Development and Characterization of Weft-Knitted Fabrics of Naturally Occurring Polymer Fibers for Sustainable and Functional Textiles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

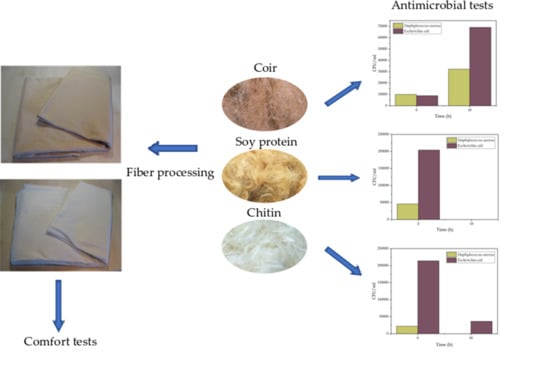

2.2. Yarn Processing

2.3. Fabric Manufacturing

2.4. Evaluation of Fiber Geometry and Mechanical Tests

2.5. Moisture Content Determination

2.6. Antimicrobial Tests

2.7. Comfort Assessment

2.8. Statistical Analysis

3. Results

3.1. Geometry and Mechanical Properties of the Natural Fibers

3.2. Moisture Content of the Natural Fibers

3.3. Antimicrobial Activity of the Natural Fibers

3.4. Comfort of the Natural Fiber Fabrics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, B.; Wang, L.; Wang, M.; Wu, S.; Wang, X.; Li, D.; Liu, C.; Feng, Z.; Chi, Y. Direct Separation and Purification of α-Lactalbumin from Cow Milk Whey by Aqueous Two-phase Flotation of Thermo-sensitive Polymer/Phosphate. J. Sci. Food Agric. 2021. [Google Scholar] [CrossRef]

- Jiang, B.; Na, J.; Wang, L.; Li, D.; Liu, C.; Feng, Z. Reutilization of food waste: One-step extration, purification and characterization of ovalbumin from salted egg white by aqueous two-phase flotation. Foods 2019, 8, 286. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liang, M.; Fu, C.; Xiao, B.; Luo, L.; Wang, Z. A fractal study for the effective electrolyte diffusion through charged porous media. Int. J. Heat Mass Transf. 2019, 137, 365–371. [Google Scholar] [CrossRef]

- Xiao, B.; Huang, Q.; Wang, Y.; Chen, H.; Chen, X.; Long, G. A fractal model for capillary flow through a single tortuous capillary with roughened surfaces in fibrous porous media. Fractals 2020. [Google Scholar] [CrossRef]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Lee, J.-W. Antimicrobial Agents and Applications on Polymeric Materials. Text. Color. Finish. 2008, 20, 39–56. [Google Scholar] [CrossRef]

- Fan, L.; Du, Y.; Zhang, B.; Yang, J.; Cai, J.; Zhang, L.; Zhou, J. Preparation and properties of alginate/water-soluble chitin blend fibers. J. Macromol. Sci. Part A Pure Appl. Chem. 2005, 42, 723–732. [Google Scholar] [CrossRef]

- Hsieh, S.H.; Huang, Z.; Huang, Z.; Tseng, Z. Antimicrobial and physical properties of woolen fabrics cured with citric acid and chitosan. J. Appl. Polym. Sci. 2004, 94, 1999–2007. [Google Scholar] [CrossRef]

- Pan, Y.; Huang, X.; Shi, X.; Zhan, Y.; Fan, G.; Pan, S.; Tian, J.; Deng, H.; Du, Y. Antimicrobial application of nanofibrous mats self-assembled with quaternized chitosan and soy protein isolate. Carbohydr. Polym. 2015, 133, 229–235. [Google Scholar] [CrossRef] [PubMed]

- Pillai, C.; Paul, W.; Sharma, C.P. Chitin and chitosan polymers: Chemistry, solubility and fiber formation. Prog. Polym. Sci. 2009, 34, 641–678. [Google Scholar] [CrossRef]

