Recent Developments of Carboxymethyl Cellulose

Abstract

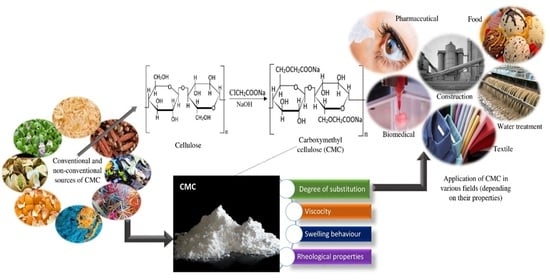

:1. Introduction

2. Characteristics of CMC

2.1. Rheological Properties

2.1.1. Stress-Strain Flow Behavior

2.1.2. Pseudoplastic and Viscoelastic Behavior

2.1.3. Thixotropy

2.2. Viscosity

2.3. Degree of Substitution

3. Synthesis of CMC from Its Various Sources

3.1. CMCs from Various Plant-Based Precursor Materials

3.2. Production of CMCs from Non-Conventional Precursor Materials

3.3. Synthesis Route of CMC

3.3.1. Factors Affecting the Characteristics of CMC

The Temperature of the Etherification Process

Dosage of the Etherifying Agent

| NaOH + Cl-CH2COONa → OH-CH2COONa + NaCl … … … … … | (iii) |

The Concentration of the Alkali

4. Application of CMC

4.1. Application in Textile Industries

4.2. Application in Food Industries

4.3. Application in the Water Treatment Process

4.4. Biomedical Application

4.4.1. 3D Bioprinting Process

4.4.2. Drug Delivery

4.4.3. Tissue Engineering

Wound Dressing

CMC in 3D Scaffold Materials

Bone-Tissue Engineering

4.4.4. Bio-Sensing and Bio-Imaging

4.5. Application of CMC in Pharmaceutical Industries

4.6. Other Applications

5. Prospects

- (a)

- Utilizing various bacterial celluloses for the synthesis of high purity CMC products.

- (b)

- Developing CMC-based nanocomposite for stimuli-sensitive control release of nutrients in the human body from food ingredients to ensure biosafety.

- (c)

- Utilizing non-toxic and susceptible CMC for smart physiological effects (smoothing, glowing, or shining) and smart protective (UV blocking, thermo-responsive) objects in cosmetics.

- (d)

- Most of the relevant water treatment studies are based on laboratory benchmarks. Therefore, the effectivity and efficiency of the fabricated CMC-based superabsorbent should be tested in pilot-scale studies for the removal of the targeted pollutants.

- (e)

- Development of new biomaterials for a 3D-bioprinting process utilizing CMCs.

- (f)

- Utilizing CMCs for in vivo bio-sensing of more organic compounds.

- (g)

- Develop 4D bio-printing technology with more innovative and complex designs using CMC composites.

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Heinze, T.; Pfeiffer, K. Studies on the synthesis and characterization of carboxymethylcellulose. Angew. Makromol. Chem. 1999, 266, 37–45. [Google Scholar] [CrossRef]

- Revol, J.F.; Goring, D. On the mechanism of the mercerization of cellulose in wood. J. Appl. Polym. Sci. 1981, 26, 1275–1282. [Google Scholar] [CrossRef]

- Scott, D.S.; Piskorz, J.; Bergougnou, M.A.; Graham, R.; Overend, R.P. The role of temperature in the fast pyrolysis of cellulose and wood. Ind. Eng. Chem. Res. 1988, 27, 8–15. [Google Scholar] [CrossRef]

- Fengel, D. The ultrastructure of cellulose from wood. Wood Sci. Technol. 1969, 3, 203–217. [Google Scholar] [CrossRef]

- Pushpamalar, V.; Langford, S.J.; Ahmad, M.; Lim, Y.Y. Optimization of reaction conditions for preparing carboxymethyl cellulose from sago waste. Carbohydr. Polym. 2006, 64, 312–318. [Google Scholar] [CrossRef]

- Singh, R.K.; Singh, A.K. Optimization of reaction conditions for preparing carboxymethyl cellulose from corn cobic agricultural waste. Waste Biomass Valor. 2013, 4, 129–137. [Google Scholar] [CrossRef]

- Mondal, M.I.H.; Yeasmin, M.S.; Rahman, M.S. Preparation of food grade carboxymethyl cellulose from corn husk agrowaste. Int. J. Biol. Macromol. 2015, 79, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Shui, T.; Feng, S.; Chen, G.; Li, A.; Yuan, Z.; Shui, H.; Kuboki, T.; Xu, C. Synthesis of sodium carboxymethyl cellulose using bleached crude cellulose fractionated from cornstalk. Biomass Bioenergy 2017, 105, 51–58. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Luangkamin, S.; Tanprasert, K.; Suriyatem, R. Carboxymethyl cellulose film from durian rind. LWT Food Sci. Technol. 2012, 48, 52–58. [Google Scholar] [CrossRef]

- Adinugraha, M.P.; Marseno, D.W. Synthesis and characterization of sodium carboxymethylcellulose from cavendish banana pseudo stem (Musa cavendishii LAMBERT). Carbohydr. Polym. 2005, 62, 164–169. [Google Scholar] [CrossRef]

- Mondal, M.I.H.; Yeasmin, M.S.; Rahman, M.S.; Sayeed, M.A. Synthesis and characterization of high-purity food grade carboxymethyl celluloses from different parts of maize waste. In Cellulose and Cellulose Derivatives; Mondal, M.I.H., Ed.; Nova Science Publisher: New York, NY, USA, 2015; p. 227. [Google Scholar]

- Gutawa, K.; Willy, A.; Nikita, G. Synthesis and characterization of sodium carboxymethylcellulose from pod husk of Cacao (Theobroma cacao L.). Int. J. Food Sci. Microbiol. 2015, 3, 99–103. [Google Scholar]

- Dapía, S.; Tovar, C.A.; Santos, V.; Parajó, J.C. Rheological behaviour of carboxymethylcellulose manufactured from TCF-bleached milox pulps. Food Hydrocoll. 2005, 19, 313–320. [Google Scholar] [CrossRef]

- Yaşar, F.; Toğrul, H.; Arslan, N. Flow properties of cellulose and carboxymethyl cellulose from orange peel. J. Food Eng. 2007, 81, 187–199. [Google Scholar] [CrossRef]

- Dai, H.; Huang, H. Enhanced swelling and responsive properties of pineapple peel carboxymethyl cellulose-g-poly (acrylic acid-co-acrylamide) superabsorbent hydrogel by the introduction of carclazyte. J. Agric. Food Chem. 2017, 65, 565–574. [Google Scholar] [CrossRef] [PubMed]

- Golbaghi, L.; Khamforoush, M.; Hatami, T. Carboxymethyl cellulose production from sugarcane bagasse with steam explosion pulping: Experimental, modeling, and optimization. Carbohydr. Polym. 2017, 174, 780–788. [Google Scholar] [CrossRef]

- Klunklin, W.; Jantanasakulwong, K.; Phimolsiripol, Y.; Leksawasdi, N.; Seesuriyachan, P.; Chaiyaso, T.; Insomphun, C.; Phongthai, S.; Jantrawut, P.; Sommano, S.R.; et al. Synthesis, Characterization, and Application of Carboxymethyl Cellulose from Asparagus Stalk End. Polymers 2020, 13, 81. [Google Scholar] [CrossRef]

- He, X.; Wu, S.; Fu, D.; Ni, J. Preparation of sodium carboxymethyl cellulose from paper sludge. J. Chem. Technol. Biotechnol. 2009, 84, 427–434. [Google Scholar] [CrossRef]

- Joshi, G.; Naithani, S.; Varshney, V.; Bisht, S.S.; Rana, V.; Gupta, P. Synthesis and characterization of carboxymethyl cellulose from office waste paper: A greener approach towards waste management. Waste Manag. 2015, 38, 33–40. [Google Scholar] [CrossRef]

- Fakrul Alam, A.; Mondal, M.I.H. Utilization of cellulosic wastes in textile and garment industries. I. Synthesis and grafting characterization of carboxymethyl cellulose from knitted rag. J. Appl. Polym. Sci. 2013, 128, 1206–1212. [Google Scholar] [CrossRef]

- Bidgoli, H.; Zamani, A.; Jeihanipour, A.; Taherzadeh, M. Preparation of carboxymethyl cellulose superabsorbents from waste textiles. Fibers Polym. 2014, 15, 431–436. [Google Scholar] [CrossRef]

- Haleem, N.; Arshad, M.; Shahid, M.; Tahir, M.A. Synthesis of carboxymethyl cellulose from waste of cotton ginning industry. Carbohydr. Polym. 2014, 113, 249–255. [Google Scholar] [CrossRef]

- Jahan, I.A.; Sultana, F.; Islam, M.N.; Hossain, M.A.; Abedin, J. Studies on indigenous cotton linters for preparation of carboxymethyl cellulose. Bangladesh J. Sci. Ind. Res. 2007, 42, 29–36. [Google Scholar] [CrossRef]

- Su, J.-F.; Huang, Z.; Yuan, X.-Y.; Wang, X.-Y.; Li, M. Structure and properties of carboxymethyl cellulose/soy protein isolate blend edible films crosslinked by Maillard reactions. Carbohydr. Polym. 2010, 79, 145–153. [Google Scholar] [CrossRef]

- Rosilio, V.; Albrecht, G.; Baszkin, A.; Merle, L. Surface properties of hydrophobically modified carboxymethylcellulose derivatives. Effect of salt and proteins. Colloids Surf. B Biointerfaces 2000, 19, 163–172. [Google Scholar] [CrossRef]

- Gregorova, A.; Saha, N.; Kitano, T.; Saha, P. Hydrothermal effect and mechanical stress properties of carboxymethylcellulose based hydrogel Food Packag. Carbohydr. Polym. 2015, 117, 559–568. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rhim, J.-W. Carboxymethyl cellulose-based antioxidant and antimicrobial active packaging film incorporated with curcumin and zinc oxide. Int. J. Biol. Macromol. 2020, 148, 666–676. [Google Scholar] [CrossRef] [PubMed]

- Kadokawa, J.-I.; Arimura, T.; Takemoto, Y.; Yamamoto, K. Self-assembly of amylose-grafted carboxymethyl cellulose. Carbohydr. Polym. 2012, 90, 1371–1377. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Khan, N.R.; Basit, H.M.; Mahmood, S. Physico-chemical based mechanistic insight into surfactant modulated sodium Carboxymethylcellulose film for skin tissue regeneration applications. J. Polym. Res. 2020, 27, 1–11. [Google Scholar] [CrossRef]

- Easson, M.; Villalpando, A.; Condon, B.D. Absorbent Properties of Carboxymethylated Fiber, Hydroentangled Nonwoven and Regenerated Cellulose: A Comparative Study. J. Eng. Fibers Fabr. 2017, 12, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Parikh, D.; Fink, T.; Rajasekharan, K.; Sachinvala, N.; Sawhney, A.; Calamari, T.; Parikh, A.D. Antimicrobial silver/sodium carboxymethyl cotton dressings for burn wounds. Text. Res. J. 2005, 75, 134–138. [Google Scholar] [CrossRef]

- Parikh, D.; Sachinvala, N.; Calamari, T.; Negulescu, I. Carboxymethylated Cotton for Moist Wound Healing. AATCC Rev. 2003, 3, 15–19. [Google Scholar]

- Yang, X.H.; Zhu, W.L. Viscosity properties of sodium carboxymethylcellulose solutions. Cellulose 2007, 14, 409–417. [Google Scholar] [CrossRef]

- Ghannam, M.T.; Esmail, M.N. Rheological properties of carboxymethyl cellulose. J. Appl. Polym. Sci. 1997, 64, 289–301. [Google Scholar] [CrossRef]

- Verma, N.; Pramanik, K.; Singh, A.K.; Biswas, A. Design of magnesium oxide nanoparticle incorporated carboxy methyl cellulose/poly vinyl alcohol composite film with novel composition for skin tissue engineering. Mater. Technol. 2021, 1–11. [Google Scholar] [CrossRef]

