Dynamic Behavior of Thermally Affected Injection-Molded High-Density Polyethylene Parts Modified by Accelerated Electrons

Abstract

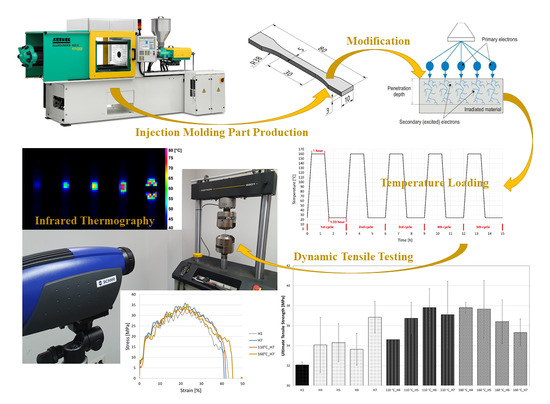

:1. Introduction

2. Materials and Methods

2.1. Material and Specimen Preparation

2.2. Radiation Cross-Linking by Accelerated Electrons

2.3. Tempereature Aging

2.4. Dynamic Tensile Test with Infrared Thermography Record

2.5. Differential Scanning Calorimetry (DSC)

2.6. Thermogravimetric Analysis (TGA)

3. Results

3.1. Dynamic Tensile Test with Infrared Thermography Record

3.2. Differential Scanning Calorimetry (DSC)

3.3. Thermogravimetric Analysis (TGA)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amjadi, M.; Fatemi, A. Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Technique, Thickness, Temperature, and Strain Rate. Polymers 2020, 12, 1857. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Fatemi, A. Creep Behavior and Modeling of High-Density Polyethylene (HDPE). Polym. Test 2021, 94, 107031. [Google Scholar] [CrossRef]

- Abeysinghe, S.; Gunasekara, C.; Bandara, C.; Nguyen, K.; Dissanayake, R.; Mendis, P. Engineering Performance of Concrete Incorporated with Recycled High-Density Polyethylene (HDPE). Polymers 2021, 13, 1885. [Google Scholar] [CrossRef]

- Wu, W.-L.; Wang, Y.-W. Modified High-Density Polyethylene Films: Preparation. Composition and Their Physical Properties. Indian Acad. Sci. 2020, 43, 143. [Google Scholar] [CrossRef]

- Wen, Y.; Tsou, C.H.; Gao, C.; Chen, J.C.; Tang, Z.; Chen, Z.; Yang, T.; Du, J.; Yu, Y.; Suen, M.C.; et al. Evaluating Distillers Grains as Bio-Fillers for High-Density Polyethylene. J. Polym. Res. 2020, 27, 167. [Google Scholar] [CrossRef]

- Silviyati, I.; Zubaidah, N.; Amin, J.M.; Supraptiah, E.; Utami, R.D.; Ramadhan, I. The Effect of Addition of High-Density Polyethylene (HDPE) as Binder on Hebel Light Brick (Celcon). Proc. J. Phys. Conf. Ser. Inst. Phys. Publ. 2020, 1500, 012083. [Google Scholar] [CrossRef]

- Viljoen, D.; Fischer, M.; Kühnert, I.; Labuschagné, J. The Tensile Behaviour of Highly Filled High-Density Polyethylene Quaternary Composites: Weld-Line Effects, Dic Curiosities and Shifted Deformation Mechanisms. Polymers 2021, 13, 527. [Google Scholar] [CrossRef]

- Qin, S.; Xu, W.H.; Jiang, H.W.; Zhang, H.H.; He, Y.; Wu, T.; Qu, J.P. Simultaneously Achieving Self-Toughening and Self-Reinforcing of Polyethylene on an Industrial Scale Using Volume-Pulsation Injection Molding. Polymer 2021, 213, 123324. [Google Scholar] [CrossRef]

- Zachariades, A.; Economy, J. Super Strong Polymers in Planar Directions. Polym. Eng. Sci. 1983, 23, 266–270. [Google Scholar] [CrossRef]

- Allan, P.S.; Bevis, M.J.; Gibson, J.R.; May, C.J.; Pinwill, I.E. Shear Controlled Orientation Technology for The Management of Reinforcing Fibres in Moulded and Extruded Composite Materials. Mater. Process. Technol. 1996, 56, 272–281. [Google Scholar] [CrossRef]