- Ifuku, S.; Saimoto, H. Chitin nanofibers: Preparations, modifications, and applications. Nanoscale 2012, 4, 3308–3318. [Google Scholar] [CrossRef]

- Dutta, P.K.; Ravikumar, M.; Dutta, J. Chitin and chitosan for versatile applications. J. Macromol. Sci. Part C Polym. Rev. 2002, 42, 307–354. [Google Scholar] [CrossRef]

- Mohammad, F. Sustainable natural fibres from animals, plants and agroindustrial wastes—An overview. In Sustainable Fibres for Fashion Industry; Springer: Berlin/Heidelberg, Germany, 2016; pp. 31–44. [Google Scholar]

- Yigit, S.; Dinjaski, N.; Kaplan, D.L. Fibrous proteins: At the crossroads of genetic engineering and biotechnological applications. Biotechnol. Bioeng. 2016, 113, 913–929. [Google Scholar] [CrossRef]

- Burgos, N.; Valdés, A.; Jiménez, A. Valorization of agricultural wastes for the production of protein-based biopolymers. J. Renew. Mater. 2016, 4, 165–177. [Google Scholar] [CrossRef] [Green Version]

- Leceta, I.; Etxabide, A.; Cabezudo, S.; de la Caba, K.; Guerrero, P. Bio-based films prepared with by-products and wastes: Environmental assessment. J. Clean. Prod. 2014, 64, 218–227. [Google Scholar] [CrossRef]

- Nishinari, K.; Fang, Y.; Guo, S.; Phillips, G.O. Soy proteins: A review on composition, aggregation and emulsification. Food Hydrocoll. 2014, 39, 301–318. [Google Scholar] [CrossRef]

- Herrero, A.M.; Jiménez-Colmenero, F.; Carmona, P. Elucidation of structural changes in soy protein isolate upon heating by Raman spectroscopy. Int. J. Food Sci. Technol. 2009, 44, 711–717. [Google Scholar] [CrossRef]

- Tang, C.-H.; Wang, C.-S. Formation and Characterization of Amyloid-like Fibrils from Soy β-Conglycinin and Glycinin. J. Agric. Food Chem. 2010, 58, 11058–11066. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.-H.; Wang, S.-S.; Huang, Q. Improvement of heat-induced fibril assembly of soy β-conglycinin (7S Globulins) at pH 2.0 through electrostatic screening. Food Res. Int. 2012, 46, 229–236. [Google Scholar] [CrossRef]

- Xia, W.; Zhang, H.; Chen, J.; Hu, H.; Rasulov, F.; Bi, D.; Huang, X.; Pan, S. Formation of amyloid fibrils from soy protein hydrolysate: Effects of selective proteolysis on β-conglycinin. Food Res. Int. 2017, 100, 268–276. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.Y.; Park, J.-W.; Batt, H.P.; Thomas, R.L. Edible films made from membrane processed soy protein concentrates. LWT Food Sci. Technol. 2007, 40, 418–423. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, W.; Tian, B.; Li, D.; Liu, C.; Jiang, B.; Feng, Z. Preparation and characterization of coating based on protein nanofibers and polyphenol and application for salted duck egg yolks. Foods 2020, 9, 449. [Google Scholar] [CrossRef] [Green Version]

- Jiang, B.; Wang, X.; Wang, L.; Wu, S.; Li, D.; Liu, C.; Feng, Z. Fabrication and Characterization of a Microemulsion Stabilized by Integrated Phosvitin and Gallic Acid. J. Agric. Food Chem. 2020, 68, 5437–5447. [Google Scholar] [CrossRef] [PubMed]

- Yi-You, L. The Soybean Protein Fibre-A Healthy & Comfortable Fibre for the 21st Century. Fibres Text. East. Eur. 2004, 12, 8–9. [Google Scholar]