- Mohan, T.; Dobaj Štiglic, A.; Beaumont, M.; Konnerth, J.; Gürer, F.; Makuc, D.; Maver, U.; Gradišnik, L.; Plavec, J.; Kargl, R. Generic Method for Designing Self-Standing and Dual Porous 3D Bioscaffolds from Cellulosic Nanomaterials for Tissue Engineering Applications. ACS Appl. Bio Mater. 2020, 3, 1197–1209. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.; Xie, F.; Tang, F.; McNally, T. Structure and properties of thermomechanically processed chitosan/carboxymethyl cellulose/graphene oxide polyelectrolyte complexed bionanocomposites. Int. J. Biol. Macromol. 2020, 158, 420–429. [Google Scholar] [CrossRef]

- Zheng, S.; Chen, H.; Zhang, T.; Yao, Y.; Chen, Y.; Zhang, S.; Bai, B. Gene-modified BMSCs encapsulated with carboxymethyl cellulose facilitate osteogenesis in vitro and in vivo. J. Biomater. Appl. 2021, 35, 814–822. [Google Scholar] [CrossRef] [PubMed]

- Sharmila, G.; Muthukumaran, C.; Kirthika, S.; Keerthana, S.; Kumar, N.M.; Jeyanthi, J. Fabrication and characterization of Spinacae olareacea extract incorporated alginate/carboxymethyl cellulose microporous scaffold for bone tissue engineering. Int. J. Biol. Macromol. 2020, 156, 430–437. [Google Scholar] [CrossRef]

- Sarkar, C.; Anuvrat, K.; Garai, S.; Sahu, S.K.; Chakraborty, J. One pot method to synthesize three-dimensional porous hydroxyapatite nanocomposite for bone tissue engineering. J. Porous Mater. 2020, 27, 225–235. [Google Scholar] [CrossRef]

- Matinfar, M.; Mesgar, A.S.; Mohammadi, Z. Evaluation of physicochemical, mechanical and biological properties of chitosan/carboxymethyl cellulose reinforced with multiphasic calcium phosphate whisker-like fibers for bone tissue engineering. Mater. Sci. Eng. C 2019, 100, 341–353. [Google Scholar] [CrossRef]

- Sadeghi, S.; Nourmohammadi, J.; Ghaee, A.; Soleimani, N. Carboxymethyl cellulose-human hair keratin hydrogel with controlled clindamycin release as antibacterial wound dressing. Int. J. Biol. Macromol. 2020, 147, 1239–1247. [Google Scholar] [CrossRef]

- Saladino, M.L.; Markowska, M.; Carmone, C.; Cancemi, P.; Alduina, R.; Presentato, A.; Scaffaro, R.; Biały, D.; Hasiak, M.; Hreniak, D. Graphene oxide carboxymethylcellulose nanocomposite for dressing materials. Materials 2020, 13, 1980. [Google Scholar] [CrossRef] [PubMed]

- Koneru, A.; Dharmalingam, K.; Anandalakshmi, R. Cellulose based nanocomposite hydrogel films consisting of sodium carboxymethylcellulose–grapefruit seed extract nanoparticles for potential wound healing applications. Int. J. Biol. Macromol. 2020, 148, 833–842. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Panda, N.; Mund, R.; Pramanik, K. Carboxymethyl cellulose enables silk fibroin nanofibrous scaffold with enhanced biomimetic potential for bone tissue engineering application. Carbohydr. Polym. 2016, 151, 335–347. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Fan, M. Chitosan/carboxymethyl cellulose polyelectrolyte complex scaffolds for pulp cells regeneration. J. Bioact. Compat. Polym. 2007, 22, 475–491. [Google Scholar] [CrossRef]

- Dahlan, N.A.; Pushpamalar, J.; Veeramachineni, A.K.; Muniyandy, S. Smart hydrogel of carboxymethyl cellulose grafted carboxymethyl polyvinyl alcohol and properties studied for future material applications. J. Polym. Environ. 2018, 26, 2061–2071. [Google Scholar] [CrossRef]

- Cai, X.; Hu, S.; Yu, B.; Cai, Y.; Yang, J.; Li, F.; Zheng, Y.; Shi, X. Transglutaminase-catalyzed preparation of crosslinked carboxymethyl chitosan/carboxymethyl cellulose/collagen composite membrane for postsurgical peritoneal adhesion prevention. Carbohydr. Polym. 2018, 201, 201–210. [Google Scholar] [CrossRef]

- Napoli, P.E.; Coronella, F.; Satta, G.M.; Zucca, I.A.; Fossarello, M. A novel OCT technique to measure in vivo the corneal adhesiveness for sodium carboxymethylcellulose in humans and its validity in the diagnosis of dry eye. Investig. Ophthalmol. Vis. Sci. 2014, 55, 3179–3185. [Google Scholar] [CrossRef] [Green Version]

- Mansur, A.A.; de Carvalho, F.G.; Mansur, R.L.; Carvalho, S.M.; de Oliveira, L.C.; Mansur, H.S. Carboxymethylcellulose/ZnCdS fluorescent quantum dot nanoconjugates for cancer cell bioimaging. Int. J. Biol. Macromol. 2017, 96, 675–686. [Google Scholar] [CrossRef]

- Javanbakht, S.; Nazeri, M.T.; Shaabani, A.; Ghorbani, M. Green one-pot synthesis of multicomponent-crosslinked carboxymethyl cellulose as a safe carrier for the gentamicin oral delivery. Int. J. Biol. Macromol. 2020, 164, 2873–2880. [Google Scholar] [CrossRef] [PubMed]

- Maver, U.; Xhanari, K.; Žižek, M.; Gradišnik, L.; Repnik, K.; Potočnik, U.; Finšgar, M. Carboxymethyl cellulose/diclofenac bioactive coatings on AISI 316LVM for controlled drug delivery, and improved osteogenic potential. Carbohydr. Polym. 2020, 230, 115612. [Google Scholar] [CrossRef] [PubMed]

- Tang, B.; Cheng, G.; Gu, J.-C.; Xu, C.-H. Development of solid self-emulsifying drug delivery systems: Preparation techniques and dosage forms. Drug Discov. Today 2008, 13, 606–612. [Google Scholar] [CrossRef] [PubMed]

- Schmidts, T.; Dobler, D.; Schlupp, P.; Nissing, C.; Garn, H.; Runkel, F. Development of multiple W/O/W emulsions as dermal carrier system for oligonucleotides: Effect of additives on emulsion stability. Int. J. Pharm. 2010, 398, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Inphonlek, S.; Sunintaboon, P.; Leonard, M.; Durand, A. Chitosan/carboxymethylcellulose-stabilized poly (lactide-co-glycolide) particles as bio-based drug delivery carriers. Carbohydr. Polym. 2020, 242, 116417. [Google Scholar] [CrossRef]

- Adeyeye, M.C.; Jain, A.C.; Ghorab, M.K.; Reilly, W.J. Viscoelastic evaluation of topical creams containing microcrystalline cellulose/sodium carboxymethyl cellulose as stabilizer. AAPS PharmSciTech 2002, 3, 16–25. [Google Scholar] [CrossRef]

- Sheikh, J.; Bramhecha, I.; Teli, M. Recycling of terry towel (cellulosic) waste into carboxymethyl cellulose (CMC) for textile printing. Fibers Polym. 2015, 16, 1113–1118. [Google Scholar] [CrossRef]

- Jeong, D.-S.; Chun, T.-I. Color Fastness of Digital Textile Printing on Silk Fabrics-The effect of the mixed pre-treatment agent. Fashion Text. Res. J. 2013, 15, 808–814. [Google Scholar] [CrossRef]

- Hebeish, A.; Higazy, A.; El-Shafei, A.; Sharaf, S. Synthesis of carboxymethyl cellulose (CMC) and starch-based hybrids and their applications in flocculation and sizing. Carbohydr. Polym. 2010, 79, 60–69. [Google Scholar] [CrossRef]

- Mohamed, Z.E.-S.; Amr, A.; Knittel, D.; Schollmeyer, E. Synthesis and application of new sizing and finishing additives based on carboxymethyl cellulose. Carbohydr. Polym. 2010, 81, 769–774. [Google Scholar] [CrossRef]

- Bozaci, E.; Akar, E.; Ozdogan, E.; Demir, A.; Altinisik, A.; Seki, Y. Application of carboxymethylcellulose hydrogel based silver nanocomposites on cotton fabrics for antibacterial property. Carbohydr. Polym. 2015, 134, 128–135. [Google Scholar] [CrossRef]

- Krizova, H.; Wiener, J. Development of carboxymethyl cellulose/polyphenols gels for textile applications. Autex Res. J. 2013, 13, 33–36. [Google Scholar] [CrossRef] [Green Version]

- Gorgieva, S.; Kokol, V. Synthesis and application of new temperature-responsive hydrogels based on carboxymethyl and hydroxyethyl cellulose derivatives for the functional finishing of cotton knitwear. Carbohydr. Polym. 2011, 85, 664–673. [Google Scholar] [CrossRef]

- Ebrahimi, Y.; Peighambardoust, S.J.; Peighambardoust, S.H.; Karkaj, S.Z. Development of Antibacterial Carboxymethyl Cellulose-Based Nanobiocomposite Films Containing Various Metallic Nanoparticles for Food Packaging Applications. J. Food Sci. 2019, 84, 2537–2548. [Google Scholar] [CrossRef] [PubMed]

- Mallett, A.; Wise, A.; Rowland, I. Hydrocolloid food additives and rat caecal microbial enzyme activities. Food Chem. Toxicol. 1984, 22, 415–418. [Google Scholar] [CrossRef]

- Bayarri, S.; González-Tomás, L.; Costell, E. Viscoelastic properties of aqueous and milk systems with carboxymethyl cellulose. Food Hydrocoll. 2009, 23, 441–450. [Google Scholar] [CrossRef]

- Fagbenro, O.; Jauncey, K. Water stability, nutrient leaching and nutritional properties of moist fermented fish silage diets. Aquac. Eng. 1995, 14, 143–153. [Google Scholar] [CrossRef]

- Cai, Z.; Wu, J.; Du, B.; Zhang, H. Impact of distribution of carboxymethyl substituents in the stabilizer of carboxymethyl cellulose on the stability of acidified milk drinks. Food Hydrocoll. 2018, 76, 150–157. [Google Scholar] [CrossRef]

- Veeramachineni, A.K.; Sathasivam, T.; Muniyandy, S.; Janarthanan, P.; Langford, S.J.; Yan, L.Y. Optimizing extraction of cellulose and synthesizing pharmaceutical grade carboxymethyl sago cellulose from malaysian sago pulp. Appl. Sci. 2016, 6, 170. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, W.; Fan, J.; Kan, T.; Zhang, W.; Liu, H.; Cheng, W.; Yang, H.; Wu, X.; Chen, H. Effect of sodium carboxymethyl cellulose addition on particulate matter emissions during biomass pellet combustion. Appl. Energy 2018, 230, 925–934. [Google Scholar] [CrossRef]

- Karkar, Z.; Guyomard, D.; Roué, L.; Lestriez, B. A comparative study of polyacrylic acid (PAA) and carboxymethyl cellulose (CMC) binders for Si-based electrodes. Electrochim. Acta 2017, 258, 453–466. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, T.; Yu, A. A carboxymethyl vegetable gum as a robust water soluble binder for silicon anodes in lithiumion batteries. J. Power Sources 2021, 489, 229530. [Google Scholar] [CrossRef]

- Dahbi, M.; Nakano, T.; Yabuuchi, N.; Ishikawa, T.; Kubota, K.; Fukunishi, M.; Shibahara, S.; Son, J.-Y.; Cui, Y.-T.; Oji, H. Sodium carboxymethyl cellulose as a potential binder for hard-carbon negative electrodes in sodium-ion batteries. Electrochem. Commun. 2014, 44, 66–69. [Google Scholar] [CrossRef]

