Physicochemical Properties and Digestion Resistance of Acetylated Starch Obtained from Annealed Starch

Abstract

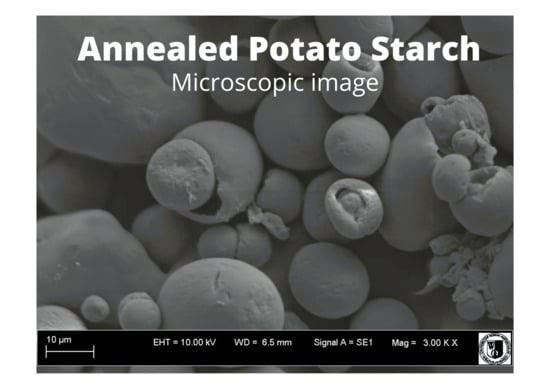

:1. Introduction

2. Materials and Methods

2.1. Annealing

2.2. Acetylation

2.3. Analytical Methods

2.3.1. Determination of the Acetylation Degree of Starch Preparations

- P0—volume of a standard HCl solution used to titrate 25 mL of a 0.5 M NaOH solution [mL].

- PW—volume of a standard HCl solution used to titrate the sample [mL].

- Nk—acid titer.

- MS—grams of starch dry matter in the sample.

2.3.2. Determination of the Swelling Power of Starch Preparations in Water at a Temperature of 20 °C

- MW—weight of the precipitate after centrifugation

- MP—weight of the sample.

2.3.3. Determination of the Resistance of Starch Preparations to the Action of Amyloglucosidase

- R—resistance of starch preparations to amyloglucosidase action (g/100 g).

- X—content of glucose read out from the standard curve (mg).

2.3.4. Determination of the Characteristics of Phase Transitions of the Starch Preparations Using Differential Scanning Calorimetry (DSC)

2.3.5. Determination of the Flow Curves of Pastes Made of Starch Preparations

- τ—shear stress (Pa)

- K—consistency coefficient (Pa·sn)

- ẏ—shear rate (s−1)

- n—flow index

- τ oc—yield point (Pa)

- ƞc—Casson’s plastic viscosity (Pa·(s))

2.4. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Ačkar, Đ.; Babić, J.; Jozinović, A.; Miličević, B.; Jokić, S.; Miličević, R.; Rajič, M.; Šubarić, D. Starch Modification by Organic Acids and Their Derivatives: A Review. Molecules 2015, 20, 19554–19570. [Google Scholar] [CrossRef] [Green Version]

- Hoover, R.; Hughes, T.; Chung, H.J.; Liu, Q. Composition, molecular structure, properties, and modification of pulse starches: A review. Food Res. Int. 2010, 43, 399–413. [Google Scholar] [CrossRef]

- van der Maarel, M.J.E.C.; Leemhuis, H. Starch modification with microbial alpha-glucanotransferase enzymes. Carbohydr. Polym. 2013, 93, 116–121. [Google Scholar] [CrossRef] [Green Version]

- Castanha, N.; Matta, M.D.J.; Augusto, P.E.D. Potato starch modification using the ozone technology. Food Hydrocoll. 2017, 66, 343–356. [Google Scholar] [CrossRef] [Green Version]

- Sweedman, M.C.; Tizzotti, M.J.; Schaefer, C.; Gilbert, R.G. Structure and physicochemical properties of octenyl succinic anhydride modified starches: A review. Carbohydr. Polym. 2013, 92, 905–920. [Google Scholar] [CrossRef]

- Devi, R.; Sit, N. Effect of single and dual steps annealing in combination with hydroxypropylation on physicochemical, functional and rheological properties of barley starch. Int. J. Biol. Macromol. 2019, 129, 1006–1014. [Google Scholar] [CrossRef]