- Pekhtasheva, E.; Neverov, A.; Kubica, S.; Zaikov, G. Biodegradation and biodeterioration of some natural polymers. Polym. Res. J. 2012, 5, 77–108. [Google Scholar] [CrossRef]

- Fernandes, J.C.; Tavaria, F.K.; Fonseca, S.C.; Ramos, Ó.S.; Pintado, M.E.; Malcata, F.X. In vitro screening for anti-microbial activity of chitosans and chitooligosaccharides, aiming at potential uses in functional textiles. J. Microbiol. Biotechnol. 2010, 20, 311–318. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Ma, K.; Li, R.; Ren, X.; Huang, T. Antimicrobial coating of modified chitosan onto cotton fabrics. Appl. Surf. Sci. 2014, 309, 138–143. [Google Scholar] [CrossRef]

- Szostak-Kotowa, J. Biodeterioration of textiles. Int. Biodeterior. Biodegrad. 2004, 53, 165–170. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, Z.; Lin, T. Barrier textiles for protection against microbes. In Antimicrobial Textiles; Elsevier: Amsterdam, The Netherlands, 2016; pp. 225–245. [Google Scholar]

- Han, S.; Yang, Y. Antimicrobial activity of wool fabric treated with curcumin. Dyes Pigment. 2005, 64, 157–161. [Google Scholar] [CrossRef]

- Esquenazi, D.; Wigg, M.D.; Miranda, M.M.; Rodrigues, H.M.; Tostes, J.B.; Rozental, S.; Da Silva, A.J.; Alviano, C.S. Antimicrobial and antiviral activities of polyphenolics from Cocos nucifera Linn.(Palmae) husk fiber extract. Res. Microbiol. 2002, 153, 647–652. [Google Scholar] [CrossRef]

- Tayel, A.A.; Moussa, S.; Wael, F.; Knittel, D.; Opwis, K.; Schollmeyer, E. Anticandidal action of fungal chitosan against Candida albicans. Int. J. Biol. Macromol. 2010, 47, 454–457. [Google Scholar] [CrossRef]

- Ryan, K.J.; Ray, C.G. Sherris Medical Microbiology; Mcgraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Ristić, T.; Zemljič, L.F.; Novak, M.; Kunčič, M.K.; Sonjak, S.; Cimerman, N.G.; Strnad, S. Antimicrobial efficiency of functionalized cellulose fibres as potential medical textiles. Sci. Against Microb. Pathog. Commun. Curr. Res. Technol. Adv. 2011, 6, 36–51. [Google Scholar]

- Sekhri, S. Textbook of Fabric Science: Fundamentals to Finishing; PHI Learning Pvt. Ltd.: New Delhi, India, 2019. [Google Scholar]

- Gandhi, K. Woven Textiles: Principles, Technologies and Applications; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar]

- Schindler, W.D.; Hauser, P.J. 3—Softening finishes. In Chemical Finishing of Textiles; Schindler, W.D., Hauser, P.J., Eds.; Woodhead Publishing: Sawston, UK, 2004; pp. 29–42. [Google Scholar] [CrossRef]

- Kawabata, S.; Niwa, M.; Yamashita, Y. Recent developments in the evaluation technology of fiber and textiles: Toward the engineered design of textile performance. J. Appl. Polym. Sci. 2002, 83, 687–702. [Google Scholar] [CrossRef]

- Behery, H. Effect of Mechanical and Physical Properties on Fabric Hand; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Raj, S.; Sreenivasan, S. Total wear comfort index as an objective parameter for characterization of overall wearability of cotton fabrics. J. Eng. Fibers Fabr. 2009, 4, 155892500900400406. [Google Scholar] [CrossRef] [Green Version]

- Paul, R. Functional Finishes for Textiles: Improving Comfort, Performance and Protection; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Shishoo, R. Textiles in Sport; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Tomczak, F.; Sydenstricker, T.H.D.; Satyanarayana, K.G. Studies on lignocellulosic fibers of Brazil. Part II: Morphology and properties of Brazilian coconut fibers. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1710–1721. [Google Scholar] [CrossRef]

