Thermoplastic Starch–Based Composite Reinforced by Conductive Filler Networks: Physical Properties and Electrical Conductivity Changes during Cyclic Deformation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of TPS–CB Composites

2.3. Mechanical Testing

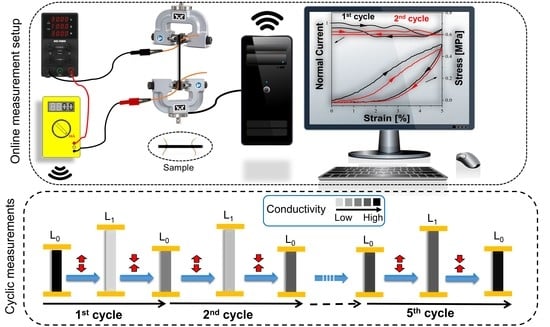

2.4. Online Measurements of Conductivity during Mechanical Deformation

2.5. Dynamic Mechanical Thermal Analysis (DMTA)

2.6. Electrical Conductivity

2.7. Rheological Measurements

3. Results and Discussion

3.1. Electrical Conductivity

3.2. Mechanical Properties

3.3. Dynamic Mechanical Thermal Analysis (DMTA)

3.4. Rheological Measurements

3.5. Conductivity during Uniaxial Deformation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Chen, Z.; Brokken-Zijp, J.C.; Michels, M. Novel phthalocyanine crystals as a conductive filler in crosslinked epoxy materials: Fractal particle networks and low percolation thresholds. J. Polym. Sci. B Polym. Phys. 2006, 44, 33–47. [Google Scholar] [CrossRef]

- Omastova, M.; Chodak, I.; Pionteck, J. Electrical and mechanical properties of conducting polymer composites. Synth. Met. 1999, 102, 1251–1252. [Google Scholar] [CrossRef]

- Youngs, I.J. Exploring the universal nature of electrical percolation exponents by genetic algorithm fitting with general effective medium theory. J. Phys. D Appl. Phys. 2002, 35, 3127. [Google Scholar] [CrossRef]

- Liu, S.; Li, X.; Chen, L.; Li, L.; Li, B.; Zhu, J. Understanding physicochemical properties changes from multi-scale structures of starch/CNT nanocomposite films. Int. J. Biol. Macromol. 2017, 104, 1330–1337. [Google Scholar] [CrossRef] [PubMed]

- Mallakpour, S.; Rashidimoghadam, S. Application of ultrasonic irradiation as a benign method for production of glycerol plasticized-starch/ascorbic acid functionalized MWCNTs nanocomposites: Investigation of methylene blue adsorption and electrical properties. Ultrason. Sonochem. 2018, 40, 419–432. [Google Scholar] [CrossRef] [PubMed]

- Shahbazi, M.; Rajabzadeh, G.; Sotoodeh, S. Functional characteristics, wettability properties and cytotoxic effect of starch film incorporated with multi-walled and hydroxylated multi-walled carbon nanotubes. Int. J. Biol. Macromol. 2017, 104, 597–605. [Google Scholar] [CrossRef] [PubMed]

- Mallakpour, S.; Nezamzadeh Ezhieh, A. Preparation and characterization of starch nanocomposite embedded with functionalized MWCNT: Investigation of optical, morphological, thermal, and copper ions adsorption properties. Adv. Polym. Technol. 2018, 37, 2195–2203. [Google Scholar] [CrossRef]

- Mallakpour, S. Fructose functionalized MWCNT as a filler for starch nanocomposites: Fabrication and characterizations. Prog. Org. Coat. 2018, 114, 244–249. [Google Scholar] [CrossRef]

- Drakopoulos, S.X.; Karger-Kocsis, J.; Psarras, G.C. The effect of micro-fibrillated cellulose upon the dielectric relaxations and DC conductivity in thermoplastic starch bio-composites. J. Appl. Polym. Sci. 2020, 137, 49573. [Google Scholar] [CrossRef]

- Ferreira, W.H.; Dahmouche, K.; Andrade, C.T. Tuning the mechanical and electrical conductivity properties of graphene-based thermoplastic starch/poly(lactic acid) hybrids. Polym. Compos. 2019, 40, E1131–E1142. [Google Scholar] [CrossRef]

