Exploring the Potential of Andean Crops for the Production of Gluten-Free Muffins

Abstract

:1. Introduction

2. Materials and Methods

2.1. Andean Crops Flours (ACF)

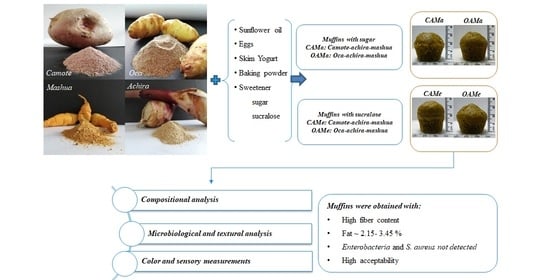

2.2. Batter Formulation and Baking Procedure

2.3. Proximate Analyses

2.4. Energy Value

2.5. pH, Acidity and Water Activity

2.6. Moisture

2.7. Specific Volume (Vs)

2.8. Texture Profile Analysis (TPA)

2.9. Color

2.10. Rheological Test

2.11. Microbiological Analysis

2.12. Sensory Analysis

2.13. Statistical Analysis

3. Results

3.1. Proximate Composition of Muffins

3.2. pH, Acidity Values and Water Activity

3.3. Moisture before and after Baking

3.4. Specific Volume (Vs)

3.5. Visual Appearance and Color

3.6. Texture Profile Analysis

3.7. Rheological Test

3.8. Microbiological Analysis

3.9. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, P.; Arora, A.; Strand, T.A.; Leffler, D.A.; Catassi, C.; Green, P.H.; Kelly, C.P.; Ahuja, V.; Makharia, G.K. Global prevalence of celiac disease: Systematic review and meta-analysis. Clin. Gastroenterol. Hepatol. 2018, 16, 823–836.e2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khalifa, I.; Barakat, H.; El-Mansy, H.; Soliman, S. Physico-chemical, organolyptical and microbiological characteristics of substituted cupcake by potato processing residues. Food Nutr. Sci. 2015, 6, 83. [Google Scholar] [CrossRef] [Green Version]

- Pacyński, M.; Wojtasiak, R.Z.; Mildner-Szkudlarz, S. Improving the aroma of gluten-free bread. LWT 2015, 63, 706–713. [Google Scholar] [CrossRef]

- Melini, F.; Melini, V.; Luziatelli, F.; Ruzzi, M. Current and Forward-Looking Approaches to Technological and Nutritional Improvements of Gluten-Free Bread with Legume Flours: A Critical Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1101–1122. [Google Scholar] [CrossRef]

- Deptford, A.; Baldi, G.; Bose, I.; Badham, J.; Knight, F.; Klemm, J.; de Pee, S. Essential nutrient requirements not met by diets high in staple foods. Crisis Oppor. Double Burd. 2018, 1, 40–48. [Google Scholar]

- Gao, J.; Brennan, M.A.; Mason, S.L.; Brennan, C.S. Effects of sugar substitution with “stevianna” on the sensory characteristics of muffins. J. Food Qual. 2017, 2017, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Karaoglu, M.M. Part-Baked Products. In Minimally Processed Foods: Technologies for Safety, Quality, and Convenience; Siddiqui, M.W., Rahman, M.S., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 151–172. [Google Scholar]

- Miñarro, B.; Albanell, E.; Aguilar, N.; Guamis, B.; Capellas, M. Effect of legume flours on baking characteristics of gluten-free bread. J. Cereal Sci. 2012, 56, 476–481. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N. Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int. J. Food Sci. 2014, 49, 2237–2244. [Google Scholar] [CrossRef]

- Pellegrini, N.; Agostoni, C. Nutritional aspects of gluten-free products. J. Sci. Food Agric. 2015, 95, 2380–2385. [Google Scholar] [CrossRef]

- Caio, G.; Volta, U.; Sapone, A.; Leffler, D.A.; De Giorgio, R.; Catassi, C.; Fasano, A. Celiac disease: A comprehensive current review. BMC Med. 2019, 17, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Capriles, V.D.; dos Santos, F.G.; Arêas, J.A.G. Gluten-free breadmaking: Improving nutritional and bioactive compounds. J. Cereal Sci. 2016, 67, 83–91. [Google Scholar] [CrossRef]

- Palacio, M.I.; Etcheverría, A.I.; Manrique, G.D. Development of gluten-free muffins utilizing squash seed dietary fiber. J. Food Sci. Technol. 2018, 55, 2955–2962. [Google Scholar] [CrossRef]