- Hu, X.; Jia, X.; Zhi, C.; Jin, Z.; Miao, M. Improving properties of normal maize starch films using dual-modification: Combination treatment of debranching and hydroxypropylation. Int. J. Biol. Macromol. 2019, 130, 197–202. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Gui, Y.; Li, J.; Zhu, Y.; Cui, B.; Guo, L. Modification of rice starch using a combination of autoclaving and triple enzyme treatment: Structural, physicochemical and digestibility properties. Int. J. Biol. Macromol. 2020, 144, 500–508. [Google Scholar] [CrossRef] [PubMed]

- Tharanathan, R.N. Starch—Value Addition by Modification. Crit. Rev. Food Sci. 2005, 45, 371–384. [Google Scholar] [CrossRef]

- Yao, T.; Sui, Z.; Janaswamy, S. Annealing. In Physical Modifications of Starch; Sui, Z., Kong, X., Eds.; Springer: Singapore, 2018; pp. 37–49. [Google Scholar] [CrossRef]

- Rocha, T.S.; Felizardo, S.G.; Jane, J.-L.; Franco Celia, M.L. Effect of annealing on the semicrystalline structure of normal and waxy corn starches. Food Hydrocoll. 2012, 29, 93–99. [Google Scholar] [CrossRef]

- Din, Z.U.; Xiong, H.; Fei, P. Physical and Chemical Modification of Starches: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 2691–2705. [Google Scholar] [CrossRef]

- Piecyk, M.; Konarzewska, M.; Sitkiewicz, I. Effect of hydrothermal modification of annealing type on some selected properties of starch pea (Pisum sativum). Żywność. Nauka. Technol. Jakość. 2009, 5, 58–71. (In Polish) [Google Scholar]

- Vamadevan, V.; Bertoft, E.; Soldatov, D.V.; Seetharaman, K. Impact on molecular organization of amylopectin in starch granules upon annealing. Carbohydr. Polym. 2013, 98, 1045–1055. [Google Scholar] [CrossRef]

- Tester, R.F.; Debon, S.J. Annealing of starch—A review. Int. J. Biol. Macromol. 2000, 27, 1–12. [Google Scholar] [CrossRef]

- Wang, H.; Xiao, N.; Wang, X.; Zhao, X.; Zhang, H. Effect of pregelatinized starch on the characteristics, microstructures, and quality attributes of glutinous rice flour and dumplings. Food Chem. 2019, 283, 248–256. [Google Scholar] [CrossRef]

- Fu, Z.-Q.; Che, L.-M.; Li, D.; Wang, L.-J.; Adhikari, B. Effect of partially gelatinized corn starch on the rheological properties of wheat dough. LWT Food Sci. Technol. 2016, 66, 324–331. [Google Scholar] [CrossRef]

- Adebowale, K.O.; Afolabi, T.A.; Olu-Owolabi, B.I. Hydrothermal treatments of Finger millet (Eleusine coracana) starch. Food Hydrocoll. 2005, 19, 974–983. [Google Scholar] [CrossRef]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT Food Sci. Technol. 2007, 40, 1723–1731. [Google Scholar] [CrossRef]

- da Rosa Zavareze, E.; Dias, A.R.G. Impact of heat-moisture treatment and annealing in starches: A review. Carbohydr. Polym. 2011, 83, 317–328. [Google Scholar] [CrossRef]

- Zhong, Y.; Xiang, X.; Zhao, J.; Wang, X.; Chen, R.; Xu, J.; Luo, S.; Wu, J.; Liu, C. Microwave pretreatment promotes the annealing modification of rice starch. Food Chem. 2020, 304, 125432. [Google Scholar] [CrossRef]

- Iftikhar, S.A.; Dutta, H. Status of polymorphism, physicochemical properties and in vitro digestibility of dual retrogradation-annealing modified rice starches. Int. J. Biol. Macromol. 2019, 132, 330–339. [Google Scholar] [CrossRef]

- Chi, C.; Li, X.; Lu, P.; Miao, S.; Zhang, Y.; Chen, L. Dry heating and annealing treatment synergistically modulate starch structure and digestibility. Int. J. Biol. Macromol. 2019, 137, 554–561. [Google Scholar] [CrossRef]

- Xu, Y.; Miladinov, V.; Hanna, M.A. Synthesis and Characterization of Starch Acetates with High Substitution. Cereal Chem. 2004, 81, 735–740. [Google Scholar] [CrossRef] [Green Version]

- EU Commission: Publications Office of the European Union. Commision Regulation (EU) No 1129/2011 of 11 November 2011. Off. J. Eur. Union L2952 2011, 295, 16–17.