- González, K.; García-Astrain, C.; Santamaria-Echart, A.; Ugarte, L.; Avérous, L.; Eceiza, A.; Gabilondo, N. Starch/graphene hydrogels via click chemistry with relevant electrical and antibacterial properties. Carbohydr. Polym. 2018, 202, 372–381. [Google Scholar] [CrossRef]

- Alvarez-Ramirez, J.; Vazquez-Arenas, J.; García-Hernández, A.; Vernon-Carter, E. Improving the mechanical performance of green starch/glycerol/Li+ conductive films through cross-linking with Ca2+. Solid State Ion. 2019, 332, 1–9. [Google Scholar] [CrossRef]

- Huang, Y.; Kormakov, S.; He, X.; Gao, X.; Zheng, X.; Liu, Y.; Sun, J.; Wu, D. Conductive polymer composites from renewable resources: An overview of preparation, properties, and applications. Polymers 2019, 11, 187. [Google Scholar] [CrossRef] [Green Version]

- Nejati, S.; Soflou, R.K.; Khorshidi, S.; Karkhaneh, A. Development of an oxygen-releasing electroconductive in-situ crosslinkable hydrogel based on oxidized pectin and grafted gelatin for tissue engineering applications. Colloids Surf. B-Biointerfaces 2020, 196, 111347. [Google Scholar] [CrossRef]

- Barra, A.; Ferreira, N.M.; Martins, M.A.; Lazar, O.; Pantazi, A.; Jderu, A.A.; Neumayer, S.M.; Rodriguez, B.J.; Enăchescu, M.; Ferreira, P. Eco-friendly preparation of electrically conductive chitosan-reduced graphene oxide flexible bionanocomposites for food packaging and biological applications. Compos. Sci. Technol. 2019, 173, 53–60. [Google Scholar] [CrossRef]

- Peidayesh, H.; Ahmadi, Z.; Khonakdar, H.A.; Abdouss, M.; Chodák, I. Fabrication and properties of thermoplastic starch/Montmorillonite composite using dialdehyde starch as a crosslinker. Polym. Int. 2020, 69, 317–327. [Google Scholar] [CrossRef]

- Peidayesh, H.; Ahmadi, Z.; Khonakdar, H.A.; Abdouss, M.; Chodák, I. Baked hydrogel from corn starch and chitosan blends cross-linked by citric acid: Preparation and properties. Polym. Adv. Technol. 2020, 31, 1256–1269. [Google Scholar] [CrossRef]

- Peidayesh, H.; Heydari, A.; Mosnáčková, K.; Chodák, I. In situ dual crosslinking strategy to improve the physico-chemical properties of thermoplastic starch. Carbohydr. Polym. 2021, 269, 118250. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, K.; Iturriaga, L.; Gonzalez, A.; Eceiza, A.; Gabilondo, N. Improving mechanical and barrier properties of thermoplastic starch and polysaccharide nanocrystals nanocomposites. Eur. Polym. J. 2020, 123, 109415. [Google Scholar] [CrossRef]

- Ivanič, F.; Jochec-Mošková, D.; Janigová, I.; Chodák, I. Physical properties of starch plasticized by a mixture of plasticizers. Eur. Polym. J. 2017, 93, 843–849. [Google Scholar] [CrossRef]

- Šmídová, N.; Šoltýs, A.; Hronský, V.; Olčák, D.; Popovič, Ľ.; Chodák, I. Aging-induced structural relaxation in cornstarch plasticized with urea and glycerol. J. Appl. Polym. Sci. 2021, 138, 50218. [Google Scholar] [CrossRef]

- Ma, X.; Yu, J.; Wang, N. Glycerol plasticized-starch/multiwall carbon nanotube composites for electroactive polymers. Compos. Sci. Technol. 2008, 68, 268–273. [Google Scholar] [CrossRef]

- Ma, X.; Chang, P.R.; Yu, J.; Lu, P. Characterizations of glycerol plasticized-starch (GPS)/carbon black (CB) membranes prepared by melt extrusion and microwave radiation. Carbohydr. Polym. 2008, 74, 895–900. [Google Scholar] [CrossRef]

