Strengthening of Precast RC Frame to Mitigate Progressive Collapse by Externally Anchored Carbon Fiber Ropes

Abstract

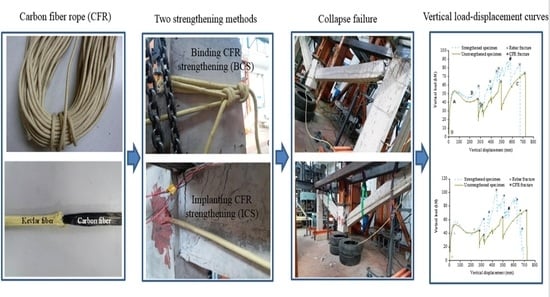

:1. Introduction

2. Experimental Preparation and Strengthening Schemes

2.1. Specimen Design

2.2. Pull-Out Test of Implanting CFR

2.3. Knot Test for Binding CFR

2.4. Strengthening Schemes

2.4.1. ICS Scheme

2.4.2. BCS Scheme

3. Experimental Results

3.1. Results of Specimen ICS

Load-Displacement Curves and Failure Process Analysis

3.2. Results of Specimen BCS

Load-Displacement Curves and Failure Process Analysis

4. Analytical Models

4.1. Analysis of Load Capacity Increment of Specimen ICS

4.2. Analysis of Load Capacity Increment of Specimen BCS

4.2.1. Calculation of CFR Elongation

4.2.2. Calculation of Load Capacity Increment of Specimen BCS

5. Construction Suggestions

5.1. Construction Suggestions for ICS

5.2. Construction Suggestions for BCS

6. Conclusions

- When the strengthened specimens collapsed, tension failure appeared at the tensile segments of CFR rather than anchorage and winding segments, indicating that the implanting and binding CFR anchoring schemes put forward in this paper can meet the strengthening requirements.

- By comparing the load-displacement curves of the strengthened and unstrengthened specimens, it can be found that the specimens ICS and BCS are the same as the unstrengthened specimen, with the increase of MCD, the stress state of the strengthened subassemblages gone through the FA, CAA and CA stages in turn. Neither of the two strengthening methods worked in the FA stage, which is beneficial to maintaining the structural state of “strong columns and weak beams”. The load capacity of the two strengthened specimens was significantly improved in the CA stage. For the specimen BCS, CFR also slightly increased the load capacity of the subassemblage in the CAA stage.

- In the two strengthening methods, CFR can help the structure consume the energy released by the fracture of reinforcements, reduce the loss rate of load capacity and improve the safety redundancy of the structure.

- For the ICS method, CFR can share the internal stress of the beam, improves the deformation capacity of the subassemblage in the early stage of CA. Construction errors will undermine the strengthening performance of ICS, in practical engineering, the implantation point of CFR should be accurately arranged and the relaxation of CFR should be strictly controlled to reduce the construction errors.

- For the BCS method, the key lies in how to effectively anchor. The method of chamfering and setting reasonable friction points adopted in this paper can effectively reduce the load at the knot, and avoid the compression and shear damage of CFR at the contact point. The construction process of BCS is simple and fast, the construction site does not need a large number of construction personnel. For the concrete frame workshop with sudden accidents (fire, explosion, design error, etc.) or the frame structures those need temporary support during construction, the BCS method can be adopted to improve the progressive collapse resistance performance of the structures and avoid upgrading the disaster.

- Finally, in order to mitigate progressive collapse of precast frame, analyical models of the load capacity increment contributed by CFR and the construction suggestions of the two strengthening methods are proposed. The Equations (9) and (16) are semi-theoretical and semi-empirical model which has the advantage of certain physical significance, and the form is simple enough, convenient for engineers to calculate by hand. However, more test data are needed to further improve the accuracy of Equations (9) and (16).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, X.K.; Tian, C.Y. Research of precast concrete structures progress. In Proceedings of the 21st National Academic Exchange Conference on Tall Building Structures, Nanjing, China, 14–16 October 2010; pp. 377–383. [Google Scholar]

- Pearson, C.; Delatte, N. Ronan Point Apartment Tower Collapse and its Effect on Building Codes. J. Perform. Constr. Facil. 2005, 19, 172–177. [Google Scholar] [CrossRef] [Green Version]

- Qian, K.; Liang, S.L.; Fu, F.; Fang, Q. Progressive collapse resistance of precast concrete beam-column sub-assemblages with high-performance dry connections. Eng. Struct. 2019, 198, 109552. [Google Scholar] [CrossRef]

- Qian, K.; Liang, S.L.; Feng, D.C.; Fu, F.; Wu, G. Experimental and numerical investigation on progressive collapse resistance of post-tensioned precast concrete beam-column subassemblages. J. Struct. Eng. 2020, 146, 04020170. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Alrubaidi, M.A.; Elsanadedy, H.M.; Almusallam, T.K.; Iqbal, R.A. Strengthening of precast RC beam-column connections for progressive collapse mitigation using bolted steel plates. Eng. Struct. 2018, 161, 146–160. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Alrubaidi, M.A.; Almusallam, T.H.; Abbas, H. Finite element analysis for progressive collapse potential of precast concrete beam-to-column connections strengthened with steel plates. J. Build. Eng. 2021, 34, 101875. [Google Scholar] [CrossRef]