- Man, S.; Păucean, A.; Muste, S.; Pop, A. Studies on the formulation and quality characteristics of gluten free muffins. J. Agroaliment. Process. Technol. 2014, 20, 122–127. [Google Scholar]

- Singh, J.P.; Kaur, A.; Singh, N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J. Food Sci. Technol. 2016, 53, 1269–1278. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shevkani, K.; Kaur, A.; Kumar, S.; Singh, N. Cowpea protein isolates: Functional properties and application in gluten-free rice muffins. LWT 2015, 63, 927–933. [Google Scholar] [CrossRef]

- Herranz, B.; Canet, W.; Jiménez, M.J.; Fuentes, R.; Alvarez, M.D. Characterisation of chickpea flour-based gluten-free batters and muffins with added biopolymers: Rheological, physical and sensory properties. Int. J. Food Sci. 2016, 51, 1087–1098. [Google Scholar] [CrossRef]

- Bhaduri, S. A comprehensive study on physical properties of two gluten-free flour fortified muffins. Int. J. Food Process. Technol. 2013, 4, 251–254. [Google Scholar] [CrossRef] [Green Version]

- Fuentes, C.; Perez-Rea, D.; Bergenståhl, B.; Carballo, S.; Sjöö, M.; Nilsson, L. Physicochemical and structural properties of starch from five Andean crops grown in Bolivia. Int. J. Biol. Macromol. 2019, 125, 829–838. [Google Scholar] [CrossRef]

- Leidi, E.O.; Altamirano, A.M.; Mercado, G.; Rodriguez, J.P.; Ramos, A.; Alandia, G.; Sørensen, M.; Jacobsen, S.-E. Andean roots and tubers crops as sources of functional foods. J. Funct. Foods 2018, 51, 86–93. [Google Scholar] [CrossRef] [Green Version]

- Skarbø, K. Multiple trends in interspecific crop diversity: A longitudinal case study from the Ecuadorian Andes. Genet. Resour. Crop Evol. 2016, 63, 1319–1343. [Google Scholar] [CrossRef]

- Montúfar, R.; Ayala, M. Perceptions of agrodiversity and seed-saving practices in the northern Andes of Ecuador. J. Ethnobiol. Ethnomed. 2019, 15, 35. [Google Scholar] [CrossRef] [Green Version]

- Choquechambi, L.A.; Callisaya, I.R.; Ramos, A.; Bosque, H.; Mújica, A.; Jacobsen, S.-E.; Sørensen, M.; Leidi, E.O. Assessing the Nutritional Value of Root and Tuber Crops from Bolivia and Peru. Foods 2019, 8, 526. [Google Scholar] [CrossRef] [Green Version]

- Decheco, A. Componentes bioactivos funcionales en raíces y tubérculos andinos. Univ. Nac. Del Callao 2013, 1, 1–17. [Google Scholar]

- Pacheco, M.T.; Escribano-Bailón, M.T.; Moreno, F.J.; Villamiel, M.; Dueñas, M. Determination by HPLC-DAD-ESI/MSn of phenolic compounds in Andean tubers grown in Ecuador. J. Food Compos. Anal. 2019, 84, 103258. [Google Scholar] [CrossRef]

- Apaza Ticona, L.N.; Tena Pérez, V.; Bermejo Benito, P. Local/traditional uses, secondary metabolites and biological activities of Mashua (Tropaeolum tuberosum Ruíz & Pavón). J. Ethnopharmacol. 2020, 247, 112152. [Google Scholar]

- Fonseca-Florido, H.A.; Gómez-Aldapa, C.A.; Velazquez, G.; Hernández-Hernández, E.; Mata-Padilla, J.M.; Solís-Rosales, S.G.; Méndez-Montealvo, G. Gelling of amaranth and achira starch blends in excess and limited water. LWT Food Sci. Technol. 2017, 81, 265–273. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis 18th Edition; The Association of Official Analytical Chemists: Washington, DC, USA, 2005. [Google Scholar]

- AOAC. Official Methods of Analysis 16th Edition. Total Dietary in Foods-Enzymatic Gravimetric Method. In Method 985.29; AOAC, Ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 1997; Volume 16. [Google Scholar]

- Francis, F.J.; Clydesdale, F.M. Food Colorimetry: Theory and Applications; AVI Publishing Co. Inc.: Westport, CT, USA, 1975. [Google Scholar]

