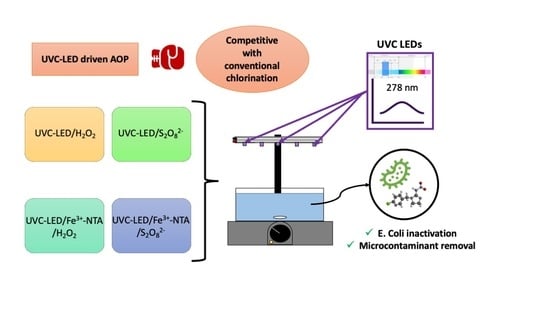

Simultaneous Disinfection and Organic Microcontaminant Removal by UVC-LED-Driven Advanced Oxidation Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Water Matrix

2.2. Experimental Setup

2.2.1. Experimental UVC-LED System

2.2.2. Experimental UVC-LED System

2.2.3. Analytical Determinations

2.2.4. Bacterial Enumeration and Quantification

3. Results and Discussion

3.1. Simultaneous E. coli Inactivation and IMD Removal by UVC-LED/H2O2 and UVC-LED/S2O82− Processes

3.1.1. Effect of H2O2 Concentration

3.1.2. Effect of S2O82− Concentration

3.2. Simultaneous E. coli Inactivation and IMD Removal by UVC-LED Mediated by the Fe3+–NTA Complex with H2O2 and S2O82−

3.3. Comparison of the UVC-LED Treatment with Conventional Chlorination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Pichel, N.; Vivar, M.; Fuentes, M. The problem of drinking water access: A review of disinfection technologies with an emphasis on solar treatment methods. Chemosphere 2019, 218, 1014–1030. [Google Scholar] [CrossRef]

- Compagni, R.D.; Gabrielli, M.; Polesel, F.; Turolla, A.; Trapp, S.; Vezzaro, L.; Antonelli, M. Risk assessment of contaminants of emerging concern in the context of wastewater reuse for irrigation: An integrated modelling approach. Chemosphere 2020, 242, 125185. [Google Scholar] [CrossRef]

- European Union. Commission Implementing Decision 2020/1161/EU of 4 August 2020 establishing a watch list of substances for Union-wide monitoring in the field of water policy pursuant to Directive 2008/105/EC of the European Parliament and of the Council. Off. J. Eur. Union 2020, L257, 32–35. [Google Scholar]

- Brillas, E.; Garcia-Segura, S. Benchmarking recent advances and innovative technology approaches of Fenton, photo-Fenton, electro-Fenton, and related processes: A review on the relevance of phenol as model molecule. Sep. Purif. Technol. 2020, 237, 116337. [Google Scholar] [CrossRef]

- Rizzo, L.; Malato, S.; Antakyali, D.; Beretsou, V.G.; Đolić, M.B.; Gernjak, W.; Heath, E.; Ivancev-Tumbas, I.; Karaolia, P.; Ribeiro, A.R.L.; et al. Consolidated vs new advanced treatment methods for the removal of contaminants of emerging concern from urban wastewater. Sci. Total Environ. 2019, 655, 986–1008. [Google Scholar] [CrossRef]

- Guzman, P.V.-; Giannakis, S.; Rtimi, S.; Grandjean, D.; Bensimon, M.; de Alencastro, L.F.; Torres-Palma, R.; Pulgarin, C. A green solar photo-Fenton process for the elimination of bacteria and micropollutants in municipal wastewater treatment using mineral iron and natural organic acids. Appl. Catal. B Environ. 2017, 219, 538–549. [Google Scholar] [CrossRef]

- Jain, B.; Singh, A.K.; Kim, H.; Lichtfouse, E.; Sharma, V.K. Treatment of organic pollutants by homogeneous and heterogeneous Fenton reaction processes. Environ. Chem. Lett. 2018, 16, 947–967. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Feng, S.; Zhang, K.; Li, J.; Wang, H.; Zhang, T.; Ma, X. Heterogeneous activation of peroxymonosulfate using ordered mesoporous Co3O4 for the degradation of chloramphenicol at neutral pH. Chem. Eng. J. 2017, 308, 505–515. [Google Scholar] [CrossRef]

