Experimental Study of Straw-Based Eco-Panel Using a Small Ignition Initiator

Abstract

:1. Introduction

Fire Characteristics of Straw-Based Eco-Panel Constructions Coated with Cardboard

2. Materials and Methods

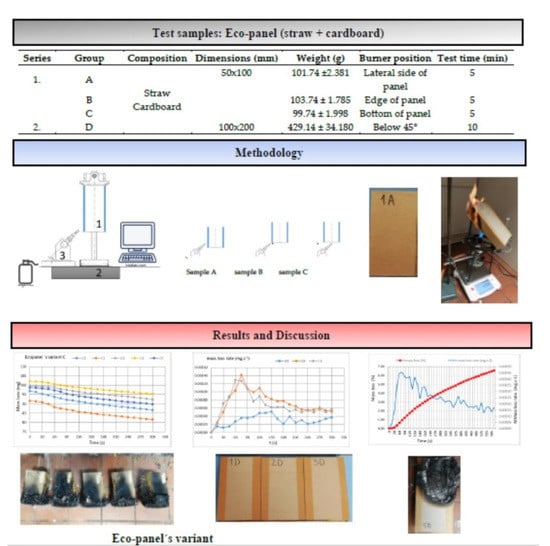

2.1. Test Samples

2.2. The Ignitability Fire Test by a Small-Time Attack Flame of Eco Panel

2.3. Test Evaluation

2.4. Weight Loss and Relative Burning Rate

2.5. Mathematical and Statistical Processing and Evaluation of Results

3. Results

Statistical Results: The Null Hypothesis Applies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al Shawaf, Z. An Experimental Study of Dry Onion Skins as Renewable Materials for Interior Finishes and Their Impact on Indoor Environment. Dissertation Work. Faculty of Engineering & IT; The British University in Dubai: Dubai, United Arab Emirates, 2014; p. 103. Available online: https://bspace.buid.ac.ae/bitstream/1234/1000/1/2013133124.pdf (accessed on 29 September 2020).

- Prečo Si Postaviť Dom Zo Slamy? Available online: https://www.stavebnictvoabyvanie.sk/stavebnictvo/4218-preco-si-postavit-dom-zo-slamy (accessed on 29 September 2020). (In Slovakian).

- Secchi, S.; Asdrubali, F.; Cellai, G.; Nannipieri, E.; Rotili, A.; Vannucchi, I. Experimental and environmental analysis of new sound-absorbing and insulating elements in recycled cardboard. J. Build. Eng. 2016, 5, 1–12. [Google Scholar] [CrossRef]

- Ekopanely-Stavební Desky Ze Slámy. Available online: https://www2.zf.jcu.cz/~moudry/databaze/Ekopanely.htm?fbclid=IwAR2OscJd9wM2Bhxm5tJBursy0YvOQtXTCxV2AvRQzXBCU6JeV07gVTWiDh0 (accessed on 18 April 2018). (In Czech).

- Spottiswoode, A.J.; Bank, L.C.; Shapira, A. Investigation of paperboard tubes as formwork for concrete bridge decks. Constr Build Mater. 2012, 30, 767–775. [Google Scholar] [CrossRef]

- Kadlicová, P.; Gašpercová, S.; Makovicka Osvaldova, L. Monitoring of Weight Loss of Fibreboard during Influence of Flame. Procedia Eng. 2017, 192, 393–398. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Neykov, N. Possibilities for Manufacturing Insulation Boards with Participation of Recycled Lignocellulosic Fibres. Manag. Sustain. Dev. 2019, 75, 72–76. [Google Scholar] [CrossRef]

- Delgado, B.; López González, D.; Godbout, S.; Lagacé, R.; Giroir-Fendler, A.; Avalos Ramirez, A. A study of torrefied cardboard characterization and applications: Composition, oxidation kinetics and methane adsorption. Sci. Total Environ. 2017, 593–594, 406–417. [Google Scholar] [CrossRef]

- EKOPANEL-Slaměný Lisovaný Panel. Available online: https://www.prirodnistavba.cz/ekopanel-slameny-lisovany-panel-3426.html (accessed on 17 April 2020). (In Czech).

- Cai, Z.; Robert, J.R. Mechanical Properties of Wood-Based Composite Materials. Wood Handbook: Wood as an Engineering Material: Chapter 12; General Technical Report FPL, GTR-190; U.S. Dept. of Agriculture: Madison, WI, USA, 2010; pp. 12.1–12.12.

- Yang, H.; Kim, D.; Kim, H. Rice straw-wood particle composite for sound absorbing wooden construction materials. Bioresour. Technol. 2003, 86, 117–121. [Google Scholar] [CrossRef]

- Sadzevicius, R.; Gurskis, V.; Ramukevičius, D. Sustainable construction of agro-industrial buildings from straw panels. In Proceedings of the Rural Development 2015, Kaunas, Lithuania, 23–24 April 2015. [Google Scholar]

- Torun, G.; Korkut, Ö. Preparation of Cement Based Composites and Cellulosic Panels from Barley Straw for Thermal Insulation. GU J. Sci. 2017, 30, 31–32. Available online: https://dergipark.org.tr/tr/download/article-file/290214 (accessed on 29 September 2020).