- Singh, J.; Kaur, A.; Shevkani, K.; Singh, N. Influence of jambolan (Syzygium cumini) and xanthan gum incorporation on the physicochemical, antioxidant and sensory properties of gluten-free eggless rice muffins. Int. J. Food Sci. 2015, 50, 1190–1197. [Google Scholar] [CrossRef]

- Belorio, M.; Gómez, M. Gluten-free muffins versus gluten containing muffins: Ingredients and nutritional differences. Trends Food Sci. Technol. 2020, 102, 249–253. [Google Scholar] [CrossRef]

- Zambrano, F.; Hikage, A.; Ormenese, R.; Montenegro, f.; Rauen, A.M. Efeito das gomas guar e xantana em bolos como substitutos de gordura. Braz. J. Food Technol. 2005, 8, 63–71. [Google Scholar]

- Aina, A.J.; Falade, K.O.; Akingbala, J.O.; Titus, P. Physicochemical properties of twenty-one Caribbean sweet potato cultivars. Int. J. Food Sci. 2009, 44, 1696–1704. [Google Scholar] [CrossRef]

- Ohizua, E.R.; Adeola, A.A.; Idowu, M.A.; Sobukola, O.P.; Afolabi, T.A.; Ishola, R.O.; Ayansina, S.O.; Oyekale, T.O.; Falomo, A. Nutrient composition, functional, and pasting properties of unripe cooking banana, pigeon pea, and sweetpotato flour blends. Food Sci. Nutr. 2017, 5, 750–762. [Google Scholar] [CrossRef] [Green Version]

- Cui, R.; Zhu, F. Physicochemical and functional properties of sweetpotato flour. J. Sci. Food Agric. 2019, 99, 4624–4634. [Google Scholar] [CrossRef]

- WHO. Diet, Nutrition and the Prevention of Chronic Diseases. In Technical Report Series 916; World Health Organization, Ed.; World Health Organization: Geneva, Switzerland, 2003. [Google Scholar]

- EC. Regulation (Ec) No 1924/2006 of of 20 December 2006 on Nutrition and Health Claims Made on Foods. In 1924/2006, edited by The European Parlament and of the Council. Official Journal of the European Union; The European Parlament and of the Council: Luxembourg, 2007. [Google Scholar]

- Bovell-Benjamin, A.C. Sweet potato: A review of its past, present, and future role in human nutrition. Adv. Food Nutr. Res. 2007, 52, 1–59. [Google Scholar] [PubMed]

- Padmaja, G. Uses and nutritional data of sweetpotato. In The sweetpotato; Springer: Berlin/Heidelberg, Germany, 2009; pp. 189–234. [Google Scholar]

- Villacres, E.; Pomboza, P.; Valle, M.; Lalaleo, L.; Vargas, H. The effect of sunlight on the content of thiocyanates, sugars and starches in accessions of tropaeolum tuberosum ruíz & pavón. Ital. J. Food Sci. 2018, 30, 126–135. [Google Scholar]

- Chisamore, A.E. Functionality of Sucralose/Maltodextrin: Isomalt Blends in Yellow Shortened Cupcakes over a 4-Day Storage Period. Master’s Thesis, The University of Georgia, Athens, Greece, 2010. [Google Scholar]

- Sarmiento, F.E. Transformación del Cupapé Usando Técnicas de Conservación. Ph.D. Thesis, Facultad de Ciencias de la Nutrición y Alimentos-Licenciatura en Gastronomía, Chiapas, Mexico, 2018. [Google Scholar]

- Pomeranz, Y. Functional Properties of Food Components; Academic Press: San Diego, CA, USA, 2012. [Google Scholar]

- Goswami, D.; Gupta, R.; Mridula, D.; Sharma, M.; Tyagi, S. Barnyard millet based muffins: Physical, textural and sensory properties. LWT 2015, 64, 374–380. [Google Scholar] [CrossRef]

- Zahn, S.; Pepke, F.; Rohm, H. Effect of inulin as a fat replacer on texture and sensory properties of muffins. Int. J. Food Sci. 2010, 45, 2531–2537. [Google Scholar] [CrossRef]

- Lancetti, R.; Palavecino, P.M.; Bustos, M.C.; León, A.E. Yacon (Smallanthus sonchifolius) flour obtention: Effect of process conditions on quality attributes and its incorporation in gluten-free muffins. LWT 2020, 125, 109217. [Google Scholar] [CrossRef]

- Clarke, C.; Schober, T.; Angst, E.; Arendt, E. Use of response surface methodology to investigate the effects of processing conditions on sourdough wheat bread quality. Eur. Food Res. Technol. 2003, 217, 23–33. [Google Scholar]

