The Structural Evolution and Mechanical Properties of Semi-Aromatic Polyamide 12T after Stretching

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Preparation Process

2.2. Characterization

3. Results and Discussion

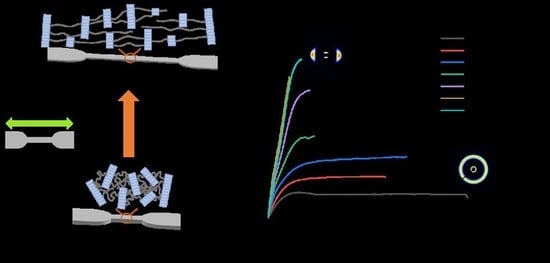

3.1. Effect of Uniaxial Stretching on Mechanical Properties

3.2. Effect of Uniaxial Stretching on Crystal Structure

3.3. Effect of Uniaxial Stretching on Dynamic Thermomechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, M.Y.; Li, K.F.; Yang, S.H.; Fu, P.; Wang, Y.D.; Zhao, Q.X. Synthesis and Thermal Decomposition of Poly(dodecamethylene terephthalamide). J. Appl. Polym. Sci. 2011, 122, 3369–3376. [Google Scholar] [CrossRef]

- Sun, J.H.; Qian, L.J.; Li, J. Flame retardancy and mechanical properties of polyamide 6 modified by multiple reactions with furan-phosphamide. Polymer 2020, 210, 122994. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Kozera, P.; Kozera, R.; Kolodziejczak, M.; Gabriel, E.; Glowacka, J.; Jalbrzykowski, M.; Kurzydlowski, K.J.; Przekop, R.E. Biocomposites Based on Polyamide 11/Diatoms with Different Sized Frustules. Polymers 2022, 14, 3153. [Google Scholar] [CrossRef] [PubMed]

- Han, B.G.; Wang, Y.; Zheng, Y.S.; Tao, Y.X.; Liu, X. Influence of multi-walled carbon nanotube content on electromagnetic wave absorption and mechanical properties of carbon nanotube/polyamide 12 composite. Polym. Compos. 2022. [Google Scholar] [CrossRef]

- Choi, E.Y.; Kim, K.; Kim, C.K.; Kang, E. Reinforcement of nylon 6,6/nylon 6,6 grafted nanodiamond composites by in situ reactive extrusion. Scientific Reports 2016, 6, 37010. [Google Scholar] [CrossRef] [Green Version]

- Marset, D.; Fages, E.; Gonga, E.; Ivorra-Martinez, J.; Sanchez-Nacher, L.; Quiles-Carrillo, L. Development and Characterization of High Environmentally Friendly Composites of Bio-Based Polyamide 1010 with Enhanced Fire Retardancy Properties by Expandable Graphite. Polymers 2022, 14, 1843. [Google Scholar] [CrossRef]

- Cai, Z.Q.; Meng, X.Y.; Zhang, X.C.; Cui, L.S.; Zhou, Q. Effects of Surface Modification of Carbon Nanofibers on the Mechanical Properties of Polyamide 1212 Composites. Journal of Applied Polymer Science 2015, 132, 41424. [Google Scholar] [CrossRef]

- Li, K.F.; Fu, P.; Liu, C.L.; Zhao, Q.X.; Liu, M.Y. Synthesis, characterization and isothermal crystallization kinetics of poly(dodecamethylene terephthalamide). In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2011; Volume 284–286, pp. 1894–1900. [Google Scholar]

- Fu, X.B.; Zhang, T.; Yang, J.C.; Zhang, G.; Zhang, M.L.; Wang, X.J.; Yang, J. Structures and properties of newly synthesized semi-aromatic polyamide thermoplastic elastomers. Polym. Chem. 2022, 13, 4980–4991. [Google Scholar] [CrossRef]

- Chen, X.J.; Zhao, W.; Zhang, Y.C.; Shi, G.; He, Y.J.; Cui, Z.; Fu, P.; Pang, X.C.; Zhang, X.M.; Liu, M.Y. Concurrent enhancement of dimensional stability and thermal conductivity of thermoplastic polyamide 12T/Boron nitride composites by constructing oriented structure. Compos. Commun. 2022, 33, 101193. [Google Scholar] [CrossRef]

- Papaspyrides, C.D.; Porfyris, A.D.; Rulkens, R.; Grolman, E.; Kolkman, A.J. The Effect of Diamine Length on the Direct Solid State Polycondensation of Semi-Aromatic Nylon Salts. J. Polym. Sci. Part A-Polym. Chem. 2016, 54, 2493–2506. [Google Scholar] [CrossRef]