- Qian, D.; Chang, P.R.; Zheng, P.; Ma, X. Preparation and characterization of plasticized starch/carbon black-oxide nanocomposites. Ind. Eng. Chem. Res. 2012, 51, 7941–7947. [Google Scholar] [CrossRef]

- Domene-López, D.; Delgado-Marín, J.J.; García-Quesada, J.C.; Martin-Gullon, I.; Montalbán, M.G. Electroconductive starch/multi-walled carbon nanotube films plasticized by 1-ethyl-3-methylimidazolium acetate. Carbohydr. Polym. 2020, 229, 115545. [Google Scholar] [CrossRef]

- Zhang, B.; Xie, F.; Shamshina, J.L.; Rogers, R.D.; McNally, T.; Wang, D.K.; Halley, P.J.; Truss, R.W.; Zhao, S.; Chen, L. Facile preparation of starch-based electroconductive films with ionic liquid. ACS Sustain. Chem. Eng. 2017, 5, 5457–5467. [Google Scholar] [CrossRef] [Green Version]

- Gürler, N.; Torğut, G. Graphene-reinforced potato starch composite films: Improvement of mechanical, barrier and electrical properties. Polym. Compos. 2021, 42, 173–180. [Google Scholar] [CrossRef]

- Zheng, P.; Ma, T.; Ma, X. Fabrication and properties of starch-grafted graphene nanosheet/plasticized-starch composites. Ind. Eng. Chem. Res. 2013, 52, 14201–14207. [Google Scholar] [CrossRef]

- Ma, T.; Chang, P.R.; Zheng, P.; Ma, X. The composites based on plasticized starch and graphene oxide/reduced graphene oxide. Carbohydr. Polym. 2013, 94, 63–70. [Google Scholar] [CrossRef]

- Aneli, J.; Zaikov, G.; Khananashvili, L. Effects of mechanical deformations on the structurization and electric conductivity of electric conducting polymer composites. J. Appl. Polym. Sci. 1999, 74, 601–621. [Google Scholar] [CrossRef]

- Flandin, L.; Hiltner, A.; Baer, E. Interrelationships between electrical and mechanical properties of a carbon black-filled ethylene–octene elastomer. Polymer 2001, 42, 827–838. [Google Scholar] [CrossRef]

- Podhradská, S.; Prokeš, J.; Omastová, M.; Chodák, I. Stability of electrical properties of carbon black-filled rubbers. J. Appl. Polym. Sci. 2009, 112, 2918–2924. [Google Scholar] [CrossRef]

- Chodák, I.; Podhradská, S.; Podhradská, J.J.; Jurčiová, J. Changes in electrical conductivity during mechanical deformation of carbon black filled elastomeric matrix. Open Macromol. J. 2010, 4, 32–36. [Google Scholar]

- Krajči, J.; Špitálský, Z.; Chodák, I. Relationship between conductivity and stress–strain curve of electroconductive composite with SBR or polycaprolactone matrices. Eur. Polym. J. 2014, 55, 135–143. [Google Scholar] [CrossRef]

- Barrau, S.; Demont, P.; Peigney, A.; Laurent, C.; Lacabanne, C. DC and AC conductivity of carbon nanotubes-polyepoxy composites. Macromolecules 2003, 36, 5187–5194. [Google Scholar] [CrossRef] [Green Version]

- Toro-Márquez, L.A.; Merino, D.; Gutiérrez, T.J. Bionanocomposite films prepared from corn starch with and without nanopackaged Jamaica (Hibiscus sabdariffa) flower extract. Food Bioprocess Technol. 2018, 11, 1955–1973. [Google Scholar] [CrossRef] [Green Version]

- Schmitt, H.; Guidez, A.; Prashantha, K.; Soulestin, J.; Lacrampe, M.; Krawczak, P. Studies on the effect of storage time and plasticizers on the structural variations in thermoplastic starch. Carbohydr. Polym. 2015, 115, 364–372. [Google Scholar] [CrossRef]

- Qiao, X.; Jiang, W.; Sun, K. Reinforced thermoplastic acetylated starch with layered silicates. Starch/Stärke 2005, 57, 581–586. [Google Scholar] [CrossRef]