- Lei, J.; Jiang, C.; Shen, K. Biaxially Self-Reinforced High-Density Polyethylene Prepared by Dynamic Packing Injection Molding. I. Processing Parameters and Mechanical Properties. J. Appl. Polym. Sci. 2004, 93, 1584–1590. [Google Scholar] [CrossRef]

- Youbing, L.; Kaizhi, S. Self-Reinforced High-Density Polyethylene Prepared by Low Frequency Vibration-Assisted Injection Molding. II: Microstructure Investigation. J. Macromol. Sci. Part B 2010, 49, 242–249. [Google Scholar] [CrossRef]

- Layser, G.S.; Coulter, J.P. Localized Effects of Dynamic Melt Manipulation on Flow Induced Orientation and Mechanical Performance of Injection Molded Products. Polym. Eng. Sci. 2007, 47, 1912–1919. [Google Scholar] [CrossRef]

- Primo Benitez-Rangel, J.; Trejo-Hernández, M.; Alberto Morales-Hernández, L.; Domínguez-González, A. Improvement of the Injection Mold Process by Using Vibration through a Mold Accessory. Mater. Manuf. Process. 2010, 25, 577–580. [Google Scholar] [CrossRef]

- Waschitschek, K.; Kech, A.; Christiansen, J.D. Influence of Push-pull Injection Moulding on Fibres and Matrix of Fibre Reinforced Polypropylene. Compos. Part A 2002, 33, 735–744. [Google Scholar] [CrossRef]

- Liu, T.; Li, W.; Li, L.; Peng, X.; Kuang, T. Effect of Dynamic Oscillation Shear Flow Intensity on the Mechanical and Morphological Properties of High-Density Polyethylene: An Integrated Experimental and Molecular Dynamics Simulation Study. Polym. Test. 2019, 80, 106122. [Google Scholar] [CrossRef]

- Chaudhary, A.K.; Vijayakumar, R.P. Effect of Chemical Treatment on Biological Degradation of High-Density Polyethylene (HDPE). Environ. Dev. Sustain. 2020, 22, 1093–1104. [Google Scholar] [CrossRef]

- Dany, H.; Dhong, W.W.; Jiat, K.W.; Leong, T.K.; Yuhana, N.Y.; Tan, G. Deodorizing Methods for Recycled High-Density Polyethylene Plastic Wastes. Mater. Plast 1964, 58, 129–136. [Google Scholar] [CrossRef]

- Yang, J.; Li, F.; Guan, C.; Xu, X.; Zhong, L.; Gao, Y.; Han, Y.; Yan, N.; Zhao, G.; Jiang, W. Brittle-Ductile Transition of Impact PP Blends: Effect of Modulus Ratio of PP Matrix to Impact Modifier. Polym. Bull. 2022. [Google Scholar] [CrossRef]

- Alsayed, Z.; Badawi, M.S.; Awad, R. Investigation of Thermal and Mechanical Behavior of HDPE/ZnFe2O4 Composite. J. Inorg. Organomet Polym. Mater. 2021, 31, 2757–2765. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Creep and Fatigue Behaviors of High-Density Polyethylene (HDPE): Effects of Temperature, Mean Stress, Frequency, and Processing Technique. Int. J. Fatigue 2020, 141, 105871. [Google Scholar] [CrossRef]

- Salakhov, I.I.; Shaidullin, N.M.; Chalykh, A.E.; Matsko, M.A.; Shapagin, A.V.; Batyrshin, A.Z.; Shandryuk, G.A.; Nifant’ev, I.E. Low-temperature Mechanical Properties of High-density and Low-density Polyethylene and Their Blends. Polymers 2021, 13, 1821. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Ramesh, M.R.; Doddamani, M.; Rangappa, S.M.; Siengchin, S. Mechanical Characterization of 3D Printed MWCNTs/HDPE Nanocomposites. Polym. Test 2022, 114, 107703. [Google Scholar] [CrossRef]