- Antov, P.; Savov, V.; Krišťák, Ľ.; Réh, R.; Mantanis, G.I. Eco-Friendly, High-Density Fiberboards Bonded with Urea-Formaldehyde and Ammonium Lignosulfonate. Polymers 2021, 13, 220. [Google Scholar] [CrossRef]

- Antov, P.; Krišt’ák, L.; Réh, R.; Savov, V.; Papadopoulos, A.N. Eco-Friendly Fiberboard Panels from Recycled Fibers Bonded with Calcium Lignosulfonate. Polymers 2021, 13, 639. [Google Scholar] [CrossRef]

- Teslík, J.; Vodičková, M.; Kutilová, K. The Assessment of Reaction to Fire of Crushed Straw. Appl. Mech. Mater. 2016, 824, 148–155. [Google Scholar] [CrossRef]

- Štenclová, E. Spúšť v Žiline. Most Poškodili Horiace Pivné Prepravky, Fľaše A Slama (Trigger in Žilina. The bridge was Damaged by Burning Beer Crates, Bottles and Straw). Available online: https://spravy.pravda.sk/regiony/clanok/512806-poziar-budovy-pivnych-prepraviek-flias-a-slamy-poskodil-zilinsky-most (accessed on 21 May 2019).

- Yang, Y.; Liu, J.; Jin, S.; Li, T. Experimental study about influence of particle size and oxygen atmosphere on straw powder’s combustion characteristics. In Proceedings of the 2011 International Conference on Electrical and Control Engineering, Yichang, China, 16–18 September 2011; pp. 3470–3473. [Google Scholar] [CrossRef]

- Pepich, Š. Slama Ako Zdroj Energie Z Poľnohospodárstva (Straw as a Source of Energy from Agriculture). Available online: http://old.agroporadenstvo.sk/oze/biomasa/slama.pdf (accessed on 17 April 2020). (In Slovakian).

- Saidur, R.; Abdelaziz, E.; Demirbas, A.; Hossain, M.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Pepich, Š. Pilotný Project Energetického Využitia Biomasy. Available online: http://www.tsup.sk/files/vyuzitie_poln.biomasy_na_energet.ucely.pdf (accessed on 1 December 2010). (In Slovakian).

- Hajinajaf, N.; Mehrabadi, A.; Tavakoli, O. Practical strategies to improve harvestable biomass energy yield in microalgal culture: A review. Biomass Bioenergy 2021, 145, 105941. [Google Scholar] [CrossRef]

- Schnorf, V.; Trutnevyte, E.; Bowman, G.; Burg, V. Biomass transport for energy: Cost, energy and CO2 performance of forest wood and manure transport chains in Switzerland. J. Clean. Prod. 2021, 293, 125971. [Google Scholar] [CrossRef]

- Xie, T.; Wei, R.; Wang, Z.; Wang, J. Comparative analysis of thermal oxidative decomposition and fire characteristics for different straw powders via thermogravimetry and cone calorimetry. Process. Saf. Environ. Prot. 2020, 134, 121–130. [Google Scholar] [CrossRef]

- Růžička, J. Požární Odolnost Obvodových Stěn Pro Pasivní Domy S Využitím Slaměných Balíků Jako Tepelné Izolace. Available online: https://stavba.tzb-info.cz/obalove-konstrukce-nizkoenergetickych-staveb/8974-pozarni-odolnost-obvodovych-sten-pro-pasivni-domy-s-vyuzitim-slamenych-baliku-jako-tepelne-izolace (accessed on 27 August 2012). (In Czech).

- Růžička, J.; Pokorný, M. Požární Odolnost Obvodových Stěn NED, PD z Přírodních a Recyklovaných Stavebních Materiálů. Stavebnictví 2011, 11, 34–39. (In Czech) [Google Scholar]

- Kozłowski, R.; Władyka-Przybylak, M. Flammability and fire resistance of composites reinforced by natural fibers. Polym. Adv. Technol. 2008, 19, 446–453. [Google Scholar] [CrossRef]

- Chybík, J. Přírodní Stavební Materiály (Natural Building Materials); Grada Publishing: Prague, Czech Republic, 2009; p. 272. (In Czech) [Google Scholar]

- Pokorný, J.; Kučera, P.; Vlček, V. Specific knowledge in assessment of local fire for design of building structures. Adv. Mat. Res. 2014, 1001, 362–367. [Google Scholar] [CrossRef]

- Hýsková, P.; Hýsek, Š.; Schönfelder, O.; Šedivka, P.; Lexa, M.; Jarský, V. Utilization of agricultural rests: Straw-based composite panels made from enzymatic modified wheat and rapeseed straw. Ind. Crops Prod. 2020, 144, 112067. [Google Scholar] [CrossRef]

- Theis, B. Straw Bale Fire Safety. Available online: http://www.naturalbuildingcoalition.ca/Resources/Documents/Technical/strawbale_fire_safety.pdf (accessed on 30 July 2003).

