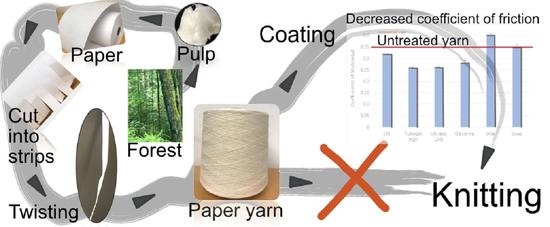

Enhanced Knittability of Paper Yarn from the Swedish Forest by Using Textile Finishing Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Yarn and Finishing Materials

- The Finishing material 102 provided from GA Lindberg (Stockholm, Sweden) is an aqueous emulsion based on siloxanes and additives.

- Tubingal RGH (CHT n.d., Tübingen, Germany) is a micro emulsion of a polysiloxande organomodifier (CHT (Safety Data Sheet)). Tubingal RGH is a hydrophilic soft handle agent suitable for all fiber types.

- Ultratex® UHS (Huntsman Corporation (HUN), TX, USA) is a micro emulsion of a functional polydimethyl siloxane. It is used as a hydrophilic finish and softener of different textile fibers.

- Glycerol from Merk KGaA (Darmstadt, Germany).

- Destofil LC Liquid is a weakly cationic wax dispersion used to improve the sliding properties of yarns of all types of fibers. The wax reduces the yarn-to-metal friction (Archroma n.d, Reinach, Switzerland).

- Soap: potassium carbonate, sodium sulfate, and water (Grumme, Orkla care, Stockholm, Sweden).

2.2. Finishing Application Method

2.3. Coefficient of Metal/Yarn Friction Test

2.4. Tensile Testing

2.5. Knitting Evaluation

2.6. Microscopy

3. Results

3.1. Yarn Coating

3.2. Coefficient of Metal Yarn Friction

3.3. Tensile Testing

3.4. Knitting Evaluation

3.5. Microscopy

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aldalbahi, A.; El-Naggar, M.E.; El-Newehy, M.H.; Rahaman, M.; Hatshan, M.R.; Khattab, T.A. Effects of technical textiles and synthetic nanofibers on environmental pollution. Polymers 2021, 13, 155. [Google Scholar] [CrossRef]

- Ferrándiz, M.; Fages, E.; Rojas-Lema, S.; Ivorra-Martinez, J.; Gomez-Caturla, J.; Torres-Giner, S. Development and characterization of weft-knitted fabrics of naturally occurring polymer fibers for sustainable and functional textiles. Polymers 2021, 13, 665. [Google Scholar] [CrossRef] [PubMed]

- Karthik, T.; Gopalakrishnan, D. Environmental Analysis of Textile Value Chain: An Overview; Springer: Singapore, 2014; pp. 153–188. [Google Scholar]

- Laitala, K.; Klepp, I.G.; Henry, B. Does use matter? Comparison of environmental impacts of clothing based on fiber type. Sustainability 2018, 10, 2524. [Google Scholar] [CrossRef] [Green Version]

- Lakshmanan, S.O.; Raghavendran, G. Regenerated Sustainable Fibres; Springer: Singapore, 2018; pp. 31–52. [Google Scholar]

- Lee, K.E. Environmental Sustainability in the Textile Industry; Springer: Singapore, 2017; pp. 17–55. [Google Scholar]

- Luján-Ornelas, C.; Güereca, L.; Franco-García, M.-L.; Heldeweg, M. A Life Cycle Thinking Approach to Analyse Sustainability in the Textile Industry: A Literature Review. Sustainability 2020, 12, 10193. [Google Scholar] [CrossRef]

- Nadi, A.; Boukhriss, A.; Bentis, A.; Jabrane, E.; Gmouh, S. Evolution in the surface modification of textiles: A review. Text. Prog. 2018, 50, 67–108. [Google Scholar] [CrossRef]

- Patti, A.; Cicala, G.; Acierno, D. Eco-sustainability of the Textile Production: Waste Recovery and Current Recycling in the Composites World. Polymers 2020, 13, 134. [Google Scholar] [CrossRef]

- TextileExchange. Preferred Fiber & Materials in Market Report; TextileExchange: Lamesa, TX, USA, 2020. [Google Scholar]

- Park, T.Y.; Lee, S.G. A study on coarse Hanji yarn manufacturing and properties of the Hanji fabric. Fibers Polym. 2013, 14, 311–315. [Google Scholar] [CrossRef]

- Sahlstrand, M.; Koplos, J. Paper Clothing, East and West. Fiberarts Mag. 1984, 11, 36–42. [Google Scholar]

- Murate, H.; Terasaki, F.; Shigematsu, M.; Tanahashi, M. Improvement in the Stretching Property of Paper Yarn by Shape Memorization Produced with High-pressure Steam Treatment. Sen’i Gakkaishi 2008, 64, 74–78. [Google Scholar] [CrossRef]

- Peterson, J.; Eckard, A.; Hjelm, J.; Morikawa, H. Mechanical-Property-Based Comparison of Paper Yarn with Cotton, Viscose, and Polyester Yarns. J. Nat. Fibers 2019, 18, 492–501. [Google Scholar] [CrossRef] [Green Version]