- Naik, T.P.; Gairola, S.; Singh, I.; Sharma, A.K. Microwave Hybrid Heating for Moulding of Sisal/Jute/HDPE Composites. J. Nat. Fibers 2022. [Google Scholar] [CrossRef]

- Al-Majali, Y.T.; Forshey, S.; Trembly, J.P. Effect of Natural Carbon Filler on Thermo-Oxidative Degradation of Thermoplastic-Based Composites. Thermochim. Acta 2022, 713, 179226. [Google Scholar] [CrossRef]

- Yağci, Ö.; Eker Gümüş, B.; Taşdemir, M. Thermal, Structural and Morphological Properties of Polypropylene and High Density Polyethylene Polymer Composites Filled with Waste Urea Formaldehyde. Polym. Bull. 2022. [Google Scholar] [CrossRef]

- Chialanza, M.R.; Sofía, S.F.; Parada, A.P. Modeling Microplastic with Polyethylene (PE) Spherical Particles: A Differential Scanning Calorimetry Approach for Quantification. Environ. Sci. Pollut. Res. 2022, 29, 2311–2324. [Google Scholar] [CrossRef]

- Savini, G.; Oréfice, R.L. Super Ductility in HDPE/EVA Blends Triggered by Synthetic Amorphous Nanotalc. J. Polym. Res. 2021, 28, 19. [Google Scholar] [CrossRef]

- Khalid, H.U.; Ismail, M.C.; Nosbi, N. Degradation Monitoring of HDPE Material in CO2-Saturated NaCl Environment through Electrochemical Impedance Spectroscopy Technique. Materials 2021, 14, 2823. [Google Scholar] [CrossRef]

- Aderikha, V.N.; Feipeng, C.; Koval, V.N.; Xiaoyu, L.; Shapovalov, V.A.; Makarenko, O.A.; Yongguang, X. Increasing the Resistance of HDPE to Abrasive Wear with Small Additions of UHMWPE. J. Frict. Wear 2022, 43, 1–7. [Google Scholar] [CrossRef]

- Mazur, K.; Jakubowska, P.; Romańska, P.; Kuciel, S. Green high density polyethylene (HDPE) reinforced with basalt fiber and agricultural fillers for technical applications. J. Compos. B Eng. 2020, 202, 108399. [Google Scholar] [CrossRef]

- Madi, N.K. Thermal and mechanical properties of injection molded recycled high density polyethylene blends with virgin isotactic polypropylene. Mater. Des. 2013, 46, 435–441. [Google Scholar] [CrossRef]

- Dolynchuk, O.; Kolesov, I.; Androsch, R.; Radusch, H.J. Kinetics and dynamics of two-way shape-memory behavior of crosslinked linear high-density and short-chain branched polyethylenes with regard to crystal orientation. Polymer 2015, 79, 146–158. [Google Scholar] [CrossRef]

- Paajanen, A.; Vaari, J.; Verho, T. Crystallization of cross-linked polyethylene by molecular dynamics simulation. Polymer 2019, 171, 80–86. [Google Scholar] [CrossRef]

- Zhao, M.; Ding, X.; Mi, J.; Zhou, H.; Wang, X. Role of high-density polyethylene in the crystallization behaviors, rheological property, and supercritical CO2 foaming of poly (lactic acid). Polym. Degrad. Stab. 2017, 146, 277–286. [Google Scholar] [CrossRef]

- Daramola, O.O.; Taiwo, A.S.; Oladele, I.O.; Olajide, J.L.; Adeleke, S.A.; Adewuyi, B.O.; Sadiku, E.R. Mechanical properties of high density polyethylene matrix composites reinforced with chitosan particles. Mater. Today Proc. 2021, 38, 682–687. [Google Scholar] [CrossRef]

- Kim, P.S.; Mong, A.L.; Kim, D. Thermal, mechanical, and electrochemical stability enhancement of Al2O3 coated polypropylene/polyethylene/polypropylene separator via poly(vinylidene fluoride)-poly(ethoxylated pentaerythritol tetraacrylate) semi-interpenetrating network binder. J. Membr. Sci. 2020, 612, 118481. [Google Scholar] [CrossRef]