- Ren, H.Q.; He, Z.C.; Xu, J.J.; Yan, X.; Liu, P.Q. Evaluation of the Abilities of Ozone Resistance for Polyamide Fibers: Structures, Properties, and Aging Mechanism. Ind. Eng. Chem. Res. 2019, 58, 17814–17823. [Google Scholar] [CrossRef]

- Werner, N.; Zibek, S. Biotechnological production of bio-based long-chain dicarboxylic acids with oleogenious yeasts. World J. Microbiol. Biotechnol. 2017, 33, 194. [Google Scholar] [CrossRef]

- Cao, M.; Huang, M.; Zhang, C. Synthesis, Characterization and Properties of Semi-aromatic Heat-resistant Nylon PA12T. Eng. Plast. Appl. 2016, 44, 1–6. [Google Scholar]

- Zhang, C.H. Progress in semicrystalline heat-resistant polyamides. e-Polymers 2018, 18, 373–408. [Google Scholar] [CrossRef]

- Liu, G.M.; Zhang, X.Q.; Wang, D.J. Tailoring Crystallization: Towards High-Performance Poly(lactic acid). Adv. Mater. 2014, 26, 6905–6911. [Google Scholar] [CrossRef]

- Osorio, D.A.; Niinivaara, E.; Jankovic, N.C.; Demir, E.C.; Benkaddour, A.; Jarvis, V.; Ayranci, C.; McDermott, M.T.; de Lannoy, C.F.; Cranston, E.D. Cellulose Nanocrystals Influence Polyamide 6 Crystal Structure, Spherulite Uniformity, and Mechanical Performance of Nanocomposite Films. ACS Appl. Polym. Mater. 2021, 3, 4673–4684. [Google Scholar] [CrossRef]

- Qin, Y.A.; Song, W.B.; Chen, M.; Litvinov, V.; Men, Y.F. Chain Entanglements and Interlamellar Links in Isotactic Polybutene-1: The Effect of Condis Crystals and Crystallization Temperature. Macromolecules 2022, 55, 5636–5644. [Google Scholar] [CrossRef]

- Wang, C.H.; Zhang, Y.W.; Yi, Y.; Lai, D.W.; Yang, J.; Wang, W.Z. Thermal, morphological and mechanical properties of glass fiber reinforced star-branched polyamide 6. Polym. Compos. 2022, 43, 1617–1625. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Meng, Y.; Zhu, F.C.; Su, J.J.; Han, J. Mechanical Reinforcement in Nylon 6 Nanocomposite Fiber Incorporated with Dopamine Reduced Graphene Oxide. Materials 2022, 15, 5095. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Shang, Y.R.; Li, J.Q.; Jiang, S.C. Structure/property relationship of semicrystalline polymers during tensile deformation: A molecular dynamics approach. Colloid Polym. Sci. 2022, 300, 675–689. [Google Scholar] [CrossRef]

- Zhou, C.X.; Dong, S.Y.; Zhu, P.; Liu, J.G.; Wang, D.J.; Dong, X. Strain-Induced Form Transition and Crystallization Behavior of the Transparent Polyamide. Polymers 2021, 13, 1028. [Google Scholar] [CrossRef] [PubMed]

- Hinrichsen, G. Studies on structure and properties of polyamides. 2. single-crystals from polyamide 6, 6. Makromol. Chem.-Macromol. Chem. Phys. 1973, 166, 291–306. [Google Scholar] [CrossRef]

- Lu, S.J.; Zhou, Z.M.; Yu, J.; Li, F.; He, M. Study on the Influence of Crystal Structures on the Performance of Low-Melting Polyamide 6. Polym.-Plast. Technol. Eng. 2013, 52, 157–162. [Google Scholar] [CrossRef]

- Tuccitto, A.V.; Anstey, A.; Sansone, N.D.; Park, C.B.; Lee, P.C. Controlling stereocomplex crystal morphology in poly(lactide) through chain alignment. Int. J. Biol. Macromol. 2022, 218, 22–32. [Google Scholar] [CrossRef]

- Chen, X.W.; Lv, F.; Su, F.M.; Ji, Y.X.; Meng, L.P.; Wan, C.X.; Lin, Y.F.; Li, X.Y.; Li, L.B. Deformation mechanism of iPP under uniaxial stretching over a wide temperature range: An in-situ synchrotron radiation SAXS/WAXS study. Polymer 2017, 118, 12–21. [Google Scholar] [CrossRef]