- Golachowski, A.; Zięba, T.; Kapelko-Żeberska, M.; Drożdż, W.; Gryszkin, A. Current research addressing starch acetylation. Food Chem. 2015, 176, 350–356. [Google Scholar] [CrossRef] [PubMed]

- Leszczyński, W. The use of modified starches in the food industry, part I. Przegląd Piek. Cukier. 2006, 54, 54–57. (In Polish) [Google Scholar]

- Zięba, T.; Juszczak, L.; Gryszkin, A. Properties of retrograded and acetylated starch preparations Part 2. Dynamics of saccharification with amyloglucosidase and rheological properties of resulting pastes and gels. LWT Food Sci. Technol. 2011, 44, 1321–1327. [Google Scholar] [CrossRef]

- Zięba, T.; Wilczak, A.; Kobryń, J.; Musiał, W.; Kapelko-Żeberska, M.; Gryszkin, A.; Meisel, M. The Annealing of Acetylated Potato Starch with Various Substitution Degrees. Molecules 2021, 26, 2096. [Google Scholar] [CrossRef] [PubMed]

- Zdybel, E.; Tomaszewska-Ciosk, E. Modification of starch with succinic acid residues. Przemysł Chem. 2015, 94, 1138–1141. (In Polish) [Google Scholar] [CrossRef]

- Zięba, T.; Kapelko-Żeberska, M.; Gryszkin, A.; Wilczak, A.; Raszewski, B.; Spychaj, R. Effect of the botanical origin on properties of RS3/4 type resistant starch. Polymers 2019, 11, 81. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zdybel, E.; Zięba, T.; Tomaszewska-Ciosk, E.; Rymowicz, W. Effect of the Esterification of Starch with a Mixture of Carboxylic Acids from Yarrowia lipolitica Fermentation Broth on Its Selected Properties. Polymers 2020, 12, 1383. [Google Scholar] [CrossRef] [PubMed]

- Zięba, T.; Kapelko, M.; Gryszkin, A. Selected properties of potato starch subjected to multiple physical and chemical modifications. Pol. J. Food Nutr. Sci. 2007, 57, 639–645. [Google Scholar]

- Leszczyński, W. Resistant starch—Classification, structure, production. Pol. J. Food Nutr. Sci. 2004, 54, 37–50. [Google Scholar]

- Chen, Z.; Schols, H.A.; Voragen, A.G.J. Differently sized granules from acetylated potato and sweet potato starches differ in the acetyl substitution pattern of their amylose populations. Carbohydr. Polym. 2004, 56, 219–226. [Google Scholar] [CrossRef]

- Kapelko-Żeberska, M.; Zięba, T.; Spychaj, R.; Gryszkin, A. Selected Rheological Properties of RS3/4 Type Resistant Starch. Pol. J. Food Nutr. Sci. 2017, 67, 293–299. [Google Scholar] [CrossRef] [Green Version]

- Ashogbon, A.O.; Akintayo, E.T. Recent trend in the physical and chemical modification of starches from different botanical sources: A review. Starch 2014, 66, 41–57. [Google Scholar] [CrossRef]

- Leszczyński, W. Starch-raw material for industry, the structure and properties. Adv. Agric. Sci. Probl. Issues 2004, 500, 69–98. (In Polish) [Google Scholar]

