Physical Properties of Thermally Crosslinked Fluorinated Polyimide and Its Application to a Liquid Crystal Alignment Layer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Neat 6FDA−ODA PI and Its Crosslinked PI Films

2.3. Instrumentation

2.4. Characterization of AL

2.5. Fabrication and Characterization of LC Cell

3. Results and Discussion

3.1. Preparation and Characterization of PI Films

3.2. Thermal Properties of Neat PI and Crosslinked PI

3.3. Solvent Resistance of Neat 6FDA−ODA PI and Crosslinked PI

3.4. Mechanical Properties of Neat PI and Crosslinked PI Free-Standing Thick Films

3.5. Dielectric Properties of Neat PI and Crosslinked PI Free-Standing Thick Films

3.6. Surface Morphologies of Neat PI and Crosslinked PI Films: Effect of Mechanical Rubbing

3.7. Rubbing Effects on Anisotropy of Neat PI and Crosslinked PI AL

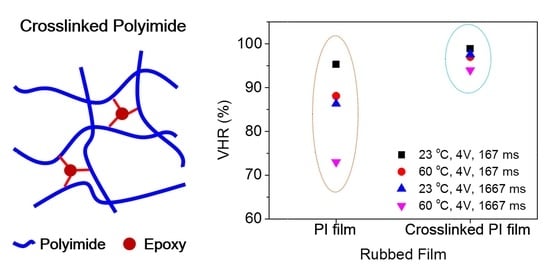

3.8. Properties of LC Cell: VHR and RDC

3.9. Chemical Stability of Neat PI and Crosslinked PI Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Murata, M.; Awaji, H.; Isurugi, M.; Uekita, M.; Tawada, Y. Alignment of nematic liquid crystals by polyimide Langmuir–Blodgett films. Jpn. J. Appl. Phys. 1992, 31, L189–L192. [Google Scholar] [CrossRef]

- Paek, S.-H. Comparative study of effects of rubbing parameters on polyimide alignment layers and liquid crystal alignment. J. Ind. Eng. Chem. 2001, 7, 316–325. [Google Scholar]

- Tong, F.; Chen, S.; Chen, Z.; Lu, X.; Lu, Q. Mesogen-co-polymerized transparent polyimide as a liquid-crystal alignment layer with enhanced anchoring energy. RSC Adv. 2018, 8, 11119–11126. [Google Scholar] [CrossRef] [Green Version]

- Van Aerle, N.A.J.M.; Tol, A.J.W. Molecular orientation in rubbed polyimide alignment layers used for liquid-crystal displays. Macromolecules 1994, 27, 6520–6526. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Wang, K.-L.; Huang, Y.-C.; Lee, K.-R.; Lai, J.-Y.; Ha, C.-S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2021, 37, 907–974. [Google Scholar] [CrossRef]

- Lee, T.R.; Kim, J.H.; Lee, S.H.; Jun, M.C.; Baik, H.K. Investigation on newly designed low resistivity polyimide-type alignment layer for reducing DC image sticking of in-plane switching liquid crystal display. Liq. Cryst. 2017, 44, 738–747. [Google Scholar] [CrossRef]

- Bi, H.-S.; Zhi, X.-X.; Wu, P.-H.; Zhang, Y.; Wu, L.; Tan, Y.-Y.; Jia, Y.-J.; Liu, J.-G.; Zhang, X.-M. Preparation and characterization of semi-alicyclic polyimide resins and the derived alignment layers for liquid crystal display technology. Polymers 2020, 12, 217. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, W.; Paek, S.-H. Chemical structural effects of polyimides on the alignment and electro-optical properties of liquid crystal cells. Macromol. Res. 2004, 12, 251–257. [Google Scholar] [CrossRef]

- Perlmutter, S.H.; Doroski, D.; Moddel, G. Degradation of liquid crystal device performance due to selective adsorption of ions. Appl. Phys. Lett. 1996, 69, 1182–1184. [Google Scholar] [CrossRef]