- Coativy, G.; Chevigny, C.; Rolland-Sabaté, A.; Leroy, E.; Lourdin, D. Interphase vs confinement in starch-clay bionanocomposites. Carbohydr. Polym. 2015, 117, 746–752. [Google Scholar] [CrossRef]

- Averous, L.; Moro, L.; Dole, P.; Fringant, C. Properties of thermoplastic blends: Starch–polycaprolactone. Polymer 2000, 41, 4157–4167. [Google Scholar] [CrossRef]

- Fričová, O.; Hutníková, M.; Peidayesh, H. DMA study of thermoplastic starch/montmorillonite nanocomposites. AIP Conf. Proc. 2021, 2411, 050004. [Google Scholar]

- Cui, L.; Tarte, N.H.; Woo, S.I. Synthesis and characterization of PMMA/MWNT nanocomposites prepared by in situ polymerization with Ni (acac) 2 catalyst. Macromolecules 2009, 42, 8649–8654. [Google Scholar] [CrossRef]

- Kasgoz, A.; Akın, D.; Durmus, A. Rheological and electrical properties of carbon black and carbon fiber filled cyclic olefin copolymer composites. Compos. B. Eng. 2014, 62, 113–120. [Google Scholar] [CrossRef]

- Stloukal, P.; Verney, V.; Commereuc, S.; Rychly, J.; Matisova-Rychlá, L.; Pis, V.; Koutny, M. Assessment of the interrelation between photooxidation and biodegradation of selected polyesters after artificial weathering. Chemosphere 2012, 88, 1214–1219. [Google Scholar] [CrossRef] [PubMed]

- Kotsilkova, R. Processing–structure–properties relationships of mechanically and thermally enhanced smectite/epoxy nanocomposites. J. Appl. Polym. Sci. 2005, 97, 2499–2510. [Google Scholar] [CrossRef]

- Kotsilkova, R.; Fragiadakis, D.; Pissis, P. Reinforcement effect of carbon nanofillers in an epoxy resin system: Rheology, molecular dynamics, and mechanical studies. J. Polym. Sci. B Polym. Phys. 2005, 43, 522–533. [Google Scholar] [CrossRef]

- Zhu, J.; Wei, S.; Yadav, A.; Guo, Z. Rheological behaviors and electrical conductivity of epoxy resin nanocomposites suspended with in-situ stabilized carbon nanofibers. Polymer 2010, 51, 2643–2651. [Google Scholar] [CrossRef]

- Swilem, A.E.; Stloukal, P.; Abd El-Rehim, H.A.; Hrabalíková, M.; Sedlařík, V. Influence of gamma rays on the physico-chemical, release and antibacterial characteristics of low-density polyethylene composite films incorporating an essential oil for application in food-packaging. Food Packag. Shelf Life 2019, 19, 131–139. [Google Scholar] [CrossRef]

- Mošková, D.J.; Janigová, I.; Nógellová, Z.; Sedničková, M.; Jankovič, L.; Komadel, P.; Šlouf, M.; Chodák, I. Prediction of compatibility of organomodified clay with various polymers using rheological measurements. Polym. Test. 2018, 69, 359–365. [Google Scholar] [CrossRef]

- Walha, F.; Lamnawar, K.; Maazouz, A.; Jaziri, M. Rheological, morphological and mechanical studies of sustainably sourced polymer blends based on poly (lactic acid) and polyamide 11. Polymers 2016, 8, 61. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Podhradska, S.; Omastova, M.; Chodak, I. Effect of uniaxial Deformation and Relaxation of Rubber/Carbon black Composites on their electrical Properties. KGK Kautschuk Gummi Kunststoffe 2015, 68, 45–51. [Google Scholar]

- Chodák, I.; Krajči, J. Structure of reinforced filler network determined by electrical conductivity of the polymer/carbon black composite. In Proceedings of the International Conference on Advances in Composite Materials and Structures, Istanbul, Turkey, 13–15 April 2015. [Google Scholar]

- Voet, A.; Cook, F.R. Investigation of carbon chains in rubber vulcanizates by means of dynamic electrical conductivity. Rubber Chem. Technol. 1968, 41, 1207–1214. [Google Scholar] [CrossRef]