- Mizera, A.; Manas, M.; Stoklasek, P. Effect of Temperature Ageing on Injection Molded High-Density Polyethylene Parts Modified by Accelerated Electrons. Materials 2022, 15, 742. [Google Scholar] [CrossRef]

- Moreno, D.D.P.; Saron, C. Low-density polyethylene waste/recycled wood composites. Compos. Struct. 2017, 176, 1152–1157. [Google Scholar] [CrossRef]

- Mohammadi, H.; Vincent, M.; Marand, H. Investigating the equilibrium melting temperature of linear polyethylene using the non-linear Hoffman-Weeks approach. Polymer 2018, 146, 344–360. [Google Scholar] [CrossRef]

- Muhammad, I.; Makwashi, N.; Manos, G. Catalytic degradation of linear low-density polyethylene over HY-zeolite via pre-degradation method. J. Anal. Appl. Pyrolysis 2019, 138, 10–21. [Google Scholar] [CrossRef] [Green Version]

- Chriaa, I.; Trigui, A.; Karkri, M.; Jedidi, I.; Abdelmouleh, M.; Boudaya, C.H. Thermal properties of shape-stabilized phase change materials based on Low Density Polyethylene, Hexadecane and SEBS for thermal energy storage. Appl. Therm. Eng. 2020, 171, 115072. [Google Scholar] [CrossRef]

- Nabiyev, A.A.; Olejniczak, A.; Pawlukojc, A.; Balasoiu, M.; Bunoiu, M.; Maharramov, A.M.; Nuriyev, M.A.; Ismayilova, R.S.; Azhibekov, A.K.; Kabyshev, A.M.; et al. Nano-ZrO2 filled high-density polyethylene composites: Structure, thermal properties, and the influence γ-irradiation. Polym. Degrad. Stab. 2020, 171, 109042. [Google Scholar] [CrossRef]

- Ahmad, H.; Rodrigue, D. Crosslinked Polyethylene: A Review on the Crosslinking Techniques, Manufacturing Methods, Applications, and Recycling. Polym. Eng. Sci. 2022, 62, 2376–2401. [Google Scholar] [CrossRef]

- Manas, D.; Manas, M.; Mizera, A.; Stoklasek, P.; Navratil, J.; Sehnalek, S.; Drabek, P. The High Density Polyethylene Composite with Recycled Radiation Cross-Linked Filler of RHDPEx. Polymers 2018, 10, 1361. [Google Scholar] [CrossRef] [Green Version]

- Manas, D.; Manas, M.; Mizera, A.; Navratil, J.; Ovsik, M.; Tomanova, K.; Sehnalek, S. Use of Irradiated Polymers after Their Lifetime Period. Polymers 2018, 10, 641. [Google Scholar] [CrossRef] [Green Version]

- Casem, D.; Lamberson, L.; Kimberly, J. Dynamic Behavior of Materials; Conference Proceedings of the Society for Experimental Mechanics Series; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; Volume 1, ISBN 978-3-319-41131-6. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L. Dynamic Compressive Behaviour of Aluminium Foams Fabricated from Rejected Precursor Materials. Ciência Tecnol. Mater. 2016, 28, 19–22. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Tanaka, S.; Hokamoto, K.; Ren, Z. Compressive Behaviour of Chiral Auxetic Cellular Structures at Different Strain Rates. Int. J. Impact Eng. 2020, 141, 103566. [Google Scholar] [CrossRef]

- Chen, L.; Kim, H.-S.; Kim, S.-K.; de Cooman, B.C. Localized Deformation Due to Portevin–LeChatelier Effect in 18Mn–0.6C TWIP Austenitic Steel. ISIJ Int. 2007, 47, 1804–1812. [Google Scholar] [CrossRef]

- Labudde, T.; Ingendahl, T.; Wildau, M.; Saeed-Akbari, A.; Hoffmann, S.; Bleck, W. Charakterisierung Der Verformungsmechanismen Bei Hoch Mn-Legierten Stählen Unter Einachsiger Zugbeanspruchung. Mater. Test. 2013, 55, 636–642. [Google Scholar] [CrossRef]

- Soares, G.C.; Vázquez-Fernández, N.I.; Hokka, M. Thermomechanical Behavior of Steels in Tension Studied with Synchronized Full-Field Deformation and Temperature Measurements. Exp. Tech. 2021, 45, 627–643. [Google Scholar] [CrossRef]

