Environmental and Qualitative Monitoring of a Transoceanic Intermodal Transport of Melons

Abstract

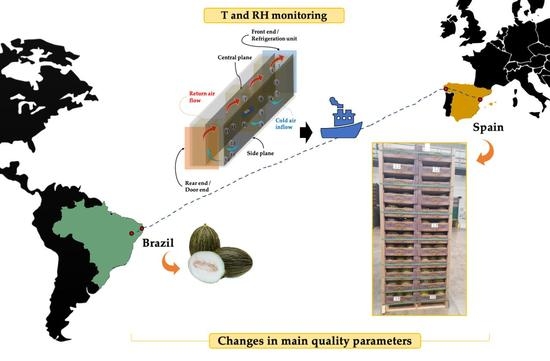

:1. Introduction

2. Materials and Methods

2.1. Experimental Setup

2.2. Quality Parameters: Firmness, Soluble Solids Content, Individual Organic Acids and Sugars, Vitamin C

2.3. Data Analysis

3. Results and Discussions

3.1. Reefer Environmental Conditions

3.2. Quality Parameters

3.3. Remaining Shelf-Life

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAOSTAT. Available online: https://www.fao.org/faostat/es/#data/TCL (accessed on 12 October 2022).

- Obando-Ulloa, J.M.; Moreno, E.; Garcia-Mas, J.; Nicolai, B.; Lammertyn, J.; Monforte, A.J.; Fernandez-Trujillo, J.P. Climacteric or non-climacteric behavior in melon fruit—1. Aroma volatiles. Postharvest Biol. Technol. 2008, 49, 27–37. [Google Scholar] [CrossRef]

- Giannakourou, M.; Taoukis, P. Holistic Approach to the Uncertainty in Shelf-life Prediction of Frozen Foods at Dynamic Cold Chain Conditions. Foods 2020, 9, 714. [Google Scholar] [CrossRef] [PubMed]

- Diezma, B.; Barreiro, P.; Baltazar, P.; Correa, E.C. A general procedure for predicting the remaining shelf-life of nectarines and peaches for virtualization of the value chain. Postharvest Biol. Technol. 2021, 181, 111677. [Google Scholar] [CrossRef]

- Sanchez-Bel, P.; Flores, F.B.; Gomez, J.; Romojaro, F.; Cabello, M.J.; Castellanos, M.T.; Ribas, F.; Martinez-Madrid, M.C. Changes in Quality and Oxidative Status of Two Cultivars of Piel de Sapo Melon Fruit during Cold Storage. In Proceedings of the 6th International Postharvest Symposium, Antalya, Turkey, 8–12 April 2009; pp. 807–813. [Google Scholar]

- Fernandez-Trujillo, J.P.; Obando, J.; Martinez, J.A.; Alarcon, A.L.; Eduardo, I.; Arus, P.; Monforte, A.J. Mapping fruit susceptibility to postharvest physiological disorders and decay using a collection of near-isogenic lines of melon. J. Am. Soc. Hortic. Sci. 2007, 132, 739–748. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.-W.; Chang, M.-S.; Lee, J.H.; Hong, Y.; Kim, J.G. Changes in Quality of Oriental Melon ‘Smartkkul’ During Vessel Transportation. Hortic. Sci. Technol. 2018, 36, 560–568. [Google Scholar] [CrossRef] [Green Version]

- Silveira, A.C.; Aguayo, E.; Artés, F. The suitability of three Galia melon cultivars and different types of cuts for the fresh-cut industry. J. Sci. Food Agric. 2013, 93, 3826–3831. [Google Scholar] [CrossRef] [PubMed]

- Salas-Millán, J.Á.; Aznar, A.; Conesa, E.; Conesa-Bueno, A.; Aguayo, E. Fruit Wine Obtained from Melon by-Products: Physico-Chemical and Sensory Analysis, and Characterization of Key Aromas by GC-MS. Foods 2022, 11, 3619. [Google Scholar] [CrossRef] [PubMed]

- Castillejo, N.; Benito Martinez-Hernandez, G.; Goffi, V.; Gomez, P.A.; Aguayo, E.; Artes, F.; Artes-Hernandez, F. Natural vitamin B12 and fucose supplementation of green smoothies with edible algae and related quality changes during their shelf-life. J. Sci. Food Agric. 2018, 98, 2411–2421. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aguayo, E.; Escalona, V.H.; Artes, F. Quality of minimally processed Cucumis melo var. saccharinus as improved by controlled atmosphere. Eur. J. Hortic. Sci. 2007, 72, 39–45. [Google Scholar]

- ASAE D271.2 APR1979 (R2005); Psychrometric Data. ASABE Standards: St. Joseph, MI, USA, 2006; pp. 20–27.