- Mizusaki, M.; Miyashita, T.; Uchida, T. Behavior of ion affecting image sticking on liquid crystal displays under application of direct current voltage. J. Appl. Phys. 2010, 108, 104903. [Google Scholar] [CrossRef]

- Xu, D.; Peng, F.; Chen, H.; Yuan, J.; Wu, S.-T.; Li, M.-C.; Lee, S.-L.; Tsai, W.-C. Image sticking in liquid crystal displays with lateral electric fields. J. Appl. Phys. 2014, 116, 193102. [Google Scholar] [CrossRef] [Green Version]

- Chung, I.S.; Kim, S.Y. Soluble polyimides from unsymmetrical diamine with trifluoromethyl pendent group. Macromolecules 2000, 33, 3190–3193. [Google Scholar] [CrossRef]

- Harris, F.W.; Lin, S.-H.; Li, F.; Cheng, S.Z.D. Organo-soluble polyimides: Synthesis and polymerization of 2,2′-disubstituted-4,4′,5,5′-biphenyltetracarboxylic dianhydrides. Polymer 1996, 37, 5049–5057. [Google Scholar] [CrossRef]

- Dhara, M.G.; Banerjee, S. Fluorinated high-performance polymers: Poly(arylene ether)s and aromatic polyimides containing trifluoromethyl groups. Prog. Polym. Sci. 2010, 35, 1022–1077. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Chang, F.-C.; Leung, M.-k.; Chou, M.-Y.; Muellen, K. High thermal stability and rigid rod of novel organosoluble polyimides and polyamides based on bulky and noncoplanar naphthalene−biphenyldiamine. Macromolecules 2005, 38, 4024–4029. [Google Scholar] [CrossRef]

- Tapaswi, P.K.; Choi, M.-C.; Jeong, K.-M.; Ando, S.; Ha, C.-S. Transparent aromatic polyimides derived from thiophenyl-substituted benzidines with high refractive index and small birefringence. Macromolecules 2015, 48, 3462–3474. [Google Scholar] [CrossRef]

- Husk, G.R.; Cassidy, P.E.; Gebert, K.L. Synthesis and characterization of a series of polyimides derived from 4,4′-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]bis [1,3-isobenzofurandione]. Macromolecules 1988, 21, 1234–1238. [Google Scholar] [CrossRef]

- Vanherck, K.; Koeckelberghs, G.; Vankelecom, I.F.J. Crosslinking polyimides for membrane applications: A review. Prog. Polym. Sci. 2013, 30, 874–896. [Google Scholar] [CrossRef]

- Gaw, K.; Kikei, M.; Kakimoto, M.; Imai, Y. Preparation of polyimide-epoxy composites. React. Funct. Polym. 1996, 30, 85–91. [Google Scholar] [CrossRef]

- Gaw, K.O.; Kakimoto, M. Polyimide-epoxy composites. In Advanced Polymer Science: Progress in Polyimide Chemistry I; Kricheldorf, H.R., Ed.; Springer: New York, NY, USA, 1999; Volume 140, pp. 107–136. [Google Scholar]

- Arafune, R.; Sakamoto, K.; Ushioda, S. Correlation between the pretilt angle of liquid crystal and the inclination angle of the polyimide backbone structure. Appl. Phys. Lett. 1997, 71, 2755–2757. [Google Scholar] [CrossRef]

- Van Aerle, N.A.J.M.; Barmentlo, M.; Hollering, R.W.J. Effect of rubbing on the molecular orientation within polyimide orienting layers of liquid-crystal displays. J. Appl. Phys. 1993, 74, 3111–3120. [Google Scholar] [CrossRef]

- Ree, M.; Kim, K.; Woo, S.H.; Chang, H. Structure, chain orientation, and properties in thin films of aromatic polyimides with various chain rigidities. J. Appl. Phys. 1997, 81, 698–708. [Google Scholar] [CrossRef]

