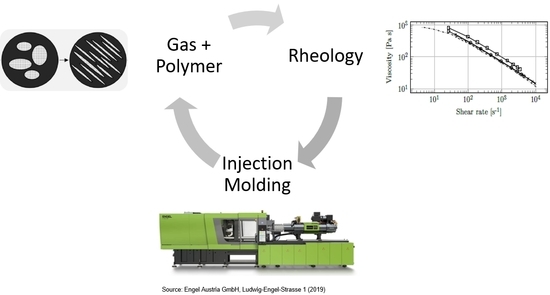

Development of a Rheology Die and Flow Characterization of Gas-Containing Polymer Melts

Abstract

:1. Introduction

2. Concept and Design of a Novel Shear-Viscosity Die

3. Experimental

3.1. Shear Viscosity—Apparent Properties

3.2. Shear Viscosity—Correction of Measurements

3.2.1. Approach 1—Weissenberg-Rabinowitsch (WR) Correction

3.2.2. Approach 2—Schümmer Approximation

3.2.3. Approach 3—Variant of WR Correction

3.3. Elongational Viscosity

3.4. Ultrasound Measurements of Volumetric Flow Rate

4. Materials and Equipment

5. Results and Discussion

5.1. Thermal Characterization and Pressure Calibration

5.2. Rheology Measurements with CBA—Shear Viscosity

5.2.1. Choice of Suitable Correction Approach for Rheology Die

5.2.2. Measurement Results

5.3. Rheology Measurements with CBA—Elongational Viscosity

Measurement Results

5.4. Ultrasound Measurements of Volumetric Flow Rate

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| CBA-1 | CBA-2 | |||||||

|---|---|---|---|---|---|---|---|---|

| P1-P2 | P2-P3 | P1-P3 | P1-P2 | P2-P3 | P1-P3 | |||

| 0% | [Pas] | 209.89 | 380.56 | 998.85 | 282.03 | 1235.14 | 741.10 | |

| [s] | 0.0040 | 0.0174 | 0.0057 | 0.0114 | 0.0742 | 0.0368 | ||

| [−] | 0.8248 | 2.1379 | 0.3398 | 1.6397 | 1.2022 | 0.9208 | ||

| [−] | 0.2539 | 0.3556 | 0.0750 | 0.3674 | 0.3305 | 0.3312 | ||

| 3% | [Pas] | 168.33 | 440.35 | 313.72 | 256.21 | 944.15 | 563.97 | |

| [s] | 0.0049 | 0.0201 | 0.0089 | 0.0101 | 0.0470 | 0.0247 | ||

| [−] | 1.4388 | 1.3521 | 0.8621 | 1.8405 | 1.1502 | 1.0644 | ||

| [−] | 0.3525 | 0.3378 | 0.2902 | 0.3650 | 0.3185 | 0.3267 | ||

| 6% | [Pas] | 171.12 | 427.71 | 331.75 | 286.25 | 1237.81 | 784.27 | |

| [s] | 0.0053 | 0.0207 | 0.0100 | 0.0118 | 0.0723 | 0.0362 | ||

| [−] | 1.3787 | 1.6147 | 0.8235 | 1.5013 | 1.0608 | 0.8040 | ||

| [−] | 0.3595 | 0.3469 | 0.2953 | 0.3597 | 0.3220 | 0.3117 |

References

- Gallego-Schmid, A.; Mendoza, J.M.F.; Azapagic, A. Improving the environmental sustainability of reusable food containers in Europe. Sci. Total Environ. 2018, 628–629, 979–989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lewis, H.; Verghese, K.; Fitzpatrick, L. Evaluating the sustainability impacts of packaging: The plastic carry bag dilemma. Packag. Technol. Sci. 2010, 23, 145–160. [Google Scholar] [CrossRef]

- Biron, M. The Plastics Industry: Economic Overview. In Thermoplastics and Thermoplastic Composites, 3rd ed.; Biron, M., Ed.; William Andrew Publishing: Oxford, UK, 2018; pp. 31–132. [Google Scholar]

- Li, G.; Gunkel, F.; Wang, J.; Park, C.B.; Altstädt, V. Solubility Measurements of N2 and CO2 in Polypropylene and Ethene/Octene Copolymer. J. Appl. Polym. Sci. 2007, 103, 2945–2953. [Google Scholar] [CrossRef]

- Sato, Y.; Fujiwara, K.; Takikawa, T.; Takishima, S.; Masuoka, H. Solubilities and diffusion coefficients of carbon dioxide and nitrogen in polypropylene, high-density polyethylene, and polystyrene under high pressures and temperatures. Fluid Phase Equilib. 1999, 162, 261–276. [Google Scholar] [CrossRef]

- Park, H.E.; Dealy, J.M. Effects of Pressure and Supercritical Fluids on the Viscosity of Polyethylene. Macromolecules 2006, 39, 5438–5452. [Google Scholar] [CrossRef]