- Yan, J.; Wu, T.; Ding, Z.; Li, X. Preparation and characterization of carbon nanotubes/chitosan composite foam with enhanced elastic property. Carbohydr. Polym. 2016, 136, 1288–1296. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Dai, K.; Zhai, Y.; Liu, H.; Zhan, P.; Gao, J.; Zheng, G.; Liu, C.; Shen, C. Flexible and lightweight pressure sensor based on carbon nanotube/thermoplastic polyurethane-aligned conductive foam with superior compressibility and stability. ACS Appl. Mater. Interfaces 2017, 9, 42266–42277. [Google Scholar] [CrossRef] [PubMed]

| Property | Amount |

|---|---|

| Iodine adsorption | 900−1200 mg/g |

| DBF adsorption | 340−420 mL/100g |

| Specific area | 800 m2/g |

| Particle diameter | 2−20 nm |

| Sample Code | CB Content (wt%) | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) |

|---|---|---|---|---|

| CB–0 | 0 | 0.30 ± 0.02 | 193.55 ± 25.21 | 0.81 ± 0.19 |

| CB–3 | 1.7 | 0.56 ± 0.01 | 130.23 ± 13.51 | 2.26 ± 0.17 |

| CB–10 | 5.5 | 1.12 ± 0.06 | 94.05 ± 5.88 | 5.60 ± 0.50 |

| CB–15 | 8.1 | 1.81 ± 0.26 | 51.76 ± 17.84 | 16.24 ± 2.97 |

| CB–20 | 10.5 | 3.18 ± 0.16 | 29.88 ± 8.12 | 32.77 ± 4.51 |

| Sample Code | 1st Peak T (°C) | 2nd Peak T (°C) |

|---|---|---|

| CB–0 | −56.1 | 3.3 |

| CB–3 | −55.5 | 9.9 |

| CB–10 | −53.2 | 12.8 |

| CB–15 | −54.2 | 3.2 |

| CB–20 | −48.8 | 9.3 |

| Sample Code | Starting Point of | Current (μA) | |||

|---|---|---|---|---|---|

| 2% Strain | 5% Strain | 10% Strain | 20% Strain | ||

| CB–15 | Cyclic deformation | 1.18 | 1.05 | 1.29 | 1.34 |

| Up–to–break | 1.23 | 1.14 | 1.83 | 1.79 | |

| CB–20 | Cyclic deformation | 2.44 | 2.68 | 2.45 | 3.64 |

| Up–to–break | 2.54 | 2.76 | 2.94 | 3.67 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peidayesh, H.; Mosnáčková, K.; Špitalský, Z.; Heydari, A.; Šišková, A.O.; Chodák, I. Thermoplastic Starch–Based Composite Reinforced by Conductive Filler Networks: Physical Properties and Electrical Conductivity Changes during Cyclic Deformation. Polymers 2021, 13, 3819. https://doi.org/10.3390/polym13213819

Peidayesh H, Mosnáčková K, Špitalský Z, Heydari A, Šišková AO, Chodák I. Thermoplastic Starch–Based Composite Reinforced by Conductive Filler Networks: Physical Properties and Electrical Conductivity Changes during Cyclic Deformation. Polymers. 2021; 13(21):3819. https://doi.org/10.3390/polym13213819

Chicago/Turabian StylePeidayesh, Hamed, Katarína Mosnáčková, Zdenko Špitalský, Abolfazl Heydari, Alena Opálková Šišková, and Ivan Chodák. 2021. "Thermoplastic Starch–Based Composite Reinforced by Conductive Filler Networks: Physical Properties and Electrical Conductivity Changes during Cyclic Deformation" Polymers 13, no. 21: 3819. https://doi.org/10.3390/polym13213819

APA StylePeidayesh, H., Mosnáčková, K., Špitalský, Z., Heydari, A., Šišková, A. O., & Chodák, I. (2021). Thermoplastic Starch–Based Composite Reinforced by Conductive Filler Networks: Physical Properties and Electrical Conductivity Changes during Cyclic Deformation. Polymers, 13(21), 3819. https://doi.org/10.3390/polym13213819