- Sendrowicz, A.; Myhre, A.O.; Wierdak, S.W.; Vinogradov, A. Challenges and Accomplishments in Mechanical Testing Instrumented by In Situ Techniques: Infrared Thermography, Digital Image Correlation, and Acoustic Emission. Appl. Sci. 2021, 11, 6718. [Google Scholar] [CrossRef]

- Fan, J.; Chen, X.; Wang, D.; Li, S.; Zhao, Y. Infrared Thermographic Analysis of Notch Effects on Tensile Behavior of 30CrMnSiA Steel. Infrared Phys. Technol. 2019, 101, 110–118. [Google Scholar] [CrossRef]

- Chin, B.L.F.; Yusup, S.; Al Shoaibi, A.; Kannan, P.; Srinivasakannan, C.; Sulaiman, S.A. Comparative Studies on Catalytic and Non-Catalytic Co-Gasification of Rubber Seed Shell and High Density Polyethylene Mixtures. J. Clean Prod. 2014, 70, 303–314. [Google Scholar] [CrossRef]

- Sharkeev, Y.P.; Vavilov, V.P.; Skrypnyak, V.A.; Legostaeva, E.V.; Eroshenko, A.Y.; Belyavskaya, O.A.; Ustinov, A.M.; Klopotov, A.A.; Chulkov, A.O.; Kozulin, A.A.; et al. Research on the Processes of Deformation and Failure in Coarse- and Ultrafine-Grain States of Zr1–Nb Alloys by Digital Image Correlation and Infrared Thermography. Mater. Sci. Eng. A 2020, 784, 139203. [Google Scholar] [CrossRef]

- Majidi, O.; de Cooman, B.C.; Barlat, F.; Lee, M.-G.; Korkolis, Y.P. Thermomechanical Response of a TWIP Steel during Monotonic and Non-Monotonic Uniaxial Loading. Mater. Sci. Eng. A 2016, 674, 276–285. [Google Scholar] [CrossRef]

- Żaba, K.; Trzepieciński, T.; Puchlerska, S.; Noga, P.; Balcerzak, M. Coupled Thermomechanical Response Measurement of Deformation of Nickel-Based Superalloys Using Full-Field Digital Image Correlation and Infrared Thermography. Materials 2021, 14, 2163. [Google Scholar] [CrossRef]

- Novak, N.; Mauko, A.; Ulbin, M.; Krstulovic-Opara, L.; Ren, Z.; Vesenjak, M. Development and characterisation of novel three-dimensional axisymmetric chiral auxetic structures. J. Mater. Res. Technol. 2022, 17, 2701–2713. [Google Scholar] [CrossRef]

| Processing Conditions | 170 U |

| Injection Rate (mm/s) | 40 |

| Injection Pressure (MPa) | 60 |

| Holding Pressure (MPa) | 40 |

| Holding Time (s) | 30 |

| Cooling Time (s) | 30 |

| Mold Temperature (°C) | 40 |

| Plastic Unit Temperature Bands | 170 U |

| Zone 1 (°C) | 180 |

| Zone 2 (°C) | 190 |

| Zone 3 (°C) | 195 |

| Zone 4 (°C) | 200 |

| Group | Abbreviation | Description |

|---|---|---|

| 1 | H1 | Nonmodified HDPE |

| 2 | H4 | Modified HDPE by irradiation dose 99 kGy |

| 2 | H5 | Modified HDPE by irradiation dose 132 kGy |

| 2 | H6 | Modified HDPE by irradiation dose 165 kGy |

| 2 | H7 | Modified HDPE by irradiation dose 198 kGy |

| 3 | 110 °C_H4 | H4 after temperature load at 5 × 110 °C |

| 3 | 110 °C_H5 | H5 after temperature load at 5 × 110 °C |

| 3 | 110 °C_H6 | H6 after temperature load at 5 × 110 °C |

| 3 | 110 °C_H7 | H7 after temperature load at 5 × 110 °C |

| 4 | 160 °C_H4 | H4 after temperature load at 5 × 160 °C |

| 4 | 160 °C_H5 | H5 after temperature load at 5 × 160 °C |

| 4 | 160 °C_H6 | H6 after temperature load at 5 × 160 °C |

| 4 | 160 °C_H7 | H7 after temperature load at 5 × 160 °C |

| Specimen | Ultimate Tensile Strength [MPa] | Surface Temperature Difference [°C] |