- Alonso Felipe, J.V. Manual Control de Calidad en Productos Textiles y Afines; Escuela Técnica Superior de Ingenieros Industriales UPM: Madrid, Spain, 2015. [Google Scholar]

- Hari, P.K. Types and properties of fibres and yarns used in weaving. In Woven Textiles; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–34. [Google Scholar]

- Yu, C. Natural textile fibres: Vegetable fibres. In Textiles and Fashion; Elsevier: Amsterdam, The Netherlands, 2015; pp. 29–56. [Google Scholar]

- Netravali, A.N. Biodegradable Natural Fiber Composites; Woodhead Publishing: Cambridge, UK, 2005; pp. 271–309. [Google Scholar] [CrossRef]

- McKenna, H.A.; Hearle, J.W.S.; O’Hear, N. Ropemaking materials. In Handbook of Fibre Rope Technology, 1st ed.; Woodhead Publishing: Sawston, UK, 2004; pp. 35–74. [Google Scholar]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Sumi, S.; Unnikrishnan, N.; Mathew, L. Surface modification of coir fibers for extended hydrophobicity and antimicrobial property for possible geotextile application. J. Nat. Fibers 2017, 14, 335–345. [Google Scholar] [CrossRef]

- Jackman, D.R.; Dixon, M.K. The Guide to Textiles for Interiors; Portage & Main Press: Winnipeg, MB, Canada, 2003. [Google Scholar]

- Singh, J.P.; Verma, S. 3—Raw materials for terry fabrics. In Woven Terry Fabrics; Singh, J.P., Verma, S., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 19–28. [Google Scholar] [CrossRef]

- Pang, F.J.; He, C.J.; Wang, Q.R. Preparation and properties of cellulose/chitin blend fiber. J. Appl. Polym. Sci. 2003, 90, 3430–3436. [Google Scholar] [CrossRef]

- Bunsell, A.R. Handbook of Properties of Textile and Technical Fibres; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar]

- Montalvo, J.; Von Hoven, T. Review of standard test methods for moisture in lint cotton. J. Cotton Sci. 2008, 12, 33. [Google Scholar]

- ASTM International. Standard Test Method for Moisture in Cotton by Oven-Drying1; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Delhom, C.; Rodgers, J. Cotton Moisture—Its Importante, Measurements and Impacts. In Proceedings of the 33rd International Cotton Conference Bremen, New Orleans, LA, USA, 16–18 March 2016. [Google Scholar]

- Hu, J.; Li, Y.; Yeung, K.-W.; Wong, A.S.; Xu, W. Moisture management tester: A method to characterize fabric liquid moisture management properties. Text. Res. J. 2005, 75, 57–62. [Google Scholar] [CrossRef]

- Higgins, L.; Anand, S.; Hall, M.; Holmes, D. Effect of tumble-drying on selected properties of knitted and woven cotton fabrics: Part I: Experimental overview and the relationship between temperature setting, time in the dryer and moisture content. J. Text. Inst. 2003, 94, 119–128. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Conventional Moisture Regains of Textiles. GB 9994-2008. In National Standard of the People’s Republic of China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2008; pp. 1–8. [Google Scholar]

- Mohanty, A.; Misra, M.; Drzal, L.T. Surface modifications of natural fibers and performance of the resulting biocomposites: An overview. Compos. Interfaces 2001, 8, 313–343. [Google Scholar] [CrossRef]

- Cunha, A.G.; Gandini, A. Turning polysaccharides into hydrophobic materials: A critical review. Part 2. Hemicelluloses, chitin/chitosan, starch, pectin and alginates. Cellulose 2010, 17, 1045–1065. [Google Scholar] [CrossRef]