- Walker, R.; Tseng, A.; Cavender, G.; Ross, A.; Zhao, Y. Physicochemical, nutritional, and sensory qualities of wine grape pomace fortified baked goods. J. Food Sci. 2014, 79, S1811–S1822. [Google Scholar] [CrossRef]

- Gómez, M.; S Sciarini, L. Gluten-free bakery products and pasta. OmniaScience Monogr. 2015, 1, 565–604. [Google Scholar]

- Chirinos, R.; Campos, D.; Warnier, M.; Pedreschi, R.; Rees, J.-F.; Larondelle, Y. Antioxidant properties of mashua (Tropaeolum tuberosum) phenolic extracts against oxidative damage using biological in vitro assays. Food Chem. 2008, 111, 98–105. [Google Scholar] [CrossRef]

- Baixauli, R.; Sanz, T.; Salvador, A.; Fiszman, S. Muffins with resistant starch: Baking performance in relation to the rheological properties of the batter. J. Cereal Sci. 2008, 47, 502–509. [Google Scholar] [CrossRef]

- Ziobro, R.; Juszczak, L.; Witczak, M.; Korus, J. Non-gluten proteins as structure forming agents in gluten free bread. J. Food Sci. Technol. 2016, 53, 571–580. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baixauli, R.; Salvador, A.; Fiszman, S.M. Textural and colour changes during storage and sensory shelf life of muffins containing resistant starch. Eur. Food Res. Technol. 2008, 226, 523–530. [Google Scholar] [CrossRef]

- Rodríguez-García, J.; Puig, A.; Salvador, A.; Hernando, I. Optimization of a Sponge Cake Formulation with Inulin as Fat Replacer: Structure, Physicochemical, and Sensory Properties. J. Food Sci. 2012, 77, C189–C197. [Google Scholar] [CrossRef] [PubMed]

- Arora, A.; Camire, M.E. Performance of potato peels in muffins and cookies. Food Res. Int. 1994, 27, 15–22. [Google Scholar] [CrossRef]

- Soto-Maldonado, C.; Concha-Olmos, J.; Zúñiga-Hansen, M.E. The effect of enzymatically treated ripe banana flour on the sensory quality and glycemic response of banana-wheat flour composite muffins. J. Food Sci. Technol. 2020, 57, 3621–3627. [Google Scholar] [CrossRef]

- Rahman, A.N.F.; Bilang, M.; Ikawati, L.N. Physical and Proximate Analysis of Green Banana Cake Premix Flour. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Makassar, Indonesia, 2 September 2020; Volume 486, p. 012051. [Google Scholar]

- Campbell, A.M. Flour Mixtures, and Cereal Products in Food Theory and Applications; Macmillan Publishing Company: New York, NY, USA, 1970. [Google Scholar]

- Andrade-Mahecha, M.M.; Tapia-Blácido, D.R.; Menegalli, F.C. Physical–chemical, thermal, and functional properties of achira (Canna indica L.) flour and starch from different geographical origin. Starch Stärke 2012, 64, 348–358. [Google Scholar] [CrossRef]

- Turkut, G.M.; Cakmak, H.; Kumcuoglu, S.; Tavman, S. Effect of quinoa flour on gluten-free bread batter rheology and bread quality. J. Cereal Sci. 2016, 69, 174–181. [Google Scholar] [CrossRef]

- Solarte-Montúfar, J.G.; Díaz-Murangal, A.E.; Osorio-Mora, O.; Mejía-España, D.F. Propiedades Reológicas y Funcionales del Almidón. Procedente de Tres Variedades de Papa Criolla. Inf. Tecnol. 2019, 30, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Cauvain, S.P. Breadmaking: Improving Quality; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Agrahar-Murugkar, D.; Zaidi, A.; Dwivedi, S. Development of gluten free eggless cake using gluten free composite flours made from sprouted and malted ingredients and its physical, nutritional, textural, rheological and sensory properties evaluation. J. Food Sci. Technol. 2018, 55, 2621–2630. [Google Scholar] [CrossRef] [PubMed]

- Rosalina, I.; Bhattacharya, M. Dynamic rheological measurements and analysis of starch gels. Carbohydr. Polym. 2002, 48, 191–202. [Google Scholar] [CrossRef]

- Zaidel, D.A.; Chin, N.; Yusof, Y. A review on rheological properties and measurements of Dough and gluten. J. Appl. Sci. 2010, 10, 2478–2490. [Google Scholar]