|---|---|---|

| H1 | 32.1 ± 0.3 | 40.0 ± 4.0 |

| H4 | 34.1 ± 2.7 | 26.4 ± 6.6 |

| H5 | 34.3 ± 1.9 | 28.2 ± 0.4 |

| H6 | 33.6 ± 1.6 | 22.8 ± 5.4 |

| H7 | 36.8 ± 1.6 | 25.5 ± 4.7 |

| 110 °C_H4 | 34.6 ± 0.1 | 17.0 ± 2.5 |

| 110 °C_H5 | 36.8 ± 1.6 | 23.4 ± 3.9 |

| 110 °C_H6 | 37.8 ±1.9 | 17.8 ± 2.5 |

| 110 °C_H7 | 37.1 ± 3.3 | 17.5 ± 10.3 |

| 160 °C_H4 | 37.8 ± 0.5 | 29.4 ± 7.2 |

| 160 °C_H5 | 37.7 ± 2.8 | 33.8 ± 8.1 |

| 160 °C_H6 | 36.4 ± 2.2 | 32.7 ± 3.7 |

| 160 °C_H7 | 35.3 ± 1.4 | 27.0 ± 4.7 |

| Specimen | Peak Temperature at 1st Heating [°C] | Peak Temperature at 1st Cooling [°C] | Peak Temperature at 2nd Heating [°C] |

|---|---|---|---|

| H1 | 132.68 | 117.39 | 130.81 |

| H4 | 133.80 | 114.71 | 131.49 |

| H5 | 134.17 | 111.76 | 134.27 |

| H6 | 131.35 | 113.17 | 131.17 |

| H7 | 131.16 | 111.98 | 130.96 |

| 110 °C_H4 | 131.97 | 115.41 | 130.84 |

| 110 °C_H5 | 131.72 | 114.10 | 131.56 |

| 110 °C_H6 | 133.42 | 111.68 | 133.04 |

| 110 °C_H7 | 130.43 | 113.35 | 130.30 |

| 160 °C_H4 | 134.58 | 114.22 | 131.81 |

| 160 °C_H5 | 134.87 | 113.04 | 132.71 |

| 160 °C_H6 | 133.74 | 112.80 | 132.12 |

| 160 °C_H7 | 133.55 | 111.77 | 132.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mizera, A.; Krstulovic-Opara, L.; Krempl, N.; Karhankova, M.; Manas, M.; Sanek, L.; Stoklasek, P.; Grebo, A. Dynamic Behavior of Thermally Affected Injection-Molded High-Density Polyethylene Parts Modified by Accelerated Electrons. Polymers 2022, 14, 4970. https://doi.org/10.3390/polym14224970

Mizera A, Krstulovic-Opara L, Krempl N, Karhankova M, Manas M, Sanek L, Stoklasek P, Grebo A. Dynamic Behavior of Thermally Affected Injection-Molded High-Density Polyethylene Parts Modified by Accelerated Electrons. Polymers. 2022; 14(22):4970. https://doi.org/10.3390/polym14224970

Chicago/Turabian StyleMizera, Ales, Lovre Krstulovic-Opara, Nina Krempl, Michaela Karhankova, Miroslav Manas, Lubomir Sanek, Pavel Stoklasek, and Alen Grebo. 2022. "Dynamic Behavior of Thermally Affected Injection-Molded High-Density Polyethylene Parts Modified by Accelerated Electrons" Polymers 14, no. 22: 4970. https://doi.org/10.3390/polym14224970

APA StyleMizera, A., Krstulovic-Opara, L., Krempl, N., Karhankova, M., Manas, M., Sanek, L., Stoklasek, P., & Grebo, A. (2022). Dynamic Behavior of Thermally Affected Injection-Molded High-Density Polyethylene Parts Modified by Accelerated Electrons. Polymers, 14(22), 4970. https://doi.org/10.3390/polym14224970