- Dechnarong, N.; Kamitani, K.; Cheng, C.H.; Masuda, S.; Nozaki, S.; Nagano, C.; Fujimoto, A.; Hamada, A.; Amamoto, Y.; Kojio, K.; et al. Microdomain structure change and macroscopic mechanical response of styrenic triblock copolymer under cyclic uniaxial and biaxial stretching modes. Polym. J. 2021, 53, 703–712. [Google Scholar] [CrossRef]

- Djezzar, K.; Penel, L.; Lefebvre, J.M.; Seguela, R.; Germain, Y. Tensile drawing of ethylene/vinyl-alcohol copolymers. Part 1. Influence of draw temperature on the mechanical behaviour. Polymer 1998, 39, 3945–3953. [Google Scholar] [CrossRef]

- Pepin, J.; Gaucher, V.; Rochas, C.; Lefebvre, J.-M. In-situ SAXS/WAXS investigations of the mechanically-induced phase transitions in semi-crystalline polyamides. Polymer 2019, 175, 87–98. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, W.; Liu, H.; Zheng, J.; Sun, A.; Li, Y.; He, S.; Zhu, C.; Yang, M. Temperature and deformation dependence of structural evolution in polyamide 1010. J. Polym. Res. 2019, 26, 284. [Google Scholar] [CrossRef]

- Penel-Pierron, L.; Seguela, R.; Lefebvre, J.M.; Miri, V.; Depecker, C.; Jutigny, M.; Pabiot, J. Structural and mechanical behavior of nylon-6 films. II. Uniaxial and biaxial drawing. J. Polym. Sci. Part B-Polym. Phys. 2001, 39, 1224–1236. [Google Scholar] [CrossRef]

- Kimata, S.; Sakurai, T.; Nozue, Y.; Kasahara, T.; Yamaguchi, N.; Karino, T.; Shibayama, M.; Kornfield, J.A. Molecular basis of the shish-kebab morphology in polymer crystallization. Science 2007, 316, 1014–1017. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Liu, X.; Zhou, Q.; Wang, Y.; Zhu, C.; Xiao, X.; Fang, D.; Bao, H. The structure evolution of polyamide 1212 after stretched at different temperatures and its correlation with mechanical properties. Polymer 2017, 117, 249–258. [Google Scholar] [CrossRef]

- Cui, L.; Dong, Y.; Liu, Y.; Fan, S.; Wang, X.; Li, X. Crystal structure of uniaxially stretched bio-based polyamide 510 films. J. Appl. Polym. Sci. 2021, 138, e50748. [Google Scholar] [CrossRef]

- Men, Y.F.; Rieger, J.; Homeyer, J. Synchrotron ultrasmall-angle X-ray scattering studies on tensile deformation of Poly(1-butene). Macromolecules 2004, 37, 9481–9488. [Google Scholar] [CrossRef]

- Uddin, A.J.; Ohkoshi, Y.; Gotoh, Y.; Nagura, M.; Endo, R.; Hara, T. Melt spinning and laser-heated drawing of a new semiaromatic polyamide, PA9-T fiber. J. Polym. Sci. Part B-Polym. Phys. 2004, 42, 433–444. [Google Scholar] [CrossRef]

- Zhu, P.W.; Edward, G. Distribution of shish-kebab structure of isotactic polypropylene under shear in the presence of nucleating agent. Macromolecules 2004, 37, 2658–2660. [Google Scholar] [CrossRef]

- Todorov, L.V.; Viana, J.C. Structure evolution of PET under step-wise and continuous deformation modes: The effect of stress relaxation on the strain-induced morphology. Int. J. Mater. Form. 2008, 1, 661–665. [Google Scholar] [CrossRef] [Green Version]

- Bao, R.-Y.; Ding, Z.-T.; Liu, Z.-Y.; Yang, W.; Xie, B.-H.; Yang, M.-B. Deformation-induced structure evolution of oriented β-polypropylene during uniaxial stretching. Polymer 2013, 54, 1259–1268. [Google Scholar] [CrossRef]

- Cai, Z.; Meng, X.; Ye, H.; Cong, C.; Wang, Y.; Cui, L.; Zhou, Q. Reinforcing polyamide 1212 nanocomposites with aligned carbon nanofibers. Mater. Des. 2014, 63, 691–698. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Zhou, W.M.; Li, J.; Liu, Y.P.; Qi, Z.M.; Li, L.B. In Situ Microscopic Infrared Imaging Study on Deformation-Induced Spatial Orientation and Phase Transition Distributions of PA12. J. Appl. Polym. Sci. 2014, 131, 40703. [Google Scholar] [CrossRef]