- Sobotka, M. The Choice of a Suitable Material for the Building of the Detached House; ČVUT Praha. Available online: http://stretech.fs.cvut.cz/2014/sbornik_2014/zdar%20nad%20sazavou_sobotka-volba%20materialu.pdf (accessed on 30 June 2014). (In Czech).

- Makovicka Osvaldova, L. Experiment Description. In Wooden Façades and Fire Safety; SpringerBriefs in Fire; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Weisberger, J.M.; Richter, J.P.; Mollendorf, J.C.; DesJardin, P.E. An emissions-based fuel mass loss measurement for wood-fired hydronic heaters. Biomass Bioenergy 2020, 142, 105731. [Google Scholar] [CrossRef]

- Kačíková, D.; Makovická, L.M. Wood burning rate of various tree parties. Acta Fac. Xylologiae 2009, 51, 27–32. Available online: https://df.tuzvo.sk/sites/default/files/04-1-09-kacikova-makovicka-osvaldova.pdf (accessed on 15 April 2021). (In Slovakian).

- Hao, H.; Chow, C.L.; Lau, D. Effect of heat flux on combustion of different wood species. Fuel 2020, 278, 118325. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, C.C.; Garcia-Ortuño, T.; Ferrandez-Garcia, M.T.; Ferrandez-Villena, M.; Ferrandez-Garcia, C.E. Fire-resistance, physical, and mechanical characterization of binderless rice straw particleboards. BioResources 2017, 12, 8539–8549. [Google Scholar] [CrossRef]

- Fire Classification. Available online: http://www.paroc.com/knowhow/fire/fire-classification (accessed on 12 June 2015).

- European Committe for Standartion. EN 13501-2+A1 2010. Fire Classification of Construction Products and Building Elements—Part 2: Classification Using Test Data from Resistance Fire Tests, Excluding Ventilation Services; European Committe for Standartion: Brussels, Belgium, 2010. [Google Scholar]

- Cao, G.L.; Zhang, X.; Wang, Y.; Zheng, F.C. Estimation of emissions from field burning of crop straw in China. Chin. Sci. Bull. 2008, 53, 784–790. [Google Scholar] [CrossRef]

- Gadde, B.; Bonnet, S.; Menke, C.; Garivait, S. Air pollutant emissions from rice straw open field burning in India, Thailand and the Philippines. Environ. Pollut. 2009, 157, 1554–1558. [Google Scholar] [CrossRef]

- Jenkins, B.B.; Miles, L.T.; Baxter, L.L. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Fire Resistance Test Report No Pr-18-2.204/En Loadbearing External Wall Made of Boards Ecopanel Eco 2 Boards; Testing Laboratory No. 1206; Testing Laboratory: Veselí nad Lužnicí, Czech Republic, 2018.

| Series | Group | Composition | Dimensions (mm) | Weight (g) | Burner Position | Test Time (min) |

|---|---|---|---|---|---|---|

| 1. | A | Straw Cardboard | 50 × 100 | 101.74 ± 2.381 | Lateral side of panel | 5 |

| B | 103.74 ± 1.785 | Edge of panel | 5 | |||

| C | 99.74 ± 1.998 | Bottom of panel | 5 | |||

| 2. | D | 100 × 200 | 429.14 ± 34.180 | Below 45° | 10 |

| Sample | Number | Mean | Standard Deviation | Variance | Standard Error |

| Time | 100 | 157.7 | 86.9299 | 7559.8181 | 8.6929 |

| A | 100 | 2.1363 | 1.4263 | 2.0343 | 0.1426 |

| B | 100 | 0.0008 | 0.0004 | 1.8864 | 4.3432 |

| C | 100 | 5.1528 | 2.9357 | 8.6183 | 0.2935 |

| Source | Df | Sum of Squares | Mean Square | F Value | p Value |

| Model (Between groups) | 3 | 1,804,842.948 | 601,614.3160 | 318.0002 | 4.6151 |

| Error | 369 | 749,179.6158 | 1,891.8677 | ||

| Total | 399 | 2,554,022.5639 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makovicka Osvaldova, L.; Markova, I.; Jochim, S.; Bares, J. Experimental Study of Straw-Based Eco-Panel Using a Small Ignition Initiator. Polymers 2021, 13, 1344. https://doi.org/10.3390/polym13081344

Makovicka Osvaldova L, Markova I, Jochim S, Bares J. Experimental Study of Straw-Based Eco-Panel Using a Small Ignition Initiator. Polymers. 2021; 13(8):1344. https://doi.org/10.3390/polym13081344

Chicago/Turabian StyleMakovicka Osvaldova, Linda, Iveta Markova, Stanislav Jochim, and Jan Bares. 2021. "Experimental Study of Straw-Based Eco-Panel Using a Small Ignition Initiator" Polymers 13, no. 8: 1344. https://doi.org/10.3390/polym13081344

APA StyleMakovicka Osvaldova, L., Markova, I., Jochim, S., & Bares, J. (2021). Experimental Study of Straw-Based Eco-Panel Using a Small Ignition Initiator. Polymers, 13(8), 1344. https://doi.org/10.3390/polym13081344