaid, M.; Bingol, S.; Adebayo, G.O.; Wong, Y.H. Natural fibre-reinforced composite for ballistic applications: A review. J. Polym. Environ. 2021, 10, 1–18. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Milanezi, T.L.; Louro, L.H.L.; Lima Jr, E.P.; Braga, F.O.; Gomes, A.V.; Drelich, J.W. Novel ballistic ramie fabric composite competing with Kevlar™ fabric in multilayered armor. Mater. Des. 2016, 96, 263–269. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Luz, F.S.; Teixeira Souza, A.; Demosthenes, L.C.C.; Pereira, A.C.; Filho, F.C.G.; Braga, F.O.; Figueiredo, A.B.H.S.; Monteiro, S.N. Tucum Fiber from Amazon Astrocaryum vulgare Palm Tree: Novel Reinforcement for Polymer Composites. Polymers 2020, 12, 2259. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, M.P.; Neuba, L.M.; da Silveira, P.H.P.M.; da Luz, F.S.; da Silva Figueiredo, A.B.H.; Monteiro, S.N.; Moreira, M.O. Mechanical, thermal and ballistic performance of epoxy composites reinforced with Cannabis sativa hemp fabric. J. Mater. Res. Technol. 2021, 12, 221–233. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Louro, L.H.L.; Trindade, W.; Elias, C.N.; Ferreira, C.L.; de Sousa Lima, E.; Weber, R.P.; Suarez, J.C.; Figueiredo, A.B.H.S.; Pinheiro, W.A.; et al. Natural curaua fiber-reinforced composites in multilayered ballistic armor. Metall. Mater. Trans. A 2015, 46, 4567–4577. [Google Scholar] [CrossRef]

- Luz, F.S.; Garcia Filho, F.C.; del-Río, M.T.G.; Nascimento, L.F.C.; Pinheiro, W.A.; Monteiro, S.N. Graphene-Incorporated Natural Fiber Polymer Composites: A First Overview. Polymers 2020, 12, 1601. [Google Scholar] [CrossRef]

- Garcia Filho, F.C.; Luz, F.S.; Oliveira, M.S.; Bezerra, W.B.A.; Barbosa, J.D.V.; Monteiro, S.N. Influence of Rigid Brazilian Natural Fiber Arrangements in Polymer Composites: Energy Absorption and Ballistic Efficiency. J. Compos. Sci. 2021, 5, 201. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; da Luz, F.S.; Candido, V.S.; da Silva, A.C.R.; Monteiro, S.N. Ballistic Performance of Guaruman Fiber Composites in Multilayered Armor System and as Single Target. Polymers 2021, 13, 1203. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, S.N.; Drelich, J.W.; Lopera, H.A.C.; Nascimento, L.F.C.; da Luz, F.S.; da Silva, L.C. Natural Fibers Reinforced Polymer Composites Applied in Ballistic Multilayered Armor for Personal Protection—An overview. In Green Materials Engineering; The Minerals, Metals & Materials Series; Ikhmayies, S., Li, J., Vieira, C., Margem Deceased, J., de Oliveira Braga, F., Eds.; Springer: Cham, Switzerland, 2019; pp. 33–47. [Google Scholar] [CrossRef]

- National Criminal Justice Reference Service. US Department of Justice, & National Institute of Justice. NIJ 0101.06. Ballistic Resistance of Body Armor. 2008. Available online: https://nij.ojp.gov/library/publications/ballistic-resistance-body-armor-nij-standard-010106 (accessed on 5 July 2021).

- Pereira, A.C.; de Assis, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Demosthenes, L.C.C.; Lopera, H.A.C.; Monteiro, S.N. Ballistic performance of multilayered armor with intermediate polyester composite reinforced with fique natural fabric and fibers. J. Mater. Res. Technol. 2019, 8, 4221–4226. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Pereira, A.C.; Nunes, L.F.; da Luz, F.S.; Braga, F.O.; Colorado, H.A.; Monteiro, S.N. Ballistic performance and statistical evaluation of multilayered armor with epoxy-fique fabric composites using the Weibull analysis. J. Mater. Res. Technol. 2019, 8, 5899–5908. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Luz, F.S.; Pereira, A.C.; Demosthenes, L.C.C.; Nascimento, L.F.C.; Lopera, H.A.C.; Monteiro, S.N. Statistical analysis of notch toughness of epoxy matrix composites reinforced with fique fabric. J. Mater. Res. Technol. 2019, 8, 6051–6057. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Luz, F.S.; Pereira, A.C.; Demosthenes, L.C.C.; Nascimento, L.F.C.; Monteiro, S.N. Tensile Properties of Epoxy Matrix Reinforced with Fique Fabric. MSF 2020, 1012, 14–19. [Google Scholar] [CrossRef]

- Brazilian Association of Technical Norms, ABNT NBR 10591/2008. Textiles Materials—Determination of Mass per Unit Area; ABNT: São Paulo, Brazil, 2008. [Google Scholar]

- Monteiro, S.N.; Assis, F.S.; Ferreira, C.L.; Simonassi, N.T.; Weber, R.P.; Oliveira, M.S.; Colorado, H.A.; Pereira, A.C. Fique Fabric: A Promising Reinforcement for Polymer Composites. Polymers 2018, 10, 246. [Google Scholar] [CrossRef] [Green Version]

- Morye, S.S.; Hine, P.J.; Duckett, R.A.; Carr, D.J.; Ward, I.M. Modelling of the energy absorption by polymer composites upon ballistic impact. Compos. Sci. Technol. 2000, 60, 2631–2642. [Google Scholar] [CrossRef]

- Luz, F.S.; Lima, E.P.; Louro, L.H.L.; Monteiro, S.N. Ballistic test of multilayered armor with intermediate epoxy composite reinforced with jute fabric. Mater. Res. 2015, 18, 170–177. [Google Scholar] [CrossRef]