- Offenbach, I.; Gupta, S.; Chung, T.C.M.; Weiss, R.A.; Cakmak, M. Real-Time Infrared–Mechano-Optical Behavior and Structural Evolution of Polypropylene and Hydroxyl-Functionalized Polypropylene during Uniaxial Deformation. Macromolecules 2015, 48, 6294–6305. [Google Scholar] [CrossRef]

- Saengbunkoet, S.; Kerddonfag, N.; Puekpoonpoal, N.; Kumsang, P.; Yoksan, R.; Jariyasakoolroj, P. Structural evolution and related physical properties of machine direction oriented poly(butylene succinate-co-adipate) films. Polymer 2022, 249, 124859. [Google Scholar] [CrossRef]

- Xiao, X.; Cai, Z.; Qian, K. Structure evolution of polyamide (11)’s crystalline phase under uniaxial stretching and increasing temperature. J. Polym. Res. 2017, 24, 81. [Google Scholar] [CrossRef]

- Cai, Z.; Bao, H.; Zhu, C.; Zhu, S.; Huang, F.; Shi, J.; Hu, J.; Zhou, Q. Structure Evolution of Polyamide 1212 during the Uniaxial Stretching Process: In Situ Synchrotron Wide-Angle X-ray Diffraction and Small-Angle X-ray Scattering Analysis. Ind. Eng. Chem. Res. 2016, 55, 7621–7627. [Google Scholar] [CrossRef]

- Zuo, F.; Keum, J.K.; Chen, X.M.; Hsiao, B.S.; Chen, H.Y.; Lai, S.Y.; Wevers, R.; Li, J. The role of interlamellar chain entanglement in deformation-induced structure changes during uniaxial stretching of isotactic polypropylene. Polymer 2007, 48, 6867–6880. [Google Scholar] [CrossRef]

- Ling, X.Y.; Spruiell, J.E. Analysis of the complex thermal behavior of poly(L-lactic acid) film. I. Samples crystallized from the glassy state. J. Polym. Sci. Part B-Polym. Phys. 2006, 44, 3200–3214. [Google Scholar] [CrossRef]

- Zhou, J.; Zheng, Y.; Shan, G.R.; Bao, Y.Z.; Wang, W.J.; Pan, P.J. Stretch-Induced alpha-to-beta Crystal Transition and Lamellae Structural Evolution of Poly(butylene adipate-ran-terephthalate) Aliphatic-Aromatic Copolyester. Macromolecules 2019, 52, 1334–1347. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, J.; Bao, Y.Z.; Shan, G.R.; Pan, P.J. Polymorphic Crystal Transition and Lamellae Structural Evolution of Poly(p-dioxanone) Induced by Annealing and Stretching. J. Phys. Chem. B 2019, 123, 3822–3831. [Google Scholar] [CrossRef]

- Song, J.B.; Zhang, H.L.; Ren, M.Q.; Chen, Q.Y.; Sun, X.H.; Wang, S.Y.; Zhang, H.F.; Mo, Z.S. Crystal transition of nylon-12,12 under drawing and annealing. Macromol. Rapid Commun. 2005, 26, 487–490. [Google Scholar] [CrossRef]

- Rhee, S.; White, J.L. Crystal structure and morphology of biaxially oriented polyamide 12 films. J. Polym. Sci. Part B-Polym. Phys. 2002, 40, 1189–1200. [Google Scholar] [CrossRef]

- Li, K.; Xiong, B.; Cao, Y. Influence of temperature on the microstructure and mechanical properties of stretched polypropylene. J. Appl. Polym. Sci. 2015, 132, 42622. [Google Scholar] [CrossRef]

- Wang, P.; Yu, H.C.; Ma, R.X.; Wang, Y.M.; Liu, C.T.; Shen, C.Y. Temperature-dependent orientation of poly(ether ether ketone) under uniaxial tensile and its correlation with mechanical properties. J. Therm. Anal. Calorim. 2020, 141, 1361–1369. [Google Scholar] [CrossRef]

- Wei, Z.Z.; Lun, R.X.; Lou, X.Q.; Tian, F.; Lin, J.Y.; Li, X.H.; Yu, J.Y.; Li, F.X. Lamellae evolution of poly(butylene succinate-co-terephthalate) copolymer induced by uniaxial stretching and subsequent heating. RSC Adv. 2014, 4, 64625–64633. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Zhou, C.B.; Zhang, Y.; Xue, F.F.; Luo, B.J.; Li, H.F.; Ren, X.K.; Li, J.Q.; Shang, Y.R.; Wu, Z.H.; et al. Direct investigations of temperature related structure transitions in strained poly(butylene succinate) with SAXS and WAXS. Colloid Polym. Sci. 2016, 294, 321–328. [Google Scholar] [CrossRef]