- Yu, M.; Han, Y.; Li, J.; Wang, L. Magnetic N-doped carbon aerogel from sodium carboxymethyl cellulose/collagen composite aerogel for dye adsorption and electrochemical supercapacitor. Int. J. Biol. Macromol. 2018, 115, 185–193. [Google Scholar] [CrossRef]

- Yu, M.; Han, Y.; Li, J.; Wang, L. Three-dimensional porous carbon aerogels from sodium carboxymethyl cellulose/poly (vinyl alcohol) composite for high-performance supercapacitors. J. Porous Mater. 2018, 25, 1679–1689. [Google Scholar] [CrossRef]

- Sirajudheen, P.; Karthikeyan, P.; Vigneshwaran, S.; Meenakshi, S. Synthesis and characterization of La (III) supported carboxymethylcellulose-clay composite for toxic dyes removal: Evaluation of adsorption kinetics, isotherms and thermodynamics. Int. J. Biol. Macromol. 2020, 161, 1117–1126. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Omer, A.; Ouyang, X.-K. Adsorptive removal of cationic methylene blue dye using carboxymethyl cellulose/k-carrageenan/activated montmorillonite composite beads: Isotherm and kinetic studies. Int. J. Biol. Macromol. 2018, 106, 823–833. [Google Scholar] [CrossRef]

- Sirajudheen, P.; Nikitha, M.R.; Karthikeyan, P.; Meenakshi, S. Perceptive removal of toxic azo dyes from water using magnetic Fe3O4 reinforced graphene oxide–carboxymethyl cellulose recyclable composite: Adsorption investigation of parametric studies and their mechanisms. Surf. Interfaces 2020, 21, 100648. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; Abdou, A.E.; Sobhy, M.E.; Fekry, N.A. Solid–solid crosslinking of carboxymethyl cellulose nanolayer on titanium oxide nanoparticles as a novel biocomposite for efficient removal of toxic heavy metals from water. Int. J. Biol. Macromol. 2017, 105, 1269–1278. [Google Scholar] [CrossRef] [PubMed]

- Kong, Q.; Preis, S.; Li, L.; Luo, P.; Hu, Y.; Wei, C. Graphene oxide-terminated hyperbranched amino polymer-carboxymethyl cellulose ternary nanocomposite for efficient removal of heavy metals from aqueous solutions. Int. J. Biol. Macromol. 2020, 149, 581–592. [Google Scholar] [CrossRef]

- Lam, B.; Déon, S.; Morin-Crini, N.; Crini, G.; Fievet, P. Polymer-enhanced ultrafiltration for heavy metal removal: Influence of chitosan and carboxymethyl cellulose on filtration performances. J. Clean. Prod. 2018, 171, 927–933. [Google Scholar] [CrossRef]

- Zong, P.; Cao, D.; Cheng, Y.; Wang, S.; Zhang, J.; Guo, Z.; Hayat, T.; Alharbi, N.S.; He, C. Carboxymethyl cellulose supported magnetic graphene oxide composites by plasma induced technique and their highly efficient removal of uranium ions. Cellulose 2019, 26, 4039–4060. [Google Scholar] [CrossRef]

- Cai, Y.; Yuan, F.; Wang, X.; Sun, Z.; Chen, Y.; Liu, Z.; Wang, X.; Yang, S.; Wang, S. Synthesis of core–shell structured Fe3O4@ carboxymethyl cellulose magnetic composite for highly efficient removal of Eu (III). Cellulose 2017, 24, 175–190. [Google Scholar] [CrossRef]

- Fatehi, P.; Kititerakun, R.; Ni, Y.; Xiao, H. Synergy of CMC and modified chitosan on strength properties of cellulosic fiber network. Carbohydr. Polym. 2010, 80, 208–214. [Google Scholar] [CrossRef]

- Fatehi, P.; Qian, L.; Kititerakun, R.; Rirksomboon, T.; Xiao, H. Complex formation of modified chitosan and carboxymethyl cellulose and its effect on paper properties. Tappi J. 2009, 8, 29–35. [Google Scholar] [CrossRef]

- Basta, A.H.; El-Saied, H. New approach for utilization of cellulose derivatives metal complexes in preparation of durable and permanent colored papers. Carbohydr. Polym. 2008, 74, 301–308. [Google Scholar] [CrossRef]

- Gencoglu, E.N.; Ozden, O.; Simseker, O. Effects of carboxymethyl cellulose as a surface sizing agent on the printable properties of newspaper. Asian J. Chem. 2010, 22, 5561. [Google Scholar]

- Obele, C.M.; Ibenta, M.E.; Chukwuneke, J.L.; Nwanonenyi, S.C. Carboxymethyl cellulose and cellulose nanocrystals from cassava stem as thickeners in reactive printing of cotton. Cellulose 2021, 28, 2615–2633. [Google Scholar] [CrossRef]

- Qiao, Z.; Gu, J.; Zuo, Y.; Tan, H.; Zhang, Y. The effect of carboxymethyl cellulose addition on the properties of starch-based wood adhesive. BioResources 2014, 9, 6117–6129. [Google Scholar] [CrossRef] [Green Version]

- Lestriez, B.; Bahri, S.; Sandu, I.; Roué, L.; Guyomard, D. On the binding mechanism of CMC in Si negative electrodes for Li-ion batteries. Electrochem. Commun. 2007, 9, 2801–2806. [Google Scholar] [CrossRef]

- Huang, F.Y.; Wu, X.J.; Ying, W.F.; Yu, Y.P.; Chi, H.X. Effect of carboxylmethyl cellulose sulfate (CMC-S) on the hydration process of cement paste. Adv. Mater. Res. 2014, 838, 123–126. [Google Scholar] [CrossRef]

- Akbar, A.Y.; Lestari, Y.; Ramadhan, G.; Candra, S.A.; Sugiarti, E. The influence of carboxy methyl cellulose (CMC) and solution pH on carbon fiber dispersion in white cement matrix. Appl. Mech. Mater. 2014, 493, 661–665. [Google Scholar] [CrossRef]

- Haberle, J.E. Calamine lotion prepared with microcrystalline cellulose. Am. J. Hosp. Pharm. 1968, 25, 180–182. [Google Scholar] [CrossRef] [PubMed]

- Musani, S.; Dugal, R.; Kothavade, M. A review of denture adhesives used in the dental profession. Ann. Essences Dent. 2010, 2, 129–133. [Google Scholar]

- Agarwal, C.; Ilindra, A.; Karadbhajne, V. Carboxymethyl cellulose versus microcrystalline cellulose in the manufacturing of liquid detergents. Indian J. Chem. Technol. 2012, 19, 149–151. [Google Scholar]

- Raafat, A.I.; Eid, M.; El-Arnaouty, M.B. Radiation synthesis of superabsorbent CMC based hydrogels for agriculture applications. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2012, 283, 71–76. [Google Scholar] [CrossRef]

- Sutradhar, S.C.; Khan, M.M.R.; Rahman, M.M.; Dafadar, N.C. The Synthesis of Superabsorbent Polymers from a Carboxymethylcellulose/acrylic Acid Blend Using Gamma Radiation and its Application in Agriculture. J. Phys. Sci. 2015, 26, 23–39. [Google Scholar]

- Dolz, M.; Jiménez, J.; Hernández, M.J.; Delegido, J.; Casanovas, A. Flow and thixotropy of non-contaminating oil drilling fluids formulated with bentonite and sodium carboxymethyl cellulose. J. Pet. Sci. Eng. 2007, 57, 294–302. [Google Scholar] [CrossRef]

- da Luz, R.C.; Fagundes, F.P.; Balaban, R.D.C. Water-based drilling fluids: The contribution of xanthan gum and carboxymethylcellulose on filtration control. Chem. Pap. 2017, 71, 2365–2373. [Google Scholar] [CrossRef]

- Yadollahi, M.; Namazi, H.; Barkhordari, S. Preparation and properties of carboxymethyl cellulose/layered double hydroxide bionanocomposite films. Carbohydr. Polym. 2014, 108, 83–90. [Google Scholar] [CrossRef]

- Rienzie, R.; Sendanayake, L.; De Costa, D.; Hossain, A.; Brestic, M.; Skalicky, M.; Vachova, P.; Adassooriya, N.M. Assessing the Carboxymethylcellulose Copper-Montmorillonite Nanocomposite for Controlling the Infection of Erwinia carotovora in Potato (Solanum tuberosum L.). Nanomaterials 2021, 11, 802. [Google Scholar] [CrossRef]

- Wongvitvichot, W.; Pithakratanayothin, S.; Wongkasemjit, S.; Chaisuwan, T. Fast and practical synthesis of carboxymethyl cellulose from office paper waste by ultrasonic assisted technique at ambient temperature. Polym. Degrad. Stabil. 2021, 184, 109473. [Google Scholar] [CrossRef]

- Hollabaugh, C.; Burt, L.H.; Walsh, A.P. Carboxymethylcellulose. Uses and applications. Ind. Eng. Chem. 1945, 37, 943–947. [Google Scholar] [CrossRef]

- Heinze, T.; Koschella, A. Carboxymethyl ethers of cellulose and starch—A review. Macromol. Symp. 2005, 223, 13–40. [Google Scholar] [CrossRef]

- Kukrety, A.; Singh, R.K.; Singh, P.; Ray, S.S. Comprehension on the synthesis of carboxymethylcellulose (CMC) utilizing various cellulose rich waste biomass resources. Waste Biomass Valor. 2018, 9, 1587–1595. [Google Scholar] [CrossRef]

- Abraham, J.; Sharika, T.; Mishra, R.; Thomas, S. Rheological characteristics of nanomaterials and nanocomposites. In Micro and Nano Fibrillar Composites (MFCs and NFCs) from Polymer Blends; Raghvendra, K.M., Sabu, T., Nandakumar, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 327–350. [Google Scholar]

- Morris, B.A. Rheology of Polymer Melts. In The Science and Technology of Flexible Packaging, 1st ed.; William Andrew: Oxford, UK, 2017; pp. 121–147. [Google Scholar]

- Benchabane, A.; Bekkour, K. Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym. Sci. 2008, 286, 1173. [Google Scholar] [CrossRef]

- Edali, M.; Esmail, M.N.; Vatistas, G.H. Rheological properties of high concentrations of carboxymethyl cellulose solutions. J. Appl. Polym. Sci. 2001, 79, 1787–1801. [Google Scholar] [CrossRef]

- Feddersen, R.L.; Thorp, S.N. Sodium carboxymethylcellulose. In Industrial Gums, 3rd ed.; Whistler, R.L., Bemiller, J.N., Eds.; Elsevie: Amsterdam, The Netherlands, 1993; pp. 537–578. [Google Scholar]

- Roy, N.; Saha, N.; Kitano, T.; Saha, P. Novel hydrogels of PVP–CMC and their swelling effect on viscoelastic properties. J. Appl. Polym. Sci. 2010, 117, 1703–1710. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, D.J.; Singh, A.; Gaur, S.R.; Shenoy, A.V. Viscoelastic properties of borax loaded CMC-g-cl-poly (AAm) hydrogel composites and their boron nutrient release behavior. J. Appl. Polym. Sci. 2016, 133, 43969. [Google Scholar] [CrossRef]

- Dong, S.; Feng, S.; Liu, F.; Li, R.; Li, W.; Liu, F.; Shi, G.; Chen, L.; Zhang, Y. Factors influencing the adhesive behavior of carboxymethyl cellulose-based hydrogel for food applications. Int. J. Biol. Macromol. 2021, 179, 398–406. [Google Scholar] [CrossRef]

- BeMiller, J.N. Polysaccharides. In Carbohydrate Chemistry for Food Scientists, 3rd ed.; Elsevier: New York, NY, USA, 2019; pp. 103–157. [Google Scholar]

- Dorey, R. Thick-film deposition techniques: How to make thick films—the processing techniques used to create films. In Ceramic Thick Films for MEMS and Microdevices, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 63–83. [Google Scholar]