- Qin, Y.; Zhu, C.; Chen, J.; Zhong, J. Preparation and characterization of silver containing chitosan fibers. J. Appl. Polym. Sci. 2007, 104, 3622–3627. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Show, P.-L.; Ng, I.-S.; Lin, G.-Y.; Chiu, C.-Y.; Chang, Y.-K. Antibacterial activity of quaternized chitosan modified nanofiber membrane. Int. J. Biol. Macromol. 2019, 126, 569–577. [Google Scholar] [CrossRef]

- Jiao, Y.; Niu, L.N.; Ma, S.; Li, J.; Tay, F.R.; Chen, J.H. Quaternary ammonium-based biomedical materials: State-of-the-art, toxicological aspects and antimicrobial resistance. Prog. Polym. Sci. 2017, 71, 53–90. [Google Scholar] [CrossRef]

- Surdu, L.; Stelescu, M.D.; Iordache, O.; Manaila, E.; Craciun, G.; Alexandrescu, L.; Christian Dinca, L. The improvement of the resistance to Candida Albicans and Trichophyton interdigitale of some cotton textile materials by treating with oxygen plasma and chitosan. J. Text. Inst. 2016, 107, 1426–1433. [Google Scholar] [CrossRef]

- Li, S.; Donner, E.; Xiao, H.; Thompson, M.; Zhang, Y.; Rempel, C.; Liu, Q. Preparation and characterization of soy protein films with a durable water resistance-adjustable and antimicrobial surface. Mater. Sci. Eng. C 2016, 69, 947–955. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, Y.; Kang, S.; Wang, K.; Xu, H. Development and evaluation of soy protein isolate-based antibacterial nanocomposite films containing cellulose nanocrystals and zinc oxide nanoparticles. Food Hydrocoll. 2020, 106, 105898. [Google Scholar] [CrossRef]

- Raeisi, M.; Mohammadi, M.A.; Coban, O.E.; Ramezani, S.; Ghorbani, M.; Tabibiazar, M.; Noori, S.M.A. Physicochemical and antibacterial effect of Soy Protein Isolate/Gelatin electrospun nanofibres incorporated with Zataria multiflora and Cinnamon zeylanicum essential oils. J. Food Meas. Charact. 2020, 1–11. [Google Scholar] [CrossRef]

- Rani, S.; Kumar, R. A Review on Material and Antimicrobial Properties of Soy Protein Isolate Film. J. Polym. Environ. 2019, 27, 1613–1628. [Google Scholar] [CrossRef]

- Cerkez, I.; Kocer, H.B.; Worley, S.; Broughton, R.; Huang, T. Multifunctional cotton fabric: Antimicrobial and durable press. J. Appl. Polym. Sci. 2012, 124, 4230–4238. [Google Scholar] [CrossRef]

- Simoncic, B.; Tomsic, B. Structures of novel antimicrobial agents for textiles-a review. Text. Res. J. 2010, 80, 1721–1737. [Google Scholar] [CrossRef]

- Gao, Y.; Cranston, R. Recent advances in antimicrobial treatments of textiles. Text. Res. J. 2008, 78, 60–72. [Google Scholar]

- Le Ouay, B.; Stellacci, F. Antibacterial activity of silver nanoparticles: A surface science insight. Nano Today 2015, 10, 339–354. [Google Scholar] [CrossRef] [Green Version]

- Vigo, T.L. Antimicrobial Polymers and Fibers: Retrospective and Prospective; ACS Publications: Washington, DC, USA, 2001. [Google Scholar]

- Schindler, W.D.; Hauser, P.J. Chemical Finishing of Textiles; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Mishra, R.; Behera, B.; Pada Pal, B. Novelty of bamboo fabric. J. Text. Inst. 2012, 103, 320–329. [Google Scholar] [CrossRef]

- Chandy, M.; Kumar, K.S. Characterisation of Silver Deposited Coir Fibers by Magnetron Sputtering. CORD 2015, 31, 7. [Google Scholar] [CrossRef]