- Rundberg, S.; Persson, L. Pappersgarn i Mode. Bachelor’s Thesis, University of Borås, Borås, Sweden, 2016. [Google Scholar]

- Amini, A.; Zohoori, S.; Mirjalili, A.; Karimi, L.; Davodiroknabadi, A. Improvement in physical properties of paper fabric using multi-wall carbon nanotubes. J. Nanostruct. Chem. 2014, 4, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Park, T.; Kim, M.-O. Manufacture and physical properties of the denim fabrics using Hanji paper yarn as weft yarn. Fash. Text. 2018, 5, 1–13. [Google Scholar] [CrossRef]

- Vasell, A.; Ronkainen, J. Mekanisk Mjukgöring av Pappersgarn: En Studie om Smärgling av Pappersgarn Samt Behandlingens Påverkan på de Taktila Egenskaperna. Bachelor’s Thesis, University of Borås, Borås, Sweden, 2017. [Google Scholar]

- Chummun, J.; Rosunee, S. Manufacture of Folded and Twisted Paper Yarn. Res. J. Text. Appar. 2012, 16, 93–99. [Google Scholar] [CrossRef]

- Pan, N. Development of a Constitutive Theory for Short Fiber Yarns: Mechanics of Staple Yarn without Slippage Effect. Text. Res. J. 1992, 62, 749–765. [Google Scholar] [CrossRef]

- Pan, N. Development of a Constitutive Theory for Short Fiber Yarns Part II: Mechanics of Staple Yarn with Slippage Effect. Text. Res. J. 1993, 63, 504–514. [Google Scholar] [CrossRef]

- Ek, M.; Gellerstedt, G.; Henriksson, G. Volume 1: Wood Chemistry and Wood Biotechnology. In Pulp and Paper Chemistry and Technology; Walter de Gruyter: Berlin, Germany, 2009. [Google Scholar]

- Ek, M.; Gellerstedt, G.; Henriksson, G. Volume 2: Pulping Chemistry and Technology. In Pulp and Paper Chemistry and Technology; Walter de Gruyter: Berlin, Germany, 2009. [Google Scholar]

- Shahinur, S.; Ullah, A.S. Quantifying the Uncertainty Associated with the Material Properties of a Natural Fiber. Procedia CIRP 2017, 61, 541–546. [Google Scholar] [CrossRef]

- Ashadujjaman, M.; Saifullah, A.; Shah, D.U.; Zhang, M.; Akonda, M.; Karim, N.; Sarker, F. Enhancing the mechanical properties of natural jute yarn suitable for structural applications. Mater. Res. Express 2021, 8, 55503. [Google Scholar] [CrossRef]

- Gurarda, A.; Yukseltan, E.; Kaplangiray, B.M.; Kanik, M. The effects of various lubricants on the friction properties of sewing threads. Text. Res. J. 2013, 83, 1273–1282. [Google Scholar] [CrossRef]

- Jawale, S.N.P.; Patil, U.J. A Review on Yarn Friction—Importance, Theory, Factors & Measurement; Textile Review; IPFonline Limited: Chennai, India, 2011. [Google Scholar]

- Çukul, D.; Candan, C.; Turan, S. Utilizing scanning electron. Microscopy stereoscopy to explain the wear behavior of latch needles. Text. Res. J. 2010, 80, 25–34. [Google Scholar]

- Eryuruk, S.H.; Kalaoglu, F. The effects of different amounts of lubricant application on the sewing thread performance properties. Text. Res. J. 2010, 80, 1232–1242. [Google Scholar] [CrossRef]

- Senthil, N.; Dhurai, B. Knittability Enhancement Study of 100% Linen yarn using Softeners. J. Nat. Fibers 2021, 1–10. [Google Scholar] [CrossRef]

- Mengüç, G.S.; Özgüney, A.T.; Dalbaşi, E.S.; Özdil, N. A comparative study on handle properties of bamboo and cotton fabrics. Ind. Text. 2019, 70, 278–284. [Google Scholar] [CrossRef]

- Shablygin, M.V.; Petrova, M.V.; Sklyarova, G.B.; Kashirina, M.A. Nature of Interaction of Lubricating Composites with Para-Aramid Yarns. Fibre Chem. 2014, 45, 376–380. [Google Scholar] [CrossRef]

- Koo, Y.S. Waxing Effect on Lint Contamination in the Knitting Process. Text. Res. J. 2008, 78, 168–173. [Google Scholar] [CrossRef]

- Ferrero, F.; Periolatto, M. Glycerol in comparison with ethanol in alcohol-assisted dyeing. J. Clean. Prod. 2012, 33, 127–131. [Google Scholar] [CrossRef]

- The Soap and Detergent Association. Glycerine: An Overview; The Soap and Detergent Association (SDA), Glycerine & Oleochemical Division: New York, NY, USA, 1990. [Google Scholar]

- Gu, Y.; Jérôme, F. Glycerol as a sustainable solvent for green chemistry. Green Chem. Int. J. Green Chem. Resour. GC 2010, 12, 1127–1138. [Google Scholar] [CrossRef]