- Raps, D.; Köppl, T.; Rios de Anda, A.; Altstädt, V. Rheological and crystallisation behaviour of high melt strength polypropylene under gas-loading. Polymer 2014, 55, 1537–1545. [Google Scholar] [CrossRef]

- Lee, M.; Tzoganakis, C.; Park, C.B. Extrusion of PE/PS blends with supercritical carbon dioxide. Polym. Eng. Sci. 1998, 38, 1112–1120. [Google Scholar] [CrossRef]

- Lee, M.; Park, C.B.; Tzoganakis, C. Measurements and modeling of PS/supercritical CO2 solution viscosities. Polym. Eng. Sci. 1999, 39, 99–109. [Google Scholar] [CrossRef]

- Lee, M.; Tzoganakis, C.; Park, C.B. Effects of supercritical CO2 on the viscosity and morphology of polymer blends. Adv. Polym. Technol. 2000, 19, 300–311. [Google Scholar] [CrossRef]

- Mei, X.Y.; Sun, H.L.; Liu, C.H.; Turng, L.S. Evaluating the gas-laden ability of polymer melt under atmospheric conditions using a modified torque rheometer. J. Cell. Plast. 2021. Available online: https://journals.sagepub.com/doi/abs/10.1177/0021955X21997351 (accessed on 5 March 2021). [CrossRef]

- Aho, J.; Syrjälä, S. Shear viscosity measurements of polymer melts using injection molding machine with adjustable slit die. Polym. Test. 2011, 30, 595–601. [Google Scholar] [CrossRef]

- Qin, X.; Thompson, M.; Hrymak, A. Rheology studies of foam flow during injection mold filling. Polym. Eng. Sci. 2007, 47, 522–529. [Google Scholar] [CrossRef]

- Kastner, C.; Steinbichler, G. Theoretical Background and Automation Approach for a Novel Measurement Method for Determining Dynamic Solubility Limits of Supercritical Fluids in Injection Foam Molding. Polym. Eng. Sci. 2020, 60, 330–340. [Google Scholar] [CrossRef] [Green Version]

- Meng, L.; Wu, D.; Kelly, A.; Woodhead, M.; Liu, Y. Experimental investigation of the rheological behaviors of polypropylene in a capillary flow. J. Appl. Polym. Sci. 2016, 133, 43459. [Google Scholar] [CrossRef] [Green Version]

- Xue, A.; Tzoganakis, C. Rheological Properties of Polystyrene/Supercritical CO2 Solutions from an Extrusion Slit Die. J. Polym. Eng. 2003, 23, 1–22. [Google Scholar] [CrossRef]

- Müller, M. Kapillarrheometrie. In Thermoplastische Elastomere als Neuartige Additive für die Kunststoffverarbeitung; Wagner, M.H., Ed.; University der TU Berlin: Berlin, Germany, 2009; pp. 52–58. [Google Scholar]

- Schümmer, P.; Worthoff, R.H. An elementary method for the evaluation of a flow curve. Chem. Eng. Sci. 1978, 33, 759–763. [Google Scholar] [CrossRef]

- Osswald, T.A.; Menges, G. Rheology of Polymer Melts. In Materials Science of Polymers for Engineers, 3rd ed.; Osswald, T.A., Menges, G., Eds.; Hanser: Munich, Germany, 2012; pp. 111–162. [Google Scholar]

- Laun, H.M. Polymer melt rheology with a slit die. Rheol. Acta 1983, 22, 171–185. [Google Scholar] [CrossRef]

- Kadijk, S.E.; Van Den Brule, B.H.A.A. On the pressure dependency of the viscosity of molten polymers. Polym. Eng. Sci. 1994, 34, 1535–1546. [Google Scholar] [CrossRef]

- Luger, H.J.; Löw-Baselli, B.; Neunhäuserer, A.; Friesenbichler, W.; Miethlinger, J. A novel hyperbolic slit contraction with constant strain rate for elongational rheology of polymer melts. Polym. Test. 2019, 73, 104–114. [Google Scholar] [CrossRef]

- Mighri, F.; Huneault, M.A.; Ajji, A.; Ko, G.H.; Watanabe, F. Rheology of EPR/PP blends. J. Appl. Polym. Sci. 2001, 82, 2113–2127. [Google Scholar] [CrossRef]

- Wang, L.; Hikima, Y.; Ohshima, M.; Yusa, A.; Yamamoto, S.; Goto, H. Development of a Simplified Foam Injection Molding Technique and Its Application to the Production of High Void Fraction Polypropylene Foams. Ind. Eng. Chem. Res. 2017, 56, 13734–13742. [Google Scholar] [CrossRef]

- Ahmadzai, A.; Behravesh, A.H.; Sarabi, M.T.; Shahi, P. Visualization of foaming phenomena in thermoplastic injection molding process. J. Cell. Plast. 2014, 50, 279–300. [Google Scholar] [CrossRef]