- Yu, J.; Gan, Y.P.; Ji, J. Behavior and design of reinforced concrete frames retrofitted with steel bracing against progressive collapse. Struct. Des. Tall. Spec. 2020, 29, e1771. [Google Scholar] [CrossRef]

- Shah, B.; Xu, F. Effects of Steel Bracings in the Progressive Collapse Resistance of Reinforced Concrete Building. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Sanya, China, 17–18 December 2019. [Google Scholar]

- Qian, K.; Weng, Y.H.; Li, B. Improving Behavior of Reinforced Concrete Frames to Resist Progressive Collapse through Steel Bracings. J. Struct. Eng. 2018, 145, 04018248. [Google Scholar] [CrossRef]

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A fractal model for capillary flow through a single tortuous capillary with roughened surfaces in fibrous porous media. Fractals 2021, 29, 2150017. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, Y.; Wang, Y.; Jiang, G.; Liang, M.; Chen, X.; Long, G. A fractal model for Kozeny–Carman constant and dimensionless permeability of fibrous porous media with roughened surfaces. Fractals 2019, 27, 1950116. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, W.; Zhang, X.; Long, G.; Fan, J.; Chen, H.; Deng, L. A novel fractal solution for permeability and Kozeny-Carman constant of fibrous porous media made up of solid particles and porous fibers. Powder Technol. 2019, 349, 92–98. [Google Scholar] [CrossRef]

- Qian, K.; Li, B. Strengthening and Retrofitting of Flat Slabs to Mitigate Progressive Collapse by Externally Bonded CFRP Laminates. J. Compos. Constr. 2013, 17, 554–565. [Google Scholar] [CrossRef]

- Yang, J. Experimental study by using CFRP laminates on preventing progressive collapse of RC frame. Master’s Thesis, Hunan University, Changsha, China, 2014. [Google Scholar]

- Lin, K.; Lu, X.; Li, Y.; Zhuo, W.; Guan, H. A novel structural detailing for the improvement of seismic and progressive collapse performances of RC frames. Earthq. Eng. Struct. Dyn. 2019, 48, 1451–1470. [Google Scholar] [CrossRef]

- Feng, P.; Qiang, H.; Qin, W.; Gao, M. A novel kinked rebar configuration for simultaneously improving the seismic performance and progressive collapse resistance of RC frame structures. Eng. Struct. 2017, 147, 752–767. [Google Scholar] [CrossRef]

- Qiu, L.; Lin, F.; Wu, K. Improving progressive collapse resistance of RC beam–column subassemblages using external steel cables. J. Perform. Constr. Facil. 2020, 34, 04019079. [Google Scholar] [CrossRef]

- DBJT08-116-2013. Standard Drawings for Construction Joints of Assembled Monolithic Concrete Residential Buildings; Shanghai Construction Engineering Design Research Institute: Shanghai, China, 2013. [Google Scholar]

- Pan, J.W.; Wang, X.; Wu, F. Strengthening of precast RC frame to mitigate progressive collapse by externally bonded CFRP sheets anchored with HFRP anchors. Adv. Civ. Eng. 2018, 2018, 8098242. [Google Scholar] [CrossRef] [Green Version]

- Hassan, T.; Rizkalla, S. Bond mechanism of NSM FRP bars for flexural strengthening of concrete structures. ACI Struct. J. 2004, 101, 830–839. [Google Scholar]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Behavior and modeling of bond of FRP rebars to concrete. J. Compos. Constr. 1997, 1, 40–51. [Google Scholar] [CrossRef]

- Kiakojouri, F.; De Biagi, V.; Chiaia, B.; Sheidaii, M.R. Progressive collapse of framed building structures: Current knowledge and future prospects. Eng. Struct. 2020, 206, 110061. [Google Scholar] [CrossRef]

- Gao, D.; Brahim, B. Bonding mechanism and calculating method for embedded length of fiber reinforced polymer rebars in concrete. J. Hydraul. Eng. 2000, 31, 70–78. [Google Scholar]

| Δ1 | Δ2 | Δ3 | Δ4 | Δ5 | Δ6 |

|---|---|---|---|---|---|

| 39.8 mm | 1.72 mm | 1.23 mm | 0.39 mm | 0.28 mm | 0.09 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, J.; Wang, X.; Dong, H. Strengthening of Precast RC Frame to Mitigate Progressive Collapse by Externally Anchored Carbon Fiber Ropes. Polymers 2021, 13, 1306. https://doi.org/10.3390/polym13081306

Pan J, Wang X, Dong H. Strengthening of Precast RC Frame to Mitigate Progressive Collapse by Externally Anchored Carbon Fiber Ropes. Polymers. 2021; 13(8):1306. https://doi.org/10.3390/polym13081306

Chicago/Turabian StylePan, Jianwu, Xian Wang, and Hao Dong. 2021. "Strengthening of Precast RC Frame to Mitigate Progressive Collapse by Externally Anchored Carbon Fiber Ropes" Polymers 13, no. 8: 1306. https://doi.org/10.3390/polym13081306

APA StylePan, J., Wang, X., & Dong, H. (2021). Strengthening of Precast RC Frame to Mitigate Progressive Collapse by Externally Anchored Carbon Fiber Ropes. Polymers, 13(8), 1306. https://doi.org/10.3390/polym13081306