- Rachtanapun, P.; Jantrawut, P.; Klunklin, W.; Jantanasakulwong, K.; Phimolsiripol, Y.; Leksawasdi, N.; Seesuriyachan, P.; Chaiyaso, T.; Insomphun, C.; Phongthai, S.; et al. Carboxymethyl bacterial cellulose from nata de coco: Effects of NaOH. Polymers 2021, 13, 348. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.Q.; Lou, D.P. Synthesis of sodium carboxymethyl cellulose based on pretreated bamboo shaving. Adv. Mater. Res. 2014, 997, 169–172. [Google Scholar] [CrossRef]

- Mondal, M.I.H.; Ahmed, F. Synthesis and grafting of carboxymethyl cellulose from environmental pollutant cellulosic wastes of textile industry. Res. J. Text. Appar. 2016, 20, 126–135. [Google Scholar] [CrossRef]

- Yeasmin, M.S.; Mondal, M.I.H. Synthesis of highly substituted carboxymethyl cellulose depending on cellulose particle size. Int. J. Biol. Macromol. 2015, 80, 725–731. [Google Scholar] [CrossRef] [PubMed]

- Theeuwen, C.; Dijk, B. Use of Carboxymethyl Cellulose (CMC) in Fruit-Based Products. U.S. Patent US20060029711A1, 9 February 2006. [Google Scholar]

- Abu-Jdayil, B.; Ghannam, M. The modification of rheological properties of sodium bentonite-water dispersions with low viscosity CMC polymer effect. Energ. Source Part A 2014, 36, 1037–1048. [Google Scholar] [CrossRef]

- Sundaram, H.; Voigts, B.; Beer, K.; Meland, M. Comparison of the rheological properties of viscosity and elasticity in two categories of soft tissue fillers: Calcium hydroxylapatite and hyaluronic acid. Dermatol. Surg. 2010, 36, 1859–1865. [Google Scholar] [CrossRef] [PubMed]

- Hamdan, M.A.; Ramli, N.A.; Othman, N.A.; Amin, K.N.M.; Adam, F. Characterization and property investigation of microcrystalline cellulose (MCC) and carboxymethyl cellulose (CMC) filler on the carrageenan-based biocomposite film. Mater. Today Proc. 2020, 42, 56–62. [Google Scholar] [CrossRef]

- Karakus, S.; Ilgar, M.; Tan, E.; Kahyaoglu, I.M.; Tasaltin, N.; Albayrak, I.; Insel, M.A.; Kilislioglu, A. Preparation and characterization of carboxymethyl cellulose/poly (ethylene glycol)-rosin pentaerythritolester polymeric nanoparticles: Role of intrinsic viscosity and surface morphology. Surf. Interfaces 2020, 21, 100642. [Google Scholar] [CrossRef]

- Arancibia, C.; Navarro-Lisboa, R.; Zúñiga, R.N.; Matiacevich, S. Application of CMC as thickener on nanoemulsions based on olive oil: Physical properties and stability. Int. J. Polym. Sci. 2016, 2016. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.S.; Alam, M.N.; van de Ven, T.G. Sustainable cellulose-based hydrogel for dewatering of orange juice. Cellulose 2020, 27, 7637–7648. [Google Scholar] [CrossRef]

- Birsan, M.; Bibire, N.; Panainte, A.D.; Silasi, O.; Antonoaea, P.; Ciurba, A.; Cristofor, A.C.; Wroblewska, M.; Sosnowska, K.J.N. The Influence of the Preparation Method on the Characteristics of a New Cosmetic Gel Based on Hyaluronic Acid and Matrix-Forming Polymers. Mater. Plast. 2020, 57, 123–130. [Google Scholar] [CrossRef]

- Casaburi, A.; Rojo, Ú.M.; Cerrutti, P.; Vázquez, A.; Foresti, M.L. Carboxymethyl cellulose with tailored degree of substitution obtained from bacterial cellulose. Food Hydrocoll. 2018, 75, 147–156. [Google Scholar] [CrossRef]

- Xiquan, L.; Tingzhu, Q.; Shaoqui, Q. Kinetics of the carboxymethylation of cellulose in the isopropyl alcohol system. Acta Polym. 1990, 41, 220–222. [Google Scholar] [CrossRef]

- Ergun, R.; Guo, J.; Huebner-Keese, B. Cellulose. In Encyclopedia of Food and Health, 1st ed.; Caballero, B., Finglas, P., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 694–702. [Google Scholar]

- Hon, D.N.-S. Cellulose: Chemistry and Technology. In Encyclopedia of Materials: Science and Technology, 1st ed.; Buschow, K.H.J., Cahn, R., Flemings, M., Ilschner, B., Kramer, E., Mahajan, S., Veyssiere, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 1039–1045. [Google Scholar]

- BeMiller, J.N. Cellulose and Cellulose-Based Hydrocolloids. In Carbohydrate Chemistry for Food Scientists, 3rd ed.; Elsevier: New York, NY, USA, 2019; pp. 223–240. [Google Scholar]

- Alabi, F.; Lajide, L.; Ajayi, O.; Adebayo, A.; Emmanuel, S.; Fadeyi, A. Synthesis and characterization of carboxymethyl cellulose from Musa paradisiaca and Tithonia diversifolia. Afr. J. Pure Appl. Chem. 2020, 14, 9–23. [Google Scholar] [CrossRef]

- Huang, C.; Chia, P.; Lim, C.S.; Nai, J.; Ding, D.Y.; Seow, P.; Wong, C.W.; Chan, E.W. Synthesis and characterisation of carboxymethyl cellulose from various agricultural wastes. Cellul. Chem. Technol. 2017, 51, 665–672. [Google Scholar]

- Kimani, P.; Kareru, P.; Madivoli, S.; Kairigo, P.; Maina, E.; Rechab, O. Comparative study of carboxymethyl cellulose synthesis from selected Kenyan biomass. Chem. Sci. Int. J. 2016, 17, 1–8. [Google Scholar] [CrossRef]

- Lakshmi, D.S.; Trivedi, N.; Reddy, C.R.K. Synthesis and characterization of seaweed cellulose derived carboxymethyl cellulose. Carbohydr. Polym. 2017, 157, 1604–1610. [Google Scholar] [CrossRef]

- Toğrul, H.; Arslan, N. Production of carboxymethyl cellulose from sugar beet pulp cellulose and rheological behaviour of carboxymethyl cellulose. Carbohydr. Polym. 2003, 54, 73–82. [Google Scholar] [CrossRef]

- Mondal, M.I.H.; Rahman, M.S.; Yeasmin, M.S.; Sayeed, M.A. Synthesis of carboxymethyl cellulose from corn leaves based on particle size-A new aspect. In Cellulose and Cellulose Derivatives; Mondal, M.I.H., Ed.; Nova Science Publisher: New York, NY, USA, 2015; p. 205. [Google Scholar]

- Chen, J.; Li, H.; Fang, C.; Cheng, Y.; Tan, T.; Han, H. Synthesis and structure of carboxymethylcellulose with a high degree of substitution derived from waste disposable paper cups. Carbohydr. Polym. 2020, 237, 116040. [Google Scholar] [CrossRef]

- Saputra, A.H.; Qadhayna, L.; Pitaloka, A.B. Synthesis and characterization of carboxymethyl cellulose (CMC) from water hyacinth using ethanol-isobutyl alcohol mixture as the solvents. Int. J. Chem. Eng. Appl. 2014, 5, 36–40. [Google Scholar] [CrossRef] [Green Version]

- Ibikunle, A.; Ogunneye, A.; Soga, I.; Sanyaolu, N.; Yussuf, S.; Sonde, O.; Badejo, O. Food grade carboxymethyl cellulose preparation from African star apple seed (Chrysophyllum albidum) shells: Optimization and characterization. Ife J. Sci. 2019, 21, 245–255. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.; Mondal, H.; Ibrahim, M.; Yeasmin, M.; Sayeed, M.A.; Hossain, M.A.; Ahmed, M.B. Conversion of lignocellulosic corn agro-waste into cellulose derivative and its potential application as pharmaceutical excipient. Processes 2020, 8, 711. [Google Scholar] [CrossRef]

- Jett, C.; Arthur, J. Chemical Modification of Cellulose and its Derivatives. In Comprehensive Polymer Science and Supplements; Elsevier: Amsterdam, The Netherlands, 1989; Volume 6, pp. 49–80. [Google Scholar]

- Coffey, D.; Bell, D.; Henderson, A. Cellulose and cellulose derivatives. In Food Polysaccharides and Their Applications, 2nd ed.; Am, S., Phillips, G.O., Williams, P., Eds.; Woodhead Publishers: Cambridge, UK, 2006; Chapter 5; pp. 147–180. [Google Scholar]

- Du, B.; Li, J.; Zhang, H.; Huang, L.; Chen, P.; Zhou, J. Influence of molecular weight and degree of substitution of carboxymethylcellulose on the stability of acidified milk drinks. Food Hydrocoll. 2009, 23, 1420–1426. [Google Scholar] [CrossRef]

- Komorowska, P.; Różańska, S.; Różański, J. Effect of the degree of substitution on the rheology of sodium carboxymethylcellulose solutions in propylene glycol/water mixtures. Cellulose 2017, 24, 4151–4162. [Google Scholar] [CrossRef]

- Wang, Y.; Pillai, P.K.; Nickerson, M.T. Effect of molecular mass and degree of substitution of carboxymethyl cellulose on the formation electrostatic complexes with lentil protein isolate. Food Res. Int. 2019, 126, 108652. [Google Scholar] [CrossRef]

- Lee, B.-R.; Oh, E.-S. Effect of molecular weight and degree of substitution of a sodium-carboxymethyl cellulose binder on Li4Ti5O12 anodic performance. J. Phys. Chem. C 2013, 117, 4404–4409. [Google Scholar] [CrossRef]

- Huang, R.; Cao, M.; Guo, H.; Qi, W.; Su, R.; He, Z. Enhanced ethanol production from pomelo peel waste by integrated hydrothermal treatment, multienzyme formulation, and fed-batch operation. J. Agric. Food Chem. 2014, 62, 4643–4651. [Google Scholar] [CrossRef] [PubMed]

- Meenakshi, P.; Noorjahan, S.; Rajini, R.; Venkateswarlu, U.; Rose, C.; Sastry, T. Mechanical and microstructure studies on the modification of CA film by blending with PS. Bull. Mater. Sci. 2002, 25, 25–29. [Google Scholar] [CrossRef]

- Fu, J.; Yang, X.; Yu, C. Preliminary research on bamboo degumming with xylanase. Biocatal. Biotransform. 2008, 26, 450–454. [Google Scholar] [CrossRef]

- Fu, J.; Li, X.; Gao, W.; Wang, H.; Cavaco-Paulo, A.; Silva, C. Bio-processing of bamboo fibres for textile applications: A mini review. Biocatal. Biotransform. 2012, 30, 141–153. [Google Scholar] [CrossRef]

- Ding, X.; Dai, R.; Chen, H.; Shan, Z. Gelatin as green adhesive for the preparation of a multifunctional biobased cryogel derived from bamboo industrial waste. Carbohydr. Polym. 2021, 255, 117340. [Google Scholar] [CrossRef] [PubMed]

- Tasaso, P. Optimization of reaction conditions for synthesis of carboxymethyl cellulose from oil palm fronds. Int. J. Chem. Eng. Appl. 2015, 6, 101. [Google Scholar] [CrossRef] [Green Version]

- Ott, E.; Spurlin, H.M.; Grafflin, M.W.; Bikales, N.M.; Segal, L. Cellulose and Cellulose Derivatives, 2nd ed.; Interscience Publishers: New York, NY, USA, 1954; Volume 5. [Google Scholar]

- Hivechi, A.; Bahrami, S.H.; Arami, M.; Karimi, A. Ultrasonic mediated production of carboxymethyl cellulose: Optimization of conditions using response surface methodology. Carbohydr. Polym. 2015, 134, 278–284. [Google Scholar] [CrossRef]