- Mao, Y.M.; Li, X.W.; Burger, C.; Hsiao, B.S.; Tsou, A.H. 2D WAXS/SAXS study on isotactic propylene-1-butylene random copolymer subjected to uniaxial stretching: The influence of temperature. Polymer 2013, 54, 1432–1439. [Google Scholar] [CrossRef]

- Kamal, T.; Shin, T.J.; Park, S.Y. Uniaxial Tensile Deformation of Poly(epsilon-caprolactone) Studied with SAXS and WAXS Techniques Using Synchrotron Radiation. Macromolecules 2012, 45, 8752–8759. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Tang, Y.J.; Rieger, J.; Enderle, H.F.; Lilge, D.; Roth, S.V.; Gehrke, R.; Heckmann, W.; Men, Y.F. Two Lamellar to Fibrillar Transitions in the Tensile Deformation of High-Density Polyethylene. Macromolecules 2010, 43, 4727–4732. [Google Scholar] [CrossRef]

- Wu, Y.; Huang, A.; Fan, S.; Liu, Y.; Liu, X. Crystal Structure and Mechanical Properties of Uniaxially Stretched PA612/SiO2 Films. Polymers 2020, 12, 711. [Google Scholar] [CrossRef]

| Stretching Temperature (°C) | Stretching Ratio | 2θ(°) | d-Spacing (nm) | Melting Temperature (°C) | Melting Enthalpy (J/g) |

|---|---|---|---|---|---|

| 90 | 4.0 | 21.05 | 0.421 | 300.3 | 58.0 |

| 150 | 4.0 | 21.63 | 0.410 | 299.8 | 71.9 |

| 180 | 4.0 | 21.96 | 0.405 | 299.4 | 71.6 |

| 210 | 4.0 | 22.07 | 0.402 | 298.0 | 72.1 |

| 240 | 4.0 | 22.03 | 0.403 | 295.1 | 76.9 |

| 210 | 1.0 | 21.01 | 0.423 | 299.5 | 61.8 |

| 210 | 1.6 | 21.47 | 0.414 | 299.3 | 63.3 |

| 210 | 2.2 | 21.6 | 0.412 | 299.2 | 67.8 |

| 210 | 2.8 | 21.74 | 0.408 | 299.0 | 69.0 |

| 210 | 3.4 | 21.76 | 0.408 | 299.1 | 67.5 |

| 210 | 4.0 | 22.07 | 0.402 | 298.0 | 72.1 |

| 210 | 4.6 | 22.09 | 0.402 | 293.8 | 67.4 |

| Stretching Temperature (°C) | Stretching Ratio | α Transition Temperature (°C) |

|---|---|---|

| 90 | 4.0 | 145.4 |

| 150 | 4.0 | 152.9 |

| 180 | 4.0 | 156.1 |

| 210 | 4.0 | 153.6 |

| 240 | 4.0 | 146.0 |

| 210 | 1.0 | 133.6 |

| 210 | 1.6 | 142.6 |

| 210 | 2.2 | 146.4 |

| 210 | 2.8 | 148.0 |

| 210 | 3.4 | 153.0 |

| 210 | 4.0 | 153.6 |

| 210 | 4.6 | 155.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, Y.; Lou, H.; Zhao, W.; Zhang, Y.; Cui, Z.; Fu, P.; Pang, X.; Zhang, X.; Liu, M. The Structural Evolution and Mechanical Properties of Semi-Aromatic Polyamide 12T after Stretching. Polymers 2022, 14, 4805. https://doi.org/10.3390/polym14224805

Shang Y, Lou H, Zhao W, Zhang Y, Cui Z, Fu P, Pang X, Zhang X, Liu M. The Structural Evolution and Mechanical Properties of Semi-Aromatic Polyamide 12T after Stretching. Polymers. 2022; 14(22):4805. https://doi.org/10.3390/polym14224805

Chicago/Turabian StyleShang, Yuting, Hongchuan Lou, Wei Zhao, Yuancheng Zhang, Zhe Cui, Peng Fu, Xinchang Pang, Xiaomeng Zhang, and Minying Liu. 2022. "The Structural Evolution and Mechanical Properties of Semi-Aromatic Polyamide 12T after Stretching" Polymers 14, no. 22: 4805. https://doi.org/10.3390/polym14224805

APA StyleShang, Y., Lou, H., Zhao, W., Zhang, Y., Cui, Z., Fu, P., Pang, X., Zhang, X., & Liu, M. (2022). The Structural Evolution and Mechanical Properties of Semi-Aromatic Polyamide 12T after Stretching. Polymers, 14(22), 4805. https://doi.org/10.3390/polym14224805