The Use of Kenaf Fibre as a Natural Anti-Degradant in Recycled High-Density Polyethylene and Natural Rubber-Based Thermoplastic Elastomers

Abstract

:1. Introduction

2. Experimental Setup

2.1. Materials

2.2. Particle Size Analyser

2.3. Preparation of the Blends

2.4. Natural Weathering

2.5. Tensile Properties

2.6. Fourier Transform Infra Spectroscopy (FTIR)

2.7. Scanning Electron Microscopy (SEM)

2.8. Thermogravimetric Analysis (TGA)

2.9. Differential Scanning Calorimetry (DSC)

3. Results and Discussion

3.1. Characterization of KP

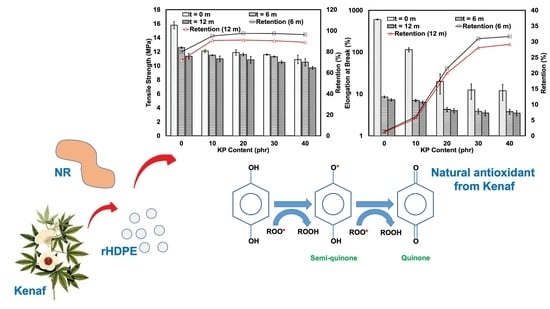

3.2. Natural Weathering

3.3. Surface Morphology

3.4. Changes in Functionalities after Natural Weathering

3.5. Differential Scanning Calorimetry

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Plastics Outlook. Available online: https://www.oecd-ilibrary.org/environment/data/global-plastic-outlook_c0821f81-en (accessed on 9 February 2023).

- Favaro, S.; Ganzerli, T.; de Carvalho Neto, A.; Da Silva, O.; Radovanovic, E. Chemical, morphological and mechanical analysis of sisal fiber-reinforced recycled high-density polyethylene composites. Express Polym. Lett. 2010, 4, 465–473. [Google Scholar] [CrossRef]

- Yam, K.L.; Gogoi, B.K.; Lai, C.C.; Selke, S.E. Composites from compounding wood fibers with recycled high density polyethylene. Polym. Eng. Sci. 1990, 30, 693–699. [Google Scholar] [CrossRef]

- Burgoa, A.; Hernandez, R.; Vilas, J.L. New ways to improve the damping properties in high-performance thermoplastic vulcanizates. Polym. Intern. 2020, 69, 467–475. [Google Scholar] [CrossRef]

- Huang, J.; Fan, J.; Cao, L.; Xu, C.; Chen, Y. A novel strategy to construct co-continuous PLA/NBR thermoplastic vulcanizates: Metal-ligand coordination-induced dynamic vulcanization, balanced stiffness-toughness and shape memory effect. Chem. Eng. J. 2020, 385, 123828. [Google Scholar] [CrossRef]

- Zheng, M.; Zhang, S.; Chen, Y.; Wu, Q.; Li, Q.; Wang, S. Structure evolution of bio-based PLA/ENR thermoplastic vulcanizates during dynamic vulcanization processing. Polym. Test 2020, 82, 106324. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Ricciardi, O.; González, S.; Verdejo, R.; López-Manchado, M.Á.; Hernández Santana, M. Development of Sustainable, Mechanically Strong, and Self-Healing Bio-Thermoplastic Elastomers Reinforced with Alginates. Polymers 2022, 14, 4607. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A. Organosolv Lignin Improved Thermoplastic Elastomeric Behavior of Polyethylene/Polyisoprene Blend. ACS Omega 2022, 7, 8483–8492. [Google Scholar] [CrossRef]

- Singh, B.; Sharma, N. Mechanistic implications of plastic degradation. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- Anderson, D.A.; Freeman, E.S. The kinetics of the thermal degradation of polystyrene and polyethylene. J. Polym. Sci. 1961, 54, 253–260. [Google Scholar] [CrossRef]

- Amiandamhen, S.O.; Osadolor, S.O. Recycled waste paper–cement composite panels reinforced with kenaf fibres: Durability and mechanical properties. J. Mater. Cycles Waste. Manag. 2020, 22, 1492–1500. [Google Scholar] [CrossRef]

- Silva, T.T.d.; Silveira, P.H.P.M.d.; Ribeiro, M.P.; Lemos, M.F.; da Silva, A.P.; Monteiro, S.N.; Nascimento, L.F.C. Thermal and Chemical Characterization of Kenaf Fiber (Hibiscus cannabinus) Reinforced Epoxy Matrix Composites. Polymers 2021, 13, 2016. [Google Scholar] [CrossRef]

- Saravana, K.M.; Sathees, S.K.; Babu, B.S.; Chakravarthy, C.H.N. Influence of fiber loading on mechanical characterization of pineapple leaf and kenaf fibers reinforced polyester composites. Mater. Today Proc. 2021, 46, 439–444. [Google Scholar]

