Facile and Green Process to Synthesize a Three-Dimensional Network Few-Layer Graphene/Carbon Nanotube Composite for Electromagnetic Interference Shielding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Preparation of FLG/CNTs/Wax Composite

2.3. Preparation of EMI Shielding Testing Plates

2.4. Characterizations

- SET ≈ SER + SEA

- SER and SEA can be calculated as follows:

- SER = −log10(1 − R)

- SEA = −log10(1 − Aeff) = −log10[T/(1 − R)]

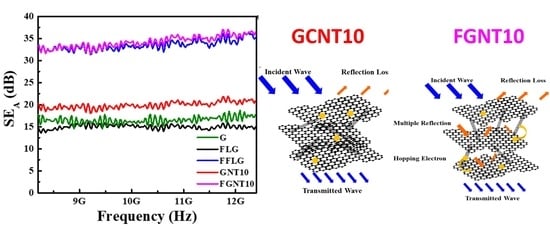

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tsydenova, O.; Bengtsson, M. Chemical hazards associated with treatment of waste electrical and electronic equipment. Waste Manag. 2011, 31, 45–58. [Google Scholar] [CrossRef] [PubMed]

- Qin, F.; Brosseau, C. A review and analysis of microwave absorption in polymer composites filled with carbonaceous particles. J. Appl. Phys. 2012, 111, 061301. [Google Scholar] [CrossRef]

- Che, R.C.; Peng, L.M.; Duan, X.F.; Chen, Q.; Liang, X.L. Microwave absorption enhancement and complex permittivity and permeability of Fe encapsulated within carbon nanotubes. Appl. Phys. Lett. 2004, 16, 401–405. [Google Scholar] [CrossRef]

- Cao, W.Q.; Wang, X.X.; Yuan, J.; Wang, W.Z.; Cao, M.S. Temperature dependent microwave absorption of ultrathin graphene composites. J. Mater. Chem. C 2015, 3, 10017–10022. [Google Scholar] [CrossRef]

- Chung, D.D. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Radasky, W.A.; Baum, C.E.; Wik, M.W. Introduction to the special issue on high-power electromagnetics (HPEM) and intentional electromagnetic interference (IEMI). IEEE Trans. Electromagn. Compat. 2004, 46, 314–321. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, C.; Ren, W.; Ma, C.; Cheng, H.M. Lightweight and flexible graphene foam composites for high-performance electromagnetic interference shielding. Adv. Mater. 2013, 25, 1296–1300. [Google Scholar] [CrossRef]

- MacGregor, D.G.; Slovic, P.; Morgan, M.G. Perception of risks from electromagnetic fields: A psychometric evaluation of a risk-communication approach. Risk Anal. 1994, 14, 815–828. [Google Scholar] [CrossRef]

- Cheng, W.H.; Hung, W.C.; Lee, C.H.; Hwang, G.L.; Jou, W.S.; Wu, T.L. Low-cost and low-electromagnetic-interference packaging of optical transceiver modules. J. Lightwave Technol. 2004, 22, 2177. [Google Scholar] [CrossRef]

- Wen, S.H.; Chung, D.D.L. Design and operation of a real-scale electromagnetic shielding evaluation system for reinforced composite construction materials. Cem. Concr. Res. 2018, 34, 329. [Google Scholar] [CrossRef]

- Fauveaux, S.; Wojkiewicz, J.L.; Miane, J.L. Broadband electromagnetic shields using polyaniline composites. Electromagnetics 2003, 23, 617. [Google Scholar] [CrossRef]

- Huang, C.J.; Chang, T.C. Studies on the electromagnetic interference shielding effectiveness of metallized PVAc-AgNO3/PET conductive films. J. Appl. Polym. Sci. 2004, 91, 270. [Google Scholar] [CrossRef]

- Azim, S.S.; Satheesh, A.; Ramu, K.K.; Ramu, S.; Venkatachari, G. Studies on graphite based conductive paint coatings. Prog. Org. Coat. 2006, 55, 1–4. [Google Scholar] [CrossRef]

- Singh, A.P.; Mishra, M.; Sambyal, P.; Gupta, B.K.; Singh, B.P.; Chandra, A. Encapsulation of γFe2O3 decorated reduced graphene oxide in polyaniline core–shell tubes as an exceptional tracker for electromagnetic environmental pollution. J. Mater. Chem. A 2014, 2, 3581–3593. [Google Scholar] [CrossRef]

- Zhang, X.J.; Wang, G.S.; Cao, W.Q.; Wei, Y.Z.; Liang, J.F.; Guo, L. Enhanced microwave absorption property of reduced graphene oxide (RGO)-MnFe2O4 nanocomposites and polyvinylidene fluoride. ACS Appl. Mater. Interfaces 2014, 6, 7471–7478. [Google Scholar] [CrossRef] [PubMed]