- Wu, Z.; Tu, M.; Yang, X.; Xu, J.; Yu, Z. Effect of cutting and storage temperature on sucrose and organic acids metabolism in postharvest melon fruit. Postharvest Biol. Technol. 2020, 161, 111081. [Google Scholar] [CrossRef]

- Jimenez-Ariza, T.; Correa, E.C.; Diezma, B.; Silveira, A.C.; Zocalo, P.; Arranz, F.J.; Moya-Gonzalez, A.; Garrido-Izard, M.; Barreiro, P.; Ruiz-Altisent, M. The Phase Space as a New Representation of the Dynamical Behaviour of Temperature and Enthalpy in a Reefer monitored with a Multidistributed Sensors Network. Food Bioprocess Technol. 2014, 7, 1793–1806. [Google Scholar] [CrossRef]

- Lang, W.; Jedermann, R.; Mrugala, D.; Jabbari, A.; Krieg-Brueckner, B.; Schill, K. The “Intelligent Container”—A Cognitive Sensor Network for Transport Management. IEEE Sens. J. 2011, 11, 688–698. [Google Scholar] [CrossRef] [Green Version]

- Tanner, D.J.; Amos, N.D. Temperature variability during shipment of fresh produce. In Proceedings of the Postharvest Unlimited International Conference, Leuven, Belgium, 11–14 June 2002; pp. 193–203. [Google Scholar]

- Hertog, M.L.A.T.M.; Lammertyn, J.; De Ketelaere, B.; Scheerlinck, N.; Nicolai, B.A. Managing quality variance in the postharvest food chain. Trends Food Sci. Technol. 2007, 18, 320–332. [Google Scholar] [CrossRef]

- Villanueva, M.J.; Tenorio, M.D.; Esteban, M.A.; Mendoza, M.C. Compositional changes during ripening of two cultivars of muskmelon fruits. Food Chem. 2004, 87, 179–185. [Google Scholar] [CrossRef]

- UNECE. Standard FFV-23 Concerning the Marketing and Commercial Quality Control of Melons. Available online: https://unece.org/fileadmin/DAM/trade/agr/standard/standard/fresh/FFV-Std/English/23_Melons.pdf (accessed on 5 October 2022).

- Miller, F.A.; Fundo, J.F.; Garcia, E.; Santos, J.R.; Miranda Silva, C.L.; Silva Brandao, T.R. Physicochemical and Bioactive Characterisation of Edible and Waste Parts of “Piel de Sapo” Melon. Horticulturae 2020, 6, 60. [Google Scholar] [CrossRef]

- Escribano, S.; Lazaro, A. Physicochemical and nutritional evaluation of Spanish melon landraces. Plant Genet. Resour. Charact. Util. 2017, 15, 177–186. [Google Scholar] [CrossRef]

- Kyriacou, M.C.; Leskovar, D.I.; Colla, G.; Rouphael, Y. Watermelon and melon fruit quality: The genotypic and agro-environmental factors implicated. Sci. Hortic. 2018, 234, 393–408. [Google Scholar] [CrossRef]

- Hertog, M.L.A.T.M.; Uysal, I.; McCarthy, U.; Verlinden, B.M.; Nicolai, B.M. Shelf-life modelling for first-expired-first-out warehouse management. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130306. [Google Scholar] [CrossRef] [PubMed]

| Multimodal Transport | From | Date | To | Date | Distance (km) | Time (days) |

|---|---|---|---|---|---|---|

| Truck (Brazil) | Jandaíra (Río Grande do Norte) | 5 March 2022 | Port of Natal | 5 March 2022 | 125 | 0.5 |

| Vessel (Brazil-Spain) | Port of Natal | 5 March 2022 | Port of Vigo | 16 March 2022 | 5995 | 11 |

| Reefer Terminal (Spain) | Port of Vigo | 16 March 2022 | Port of Vigo | 23 March 2022 | 1 | 7 |

| Port of Vigo | 23 March 2022 | Border Inspection Posts (BIP) | 24 March 2022 | 1 | 1 | |

| Truck (Spain) | Vigo BIP reefer terminal | 24 March 2022 | Castellón | 25 March 2022 | 1022 | 1 |

| TOTAL | 7144 | 20.5 |

| Sensor Range ± Accuracy | On-Board Data Memory | Interface | Size (mm) | Test Characteristics | |||

|---|---|---|---|---|---|---|---|

| Sensors (Number) | Data/ Sensor | Period (min/data) | |||||

Xsense® | −12 °C to +50 °C ± 0.5 °C 20 to 95% RH ± 5% | 1000 per channel | RFID at 433.05 MHz | 28 × 34 × 114 | 1 | 517 | 60 |

ibutton® | −20 °C to +85 °C ± 0.5 °C 0 to 100% RH ± 5% | 4096 per channel | 1-wire RJ-45 | ϕ: 16.25 high: 5.9 | 15 | 2611 | 9 |