- Garcia Filho, F.D.C.; Oliveira, M.S.; Pereira, A.C.; Nascimento, L.F.C.; Matheus, J.R.G.; Monteiro, S.N. Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition. J. Mater. Res. Technol. 2020, 9, 1734–1741. [Google Scholar] [CrossRef]

- Nascimento, L.F.C.; Louro, L.H.L.; Monteiro, S.N.; Lima, É.P.; Luz, F.S. Mallow fiber-reinforced epoxy composites in multilayered armor for personal ballistic protection. JOM 2017, 69, 2052–2056. [Google Scholar] [CrossRef]

- Nascimento, L.F.C.; Louro, L.H.L.; Monteiro, S.N.; Braga, F.O.; da Luz, F.S.; dos Santos, J.L.; Marçal, R.L.S.B.; Freitas, H.C.O.; Lima Júnior, É.P. Limit Speed Analysis and Absorbed Energy in Multilayer Armor with Epoxy Composite Reinforced with Mallow Fibers and Mallow and Jute Hybrid Fabric. In Characterization of Minerals, Metals, and Materials 2018; The Minerals, Metals & Materials Series; Li, B., Ed.; Springer: Cham, Switzerland, 2018; pp. 597–604. [Google Scholar] [CrossRef]

| Nomenclature | Material |

|---|---|

| EC15BF | Epoxy composite with 15 vol% fique fabric |

| EC30FF | Epoxy composite with 30 vol% fique fabric |

| EC40BF | Epoxy composite with 40 vol% fique fabric |

| EC50BF | Epoxy composite with 50 vol% fique fabric |

| Stand-Alone 10 mm Thick Plate Target | (m/s) | (m/s) | (J) | (m/s) | Ref. |

|---|---|---|---|---|---|

| EC15FF | 839 ± 7 | 814 ± 6 | 203 ± 26 | 204 ± 13 | PW |

| EC30FF | 840 ± 8 | 813 ± 8 | 209 ± 55 | 206 ± 25 | PW |

| EC40FF | 837 ± 4 | 812 ± 10 | 200 ± 56 | 202 ± 28 | PW |

| EC50FF | 843 ± 4 | 816 ± 5 | 219 ± 59 | 211 ± 27 | PW |

| DGEBA/TETA epoxy | 850 ± 2 | 827 ± 6 | 190 ± 61 | 196 ± 32 | [11] |

| Kevlar (ply of aramid fabric) | 848 ± 6 | 841 ± 7 | 58 ± 29 | 109 ± 7 | [24] |

| Stand-Alone Composite Plate Target | β | θ (J) | R2 |

|---|---|---|---|

| EC15FF | 7.85 | 214.6 | 0.96 |

| EC30FF | 4.01 | 231.8 | 0.73 |

| EC40FF | 3.78 | 221.7 | 0.93 |

| EC50FF | 4.05 | 241.2 | 0.88 |

| Variation Causes | Sum of Squares | DF | Mean of Squares | Fcalc | Fcrit | p-Value |

|---|---|---|---|---|---|---|

| Treatment | 2304.48 | 4 | 576.12 | 0.22 | 2.74 | 0.93 |

| Residual | 69,215.74 | 26 | 2662.14 | |||

| Total | 71,520.22 | 30 |

| Epoxy Composite | (m/s) | Reference |

|---|---|---|

| 15 vol% fique fabric | 204 ± 13 | PW |

| 30 vol% fique fabric | 206 ± 25 | PW |

| 40 vol% fique fabric | 202 ± 28 | PW |

| 50 vol% fique fabric | 211 ± 27 | PW |

| 10 vol% piassava fiber | 236 ± 8 | [25] |

| 20 vol% piassava fiber | 200 ± 9 | [25] |

| 30 vol% piassava fiber | 202 ± 7 | [25] |

| 40 vol% piassava fiber | 198 ± 6 | [25] |

| 50 vol% piassava fiber | 204 ± 2 | [25] |

| 30 vol% mallow fiber | 231 ± 18 | [26] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, M.S.; Luz, F.S.d.; Lopera, H.A.C.; Nascimento, L.F.C.; Garcia Filho, F.d.C.; Monteiro, S.N. Energy Absorption and Limit Velocity of Epoxy Composites Incorporated with Fique Fabric as Ballistic Armor—A Brief Report. Polymers 2021, 13, 2727. https://doi.org/10.3390/polym13162727

Oliveira MS, Luz FSd, Lopera HAC, Nascimento LFC, Garcia Filho FdC, Monteiro SN. Energy Absorption and Limit Velocity of Epoxy Composites Incorporated with Fique Fabric as Ballistic Armor—A Brief Report. Polymers. 2021; 13(16):2727. https://doi.org/10.3390/polym13162727

Chicago/Turabian StyleOliveira, Michelle Souza, Fernanda Santos da Luz, Henry Alonso Colorado Lopera, Lucio Fabio Cassiano Nascimento, Fabio da Costa Garcia Filho, and Sergio Neves Monteiro. 2021. "Energy Absorption and Limit Velocity of Epoxy Composites Incorporated with Fique Fabric as Ballistic Armor—A Brief Report" Polymers 13, no. 16: 2727. https://doi.org/10.3390/polym13162727

APA StyleOliveira, M. S., Luz, F. S. d., Lopera, H. A. C., Nascimento, L. F. C., Garcia Filho, F. d. C., & Monteiro, S. N. (2021). Energy Absorption and Limit Velocity of Epoxy Composites Incorporated with Fique Fabric as Ballistic Armor—A Brief Report. Polymers, 13(16), 2727. https://doi.org/10.3390/polym13162727