- He, S.; Wang, G.S.; Lu, C.; Liu, J.; Wen, B.; Liu, H. Enhanced wave absorption of nanocomposites based on the synthesized complex symmetrical CuS nanostructure and poly (vinylidene fluoride). J. Mater. Chem. A 2013, 1, 4685–4692. [Google Scholar] [CrossRef]

- Singh, B.; Choudhary, V.; Saini, P.; Pande, S.; Singh, V.; Mathur, R. Enhanced microwave shielding and mechanical properties of high loading MWCNT–epoxy composites. J. Nanoparticle Res. 2013, 15, 1554. [Google Scholar] [CrossRef]

- Thomassin, J.M.; Jerome, C.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. R Rep. 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Choi, W.H.; Kim, C.G. Broadband microwave-absorbing honeycomb structure with novel design concept. Compos. Part B Eng. 2015, 83, 14. [Google Scholar] [CrossRef]

- Lee, K.P.M.; Czajka, M.; Shanks, R.; Daver, F. Low-defect graphene–polyamide-6 composites and modeling the filler–matrix interface. J. Appl. Polym. Sci. 2020, 137, 48630. [Google Scholar] [CrossRef]

- Yuan, Y.; Yin, W.; Yang, M.; Xu, F.; Zhao, X.; Li, J.; Peng, Q.; He, X.; Du, S.; Li, Y. Lightweight flexible and strong core-shell non-woven fabrics covered by reduced graphene oxide for high-performance electromagnetic interference shielding. Carbon 2018, 130, 59–68. [Google Scholar] [CrossRef]

- Yan, D.X.; Pang, H.; Li, B.; Vajtai, R.; Xu, L.; Ren, P.G.; Wang, J.H.; Li, Z.M. Structured reduced graphene oxide/polymer composites for ultra-efficient electromagnetic interference shielding. Adv. Funct. Mater. 2015, 25, 559–566. [Google Scholar] [CrossRef]

- Zhang, H.B.; Yan, Q.; Zheng, W.G.; He, Z.; Yu, Z.Z. Tough graphene-polymer microcellular foams for electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2011, 3, 918–924. [Google Scholar] [CrossRef] [PubMed]

- Alam, F.E.; Yu, J.; Shen, D.; Dai, W.; Li, H.; Zeng, X.; Yao, Y.; Du, S.; Jiang, N.; Lin, C.T. Highly conductive 3D segregated graphene architecture in polypropylene composite with efficient EMI shielding. Polymers 2017, 9, 662. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Chai, N.; Yu, Z.; Xu, H.; Li, X.; Liu, J.; Yin, X.; Riedel, R. Ultra-light, high flexible and efficient CNTs/Ti3C2-sodium alginate foam for electromagnetic absorption application. J. Mater. Sci. Technol. 2019, 35, 2859–2867. [Google Scholar] [CrossRef]

- Wang, H.; Shao, Y.; Mei, S.; Lu, Y.; Zhang, M.; Sun, J.-K.; Matyjaszewski, K.; Antonietti, M.; Yuan, J. Polymer-derived heteroatom-doped porous carbon materials. Chem. Rev. 2020, 120, 9363–9419. [Google Scholar] [CrossRef]

- Tuccitto, N.; Spitaleri, L.; Li-Destri, G.; Pappalardo, A.; Gulino, A.; Sfrazzetto, T.G. Supramolecular sensing of a chemical warfare agents simulant by functionalized carbon nanoparticles. Molecules 2020, 25, 5731. [Google Scholar] [CrossRef]

- Jang, D.; Park, J.-E.; Kim, Y.-K. Evaluation of (CNT@CIP)-embedded magneto-resistive sensor based on carbon nanotube and carbonyl iron powder polymer composites. Polymers 2022, 14, 542. [Google Scholar] [CrossRef]

- Song, P.; Liang, C.; Wang, L.; Qiu, H.; Gu, H.; Kong, J.; Gu, J. Obviously improved electromagnetic interference shielding performances for epoxy composites via constructing honeycomb structural reduced graphene oxide. Compos. Sci. Technol. 2019, 181, 107698. [Google Scholar] [CrossRef]

- Alam, F.E.; Dai, W.; Yang, M.; Du, S.; Li, X.; Yu, J.; Jiang, N.; Lin, C.T. Potential applications of quantum dots in mapping sentinel lymph node and detection of micrometastases in breast carcinoma. J. Breast Cancer 2013, 16, 1–11. [Google Scholar] [CrossRef]