- Lorenzo, G.; Zaritzky, N.; Califano, A. Optimization of non-fermented gluten-free dough composition based on rheological behavior for industrial production of “empanadas” and pie-crusts. J. Cereal. Sci. 2008, 48, 224–231. [Google Scholar] [CrossRef]

- Abdel–Shafi, M.; Wei–ning, H.; Zhen–ni, L.; Chung, O.K. Effects of acrylamide inhibition by asparagynase and sugar substitution on cookie dough rheology and baking attributes. Food Sci. 2011, 32, 157–167. [Google Scholar]

- Ng, S.H.; Woi, P.M.; Basri, M.; Ismail, Z. Characterization of structural stability of palm oil esters-based nanocosmeceuticals loaded with tocotrienol. J. Nanobiotechnol. 2013, 11, 1–7. [Google Scholar]

- Miñarro, B.; Normahomed, I.; Guamis, B.; Capellas, M. Influence of unicellular protein on gluten-free bread characteristics. Eur. Food Res. Technol. 2010, 231, 171–179. [Google Scholar] [CrossRef]

- Wang, J.; Rosell, C.M.; de Barber, C.B. Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002, 79, 221–226. [Google Scholar] [CrossRef]

- Grau, A.; Dueñas, R.; Cabrera, C.; Hermann, M. Mashua (Tropaeolum tuberosum Ruíz & Pav.). Promoting the conservation and use of underutilized and neglected crops. 25. International Potato Center, Lima, Peru/International Plant Genetic Resources Institute, Rome, Italy. IPGRI Dei Tre. Denari. 2003, 472, 6–65. [Google Scholar]

- Traka, M.; Mithen, R. Glucosinolates, isothiocyanates and human health. Phytochem. Rev. 2009, 8, 269–282. [Google Scholar] [CrossRef]

- Hathorn, C.; Biswas, M.; Gichuhi, P.; Bovell-Benjamin, A. Comparison of chemical, physical, micro-structural, and microbial properties of breads supplemented with sweetpotato flour and high-gluten dough enhancers. LWT 2008, 41, 803–815. [Google Scholar] [CrossRef]

- Ramcharitar, A.; Badrie, N.; Mattfeldt-Beman, M.; Matsuo, H.; Ridley, C. Consumer acceptability of muffins with flaxseed (Linum usitatissimum). J. Food Sci. 2005, 70, s504–s507. [Google Scholar] [CrossRef]

- Johnson, H.; Swanson, R.; Savage, E. Descriptive sensory analysis of yellow cupcakes prepared with nutritive and high intensity sweeteners. J. Am. Diet. Assoc. 2005, 105, 48. [Google Scholar] [CrossRef]

- Sabanis, D.; Lebesi, D.; Tzia, C. Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT 2009, 42, 1380–1389. [Google Scholar] [CrossRef]

| Ingredients (%) | Control | CAMa | OAMa | CAMe | OAMe |

|---|---|---|---|---|---|

| Wheat | 33.02 | - | - | - | - |

| Camote | - | 14.86 | - | 15.74 | - |

| Oca | - | - | 14.86 | - | 15.74 |

| Achira | - | 14.86 | 14.86 | 15.74 | 15.74 |

| Mashua | - | 3.30 | 3.30 | 3.50 | 3.50 |

| Sunflower oil | 4.72 | 4.72 | 4.72 | 5.00 | 5.00 |

| Eggs | 23.58 | 23.58 | 23.58 | 24.99 | 24.99 |

| Skim Yogurt | 32.08 | 32.08 | 32.08 | 33.98 | 33.98 |

| Bakery powder | 0.94 | 0.94 | 0.94 | 1.00 | 1.00 |

| Sweetener | - | - | - | - | - |

| sugar | 5.66 | 5.66 | 5.66 | - | - |

| sucralose | - | - | - | 0.06 | 0.06 |

| Parameters | Control | CAMa | OAMa | CAMe | OAMe |

|---|---|---|---|---|---|

| Moisture | 36.95 ± 0.07 a | 37.14 ± 0.40 a | 37.10 ± 0.42 a | 37.28 ± 0.72 a | 37.14 ± 0.76 a |

| Protein | 3.99 ± 0.05 a | 1.92 ± 0.04 d | 1.82 ± 0.02 d | 2.33 ± 0.03 b | 2.09 ± 0.05 c |