- Fabiyi, J.S.; McDonald, A.G.; Wolcott, M.P.; Griffiths, P.R. Wood plastic composites weathering: Visual appearance and chemical changes. Polym. Degrad. Stab. 2008, 93, 1405–1414. [Google Scholar] [CrossRef]

- Schneider, J.P.; Myers, G.E.; Clemons, C.M.; English, B.W. Biofibers as reinforcing fillers in thermoplastic composites. J. Viny. Addv. Technol. 1995, 1, 103–108. [Google Scholar] [CrossRef]

- Nandagopalan, V.; Johnson, G.M.; Doss, A. GC-MS analysis of bioactive components of the methanol extract of Hibiscus tiliaceus Linn. Asian. J. Plant Sci. Res. 2015, 5, 6–10. [Google Scholar]

- Obouayeba, A.P.; Diarrassouba, M.; Soumahin, E.F.; Kouakou, T.H. Phytochemical analysis, purification and identification of Hibiscus anthocyanins. J. Pharm. Chem. Biol. Sci. 2015, 3, 156–168. [Google Scholar]

- Ismail, H.; Osman, H.; Mariatti, M. Effects of Natural Weathering on Properties of Recycled Newspaper-filled Polypropylene (PP)/Natural Rubber (NR) Composites. Polym.-Plast. Technol. Eng. 2008, 47, 697–707. [Google Scholar] [CrossRef]

- Surface Temperature in Malaysia. Available online: https://www.met.gov.my/en/projection/temperature/ (accessed on 9 February 2023).

- Richardson, M.J. Thermal analysis of polymers using quantitative differential scanning calorimetry. Polym. Test 1984, 4, 101–115. [Google Scholar] [CrossRef]

- Gwon, J.G.; Lee, S.Y.; Chun, S.J.; Doh, G.H.; Kim, J.H. Effects of chemical treatments of hybrid fillers on the physical and thermal properties of wood plastic composites. Compos. Part A Appl. Sci. Manufact. 2010, 41, 1491–1497. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Interfacial, dynamic mechanical, and thermal fiber reinforced behavior of MAPE treated sisal fiber reinforced HDPE composites. J. Appl. Polym. Sci. 2006, 102, 3306–3315. [Google Scholar] [CrossRef]

- Nuñez, A.J.; Kenny, J.M.; Reboredo, M.M.; Aranguren, M.I.; Marcovich, N.E. Thermal and dynamic mechanical characterization of polypropylene- woodflour composites. Polym. Eng. Sci. 2002, 42, 733–742. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Basak, R.K.; Rana, A.K. Study of the thermal behavior of alkali-treated jute fibers. J. Appl. Polym. Sci. 2002, 85, 2594–2599. [Google Scholar] [CrossRef]

- Rachini, A.; Le Troedec, M.; Peyratout, C.; Smith, A. Comparison of the thermal degradation of natural, alkali-treated and silane-treated hemp fibers under air and an inert atmosphere. J. Appl. Polym. Sci. 2009, 112, 226–234. [Google Scholar] [CrossRef]

- Alter, H. Filler particle size and mechanical properties of polymers. J. Appl. Polym. Sci. 1965, 9, 1525–1531. [Google Scholar] [CrossRef]

- Vinod, V.S.; Varghese, S.; Kuriakose, B. Degradation behaviour of natural rubber–aluminium powder composites: Effect of heat, ozone and high energy radiation. Polym. Degrad. Stab. 2002, 75, 405–412. [Google Scholar] [CrossRef]

- Leong, Y.W.; Abu Bakar, M.B.; Mohd Ishak, Z.A.; Ariffin, A. Characterization of talc/calcium carbonate filled polypropylene hybrid composites weathered in a natural environment. Polym. Degrad. Stab. 2004, 83, 411–422. [Google Scholar] [CrossRef]

- Abu-Sharkh, B.F.; Hamid, H. Degradation study of date palm fibre/polypropylene composites in natural and artificial weathering: Mechanical and thermal analysis. Polym. Degrad. Stab. 2004, 85, 967–973. [Google Scholar] [CrossRef]

- Ryu, J.; Kwon, S.-J.; Ahn, J.-W.; Jo, Y.D.; Kim, S.H.; Jeong, S.W.; Kim, J.-B.; Kang, S.-Y. Phytochemicals and antioxidant activity in the kenaf plant (Hibiscus cannabinus L.). J. Plant Biotechnol. 2017, 44, 191–202. [Google Scholar] [CrossRef]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Moving towards the second generation of lignocellulosic biorefineries in the EU: Drivers, challenges, and opportunities. Renew Sustain. Energy Rev. 2019, 101, 590–599. [Google Scholar] [CrossRef]

- Tadapaneni, R.K.; Banaszewski, K.; Patazca, E.; Edirisinghe, I.; Cappozzo, J.; Jackson, L.; Freeman, B.B. Effect of High-Pressure Processing and Milk on the Anthocyanin Composition and Antioxidant Capacity of Strawberry-Based Beverages. J. Agri. Food. Chem. 2012, 60, 5795–5802. [Google Scholar] [CrossRef]