- Li, X.H.; Li, X.; Liao, K.N.; Min, P.; Liu, T.; Dasari, A.; Yu, Z.Z. Thermally annealed anisotropic graphene aerogels and their electrically conductive epoxy composites with excellent electromagnetic interference shielding efficiencies. ACS Appl. Mater. Interfaces 2016, 8, 33230–33239. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, L.; Zhang, J.; Song, P.; Xiao, Z.; Liang, C.; Qiu, H.; Kong, J.; Gu, J. Fabrication and investigation on the ultra-thin and flexible Ti3C2Tx/co-doped polyaniline electromagnetic interference shielding composite films. Compos. Sci. Technol. 2019, 183, 107833. [Google Scholar] [CrossRef]

- Dai, W.; Ma, T.; Yan, Q.; Gao, J.; Tan, X.; Lv, L.; Hou, H.; Wei, Q.; Yu, J.; Wu, J.; et al. Metal-level thermally conductive yet soft graphene thermal interface materials. ACS Nano 2019, 13, 11561–11571. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.D.; Tai, N.H.; Chen, S.Y.; Chueh, Y.L. Controlled growth of carbon nanotube-graphene hybrid materials for flexible and transparent conductors and electron field emitters. Nanoscale 2012, 4, 632–638. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Dai, L. Self-assembled graphene/carbon nanotube hybrid films for supercapacitors. J. Phys. Chem. Lett. 2010, 1, 467–470. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, B.H.; Liu, Y.; Wang, Q.; Liu, Z.; Mai, Y.W.; Yu, Z.Z. Magnetic electrically conductive and lightweight graphene/iron pentacarbonyl porous films enhanced with chitosan for highly efficient broadband electromagnetic interference shielding. Compos. Sci. Technol. 2017, 151, 71–78. [Google Scholar] [CrossRef]

- Fu, H.; Yang, Z.; Zhang, Y.; Zhu, M.; Jia, Y.; Chao, Z.; Hu, D.; Li, Q. SWCNT-modulated folding-resistant sandwich-structured graphene film for high-performance electromagnetic interference shielding. Carbon 2020, 162, 490–496. [Google Scholar] [CrossRef]

- Bagotia, N.; Choudhary, V.; Sharma, D.K. Synergistic effect of graphene/multiwalled carbon nanotube hybrid fillers on mechanical, electrical and EMI shielding properties of polycarbonate/ethylene methyl acrylate nanocomposites. Compos. Part B Eng. 2019, 159, 378–388. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Gao, Q.; Zong, M.; Wang, M.; Qin, J. Electrically electromagnetic interference shielding microcellular composite foams with 3D hierarchical graphene-carbon nanotube hybrids. Compos. Part A 2020, 130, 105773. [Google Scholar] [CrossRef]

- Zhu, S.; Xing, C.; Wu, F.; Zuo, X.; Zhang, Y.; Yu, C.; Chen, M.; Li, W.; Li, Q.; Liu, L. Cake-like flexible carbon nanotubes/graphene composite prepared via a facile method for high-performance electromagnetic interference shielding. Carbon 2019, 145, 259–265. [Google Scholar] [CrossRef]

- Liang, J.J.; Wang, Y.; Huang, Y.; Ma, Y.F.; Liu, Z.F.; Cai, J.M.; Zhang, C.D.; Gao, H.J.; Chen, Y.S. A highly efficient gas-phase route for the oxygen functionalization of carbon nanotubes based on nitric acid vapor. Carbon 2009, 47, 922–925. [Google Scholar] [CrossRef]

- Yan, D.X.; Pang, H.; Xu, L.; Bao, Y.; Ren, P.G.; Lei, J.; Li, Z.M. Electromagnetic interference shielding of segregated polymer composite with an ultralow loading of in situ thermally reduced graphene oxide. Nanotechnology 2014, 25, 145705. [Google Scholar] [CrossRef] [PubMed]

- Hsiao, S.T.; Ma, C.C.M.; Tien, H.W.; Liao, W.H.; Wang, Y.S.; Li, S.M.; Huang, Y.C. Using a non-covalent modification to prepare a high electromagnetic interference shielding performance graphene nanosheet/water-borne polyurethane composite. Carbon 2013, 60, 57–66. [Google Scholar] [CrossRef]

- Yan, D.X.; Ren, P.G.; Pang, H.; Fu, Q.; Yang, M.B.; Li, Z.M. Efficient electromagnetic interference shielding of lightweight graphene/polystyrene composite. J. Mater. Chem. 2012, 22, 18772–18774. [Google Scholar] [CrossRef]

- Song, W.L.; Cao, M.S.; Lu, M.M.; Bi, S.; Wang, C.Y.; Liu, J.; Yuan, J.; Fan, L.Z. Flexible graphene/polymer composite films in sandwich structures for effective electromagnetic interference shielding. Carbon 2014, 66, 67–76. [Google Scholar] [CrossRef]