| Temperature (°C) | Relative Humidity (%) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | CV | Range | Mean | SD | CV | Range | ||||||||||

| Xsense | Whole journey | 17.03 | 4.15 | 24.40 | 17.75 | - | 68.45 | 8.17 | 11.94 | 42 | |||||||

| Start up | 22.61 | 5.69 | 25.17 | 15.75 | - | 59.31 | 11.66 | 19.66 | 42 | ||||||||

| Steady-state | 15.54 | 0.09 | 0.58 | 0.25 | - | 69.86 | 1.61 | 2.31 | 11 | ||||||||

| M | SD | M | SD | M | SD | M | SD | M | SD | M | SD | M | SD | M | SD | ||

| Ibutton-set | Start up | - | - | - | - | - | - | - | - | ||||||||

| Steady-state (n = 15) | 15.92 | 0.99 | 0.36 | 0.10 | 2.23 | 0.59 | 1.68 | 0.43 | 71.8 | 3.25 | 1.98 | 0.39 | 2.77 | 0.60 | 13.73 | 2.78 |

| Steady-state (n = 2177) | 15.92 | 0.29 | 1.02 | 0.097 | 6.38 | 0.56 | 3.30 | 0.37 | 71.8 | 1.78 | 3.37 | 0.42 | 4.69 | 0.60 | 9.96 | 1.75 |

| Variables | Departure | Arrival | Ratio Arrival/Departure | F | p | ||

|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | ||||

| Firmness (N) | 94.20 z | 11.59 | 68.12 | 12.75 | 0.72 | 374.44 | 0.0000 |

| SSC (°Brix) | 11.08 y | 0.98 | 10.80 | 0.90 | 0.97 | 3.91 | 0.0495 |

| Glucose (g kg−1) | 9.78 y | 0.80 | 11.10 | 0.90 | 1.13 | 61.29 | 0.0000 |

| Fructose (g kg−1) | 11.02 y | 0.98 | 9.97 | 0.82 | 0.90 | 30.45 | 0.0000 |

| Sucrose (g kg−1) | 21.68 y | 1.96 | 19.85 | 3.62 | 0.92 | 12.44 | 0.0006 |

| TOTAL sugars (g kg−1) | 42.48 y | 3.53 | 40.63 | 4.22 | 0.96 | 5.86 | 0.0171 |

| Citric acid (g kg−1) | 3.65 y | 0.37 | 2.98 | 0.44 | 0.82 | 72.97 | 0.0000 |

| Malic acid (g kg−1) | 1.17 y | 0.31 | 1.25 | 0.24 | 1.06 | 1.55 | 0.2153 |

| Succinic acid (g kg−1) | 2.79 y | 0.37 | 1.49 | 0.26 | 0.53 | 359.21 | 0.0000 |

| Fumaric acid (g kg−1) | 0.01 y | 0.00 | 0.01 | 0.00 | 0.87 | 138.93 | 0.0000 |

| TOTAL acids (g kg−1) | 7.63 y | 0.88 | 5.72 | 0.88 | 0.75 | 115.52 | 0.0000 |

| Vitamin C (mg kg−1) | 106.48 y | 9.94 | 80.06 | 14.10 | 0.75 | 93.00 | 0.0000 |

| Overall Quality (1–9) | 7.53 x | 0.42 | 5.74 | 0.94 | 1.31 | 89.72 | 0.0000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Correa, E.C.; Castillejo, N.; Barreiro, P.; Diezma, B.; Garrido-Izard, M.; Barbosa Menezes, J.; Aguayo, E. Environmental and Qualitative Monitoring of a Transoceanic Intermodal Transport of Melons. Agronomy 2023, 13, 33. https://doi.org/10.3390/agronomy13010033

Correa EC, Castillejo N, Barreiro P, Diezma B, Garrido-Izard M, Barbosa Menezes J, Aguayo E. Environmental and Qualitative Monitoring of a Transoceanic Intermodal Transport of Melons. Agronomy. 2023; 13(1):33. https://doi.org/10.3390/agronomy13010033

Chicago/Turabian StyleCorrea, Eva Cristina, Noelia Castillejo, Pilar Barreiro, Belén Diezma, Miguel Garrido-Izard, Jossivan Barbosa Menezes, and Encarna Aguayo. 2023. "Environmental and Qualitative Monitoring of a Transoceanic Intermodal Transport of Melons" Agronomy 13, no. 1: 33. https://doi.org/10.3390/agronomy13010033

APA StyleCorrea, E. C., Castillejo, N., Barreiro, P., Diezma, B., Garrido-Izard, M., Barbosa Menezes, J., & Aguayo, E. (2023). Environmental and Qualitative Monitoring of a Transoceanic Intermodal Transport of Melons. Agronomy, 13(1), 33. https://doi.org/10.3390/agronomy13010033