- Kim, S.-U.; Lee, C.; Sundar, S.; Jang, W.B.; Yang, S.-J.; Han, H. Synthesis and characterization of soluble polyimides containing trifluoromethyl groups in their backbone. J. Polym. Sci. Polym. Phys. 2004, 42, 4303–4312. [Google Scholar] [CrossRef]

- Schadt, M. Liquid crystal materials and liquid crystal displays. Ann. Rev. Mater. Sci. 1997, 27, 305–379. [Google Scholar] [CrossRef] [Green Version]

- Mizusaki, M.; Yoshimura, Y.; Yamada, Y.; Okamoto, K. Analysis of ion behavior affecting voltage holding property of liquid crystal displays. Jpn. J. Appl. Phys. 2012, 51, 014102. [Google Scholar] [CrossRef]

- Zhi, X.-X.; Bi, H.-S.; Gao, Y.-S.; Liu, J.-G.; Chen, J.; Gao, K.-Y.; Zhang, X.-M. Preparation and characterization of novel preimidized semi-alicyclic polyimide alignment layers with low curing temperature and high voltage holding ratio for TFT-LCDs. Chem. Lett. 2019, 48, 654–657. [Google Scholar] [CrossRef]

- Mizusaki, M.; Miyashita, T.; Uchida, T.; Yamada, Y.; Ishii, Y.; Mizushima, S. Generation mechanism of residual direct current voltage in a liquid crystal display and its evaluation parameters related to liquid crystal and alignment layer materials. J. Appl. Phys. 2007, 102, 014904. [Google Scholar] [CrossRef]

- Mizusaki, M.; Miyashita, T.; Uchida, T. Kinetic analysis of image sticking with adsorption and desorption of ions to a surface of an alignment layer. J. Appl. Phys. 2012, 112, 044510. [Google Scholar] [CrossRef]

- Mizusaki, M.; Enomoto, S. Characteristics of voltage holding ratio and residual direct current voltage for polymer-sustained-alignment liquid crystal cells formed from mixed monomers containing biphenyl- and benzilketal-groups. Mol. Cryst. Liq. Cryst. 2020, 703, 13–22. [Google Scholar] [CrossRef]

- Choi, J.-C.; Lee, D.-J.; Park, M.-K.; Park, J.-S.; Lee, J.-H.; Baek, J.-H.; Choi, H.C.; Kim, H.-R. Highly enhanced voltage holding property for low-frequency-driven fringe-field switching liquid crystal mode by charge-trapping effect of carbon-nanotube-doped surface. Opt. Express 2019, 27, 29178–29195. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, J.-S.; Park, S.H.; Kwon, N.Y.; Cho, M.J.; Paek, S.-H.; Choi, D.H. Physical Properties of Thermally Crosslinked Fluorinated Polyimide and Its Application to a Liquid Crystal Alignment Layer. Polymers 2021, 13, 3903. https://doi.org/10.3390/polym13223903

Ahn J-S, Park SH, Kwon NY, Cho MJ, Paek S-H, Choi DH. Physical Properties of Thermally Crosslinked Fluorinated Polyimide and Its Application to a Liquid Crystal Alignment Layer. Polymers. 2021; 13(22):3903. https://doi.org/10.3390/polym13223903

Chicago/Turabian StyleAhn, Jong-Soo, Su Hong Park, Na Yeon Kwon, Min Ju Cho, Sang-Hyon Paek, and Dong Hoon Choi. 2021. "Physical Properties of Thermally Crosslinked Fluorinated Polyimide and Its Application to a Liquid Crystal Alignment Layer" Polymers 13, no. 22: 3903. https://doi.org/10.3390/polym13223903

APA StyleAhn, J. -S., Park, S. H., Kwon, N. Y., Cho, M. J., Paek, S. -H., & Choi, D. H. (2021). Physical Properties of Thermally Crosslinked Fluorinated Polyimide and Its Application to a Liquid Crystal Alignment Layer. Polymers, 13(22), 3903. https://doi.org/10.3390/polym13223903