- Rodríguez-Chueca, J.; Guerra-Rodríguez, S.; Raez, J.M.; López-Muñoz, M.-J.; Rodríguez, E. Assessment of different iron species as activators of S2O82− and HSO5− for inactivation of wild bacteria strains. Appl. Catal. B Environ. 2019, 248, 54–61. [Google Scholar] [CrossRef]

- Ahile, U.J.; Wuana, R.; Itodo, A.U.; Sha’Ato, R.; Dantas, R.F. A review on the use of chelating agents as an alternative to promote photo-Fenton at neutral pH: Current trends, knowledge gap and future studies. Sci. Total Environ. 2020, 710, 134872. [Google Scholar] [CrossRef] [PubMed]

- Fiorentino, A.; Esteban, B.; Garrido-Cardenas, J.A.; Kowalska, K.; Rizzo, L.; Aguera, A.; Pérez, J.A.S. Effect of solar photo-Fenton process in raceway pond reactors at neutral pH on antibiotic resistance determinants in secondary treated urban wastewater. J. Hazard. Mater. 2019, 378, 120737. [Google Scholar] [CrossRef]

- López-Vinent, N.; Cruz-Alcalde, A.; Romero, L.; Chávez, M.; Marco, P.; Giménez, J.; Esplugas, S. Synergies, radiation and kinetics in photo-Fenton process with UVA-LEDs. J. Hazard. Mater. 2019, 380, 120882. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Miino, M.C.; Caccamo, F.M.; Torretta, V.; Rada, E.C.; Sorlini, S. Disinfection of Wastewater by UV-Based Treatment for Reuse in a Circular Economy Perspective. Where Are We at? Int. J. Environ. Res. Public Health 2020, 18, 77. [Google Scholar] [CrossRef] [PubMed]

- Guerra-Rodríguez, S.; Ribeiro, A.R.L.; Ribeiro, R.S.; Rodríguez, E.; Silva, A.M.; Rodríguez-Chueca, J. UV-A activation of peroxymonosulfate for the removal of micropollutants from secondary treated wastewater. Sci. Total Environ. 2021, 770, 145299. [Google Scholar] [CrossRef]

- Giannakis, S.; Androulaki, B.; Comninellis, C.; Pulgarin, C. Wastewater and urine treatment by UVC-based advanced oxidation processes: Implications from the interactions of bacteria, viruses, and chemical contaminants. Chem. Eng. J. 2018, 343, 270–282. [Google Scholar] [CrossRef]

- Rivas, G.; Carra, I.; Sánchez, J.G.; López, J.L.C.; Malato, S.; Pérez, J.S. Modelling of the operation of raceway pond reactors for micropollutant removal by solar photo-Fenton as a function of photon absorption. Appl. Catal. B Environ. 2015, 178, 210–217. [Google Scholar] [CrossRef]

- Aillet, T.; Loubiere, K.; Dechy-Cabaret, O.; Prat, L.E. Accurate Measurement of the Photon Flux Received Inside Two Continuous Flow Microphotoreactors by Actinometry. Int. J. Chem. React. Eng. 2014, 12, 257–269. [Google Scholar] [CrossRef] [Green Version]

- European Union. Commission Implementing Decision 2018/840/EU of 5th June 2018 establishing a watch list of substances for Union-wide monitoring in the field of water policy pursuant to Directive 2008/105/EC of the European Parliament and of the Council and repealing Commission Implementing Decision (EU) 2015/495. Off. J. Eur. Union 2018, L141, 9–12. [Google Scholar]

- Mejri, A.; Soriano-Molina, P.; Miralles-Cuevas, S.; Pérez, J.A.S. Fe3+-NTA as iron source for solar photo-Fenton at neutral pH in raceway pond reactors. Sci. Total Environ. 2020, 736, 139617. [Google Scholar] [CrossRef]

- EPA. Guidelines for Water Reuse; EPA/600/R-12/618; Environmental Protection Agency: Wahington, DC, USA, 2012. [Google Scholar]

- Liang, C.; Huang, C.-F.; Mohanty, N.; Kurakalva, R.M. A rapid spectrophotometric determination of persulfate anion in ISCO. Chemosphere 2008, 73, 1540–1543. [Google Scholar] [CrossRef]

- Zhang, Y.; Chelme-Ayala, P.; Klamerth, N.; El-Din, M.G. Application of UV-irradiated Fe(III)-nitrilotriacetic acid (UV-Fe(III)NTA) and UV-NTA-Fenton systems to degrade model and natural occurring naphthenic acids. Chemosphere 2017, 179, 359–366. [Google Scholar] [CrossRef]