- Temiz, A.; Yildiz, U.C.; Aydin, I.; Eikenes, M.; Alfredsen, G.; Çolakoglu, G. Surface roughness and color characteristics of wood treated with preservatives after accelerated weathering test. Appl. Surf. Sci. 2005, 250, 35–42. [Google Scholar] [CrossRef]

- Kaci, M.; Sadoun, T.; Cimmino, S. Crystallinity Measurements of Unstabilized and HALS-stabilized LDPE Films Exposed to Natural Weathering by FT-IR, DSC and WAXS Analyses. Intern. J. Polym. Anal. Character. 2001, 6, 455–464. [Google Scholar] [CrossRef]

- Joseph, P.V.; Rabello, M.S.; Mattoso, L.H.C.; Joseph, K.; Thomas, S. Environmental effects on the degradation behaviour of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2002, 62, 1357–1372. [Google Scholar] [CrossRef]

- Bhateja, S.; Andrews, E.; Yarbrough, S. Radiation Induced Crystallinity Changes in Linear Polyethylenes: Long Term Aging Effects. Polym. J. 1989, 21, 739–750. [Google Scholar] [CrossRef]

- Budhiraja, V.; Mušič, B.; Krzan, A. Magnetic Extraction of Weathered Tire Wear Particles and Polyethylene Microplastics. Polymers 2022, 14, 5189. [Google Scholar] [CrossRef]

| Chemical Component | Amount (%) |

|---|---|

| Cellulose | 46 ± 0.5 |

| Hemicellulose | 33 ± 2.0 |

| Lignin | 20 ± 1.0 |

| Extractives | 2.2 ± 0.5 |

| Ash | 3.0 ± 0.4 |

| Filler | d10 (µm) a | d50 (µm) a | d90 (µm) a | Span Factor | Surface Area (m2/g) a | Density (g/cm3) b |

|---|---|---|---|---|---|---|

| KP | 8.4 | 43.8 | 105.2 | 2.2 | 0.383 | 1.48 |

| Sample | Before Weathering | Weathering for 6 Months | Weathering for 12 Months | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Tm (°C) | ∆Hf(com) (J/g) | XrHDPE (%) | Tm (°C) | ∆Hf(com) (J/g) | XrHDPE (%) | Tm (°C) | ∆Hf(com) (J/g) | XrHDPE (%) | |

| 0 KP | 131.95 | 104.61 | 51 | 133.20 | 119.67 | 58.35 | 133.39 | 120.00 | 58.51 |

| 10 KP | 132.95 | 93.35 | 50.07 | 132.84 | 117.32 | 62.92 | 132.87 | 116.21 | 62.33 |

| 20 KP | 132.58 | 75.49 | 51.52 | 132.78 | 97.06 | 66.25 | 132.33 | 79.67 | 54.38 |

| Source of Variation | Tm (oC) | ∆Hf(com) (J/g) | XrHDPE (%) | |||

|---|---|---|---|---|---|---|

| p-Value | p < 0.05 | p-Value | p < 0.05 | p-Value | p < 0.05 | |

| KP Content | 0.552 | No | 0.031 | Yes | 0.043 | Yes |

| Weathering Time | 0.708 | No | 0.006 | Yes | 0.73 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hayeemasae, N.; Viet, C.X.; Masa, A.; Shuib, R.K.; Ismail, H.; Surya, I. The Use of Kenaf Fibre as a Natural Anti-Degradant in Recycled High-Density Polyethylene and Natural Rubber-Based Thermoplastic Elastomers. Polymers 2023, 15, 1237. https://doi.org/10.3390/polym15051237

Hayeemasae N, Viet CX, Masa A, Shuib RK, Ismail H, Surya I. The Use of Kenaf Fibre as a Natural Anti-Degradant in Recycled High-Density Polyethylene and Natural Rubber-Based Thermoplastic Elastomers. Polymers. 2023; 15(5):1237. https://doi.org/10.3390/polym15051237

Chicago/Turabian StyleHayeemasae, Nabil, Cao Xuan Viet, Abdulhakim Masa, Raa Khimi Shuib, Hanafi Ismail, and Indra Surya. 2023. "The Use of Kenaf Fibre as a Natural Anti-Degradant in Recycled High-Density Polyethylene and Natural Rubber-Based Thermoplastic Elastomers" Polymers 15, no. 5: 1237. https://doi.org/10.3390/polym15051237

APA StyleHayeemasae, N., Viet, C. X., Masa, A., Shuib, R. K., Ismail, H., & Surya, I. (2023). The Use of Kenaf Fibre as a Natural Anti-Degradant in Recycled High-Density Polyethylene and Natural Rubber-Based Thermoplastic Elastomers. Polymers, 15(5), 1237. https://doi.org/10.3390/polym15051237