- Mathobo, V.M.; Silungwe, H.; Ramashia, S.E.; Anyasi, T.A. Effects of heat-moisture treatment on the thermal, functional properties and composition of cereal, legume and tuber starches-a review. J. Food. Sci. Technol. 2021, 58, 412–426. [Google Scholar] [CrossRef]

- Tomaszewska-Ciosk, E.; Zdybel, E.; Drożdż, W. Model of retrogradation of extruded potato starch. Starch 2020, 72, 1900145. [Google Scholar] [CrossRef]

- Juszczak, L.; Fortuna, T.; Krok, F. Non-contact atomic force microscopy of starch granules surface. Part I. Potato and tapioca starches. Starch 2003, 55, 1–7. [Google Scholar] [CrossRef]

- Juszczak, L.; Fortuna, T.; Krok, F. Non-contact atomic force microscopy of starch granules surface. Part II. Selected cereal starches. Starch 2003, 55, 8–16. [Google Scholar] [CrossRef]

- Pinto, V.Z.; Vanier, N.L.; Deon, V.G.; Moomand, K.; El Halal, S.L.M.; Zavareze, E.D.R.; Lim, L.T.; Dias, A.R.G. Effects of single and dual physical modifications on pinhão starch. Food Chem. 2015, 187, 98–105. [Google Scholar] [CrossRef] [Green Version]

- Dias, A.R.G.; da Rosa Zavareze, E.; Spier, F.; Castro, L.A.S.; Gutkoski, L.C. Effects of annealing on the physicochemical properties and enzymatic susceptibility of rice starches with different amylose contents. Food Chem. 2010, 123, 711–719. [Google Scholar] [CrossRef]

- Falade, K.O.; Ayetigbo, O.E. Effects of annealing, acid hydrolysis and citric acid modifications on physical and functional properties of starches from four yam (Dioscorea spp.) cultivars. Food Hydrocoll. 2015, 43, 529–539. [Google Scholar] [CrossRef]

- Jayakody, L.; Hoover, R. Effect of annealing on the molecular structure and physicochemical properties of starches from different botanical origins–A review. Carbohydr. Polym. 2008, 74, 691–703. [Google Scholar] [CrossRef]

- Zięba, T.; Kapelko, M.; Szumny, A. Effect of preparation method on the properties of potato starch acetates with an equal degree of substitution. Carbohydr. Polym. 2013, 94, 193–198. [Google Scholar] [CrossRef] [PubMed]

- Wickramasinghe, H.A.M.; Yamamoto, K.; Yamauchi, H.; Noda, T. Effect of Low Level of Starch Acetylation on Physicochemical Properties of Potato Starch. Food Sci. Biotechnol. 2009, 18, 118–123. [Google Scholar]

- Golachowski, A. Properties of acetylated starch obtained from SO2-treated starch milk. Electron. J. Pol. Agric. Univ. 2003, 6, 1. [Google Scholar]

- Adamczyk, G.; Krystyjan, M.; Dobosz, A.; Sikora, M. Thixotropic properties of starch. Żywność Nauka Technol. Jakość 2013, 6, 16–31. (In Polish) [Google Scholar]

- Le Thanh-Blicharz, J.; Lubiewski, Z.; Voelkel, E.; Lewandowicz, G. Evaluation of rheological properties of commercial native starches. Żywność Nauka Technol. Jakość 2011, 3, 53–65. (In Polish) [Google Scholar]

- Wang, S.; Wang, J.; Wang, S.; Wang, S. Annealing improves paste viscosity and stability of starch. Food Hydrocoll. 2017, 62, 203–211. [Google Scholar] [CrossRef]