| Fat | 4.43 ± 0.05 a | 2.15 ± 0.03 d | 3.33 ± 0.03 b | 2.58 ± 0.05 c | 3.45 ± 0.06 b |

| Fiber | 1.80 ± 0.06 e | 8.38 ± 0.02 c | 5.89 ± 0.28 d | 13.68 ± 0.08 b | 14.69 ± 0.04 a |

| Ash | 1.12 ± 0.06 c | 2.44 ± 0.04 b | 2.72 ± 0.09 a | 2.70 ± 0.03 a | 2.83 ± 0.05 a |

| Carbohydrates | 51.72 ± 0.29 a | 47.97 ± 0.49 b | 49.14 ± 0.80 b | 41.43 ± 0.85 c | 39.80 ± 0.94 c |

| Calories (Kcal/100 g) | 266.29 ± 0.39 a | 235.67 ± 0.93 c | 245.58 ± 0.18 b | 225.62 ± 1.56 e | 227.98 ± 0.27 d |

| pH | 7.96 ± 0.28 c | 7,44 ± 0.14 a,b | 7.59 ± 0.23 b | 7.31 ± 0.03 a | 7.65 ± 0.08 b |

| Acidity | 0.06 ± 0.01 a | 0.08 ± 0.01 c | 0.07 ± 0.01 bc | 0.08 ± 0.03 c | 0.07 ± 0.03 ab |

| aw | 0.947 ± 0.002 b | 0.929 ± 0.003 a | 0.948 ± 0.002 bc | 0.945 ± 0.002 b | 0.957 ± 0.001 c |

| Sample | Moisture in the Raw Dough (%) | Moisture of the Crumb (%) | Moisture Lost during Baking (%) |

|---|---|---|---|

| Control | 49.70 ± 0.68 a | 37.61 ± 0.56 ab | 12.09 ± 0.98 a |

| CAMa | 50.23 ± 0.05 a | 38.32 ± 0.28 a | 11.91 ± 0.93 a |

| OAMa | 50.34 ± 0.85 a | 36.95 ± 0.36 b | 13.39 ± 0.36 ab |

| CAMe | 50.69 ± 0.86 a | 37.31 ± 0.18 b | 13.38 ± 0.95 ab |

| OAMe | 50.74 ± 0.21 a | 35.71 ± 0.12 b | 15.03 ± 0.26 b |

| Sample | n′ | K′ (Pa.s n′) | n″ | K″ (Pa.s n″) |

|---|---|---|---|---|

| G′ = K′·ωn′ | G″ = K″·ωn″ | |||

| C | 0.14 ± 0.01 d | 29.79 ± 1.01 c | 0.21 ± 0.01 b | 38.92 ± 1.03 d |

| CAMa | 0.26 ± 0.02 c | 17.75 ± 1.04 e | 0.28 ± 0.03 a | 30.07 ± 1.07 e |

| OAMa | 0.31 ± 0.01 b | 48.11 ± 1.03 b | 0.28 ± 0.03 a | 95.01 ± 1.05 b |

| CAMe | 0.37 ± 0.01 a | 21.78 ± 1.04 d | 0.27 ± 0.02 a | 56.28 ± 1.01 c |

| OAMe | 0.26 ± 0.02 c | 76.87 ± 1.04 a | 0.21 ± 0.03 b | 160.23 ± 1.07 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salazar, D.; Arancibia, M.; Silva, D.R.; López-Caballero, M.E.; Montero, M.P. Exploring the Potential of Andean Crops for the Production of Gluten-Free Muffins. Agronomy 2021, 11, 1642. https://doi.org/10.3390/agronomy11081642

Salazar D, Arancibia M, Silva DR, López-Caballero ME, Montero MP. Exploring the Potential of Andean Crops for the Production of Gluten-Free Muffins. Agronomy. 2021; 11(8):1642. https://doi.org/10.3390/agronomy11081642

Chicago/Turabian StyleSalazar, Diego, Mirari Arancibia, Diego R. Silva, María Elvira López-Caballero, and María Pilar Montero. 2021. "Exploring the Potential of Andean Crops for the Production of Gluten-Free Muffins" Agronomy 11, no. 8: 1642. https://doi.org/10.3390/agronomy11081642

APA StyleSalazar, D., Arancibia, M., Silva, D. R., López-Caballero, M. E., & Montero, M. P. (2021). Exploring the Potential of Andean Crops for the Production of Gluten-Free Muffins. Agronomy, 11(8), 1642. https://doi.org/10.3390/agronomy11081642