- Li, S.; Zhou, G.; Liu, Z.; Wang, N.; Wei, Z.; Liu, W. Synthesis and performance characteristics of a new ecofriendly crust-dust suppressant extracted from waste paper for surface mines. J. Clean. Prod. 2020, 258, 120620. [Google Scholar] [CrossRef]

- Prasad, D.Y.; Heitmann, J.A.; Joyce, T.W. Enzymatic deinking of colored offset newsprint. Nord. Pulp Pap. Res. J. 1993, 8, 284–286. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Rattanapanone, N. Synthesis and characterization of carboxymethyl cellulose powder and films from Mimosa pigra. J. Appl. Polym. Sci. 2011, 122, 3218–3226. [Google Scholar] [CrossRef]

- Ibrahim, A.A.; Adel, A.M.; Abd El-Wahab, Z.H.; Al-Shemy, M.T. Utilization of carboxymethyl cellulose based on bean hulls as chelating agent. Synthesis, characterization and biological activity. Carbohydr. Polym. 2011, 83, 94–115. [Google Scholar] [CrossRef]

- Vieira, M.; Heinze, T.; Antonio-Cruz, R.; Mendoza-Martinez, A. Cellulose derivatives from cellulosic material isolated from Agave lechuguilla and fourcroydes. Cellulose 2002, 9, 203–212. [Google Scholar] [CrossRef]

- Bi, Y.; Liu, M.; Wu, L.; Cui, D. Synthesis of carboxymethyl potato starch and comparison of optimal reaction conditions from different sources. Polym. Adv. Technol. 2008, 19, 1185–1192. [Google Scholar] [CrossRef]

- Mastrantonio, G.; Battaioto, L.; Jones, C.; Coustet, M.; Chandi, H.; Yamul, D.K. Chemical conversion of paper industry effluents into carboxymethylcellulose. Process Saf. Environ. Prot. 2015, 94, 315–321. [Google Scholar] [CrossRef]

- Silva, D.A.; De Paula, R.C.; Feitosa, J.P.; De Brito, A.C.; Maciel, J.S.; Paula, H.C. Carboxymethylation of cashew tree exudate polysaccharide. Carbohydr. Polym. 2004, 58, 163–171. [Google Scholar] [CrossRef]

- Barai, B.K.; Singhal, R.S.; Kulkarni, P. Optimization of a process for preparing carboxymethyl cellulose from water hyacinth (Eichornia crassipes). Carbohydr. Polym. 1997, 32, 229–231. [Google Scholar] [CrossRef]

- Bhandari, P.N.; Jones, D.D.; Hanna, M.A. Carboxymethylation of cellulose using reactive extrusion. Carbohydr. Polym. 2012, 87, 2246–2254. [Google Scholar] [CrossRef]

- An, F.; Fang, K.; Liu, X.; Li, C.; Liang, Y.; Liu, H. Rheological properties of carboxymethyl hydroxypropyl cellulose and its application in high quality reactive dye inkjet printing on wool fabrics. Int. J. Biol. Macromol. 2020, 164, 4173–4182. [Google Scholar] [CrossRef]

- Kolman, K.; Nechyporchuk, O.; Persson, M.; Holmberg, K.; Bordes, R. Preparation of silica/polyelectrolyte complexes for textile strengthening applied to painting canvas restoration. Colloids Surf. A Physicochem. Eng. Asp. 2017, 532, 420–427. [Google Scholar] [CrossRef]

- Varaprasad, K.; Jayaramudu, T.; Sadiku, E.R. Removal of dye by carboxymethyl cellulose, acrylamide and graphene oxide via a free radical polymerization process. Carbohydr. Polym. 2017, 164, 186–194. [Google Scholar] [CrossRef]

- Suchý, P.; Paprskářová, A.; Chalupová, M.; Marholdová, L.; Nešporová, K.; Klusáková, J.; Kuzmínová, G.; Hendrych, M.; Velebný, V. Composite Hemostatic Nonwoven Textiles Based on Hyaluronic Acid, Cellulose, and Etamsylate. Mater. Corros. 2020, 13, 1627. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roy, J.; Ferri, A.; Salaün, F.; Giraud, S.; Chen, G.; Jinping, G. Chitosan-carboxymethylcellulose based microcapsules formulation for controlled release of active ingredients from cosmeto textile. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 072020. [Google Scholar] [CrossRef]

- Tenorová, K.; Masteiková, R.; Jarábková, J.; Vetchý, D.; Bernatonien, J. Collagen in combination with the acid form of carboxymethylcellulose in the form of a nonwoven textile as a modern wound dressing-formulation, preparation and evaluation. Ces. Slov. Farm. 2020, 69, 163–171. [Google Scholar]

- Miao, Y.; Wan, L.; Ling, X.; Chen, B.; Pan, L.; Gao, Y. Mask-free preparation of patterned carbonized carboxymethyl cellulose on fabrics for flexible electronics. ACS Appl. Electron. Mater. 2020, 2, 855–862. [Google Scholar] [CrossRef]

- Montaser, A.S.; Jlassi, K.; Ramadan, M.A.; Selem, A.A.; Attia, M.F. Alginate, gelatin, and carboxymethyl cellulose coated nonwoven fabrics containing antimicrobial AgNPs for skin wound healing in rats. Int. J. Biol. Macromol. 2021, 173, 203–210. [Google Scholar] [CrossRef]

- Liu, B.; Hu, J. The application of temperature-sensitive hydrogels to textiles: A review of Chinese and Japanese investigations. Fibres Text. East. Eur. 2005, 13, 45–49. [Google Scholar]

- Promphet, N.; Rattanawaleedirojn, P.; Siralertmukul, K.; Soatthiyanon, N.; Potiyaraj, P.; Thanawattano, C.; Hinestroza, J.P.; Rodthongkum, N. Non-invasive textile based colorimetric sensor for the simultaneous detection of sweat pH and lactate. Talanta 2019, 192, 424–430. [Google Scholar] [CrossRef] [PubMed]

- Dickinson, E. Hydrocolloids as emulsifiers and emulsion stabilizers. Food Hydrocoll. 2009, 23, 1473–1482. [Google Scholar] [CrossRef]

- Meyers, S.; Butler, D.; Hastings, W. Alginates as binders for crustacean rations. Progress. Fish Cult. 1972, 34, 9–12. [Google Scholar] [CrossRef]

- Lee, H.; Yoo, B. Agglomerated xanthan gum powder used as a food thickener: Effect of sugar binders on physical, microstructural, and rheological properties. Powder Technol. 2020, 362, 301–306. [Google Scholar] [CrossRef]

- Zhang, L.-M. New Water-Soluble Cellulosic Polymers: A Review. Macromol. Mater. Eng. 2001, 286, 267–275. [Google Scholar] [CrossRef]

- McClements, D.J. Food Emulsions: Principles, Practices, and Techniques, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Mirhosseini, H.; Tan, C.P.; Aghlara, A.; Hamid, N.S.; Yusof, S.; Chern, B.H. Influence of pectin and CMC on physical stability, turbidity loss rate, cloudiness and flavor release of orange beverage emulsion during storage. Carbohydr. Polym. 2008, 73, 83–91. [Google Scholar] [CrossRef]

- Arancibia, C.; Bayarri, S.; Costell, E. Comparing carboxymethyl cellulose and starch as thickeners in oil/water emulsions. Implications on rheological and structural properties. Food Biophys. 2013, 8, 122–136. [Google Scholar] [CrossRef]

- Bayarri, S.; Chuliá, I.; Costell, E. Comparing λ-carrageenan and an inulin blend as fat replacers in carboxymethyl cellulose dairy desserts. Rheological and sensory aspects. Food Hydrocoll. 2010, 24, 578–587. [Google Scholar] [CrossRef] [Green Version]

- Sebayang, F.; Sembiring, H. Synthesis of CMC from palm midrib cellulose as stabilizer and thickening agent in food. Orient. J. Chem. 2017, 33, 519–530. [Google Scholar] [CrossRef] [Green Version]

- Bosso, A.; Salmaso, D.; De Faveri, E.; Guaita, M.; Franceschi, D. The use of carboxymethylcellulose for the tartaric stabilization of white wines, in comparison with other oenological additives. J. Vitis 2010, 49, 95–99. [Google Scholar]

- Liu, X.; Mu, T.; Sun, H.; Zhang, M.; Chen, J.; Fauconnier, M.L. Influence of different hydrocolloids on dough thermo mechanical properties and in vitro starch digestibility of gluten free steamed bread based on potato flour. Food Chem. 2018, 239, 1064–1074. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hajmohammadi, A.; Pirouzifard, M.; Shahedi, M.; Alizadeh, M. Enrichment of a fruit-based beverage in dietary fiber using basil seed: Effect of carboxymethyl cellulose and gum tragacanth on stability. LWT Food Sci. Technol. 2016, 74, 84–91. [Google Scholar] [CrossRef]

- Dafe, A.; Etemadi, H.; Zarredar, H.; Mahdavinia, G.R. Development of novel carboxymethyl cellulose/k-carrageenan blends as an enteric delivery vehicle for probiotic bacteria. Int. J. Biol. Macromol. 2017, 97, 299–307. [Google Scholar] [CrossRef]

- Ngamekaue, N.; Chitprasert, P. Effects of beeswax-carboxymethyl cellulose composite coating on shelf-life stability and intestinal delivery of holy basil essential oil-loaded gelatin microcapsules. Int. J. Biol. Macromol. 2019, 135, 1088–1097. [Google Scholar] [CrossRef] [PubMed]

- Raeisi, M.; Tajik, H.; Aliakbarlu, J.; Mirhosseini, S.H.; Hosseini, S.M.H. Effect of carboxymethyl cellulose-based coatings incorporated with Zataria multiflora Boiss. essential oil and grape seed extract on the shelf life of rainbow trout fillets. LWT Food Sci. Technol. 2015, 64, 898–904. [Google Scholar] [CrossRef]

- Gibis, M.; Schuh, V.; Weiss, J. Effects of carboxymethyl cellulose (CMC) and microcrystalline cellulose (MCC) as fat replacers on the microstructure and sensory characteristics of fried beef patties. Food Hydrocoll. 2015, 45, 236–246. [Google Scholar] [CrossRef]

- Han, M.; Bertram, H.C. Designing healthier comminuted meat products: Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Khezrian, A.; Shahbazi, Y. Application of nanocompostie chitosan and carboxymethyl cellulose films containing natural preservative compounds in minced camel’s meat. Int. J. Biol. Macromol. 2018, 106, 1146–1158. [Google Scholar] [CrossRef]

- Roy, N.; Saha, N.; Kitano, T.; Saha, P. Biodegradation of PVP–CMC hydrogel film: A useful Food Packag. material. Carbohydr. Polym. 2012, 89, 346–353. [Google Scholar] [CrossRef]

- Youssef, H.; El-Naggar, M.E.; Fouda, F.; Youssef, A.M. Antimicrobial packaging film based on biodegradable CMC/PVA-zeolite doped with noble metal cations. Food Packag. 2019, 22, 100378. [Google Scholar] [CrossRef]

- Akhtar, H.M.S.; Riaz, A.; Hamed, Y.S.; Abdin, M.; Chen, G.; Wan, P.; Zeng, X. Production and characterization of CMC-based antioxidant and antimicrobial films enriched with chickpea hull polysaccharides. Int. J. Biol. Macromol. 2018, 118, 469–477. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Gu, L.; Zhang, Y.; Chen, H.; Jiang, B.; Zhao, H.; Jin, Y.; Xiao, H. Bioinspired self-assembled films of carboxymethyl cellulose–dopamine/montmorillonite. J. Mater. Chem. A 2019, 7, 14033–14041. [Google Scholar] [CrossRef]

- Yu, M.; Li, J.; Wang, L. KOH-activated carbon aerogels derived from sodium carboxymethyl cellulose for high-performance supercapacitors and dye adsorption. Chem. Eng. J. 2017, 310, 300–306. [Google Scholar] [CrossRef]