- Huang, J.C.; Leong, K.S. Shear viscosity, extensional viscosity, and die swell of polypropylene in capillary flow with pressure dependency. J. Appl. Polym. Sci. 2002, 84, 1269–1276. [Google Scholar] [CrossRef]

- Pendse, A.V.; Collier, J.R. Elongational viscosity of polymer melts: A lubricated skin-core flow approach. J. Appl. Polym. Sci. 1996, 59, 1305–1314. [Google Scholar] [CrossRef]

- Rauwendaal, C. Important Polymer Properties. In Polymer Extrusion, 5th ed.; Rauwendaal, C., Ed.; Hanser: Munich, Germany, 2014; pp. 191–253. [Google Scholar]

- Ng, S.L.; Mun, R.P.; Boger, D.V.; James, D.F. Extensional viscosity measurements of dilute solutions of various polymers. J. Non-Newton. Fluid Mech. 1996, 65, 291–298. [Google Scholar] [CrossRef]

- Różańska, S.; Różański, J.; Ochowiak, M.; Mitkowski, P.T. Extensional viscosity measurements of concentrated emulsions with the use of the opposed nozzles device. Braz. J. Chem. Eng. 2014, 31, 47–55. [Google Scholar] [CrossRef]

- Binding, D.M.; Couch, M.A.; Walters, K. The pressure dependence of the shear and elongational properties of polymer melts. J. Non-Newton. Fluid Mech. 1998, 79, 137–155. [Google Scholar] [CrossRef]

- Bach, A.; Rasmussen, H.; Hassager, O. Extensional viscosity for polymer melts measured in the filament stretching rheometer. J. Rheol. 2003, 47, 429–441. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Dimension |

|---|---|

| Width, | 20 mm |

| Height, | 1 mm |

| Total die length | 120 mm |

| Distance between pressure transducers | 30 mm |

| Distance from inlet to first transducer | 30 mm |

| Distance from last transducer to outlet | 30 mm |

| Section | Parameter | Dimension |

|---|---|---|

| Slit Section 1 | Height, | 2 mm |

| Width, | 20 mm | |

| Length, | 65 mm | |

| Slit Section 2 | Height, | 0.5 mm |

| Width, | 5 mm | |

| Length, | 5 mm | |

| Contraction section | Length, | 5 mm |

| Injection Molding | Extrusion | Supplier | |

|---|---|---|---|

| Polymer | PPH-1 | PPH-1 | Borealis Polyolefine GmbH, Linz, Austria |

| PPH-2 1 | |||

| CBA | CBA-1 | CBA-1 | Trexel, Inc., Wilmington, MA, USA |

| CBA-2 | Clariant AG, Muttenz, Switzerland |

| CBA-1 | CBA-2 | |||||||

|---|---|---|---|---|---|---|---|---|

| Content Range | P1-P2 | P2-P3 | P1-P3 | Grand Average | P1-P2 | P2-P3 | P1-P3 | Grand Average |

| 0–3 | 0.34 | −2.97 | −1.92 | −1.52 | −2.60 | −2.40 | −2.39 | −2.47 |

| 3–6 | −0.88 | −0.05 | −0.76 | −0.56 | −0.78 | −0.20 | −0.98 | −0.65 |

| 0–6 | −0.52 | −3.04 | −2.66 | −2.07 | −3.36 | −2.60 | −3.35 | −3.10 |

| [cm3 s−1] | [g] | [cm3] | [%] | [s] | [s] | [cm3 s−1] | [cm3 s−1] |

|---|---|---|---|---|---|---|---|

| 5 | 74.13 | 101.56 | 0.28 | 19.89 | 0.02 | 5.11 | 0.02 |

| 10 | 73.90 | 101.24 | 0.36 | 9.95 | 0.00 | 10.18 | 0.04 |

| 20 | 73.97 | 101.33 | 0.16 | 5.15 | 0.00 | 19.68 | 0.03 |

| Average | 74.00 | 101.38 | 0.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kastner, C.; Altmann, D.; Kobler, E.; Steinbichler, G. Development of a Rheology Die and Flow Characterization of Gas-Containing Polymer Melts. Polymers 2021, 13, 3305. https://doi.org/10.3390/polym13193305

Kastner C, Altmann D, Kobler E, Steinbichler G. Development of a Rheology Die and Flow Characterization of Gas-Containing Polymer Melts. Polymers. 2021; 13(19):3305. https://doi.org/10.3390/polym13193305

Chicago/Turabian StyleKastner, Clemens, Dominik Altmann, Eva Kobler, and Georg Steinbichler. 2021. "Development of a Rheology Die and Flow Characterization of Gas-Containing Polymer Melts" Polymers 13, no. 19: 3305. https://doi.org/10.3390/polym13193305

APA StyleKastner, C., Altmann, D., Kobler, E., & Steinbichler, G. (2021). Development of a Rheology Die and Flow Characterization of Gas-Containing Polymer Melts. Polymers, 13(19), 3305. https://doi.org/10.3390/polym13193305