- Abatenh, E.; Gizaw, B.; Tsegaye, Z.; Wassie, M. The role of microorganisms in bioremediation—A review. Open J. Environ. Biol. 2017, 2, 038–046. [Google Scholar] [CrossRef] [Green Version]

- Behera, B. Comfort and handle behaviour of linen-blended fabrics. AUTEX Res. J. 2007, 7, 33–47. [Google Scholar]

- Shabbir, M. Textiles and Clothing: Environmental Concerns and Solutions; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Raheel, M. Modern Textile Characterization Methods; Routledge: London, UK, 2017. [Google Scholar]

- Varghese, N.; Thilagavathi, G. Handle and comfort characteristics of cotton core spun lycra and polyester/lycra fabrics for application as blouse. J. Text. Appar. Technol. Manag. 2014, 8, 1–13. [Google Scholar]

- Sun, D.; Stylios, G.K. Cotton fabric mechanical properties affected by post-finishing processes. Fibers Polym. 2012, 13, 1050–1057. [Google Scholar] [CrossRef]

- Jariyapunya, N.; Musilová, B.; Koldinská, M. Evaluating the Influence of Fiber Composition and Structure of Knitting Fabrics on Total Hand Value (THV). Proc. Appl. Mech. Mater. 2016, 211–215. [Google Scholar] [CrossRef]

- Ji, D.S.; Lee, J.J. Mechanical properties and hand evaluation of hemp woven fabrics treated with liquid ammonia. Fibers Polym. 2016, 17, 143–150. [Google Scholar] [CrossRef]

- Sun, D.; Stylios, G. Investigating the plasma modification of natural fiber fabrics-the effect on fabric surface and mechanical properties. Text. Res. J. 2005, 75, 639–644. [Google Scholar] [CrossRef]

- Verdu, P.; Rego, J.M.; Nieto, J.; Blanes, M. Comfort analysis of woven cotton/polyester fabrics modified with a new elastic fiber, part 1 preliminary analysis of comfort and mechanical properties. Text. Res. J. 2009, 79, 14–23. [Google Scholar] [CrossRef]

| Properties | SP Fiber | Chitin Fiber | Coir Fiber |

|---|---|---|---|

| Density (g/cm3) | 1.29 | 1.43 | 1.40 |

| Fiber length (mm) | 38 | 37–39 | 50–150 |

| Linear density (dtex) | 0.9–3.0 | 1.57–1.77 | - |

| Tenacity (g/tex) | 38.8–40.8 * | 23.4–27.5 | 10.0 |

| Elongation at break (%) | 18–21 * | 18–22 | 30 |

| Moisture content (%) | 8.6 | < 20 | 8 |

| Type of Fiber | Fiber Fineness (dtex) |

|---|---|

| Thick fibers | >7 |

| Semi-fine fibers | 7–2.4 |

| Fine fibers | 2.4–1 |

| Microfibers | 1–0.3 |

| Super microfibers | < 0.3 |

| Test | Primary Hand Parameters |

|---|---|

| Koshi | Stiffness and stiffness/elasticity when folded |

| Numeri | Smoothness |

| Fukurami | Fullness and softness |

| PHV | Feeling Grade |

|---|---|

| 10 | Extremely strong |

| 9 | Strong |

| 8 | - |

| 7 | - |

| 6 | - |

| 5 | Average |

| 4 | - |

| 3 | - |

| 2 | Weaker |

| 1 | Extremely weak |

| 0 | No feeling |

| THV | Grade |

|---|---|

| 5 | Excellent |

| 4 | Good |

| 3 | Average |

| 2 | Fair |

| 1 | Poor |

| 0 | Not useful |

| Properties | Fineness (dtex) | Length (mm) | Tensile Strength (cN) | Elongation at Break (%) | Tenacity (cN/tex) |

|---|---|---|---|---|---|

| SP fiber | 2.45 ± 0.88 a | 108.12 ± 0.74 a | 7.87 ± 0.63 a | 16.21 ± 0.98 a | 32.12 ± 1.10 a |