- Tanzifi, M.; Yaraki, M.T.; Beiramzadeh, Z.; Saremi, L.H.; Najafifard, M.; Moradi, H.; Mansouri, M.; Karami, M.; Bazgir, H. Carboxymethyl cellulose improved adsorption capacity of polypyrrole/CMC composite nanoparticles for removal of reactive dyes: Experimental optimization and DFT calculation. Chemosphere 2020, 255, 127052. [Google Scholar] [CrossRef] [PubMed]

- Salama, A.; Etri, S.; Mohamed, S.A.; El-Sakhawy, M. Carboxymethyl cellulose prepared from mesquite tree: New source for promising nanocomposite materials. Carbohydr. Polym. 2018, 189, 138–144. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, Y.; Wang, X.; Sun, Z.; Ma, J.; Wu, T.; Xing, F.; Gao, J. Porous graphene oxide/carboxymethyl cellulose monoliths, with high metal ion adsorption. Carbohydr. Polym. 2014, 101, 392–400. [Google Scholar] [CrossRef]

- Godiya, C.B.; Cheng, X.; Li, D.; Chen, Z.; Lu, X. Carboxymethyl cellulose/polyacrylamide composite hydrogel for cascaded treatment/reuse of heavy metal ions in wastewater. J. Hazard. Mater. 2019, 364, 28–38. [Google Scholar] [CrossRef] [PubMed]

- Eberhardt, T.L.; Min, S.-H.; Han, J.S. Phosphate removal by refined aspen wood fiber treated with carboxymethyl cellulose and ferrous chloride. Bioresour. Technol. 2006, 97, 2371–2376. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.H.; Okabe, H.; Hidaka, Y.; Hara, K. Removal of metal ions from aqueous solutions using carboxymethyl cellulose/sodium styrene sulfonate gels prepared by radiation grafting. Carbohydr. Polym. 2017, 157, 335–343. [Google Scholar] [CrossRef] [PubMed]

- Shao, D.; Jiang, Z.; Wang, X.; Li, J.; Meng, Y. Plasma induced grafting carboxymethyl cellulose on multiwalled carbon nanotubes for the removal of UO22+ from aqueous solution. J. Phys. Chem. B 2009, 113, 860–864. [Google Scholar] [CrossRef]

- Rethinasabapathy, M.; Kang, S.-M.; Lee, I.; Lee, G.-W.; Hwang, S.K.; Roh, C.; Huh, Y.S. Layer-structured POSS-modified Fe-aminoclay/carboxymethyl cellulose composite as a superior adsorbent for the removal of radioactive cesium and cationic dyes. Ind. Eng. Chem. Res. 2018, 57, 13731–13741. [Google Scholar] [CrossRef]

- Janarthanan, G.; Tran, H.N.; Cha, E.; Lee, C.; Das, D.; Noh, I. 3D printable and injectable lactoferrin-loaded carboxymethyl cellulose-glycol chitosan hydrogels for tissue engineering applications. Mater. Sci. Eng. C 2020, 113, 111008. [Google Scholar] [CrossRef]

- Tkaczyk, A.; Mitrowska, K.; Posyniak, A. Synthetic organic dyes as contaminants of the aquatic environment and their implications for ecosystems: A review. Sci. Total Environ. 2020, 717, 137222. [Google Scholar] [CrossRef] [PubMed]

- Boncel, S.; Kyzioł-Komosińska, J.; Krzyżewska, I.; Czupioł, J. Interactions of carbon nanotubes with aqueous/aquatic media containing organic/inorganic contaminants and selected organisms of aquatic ecosystems—A review. Chemosphere 2015, 136, 211–221. [Google Scholar] [CrossRef]

- Croce, R.; Cinà, F.; Lombardo, A.; Crispeyn, G.; Cappelli, C.I.; Vian, M.; Maiorana, S.; Benfenati, E.; Baderna, D. Aquatic toxicity of several textile dye formulations: Acute and chronic assays with Daphnia magna and Raphidocelis subcapitata. Ecotoxicol. Environ. Saf. 2017, 144, 79–87. [Google Scholar] [CrossRef]

- Bae, J.-S.; Freeman, H.S.; Kim, S.D. Influences of new azo dyes to the aquatic ecosystem. Fibers Polym. 2006, 7, 30–35. [Google Scholar] [CrossRef]

- Boguniewicz-Zablocka, J.; Klosok-Bazan, I.; Callegari, A.; Capodaglio, A.G. Snack-food industry effluent pre-treatment for annatto dye and yeast removal: Process improvement for effectiveness and sustainability. J. Clean. Prod. 2020, 277, 124117. [Google Scholar] [CrossRef]

- Yaseen, D.; Scholz, M. Textile dye wastewater characteristics and constituents of synthetic effluents: A critical review. Int. J. Environ. Sci. Technol. 2019, 16, 1193–1226. [Google Scholar] [CrossRef] [Green Version]

- Tan, B.H.; Teng, T.T.; Omar, A.M. Removal of dyes and industrial dye wastes by magnesium chloride. Water Res. 2000, 34, 597–601. [Google Scholar] [CrossRef]

- Niu, P.; Hao, J. Fabrication of titanium dioxide and tungstophosphate nanocomposite films and their photocatalytic degradation for methyl orange. Langmuir 2011, 27, 13590–13597. [Google Scholar] [CrossRef] [PubMed]

- Duruibe, J.O.; Ogwuegbu, M.; Egwurugwu, J. Heavy metal pollution and human biotoxic effects. Int. J. Phys. Sci. 2007, 2, 112–118. [Google Scholar]

- Rai, L.; Gaur, J.; Kumar, H. Phycology and heavy-metal pollution. Biol. Rev. 1981, 56, 99–151. [Google Scholar] [CrossRef]

- Cho, C.-W.; Pham, T.P.T.; Jeon, Y.-C.; Vijayaraghavan, K.; Choe, W.-S.; Yun, Y.-S. Toxicity of imidazolium salt with anion bromide to a phytoplankton Selenastrum capricornutum: Effect of alkyl-chain length. Chemosphere 2007, 69, 1003–1007. [Google Scholar] [CrossRef]

- Deng, S.-Q.; Mo, X.-J.; Zheng, S.-R.; Jin, X.; Gao, Y.; Cai, S.-L.; Fan, J.; Zhang, W.-G. Hydrolytically stable nanotubular cationic metal–organic framework for rapid and efficient removal of toxic oxo-anions and dyes from water. Inorg. Chem. 2019, 58, 2899–2909. [Google Scholar] [CrossRef]

- Manzoor, K.; Ahmad, M.; Ahmad, S.; Ikram, S. Removal of Pb (ii) and Cd (ii) from wastewater using arginine cross-linked chitosan–carboxymethyl cellulose beads as green adsorbent. RSC Adv. 2019, 9, 7890–7902. [Google Scholar] [CrossRef] [Green Version]

- Gasemloo, S.; Khosravi, M.; Sohrabi, M.R.; Dastmalchi, S.; Gharbani, P. Response surface methodology (RSM) modeling to improve removal of Cr (VI) ions from tannery wastewater using sulfated carboxymethyl cellulose nanofilter. J. Clean. Prod. 2019, 208, 736–742. [Google Scholar] [CrossRef]

- Wei, W.; Kim, S.; Song, M.-H.; Bediako, J.K.; Yun, Y.-S. Carboxymethyl cellulose fiber as a fast binding and biodegradable adsorbent of heavy metals. J. Taiwan Inst. Chem. Eng. 2015, 57, 104–110. [Google Scholar] [CrossRef]

- Park, S.-M.; Lee, J.; Jeon, E.-K.; Kang, S.; Alam, M.S.; Tsang, D.C.; Alessi, D.S.; Baek, K. Adsorption characteristics of cesium on the clay minerals: Structural change under wetting and drying condition. Geoderma 2019, 340, 49–54. [Google Scholar] [CrossRef]

- Leaphart, J.C.; Wilms, K.C.; Bryan, A.L., Jr.; Beasley, J.C. Bioaccumulation of 137Cs in anuran larvae utilizing a contaminated effluent canal on the US Department of Energy’s Savannah River Site. J. Environ. Radioact. 2019, 203, 25–29. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, S.; Hu, J.; Shi, J.; Guo, Y.; Deng, T. Robust and recyclable sodium carboxymethyl cellulose–ammonium phosphomolybdate composites for cesium removal from wastewater. RSC Adv. 2020, 10, 6139–6145. [Google Scholar] [CrossRef]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef]

- Skardal, A.; Atala, A. Biomaterials for integration with 3-D bioprinting. Ann. Biomed. Eng. 2015, 43, 730–746. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Gungor-Ozkerim, P.S.; Zhang, Y.S.; Yue, K.; Zhu, K.; Liu, W.; Pi, Q.; Byambaa, B.; Dokmeci, M.R.; Shin, S.R. Direct 3D bioprinting of perfusable vascular constructs using a blend bioink. Biomaterials 2016, 106, 58–68. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Habib, A.; Sathish, V.; Mallik, S.; Khoda, B. 3D printability of alginate-carboxymethyl cellulose hydrogel. Materials 2018, 11, 454. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, M.S.; Park, S.J.; Gu, B.K.; Kim, C.-H. Ionically crosslinked alginate–carboxymethyl cellulose beads for the delivery of protein therapeutics. Appl. Surf. Sci. 2012, 262, 28–33. [Google Scholar] [CrossRef]

- Agarwal, T.; Narayana, S.G.H.; Pal, K.; Pramanik, K.; Giri, S.; Banerjee, I. Calcium alginate-carboxymethyl cellulose beads for colon-targeted drug delivery. Int. J. Biol. Macromol. 2015, 75, 409–417. [Google Scholar] [CrossRef] [PubMed]

- Calcagnile, P.; Cacciatore, G.; Demitri, C.; Montagna, F.; Esposito Corcione, C. A Feasibility Study of Processing Polydimethylsiloxane–Sodium Carboxymethylcellulose Composites by a Low-Cost Fused Deposition Modeling 3D Printer. Materials 2018, 11, 1578. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Janarthanan, G.; Shin, H.S.; Kim, I.-G.; Ji, P.; Chung, E.-J.; Lee, C.; Noh, I. Self-crosslinking hyaluronic acid–carboxymethylcellulose hydrogel enhances multilayered 3D-printed construct shape integrity and mechanical stability for soft tissue engineering. Biofabrication 2020, 12, 045026. [Google Scholar] [CrossRef]

- Ji, S.; Abaci, A.; Morrison, T.; Gramlich, W.M.; Guvendiren, M. Novel bioinks from UV-responsive norbornene-functionalized carboxymethyl cellulose macromers. Bioprinting 2020, 18, e00083. [Google Scholar] [CrossRef]

- Melilli, G.; Carmagnola, I.; Tonda-Turo, C.; Pirri, F.; Ciardelli, G.; Sangermano, M.; Hakkarainen, M.; Chiappone, A. DLP 3D Printing Meets Lignocellulosic Biopolymers: Carboxymethyl Cellulose Inks for 3D Biocompatible Hydrogels. Polymers 2020, 12, 1655. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, R.N.; Moreira, A.P.D.; Thiré, R.M.d.S.M.; Quilty, B.; Passos, T.M.; Simon, P.; Mancini, M.C.; McGuinness, G.B. Absorbent polyvinyl alcohol–sodium carboxymethyl cellulose hydrogels for propolis delivery in wound healing applications. Polym. Eng. Sci. 2017, 57, 1224–1233. [Google Scholar] [CrossRef]

- Namazi, H.; Rakhshaei, R.; Hamishehkar, H.; Kafil, H.S. Antibiotic loaded carboxymethylcellulose/MCM-41 nanocomposite hydrogel films as potential wound dressing. Int. J. Biol. Macromol. 2016, 85, 327–334. [Google Scholar] [CrossRef]

- Agarwal, R.; Alam, M.S.; Gupta, B. Polyvinyl alcohol-polyethylene oxide-carboxymethyl cellulose membranes for drug delivery. J. Appl. Polym. Sci. 2013, 129, 3728–3736. [Google Scholar] [CrossRef]