- Hong, J.; Zeng, X.A.; Brennan, C.S.; Brennan, M.; Han, Z. Recent Advances in Techniques for Starch Esters and the Applications: A Review. Foods 2016, 5, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kapelko, M.; Zięba, T.; Michalski, A. Effect of the production method on the properties of RS3/RS4 type resistant starch. Part 2. Effect of a degree of substitution on the selected properties of acetylated retrograded starch. Food Chem. 2012, 135, 2035–2042. [Google Scholar] [CrossRef] [PubMed]

| Preparation Type | Annealing Temperature | Onset Temperature (°C) | End Temperature (°C) | Gelatinization Enthalpy (J/g) |

|---|---|---|---|---|

| Annealed starch | 51 °C | 62.66 | 73.41 | 14.03 |

| 53.5 °C | 65.90 | 74.66 | 14.66 | |

| 56 °C | 66.68 | 77.81 | 16.03 | |

| 58.5 °C | 68.38 | 76.61 | 16.06 | |

| 61 °C | 67.90 | 77.72 | 10.48 | |

| Acetylated starch | - | 48.91 | 66.02 | 13.03 |

| Acetylated annealed starch | 51 °C | 52.36 | 66.46 | 11.15 |

| 53.5 °C | 54.73 | 68.37 | 11.21 | |

| 56 °C | 61.72 | 72.42 | 14.27 | |

| 58.5 °C | 57.68 | 70.29 | 13.81 | |

| 61 °C | 63.18 | 76.11 | 8.62 | |

| LSD | 0.81 | 1.47 | 0.19 | |

| Preparation Type | Annealing Temperature | Consistency Coefficient [Pa ⋯ sn] | Yield Point [Pa] | Casson’s Plastic Viscosity [Pa ⋯ s] |

|---|---|---|---|---|

| Annealed starch | 51 °C | 9.77 | 25.06 | 0.42 |

| 53.5 °C | 14.00 | 34.69 | 0.40 | |

| 56 °C | 21.78 | 50.17 | 0.36 | |

| 58.5 °C | 20.35 | 47.20 | 0.36 | |

| 61 °C | 9.43 | 22.64 | 0.19 | |

| Acetylated starch | - | 4.78 | 12.41 | 0.28 |

| Acetylated annealed starch | 51 °C | 6.66 | 17.24 | 0.30 |

| 53.5 °C | 6.45 | 16.71 | 0.28 | |

| 56 °C | 10.67 | 26.20 | 0.28 | |

| 58.5 °C | 8.5 | 21.96 | 0.37 | |

| 61 °C | 13.53 | 30.78 | 0.20 | |

| LSD | 1.09 | 3.27 | 0.06 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zdybel, E.; Wilczak, A.; Kapelko-Żeberska, M.; Tomaszewska-Ciosk, E.; Gryszkin, A.; Gawrońska, A.; Zięba, T. Physicochemical Properties and Digestion Resistance of Acetylated Starch Obtained from Annealed Starch. Polymers 2021, 13, 4141. https://doi.org/10.3390/polym13234141

Zdybel E, Wilczak A, Kapelko-Żeberska M, Tomaszewska-Ciosk E, Gryszkin A, Gawrońska A, Zięba T. Physicochemical Properties and Digestion Resistance of Acetylated Starch Obtained from Annealed Starch. Polymers. 2021; 13(23):4141. https://doi.org/10.3390/polym13234141

Chicago/Turabian StyleZdybel, Ewa, Aleksandra Wilczak, Małgorzata Kapelko-Żeberska, Ewa Tomaszewska-Ciosk, Artur Gryszkin, Anna Gawrońska, and Tomasz Zięba. 2021. "Physicochemical Properties and Digestion Resistance of Acetylated Starch Obtained from Annealed Starch" Polymers 13, no. 23: 4141. https://doi.org/10.3390/polym13234141

APA StyleZdybel, E., Wilczak, A., Kapelko-Żeberska, M., Tomaszewska-Ciosk, E., Gryszkin, A., Gawrońska, A., & Zięba, T. (2021). Physicochemical Properties and Digestion Resistance of Acetylated Starch Obtained from Annealed Starch. Polymers, 13(23), 4141. https://doi.org/10.3390/polym13234141