- Alvarez, M.G.; Segarra, A.M.; Contreras, S.; Sueiras, J.E.; Medina, F.; Figueras, F. Enhanced use of renewable resources: Transesterification of glycerol catalyzed by hydrotalcite-like compounds. Chem. Eng. J. 2010, 161, 340–345. [Google Scholar] [CrossRef]

- Behr, A.; Eilting, J.; Irawadi, K.; Leschinski, J.; Lindner, F. Improved utilisation of renewable resources: New important derivatives of glycerol. Green Chem. 2007, 10, 13–30. [Google Scholar] [CrossRef]

- Wolfson, A.; Dlugy, C.; Shotland, Y. Glycerol as a green solvent for high product yields and selectivities. Environ. Chem. Lett. 2006, 5, 67–71. [Google Scholar] [CrossRef] [Green Version]

- Aloui, H.; Khwaldia, K.; Ben Slama, M.; Hamdi, M. Effect of glycerol and coating weight on functional properties of biopolymer-coated paper. Carbohydr. Polym. 2011, 86, 1063–1072. [Google Scholar] [CrossRef]

- Mondal, S.; Reddy, V.; Sarkar, A.; Aravindakshan, P.; Ghatak, A. Effect of surface modification on frictional properties of polyester fabric. Tribol. Int. 2016, 97, 38–48. [Google Scholar] [CrossRef]

- Wei, Y.; Zheng, C.; Chen, P.; Yu, Q.J.; Mao, T.; Lin, J.; Liu, L. Synthesis of multiblock linear polyether functional amino silicone softener and its modification of surface properties on cotton fabrics. Polym. Bull. 2018, 76, 447–467. [Google Scholar] [CrossRef]

- Zia, K.M.; Tabassum, S.; Barkaat-Ul-Hasin, S.; Zuber, M.; Jamil, T.; Jamal, M.A. Preparation of rich handles soft cellulosic fabric using amino silicone based softener. Part-I: Surface smoothness and softness properties. Int. J. Biol. Macromol. 2011, 48, 482–487. [Google Scholar] [CrossRef]

- Xu, Y.; Yin, H.; Zheng, H.; Yuan, S.; Chen, Z. Application performance and surface morphologies of amino polysiloxanes with different amino values and amino types. J. Appl. Polym. Sci. 2010, 119, 2326–2333. [Google Scholar] [CrossRef]

- Abolhasani, M.M.; Jalaei, A.; Tavana, R.; Kashani, F.Z. Processing and performance properties of amino silicone-based softener on various textile substrates. Polym. Bull. 2019, 77, 2557–2572. [Google Scholar] [CrossRef]

- Peterson, J.; Vegborn, E. Development of a pre-knitting friction test method and study of friction and bending of yarns with high stiffness. In Magisteruppsats; University of Borås/Swedish School of Textiles: Borås, Sweden, 2009. [Google Scholar]

- ASTM. D3108/D3108M Standard Test Method for Coefficient of Friction, Yarn to Solid Material; ASTM International: West Consohohocken, PA, USA, 2020. [Google Scholar]

- ISO 2062:2009 Textiles—Yarns from Packages—Determination of Single-End Breaking Force and Elongation at Break Using a Constant Rate of Extension (CRE) Tester; International Organization for Standardization: Geneva, Switzerland, 2009.

| Finishing Material | Δ-Tenacity [%] | Δ-Strength [%] | Δ-Elongation [%] |

|---|---|---|---|

| Reference | 0 | 0 | 0 |

| Wax | 4.78 | 4.82 | −31.03 |

| Soap | −11.18 | −11.12 | −21.83 |

| 102 | −9.04 | −8.98 | 5.74 |

| Glycerol | −36.85 | −36.86 | 0 |

| Tubingal RGH | −31.62 | −31.63 | −26.43 |

| Ultratex UHS | −23.14 | −23.19 | −11.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syrén, F.; Andersson Drugge, G.; Peterson, J.; Kadi, N. Enhanced Knittability of Paper Yarn from the Swedish Forest by Using Textile Finishing Materials. Polymers 2021, 13, 3628. https://doi.org/10.3390/polym13213628

Syrén F, Andersson Drugge G, Peterson J, Kadi N. Enhanced Knittability of Paper Yarn from the Swedish Forest by Using Textile Finishing Materials. Polymers. 2021; 13(21):3628. https://doi.org/10.3390/polym13213628

Chicago/Turabian StyleSyrén, Felicia, Gabriella Andersson Drugge, Joel Peterson, and Nawar Kadi. 2021. "Enhanced Knittability of Paper Yarn from the Swedish Forest by Using Textile Finishing Materials" Polymers 13, no. 21: 3628. https://doi.org/10.3390/polym13213628

APA StyleSyrén, F., Andersson Drugge, G., Peterson, J., & Kadi, N. (2021). Enhanced Knittability of Paper Yarn from the Swedish Forest by Using Textile Finishing Materials. Polymers, 13(21), 3628. https://doi.org/10.3390/polym13213628