- Du, S.; Chen, X.; Chen, X.; Li, S.; Yuan, G.; Zhou, T.; Li, J.; Jia, Y.; Xiong, D.; Tan, H. Covalent Chitosan-Cellulose Hydrogels via Schiff-Base Reaction Containing Macromolecular Microgels for pH-Sensitive Drug Delivery and Wound Dressing. Macromol. Chem. Phys. 2019, 220, 1900399. [Google Scholar] [CrossRef]

- Joorabloo, A.; Khorasani, M.T.; Adeli, H.; Mansoori-Moghadam, Z.; Moghaddam, A. Fabrication of heparinized nano ZnO/poly (vinylalcohol)/carboxymethyl cellulose bionanocomposite hydrogels using artificial neural network for wound dressing application. Ind. Eng. Chem. 2019, 70, 253–263. [Google Scholar] [CrossRef]

- Kalmer, R.R.; Mohammadi, M.; Karimi, A.; Najafpour, G.; Haghighatnia, Y. Fabrication and evaluation of carboxymethylated diethylaminoethyl cellulose microcarriers as support for cellular applications. Carbohydr. Polym. 2019, 226, 115284. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, X.; Cao, Y.; Tian, C.; Li, Y.; Wang, M.; Zhao, Y.; Zhao, G. Centrifugal microfluidics for ultra-rapid fabrication of versatile hydrogel microcarriers. Appl. Mater. Today 2018, 13, 116–125. [Google Scholar] [CrossRef]

- Kandalam, S.; De Berdt, P.; Ucakar, B.; Vanvarenberg, K.; Bouzin, C.; Gratpain, V.; Diogenes, A.; Montero-Menei, C.N.; des Rieux, A. Human dental stem cells of the apical papilla associated to BDNF-loaded pharmacologically active microcarriers (PAMs) enhance locomotor function after spinal cord injury. Int. J. Pharm. 2020, 587, 119685. [Google Scholar] [CrossRef]

- Ahmadi, R.; Mordan, N.; Forbes, A.; Day, R. Enhanced attachment, growth and migration of smooth muscle cells on microcarriers produced using thermally induced phase separation. Acta Biomater. 2011, 7, 1542–1549. [Google Scholar] [CrossRef] [PubMed]

- Lan, W.; He, L.; Liu, Y. Preparation and properties of sodium carboxymethyl cellulose/sodium alginate/chitosan composite film. Coatings 2018, 8, 291. [Google Scholar] [CrossRef] [Green Version]

- Abdollahi, M.; Damirchi, S.; Shafafi, M.; Rezaei, M.; Ariaii, P. Carboxymethyl cellulose-agar biocomposite film activated with summer savory essential oil as an antimicrobial agent. Int. J. Biol. Macromol. 2019, 126, 561–568. [Google Scholar] [CrossRef]

- Jantrawut, P.; Bunrueangtha, J.; Suerthong, J.; Kantrong, N. Fabrication and characterization of low methoxyl pectin/gelatin/carboxymethyl cellulose absorbent hydrogel film for wound dressing applications. Materials 2019, 12, 1628. [Google Scholar] [CrossRef] [Green Version]

- Simmons, P.A.; Vehige, J.G. Investigating the potential benefits of a new artificial tear formulation combining two polymers. Clin. Ophthalmol. 2017, 11, 1637–1642. [Google Scholar] [CrossRef] [Green Version]

- Agate, S.; Argyropoulos, D.S.; Jameel, H.; Lucia, L.; Pal, L. 3D Photoinduced spatiotemporal resolution of cellulose-based hydrogels for fabrication of biomedical devices. ACS Appl. Bio Mater. 2020, 3, 5007–5019. [Google Scholar] [CrossRef]

- Wang, M.; Xu, L.; Hu, H.; Zhai, M.; Peng, J.; Nho, Y.; Li, J.; Wei, G. Radiation synthesis of PVP/CMC hydrogels as wound dressing. Nucl. Instrum. Methods Phys. Res. B Beam Interact. Mater. At. 2007, 265, 385–389. [Google Scholar] [CrossRef]

- Hebeish, A.; Hashem, M.; Abd El-Hady, M.; Sharaf, S. Development of CMC hydrogels loaded with silver nano-particles for medical applications. Carbohydr. Polym. 2013, 92, 407–413. [Google Scholar] [CrossRef] [PubMed]

- Spera, M.B.; Taketa, T.B.; Beppu, M.M. Roughness dynamic in surface growth: Layer-by-layer thin films of carboxymethyl cellulose/chitosan for biomedical applications. Biointerphases 2017, 12, 04E401-6. [Google Scholar] [CrossRef]

- Boateng, J.S.; Stevens, H.N.; Eccleston, G.M.; Auffret, A.D.; Humphrey, M.J.; Matthews, K.H. Development and mechanical characterization of solvent-cast polymeric films as potential drug delivery systems to mucosal surfaces. Drug Dev. Ind. Pharm. 2009, 35, 986–996. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Deng, L.; Zhang, J.; Yin, L.; Dong, A. Composites of electrospun-fibers and hydrogels: A potential solution to current challenges in biological and biomedical field. J. Biomed. Mater. Res. B Appl. Biomater. 2016, 104, 640–656. [Google Scholar] [CrossRef]

- Riaz, S.; Malik, S.; Hussain, T.; Ashraf, M.; Iftikhar, F.; Younus, A.; Abid, S.; Zahir, A. Development of antibacterial fibers and study on effect of guar-gum addition on properties of carboxymethylcellulose (CMC)/alginate fibers. IOP Conf. Ser. Mater. Sci. Eng. 2018, 414, 012020. [Google Scholar] [CrossRef] [Green Version]

- El-Newehy, M.H.; El-Naggar, M.E.; Alotaiby, S.; El-Hamshary, H.; Moydeen, M.; Al-Deyab, S. Preparation of biocompatible system based on electrospun CMC/PVA nanofibers as controlled release carrier of diclofenac sodium. J. Macromol. Sci. A 2016, 53, 566–573. [Google Scholar] [CrossRef]

- Boateng, J.S.; Auffret, A.D.; Matthews, K.H.; Humphrey, M.J.; Stevens, H.N.; Eccleston, G.M. Characterisation of freeze-dried wafers and solvent evaporated films as potential drug delivery systems to mucosal surfaces. Int. J. Pharm. 2010, 389, 24–31. [Google Scholar] [CrossRef] [PubMed]

- Boateng, J.S.; Matthews, K.H.; Auffret, A.D.; Humphrey, M.J.; Stevens, H.N.; Eccleston, G.M. In vitro drug release studies of polymeric freeze-dried wafers and solvent-cast films using paracetamol as a model soluble drug. Int. J. Pharm. 2009, 378, 66–72. [Google Scholar] [CrossRef] [PubMed]

- Rezvanian, M.; Tan, C.-K.; Ng, S.-F. Simvastatin-loaded lyophilized wafers as a potential dressing for chronic wounds. Drug Dev. Ind. Pharm. 2016, 42, 2055–2062. [Google Scholar] [CrossRef]

- Zheng, W.; Chen, C.; Zhang, X.; Wen, X.; Xiao, Y.; Li, L.; Xu, Q.; Fu, F.; Diao, H.; Liu, X. Layer-by-layer coating of carboxymethyl chitosan-gelatin-alginate on cotton gauze for hemostasis and wound healing. Surf. Coat. Technol. 2020, 406, 126644. [Google Scholar] [CrossRef]

- Edwards, J.V.; Yager, D.R.; Cohen, I.K.; Diegelmann, R.F.; Montante, S.; Bertoniere, N.; Bopp, A.F. Modified cotton gauze dressings that selectively absorb neutrophil elastase activity in solution. Wound Repair Regen. 2001, 9, 50–58. [Google Scholar] [CrossRef]

- Sitthichai, S.; Pilapong, C.; Thongtem, T.; Thongtem, S. CMC-coated Fe3O4 nanoparticles as new MRI probes for hepatocellular carcinoma. Appl. Surf. Sci. 2015, 356, 972–977. [Google Scholar] [CrossRef]

- Neacsu, I.A.; Leau, S.A.; Marin, S.; Holban, A.M.; Vasile, B.S.; Nicoara, A.I.; Ene, V.L.; Bleotu, C.; Albu Kaya, M.G.; Ficai, A. Collagen-Carboxymethylcellulose Biocomposite Wound-Dressings with Antimicrobial Activity. Materials. 2020, 14, 1153. [Google Scholar] [CrossRef]

- Zhang, T.; Li, G.; Guo, L.; Chen, H. Synthesis of thermo-sensitive CS-g-PNIPAM/CMC complex nanoparticles for controlled release of 5-FU. Int. J. Biol. Macromol. 2012, 51, 1109–1115. [Google Scholar] [CrossRef] [PubMed]

- Hebeish, A.; Sharaf, S. Novel nanocomposite hydrogel for wound dressing and other medical applications. RSC Adv. 2015, 5, 103036–103046. [Google Scholar] [CrossRef]

- Varaprasad, K.; Raghavendra, G.M.; Jayaramudu, T.; Yallapu, M.M.; Sadiku, R. A mini review on hydrogels classification and recent developments in miscellaneous applications. Mater. Sci. Eng. C 2017, 79, 958–971. [Google Scholar] [CrossRef]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ogushi, Y.; Sakai, S.; Kawakami, K. Synthesis of enzymatically-gellable carboxymethylcellulose for biomedical applications. J. Biosci. Bioeng. 2007, 104, 30–33. [Google Scholar] [CrossRef]

- Malik, M.H.; Shahzadi, L.; Batool, R.; Safi, S.Z.; Khan, A.S.; Khan, A.F.; Chaudhry, A.A.; Rehman, I.U.; Yar, M. Thyroxine-loaded chitosan/carboxymethyl cellulose/hydroxyapatite hydrogels enhance angiogenesis in in-ovo experiments. Int. J. Biol. Macromol. 2020, 145, 1162–1170. [Google Scholar] [CrossRef] [PubMed]

- Capanema, N.S.; Mansur, A.A.; de Jesus, A.C.; Carvalho, S.M.; de Oliveira, L.C.; Mansur, H.S. Superabsorbent crosslinked carboxymethyl cellulose-PEG hydrogels for potential wound dressing applications. Int. J. Biol. Macromol. 2018, 106, 1218–1234. [Google Scholar] [CrossRef] [PubMed]

- Basu, A.; Celma, G.; Strømme, M.; Ferraz, N. In vitro and in vivo evaluation of the wound healing properties of nanofibrillated cellulose hydrogels. ACS Appl. Bio Mater. 2018, 1, 1853–1863. [Google Scholar] [CrossRef]

- Zhong, Y.; Wang, J.; Yuan, Z.; Wang, Y.; Xi, Z.; Li, L.; Liu, Z.; Guo, X. A mussel-inspired carboxymethyl cellulose hydrogel with enhanced adhesiveness through enzymatic crosslinking. Colloids Surf. B Biointerfaces 2019, 179, 462–469. [Google Scholar] [CrossRef]

- Bayindir Bilgic, M.; Lacin, N.T.; Berber, H.; Mansuroglu, B. In vitro evaluation of alpha-tocopherol loaded carboxymethylcellulose chitosan copolymers as wound dressing materials. Mater. Technol. 2019, 34, 386–393. [Google Scholar] [CrossRef]

- Ali, N.H.; Amin, M.C.I.M.; Ng, S.-F. Sodium carboxymethyl cellulose hydrogels containing reduced graphene oxide (rGO) as a functional antibiofilm wound dressing. J. Biomater. Sci. Polym. Ed. 2019, 30, 629–645. [Google Scholar] [CrossRef]

- Rakhshaei, R.; Namazi, H. A potential bioactive wound dressing based on carboxymethyl cellulose/ZnO impregnated MCM-41 nanocomposite hydrogel. Mater. Sci. Eng. C 2017, 73, 456–464. [Google Scholar] [CrossRef]