- Gedler, G.; Antunes, M.; Velasco, J.I.; Ozisik, R. Electromagnetic shielding effectiveness of polycarbonate/graphene nanocomposite foams processed in 2-steps with supercritical carbon dioxide. Mater Lett. 2015, 160, 41–44. [Google Scholar] [CrossRef] [Green Version]

- Zhan, Y.; Oliviero, M.; Wang, J.; Sorrentino, A.; Buonocore, G.G.; Sorrentino, L.; Lavorgna, M.; Xia, H.; Iannace, S. Enhancing the EMI shielding of natural rubber-based supercritical CO2 foams by exploiting their porous morphology and CNT segregated networks. Nanoscale 2019, 11, 1011–1020. [Google Scholar] [CrossRef]

- Jia, L.C.; Yan, D.X.; Yang, Y.; Zhou, D.; Cui, C.H.; Bianco, E.; Lou, J.; Vajtai, R.; Li, B.; Ajayan, P.M.; et al. High strain tolerant EMI shielding using carbon nanotube network stabilized rubber composite. Adv. Mater. Technol. 2017, 2, 1700078. [Google Scholar] [CrossRef]

- Abraham, J.; Arif, M.P.; Xavier, P.; Bose, S.; George, S.C.; Kalarikkal, N.; Thomas, S. Investigation into dielectric behaviour and electromagnetic interference shielding effectiveness of conducting styrene butadiene rubber composites containing ionic liquid modified MWCNT. Polymer 2017, 112, 102–115. [Google Scholar] [CrossRef]

- Joseph, N.; Janardhanan, C.; Sebastian, M.T. Electromagnetic interference shielding properties of butyl rubber-single walled carbon nanotube composites. Compos. Sci. Technol. 2014, 101, 139–144. [Google Scholar] [CrossRef]

- Giofrè, S.V.; Tiecco, M.; Celesti, C.; Patanè, S.; Triolo, C.; Gulino, A.; Spitaleri, L.; Scalese, S.; Scuderi, M.; Iannazzo, D. Eco-friendly 1,3-dipolar cycloaddition reactions on graphene quantum dots in natural deep eutectic solvent. Nanomaterials 2020, 10, 2549. [Google Scholar] [CrossRef] [PubMed]

- Contino, A.; Maccarrone, G.; Fragalà, E.M.; Spitaleri, L.; Gulino, A. Conjugated gold–porphyrin monolayers assembled on inorganic surfaces. Chem. Eur. J. 2017, 23, 14937–14943. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Yang, J.; Park, J.; Gou, X.; Wang, B.; Liu, H.; Yao, J. Facile synthesis and characterization of graphene nanosheets. J. Phys. Chem. C 2008, 112, 8192–8195. [Google Scholar]

- Tuccitto, N.; Riela, L.; Zammataro, A.; Spitaleri, L.; Li-Destri, G.; Sfuncia, G.; Nicotra, G.; Pappalardo, A.; Capizzi, G.; Sfrazzetto, T.G. Functionalized carbon nanoparticle-based sensors for chemical warfare agents. ACS Appl. Nano Mater. 2020, 3, 8182–8191. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeh, Y.-H.; Hsu, K.-T.; Huang, C.-H.; Liu, W.-R. Facile and Green Process to Synthesize a Three-Dimensional Network Few-Layer Graphene/Carbon Nanotube Composite for Electromagnetic Interference Shielding. Polymers 2022, 14, 1892. https://doi.org/10.3390/polym14091892

Yeh Y-H, Hsu K-T, Huang C-H, Liu W-R. Facile and Green Process to Synthesize a Three-Dimensional Network Few-Layer Graphene/Carbon Nanotube Composite for Electromagnetic Interference Shielding. Polymers. 2022; 14(9):1892. https://doi.org/10.3390/polym14091892

Chicago/Turabian StyleYeh, Yu-Hong, Kuei-Ting Hsu, Chia-Hung Huang, and Wei-Ren Liu. 2022. "Facile and Green Process to Synthesize a Three-Dimensional Network Few-Layer Graphene/Carbon Nanotube Composite for Electromagnetic Interference Shielding" Polymers 14, no. 9: 1892. https://doi.org/10.3390/polym14091892

APA StyleYeh, Y. -H., Hsu, K. -T., Huang, C. -H., & Liu, W. -R. (2022). Facile and Green Process to Synthesize a Three-Dimensional Network Few-Layer Graphene/Carbon Nanotube Composite for Electromagnetic Interference Shielding. Polymers, 14(9), 1892. https://doi.org/10.3390/polym14091892