| Chitin fiber | 3.25 ± 1.21 b | 87.26 ± 0.96 b | 8.04 ± 0.74 b | 17.87 ± 0.93 a | 24.73 ± 0.79 b |

| Coir fiber * | - | 98.40 | - | 30.00 | 9.80 |

| Fabrics | Water Vapor Resistance (m2·Pa/W) | Thermal Resistance (m2·K/W) | Air Permeability (mm/s) |

|---|---|---|---|

| Chitin | 4.38 ± 0.11 a | 0.0426 ± 0.0023 a | 2716 ± 40 a |

| SP | 5.01 ± 0.11 b | 0.0463 ± 0.0017 a | 1792 ± 70 b |

| Cotton | 4.82 ± 0.07 c | 0.0425 ± 0.0019 a | 1638 ± 150 c |

| Cotton/Polyester (65/35) | 4.85 ± 0.03 c | 0.0417 ± 0.0010 a | 1829 ± 90 b |

| Cotton/Acrylic (60/40) | 4.44 ± 0.05 a | 0.0379 ± 0.0008 b | 1614 ± 120 c |

| Fabric | PHVs | THVs | ||||||

|---|---|---|---|---|---|---|---|---|

| Koshi | Fukurami | Numeri | ||||||

| Value | Grade | Value | Grade | Value | Grade | Value | Grade | |

| SP | 7.71 ± 0.08 a | Strong | 4.70 ± 0.21 a | Average | 4.06 ± 0.05 a | Average | 3.23 ± 0.06 a | Average |

| Chitin | 8.40 ± 0.04 b | Strong | 3.94 ± 0.15 b | Average | 6.15 ± 0.04 b | Average | 3.42 ± 0.07 b,c | Average |

| Cotton | 7.90 ± 0.05 b,c | Strong | 4.44 ± 0.11 a,b | Average | 8.56 ± 0.07 c | Strong | 3.72 ± 0.09 c | Good |

| Cotton/polyester (35/65) | 7.44 ± 0.03 c | Strong | 5.43 ± 0.09 c | Average | 6.81 ± 0.12 d | Average | 3.60 ± 0.07 c | Good |

| Cotton/acrylic (40/60) | 8.16 ± 0.10 b | Strong | 1.54 ± 0.19 d | Weak | 3.77 ± 0.03 e | Weak | 2.72 ± 0.13 d | Average |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrándiz, M.; Fages, E.; Rojas-Lema, S.; Ivorra-Martinez, J.; Gomez-Caturla, J.; Torres-Giner, S. Development and Characterization of Weft-Knitted Fabrics of Naturally Occurring Polymer Fibers for Sustainable and Functional Textiles. Polymers 2021, 13, 665. https://doi.org/10.3390/polym13040665

Ferrándiz M, Fages E, Rojas-Lema S, Ivorra-Martinez J, Gomez-Caturla J, Torres-Giner S. Development and Characterization of Weft-Knitted Fabrics of Naturally Occurring Polymer Fibers for Sustainable and Functional Textiles. Polymers. 2021; 13(4):665. https://doi.org/10.3390/polym13040665

Chicago/Turabian StyleFerrándiz, Marcela, Eduardo Fages, Sandra Rojas-Lema, Juan Ivorra-Martinez, Jaume Gomez-Caturla, and Sergio Torres-Giner. 2021. "Development and Characterization of Weft-Knitted Fabrics of Naturally Occurring Polymer Fibers for Sustainable and Functional Textiles" Polymers 13, no. 4: 665. https://doi.org/10.3390/polym13040665

APA StyleFerrándiz, M., Fages, E., Rojas-Lema, S., Ivorra-Martinez, J., Gomez-Caturla, J., & Torres-Giner, S. (2021). Development and Characterization of Weft-Knitted Fabrics of Naturally Occurring Polymer Fibers for Sustainable and Functional Textiles. Polymers, 13(4), 665. https://doi.org/10.3390/polym13040665