- Chen, Y.M.; Sun, L.; Yang, S.A.; Shi, L.; Zheng, W.J.; Wei, Z.; Hu, C. Self-healing and photoluminescent carboxymethyl cellulose-based hydrogels. Eur. Polym. J. 2017, 94, 501–510. [Google Scholar] [CrossRef]

- Li, D.; Ye, Y.; Li, D.; Li, X.; Mu, C. Biological properties of dialdehyde carboxymethyl cellulose crosslinked gelatin–PEG composite hydrogel fibers for wound dressings. Carbohydr. Polym. 2016, 137, 508–514. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Lim, S.-J.; Oh, D.H.; Ku, S.K.; Li, D.X.; Yong, C.S.; Choi, H.-G. Wound healing evaluation of sodium fucidate-loaded polyvinylalcohol/sodium carboxymethylcellulose-based wound dressing. Arch. Pharm. Res. 2010, 33, 1083–1089. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, C.; Fan, D.; Fu, R.; Ma, P.; Duan, Z.; Li, X.; Lei, H.; Chi, L. A Bi-Layer PVA/CMC/PEG Hydrogel with Gradually Changing Pore Sizes for Wound Dressing. Macromol. Biosci. 2019, 19, 1800424. [Google Scholar] [CrossRef] [PubMed]

- Sharma, M.; Dube, A.; Majumder, S.K. Antibacterial photodynamic activity of photosensitizer-embedded alginate-pectin-carboxymethyl cellulose composite biopolymer films. Lasers Med. Sci. 2020, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Waring, M.; Parsons, D. Physico-chemical characterisation of carboxymethylated spun cellulose fibres. Biomaterials 2001, 22, 903–912. [Google Scholar] [CrossRef]

- Zhao, J.; Tang, Y.; Liu, Y.; Cui, L.; Xi, X.; Zhang, N.; Zhu, P. Design carboxymethyl cotton knitted fabrics for wound dressing applications: Solvent effects. Mater. Des. 2015, 87, 238–244. [Google Scholar] [CrossRef]

- Doh, S.J.; Lee, J.Y.; Lim, D.Y.; Im, J.N. Manufacturing and analyses of wet-laid nonwoven consisting of carboxymethyl cellulose fibers. Fibers Polym. 2013, 14, 2176–2184. [Google Scholar] [CrossRef]

- Zhang, X.-M.; Ma, M.-G.; Yang, J.; Xiang, Z.; Zhu, J.-F.; Alias, Y. Recent advances in cellulose-based materials: Synthesis, characterization, and their applications. Int. J. Polym. Sci. 2016, 2016, 8730573. [Google Scholar] [CrossRef]

- Fan, X.; Yang, L.; Wang, T.; Sun, T.; Lu, S. pH-responsive cellulose-based dual drug-loaded hydrogel for wound dressing. Eur. Polym. J. 2019, 121, 109290. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, G.; Peng, Y.; Chen, L.; Fu, S. Effects of cellulose nanofibrils on dialdehyde carboxymethyl cellulose based dual responsive self-healing hydrogel. Cellulose 2019, 26, 8813–8827. [Google Scholar] [CrossRef]

- Ehrlich, H. Chitin and collagen as universal and alternative templates in biomineralization. Int. Geol. Rev. 2010, 52, 661–699. [Google Scholar] [CrossRef]

- Ehrlich, H.; Hanke, T.; Born, R.; Fischer, C.; Frolov, A.; Langrock, T.; Hoffmann, R.; Schwarzenbolz, U.; Henle, T.; Simon, P. Mineralization of biomimetically carboxymethylated collagen fibrils in a model dual membrane diffusion system. J. Membr. Sci. 2009, 326, 254–259. [Google Scholar] [CrossRef]

- Ehrlich, H.; Hanke, T.; Frolov, A.; Langrock, T.; Hoffmann, R.; Fischer, C.; Schwarzenbolz, U.; Henle, T.; Born, R.; Worch, H. Modification of collagen in vitro with respect to formation of Nɛ-carboxymethyllysine. Int. J. Biol. Macromol. 2009, 44, 51–56. [Google Scholar] [CrossRef]

- Pompe, W.; Worch, H.; Habraken, W.J.; Simon, P.; Kniep, R.; Ehrlich, H.; Paufler, P. Octacalcium phosphate—A metastable mineral phase controls the evolution of scaffold forming proteins. J. Mater. Chem. B 2015, 3, 5318–5329. [Google Scholar] [CrossRef] [Green Version]

- Zahedi, E.; Esmaeili, A.; Eslahi, N.; Shokrgozar, M.A.; Simchi, A. Fabrication and characterization of Core-Shell electrospun fibrous Mats containing medicinal herbs for wound healing and skin tissue engineering. Mar. Drugs 2019, 17, 27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maji, K.; Dasgupta, S.; Pramanik, K.; Bissoyi, A. Preparation and evaluation of gelatin-chitosan-nanobioglass 3D porous scaffold for bone tissue engineering. Int. J. Biomater. 2016, 2016, 9825659. [Google Scholar] [CrossRef] [Green Version]

- Szatkowski, T.; Kołodziejczak-Radzimska, A.; Zdarta, J.; Szwarc-Rzepka, K.; Paukszta, D.; Wysokowski, M.; Ehrlich, H.; Jesionowski, T. Synthesis and characterization of hydroxyapatite/chitosan composites. Physicochem. Probl. Miner. Process. 2015, 51, 575–585. [Google Scholar]

- Eslahi, N.; Mahmoodi, A.; Mahmoudi, N.; Zandi, N.; Simchi, A. Processing and properties of nanofibrous bacterial cellulose-containing polymer composites: A review of recent advances for biomedical applications. Polym. Rev. 2020, 60, 144–170. [Google Scholar] [CrossRef]

- Stancu, I.-C.; Dragusin, D.M.; Vasile, E.; Trusca, R.; Antoniac, I.; Vasilescu, D.S. Porous calcium alginate–gelatin interpenetrated matrix and its biomineralization potential. J. Mater. Sci. Mater. Med. 2011, 22, 451–460. [Google Scholar] [CrossRef]

- Devi, N.; Maji, T.K. Preparation and evaluation of gelatin/sodium carboxymethyl cellulose polyelectrolyte complex microparticles for controlled delivery of isoniazid. AAPS PharmSciTech 2009, 10, 1412–1419. [Google Scholar] [CrossRef]

- Gheysari, H.; Mohandes, F.; Mazaheri, M.; Dolatyar, B.; Askari, M.; Simchi, A. Extraction of Hydroxyapatite Nanostructures from Marine Wastes for the Fabrication of Biopolymer-Based Porous Scaffolds. Mar. Drugs 2020, 18, 26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Abboodi, A.; Fu, J.; Doran, P.M.; Tan, T.T.; Chan, P.P. Injectable 3D Hydrogel Scaffold with Tailorable Porosity Post-Implantation. Adv. Healthc. Mater. 2014, 3, 725–736. [Google Scholar] [CrossRef] [PubMed]

- Ninan, N.; Muthiah, M.; Park, I.-K.; Elain, A.; Thomas, S.; Grohens, Y. Pectin/carboxymethyl cellulose/microfibrillated cellulose composite scaffolds for tissue engineering. Carbohydr. Polym. 2013, 98, 877–885. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Y.; Wang, X.; Zhang, L.; Wen, J.; Gong, M. Preparation and properties of nano-hydroxyapatite/chitosan/carboxymethyl cellulose composite scaffold. Carbohydr. Polym. 2008, 74, 680–684. [Google Scholar] [CrossRef]

- Rodrigues, C.; de Assis, A.M.; Moura, D.J.; Halmenschlager, G.; Saffi, J.; Xavier, L.L.; da Cruz Fernandes, M.; Wink, M.R. New therapy of skin repair combining adipose-derived mesenchymal stem cells with sodium carboxymethylcellulose scaffold in a pre-clinical rat model. PLoS ONE 2014, 9, e96241. [Google Scholar] [CrossRef] [PubMed]

- Kanimozhi, K.; Basha, S.K.; Kumari, V.S.; Kaviyarasu, K. Development of biomimetic hybrid porous scaffold of chitosan/polyvinyl alcohol/carboxymethyl cellulose by freeze-dried and salt leached technique. J. Nanosci. Nanotechnol. 2018, 18, 4916–4922. [Google Scholar] [CrossRef] [PubMed]

- Qi, P.; Ohba, S.; Hara, Y.; Fuke, M.; Ogawa, T.; Ohta, S.; Ito, T. Fabrication of calcium phosphate-loaded carboxymethyl cellulose non-woven sheets for bone regeneration. Carbohydr. Polym. 2018, 189, 322–330. [Google Scholar] [CrossRef]

- Aoshima, M.; Jo, Y. Augmentation for Cell Spreading and Migration by A Soluble Fraction of Cotton-Derived Carboxymethyl Cellulose. Kobunshi Ronbunshu 2013, 70, 273–281. [Google Scholar] [CrossRef]

- Clarke, S.; Hoskins, N.; Jordan, G.; Henderson, S.; Marsh, D. In vitro testing of Advanced JAX™ Bone Void Filler System: Species differences in the response of bone marrow stromal cells to β tri-calcium phosphate and carboxymethylcellulose gel. J. Mater. Sci. Mater. Med. 2007, 18, 2283–2290. [Google Scholar] [CrossRef]

- Agis, H.; Beirer, B.; Watzek, G.; Gruber, R. Effects of carboxymethylcellulose and hydroxypropylmethylcellulose on the differentiation and activity of osteoclasts and osteoblasts. J. Biomed. Mater. Res. A 2010, 95, 504–509. [Google Scholar] [CrossRef]

- Namkaew, J.; Laowpanitchakorn, P.; Sawaddee, N.; Jirajessada, S.; Honsawek, S.; Yodmuang, S. Carboxymethyl Cellulose Entrapped in a Poly (vinyl) Alcohol Network: Plant-Based Scaffolds for Cartilage Tissue Engineering. Molecules 2021, 26, 578. [Google Scholar] [CrossRef] [PubMed]

- Manjubala, I.; Basu, P.; Narendrakumar, U. In situ synthesis of hydroxyapatite/carboxymethyl cellulose composites for bone regeneration applications. Colloid Polym. Sci. 2018, 296, 1729–1737. [Google Scholar] [CrossRef]

- Hasan, A.; Waibhaw, G.; Saxena, V.; Pandey, L.M. Nano-biocomposite scaffolds of chitosan, carboxymethyl cellulose and silver nanoparticle modified cellulose nanowhiskers for bone tissue engineering applications. Int. J. Biol. Macromol. 2018, 111, 923–934. [Google Scholar] [CrossRef] [PubMed]

- Sainitya, R.; Sriram, M.; Kalyanaraman, V.; Dhivya, S.; Saravanan, S.; Vairamani, M.; Sastry, T.; Selvamurugan, N. Scaffolds containing chitosan/carboxymethyl cellulose/mesoporous wollastonite for bone tissue engineering. Int. J. Biol. Macromol. 2015, 80, 481–488. [Google Scholar] [CrossRef]

- Chen, C.; Li, H.; Pan, J.; Yan, Z.; Yao, Z.; Fan, W.; Guo, C. Biodegradable composite scaffolds of bioactive glass/chitosan/carboxymethyl cellulose for hemostatic and bone regeneration. Biotechnol. Lett. 2015, 37, 457–465. [Google Scholar] [CrossRef]

- Liuyun, J.; Yubao, L.; Chengdong, X. Preparation and biological properties of a novel composite scaffold of nano-hydroxyapatite/chitosan/carboxymethyl cellulose for bone tissue engineering. J. Biomed. Sci. 2009, 16, 65. [Google Scholar] [CrossRef] [Green Version]

- Priya, G.; Madhan, B.; Narendrakumar, U.; Suresh Kumar, R.V.; Manjubala, I. In Vitro and In Vivo Evaluation of Carboxymethyl Cellulose Scaffolds for Bone Tissue Engineering Applications. ACS Omega 2021, 6, 1246–1253. [Google Scholar] [CrossRef]