- García-Fernández, I.; López, M.I.P.; Oller, I.; Fernández-Ibáñez, P. Bacteria and fungi inactivation using Fe3+/sunlight, H2O2/sunlight and near neutral photo-Fenton: A comparative study. Appl. Catal. B Environ. 2012, 121–122, 20–29. [Google Scholar] [CrossRef]

- European Union. Regulation (EU) 2020/741 of the european parliament and of the council of 25 May 2020 on minimum requirements for water reuse. Off. J. Eur. Union 2020, L177, 32–55. [Google Scholar]

- Acosta-Rangel, A.; Sánchez-Polo, M.; Polo, A.; Rivera-Utrilla, J.; Berber-Mendoza, M. Sulfonamides degradation assisted by UV, UV/H2O2 and UV/K2S2O8: Efficiency, mechanism and byproducts cytotoxicity. J. Environ. Manag. 2018, 225, 224–231. [Google Scholar] [CrossRef] [PubMed]

- De la Obra, I.; Esteban, B.; Rivas, G.; Casas, J.L.; Pérez, J.L.S. Continuous flow disinfection of WWTP secondary effluents by solar photo Fenton at neutral pH in raceway pond reactors at pilot plant scale. Appl. Catal. B Environ. 2019, 247, 115–123. [Google Scholar] [CrossRef]

- Sichel, C.; Fernández-Ibáñez, P.; De Cara, M.; Tello, J. Lethal synergy of solar UV-radiation and H2O2 on wild Fusarium solani spores in distilled and natural well water. Water Res. 2009, 43, 1841–1850. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Montes, I.; García, I.S.; Ibañez, G.R.; Aquino, J.M.; Polo-López, M.I.; Malato, S.; Oller, I. UVC-based advanced oxidation processes for simultaneous removal of microcontaminants and pathogens from simulated municipal wastewater at pilot plant scale. Environ. Sci. Water Res. Technol. 2020, 6, 2553–2566. [Google Scholar] [CrossRef]

- Zhou, K.; Wang, Z.; Wang, X.; Jiao, G.; Li, Y.; Sun, S.-P.; Chen, X.D. Degradation of emerging pharmaceutical micropollutants in municipal secondary effluents by low-pressure UVC-activated HSO5− and S2O82− AOPs. Chem. Eng. J. 2020, 393, 124712. [Google Scholar] [CrossRef]

- Perini, J.A.L.; Tonetti, A.L.; Vidal, C.; Montagner, C.C.; Nogueira, R.F.P. Simultaneous degradation of ciprofloxacin, amoxicillin, sulfathiazole and sulfamethazine, and disinfection of hospital effluent after biological treatment via photo-Fenton process under ultraviolet germicidal irradiation. Appl. Catal. B Environ. 2018, 224, 761–771. [Google Scholar] [CrossRef] [Green Version]

- De Luca, A.; Dantas, R.F.; Esplugas, S. Study of Fe(III)-NTA chelates stability for applicability in photo-Fenton at neutral pH. Appl. Catal. B Environ. 2015, 179, 372–379. [Google Scholar] [CrossRef]

- Fiorentino, A.; Cucciniello, R.; Di Cesare, A.; Fontaneto, D.; Prete, P.; Rizzo, L.; Corno, G.; Proto, A. Disinfection of urban wastewater by a new photo-Fenton like process using Cu-iminodisuccinic acid complex as catalyst at neutral pH. Water Res. 2018, 146, 206–215. [Google Scholar] [CrossRef] [PubMed]

- Silva, G.D.; Marson, E.O.; Batista, L.L.; Ueira-Vieira, C.; Starling, M.C.V.; Trovó, A.G. Contrasting the performance of photo-Fenton at neutral pH in the presence of different organic iron-complexes using hydrogen peroxide or persulfate as oxidants for naproxen degradation and removal of antimicrobial activity. Process. Saf. Environ. Prot. 2021, 147, 798–807. [Google Scholar] [CrossRef]

| Treatments | kE. coli ± SD (min−1) | kIMD ± SD (min−1) | Time E. coli/IMD (min) | UV Dose E. coli/IMD (kJ/m2) | QUVC E. coli/IMD (kJ/L) |

|---|---|---|---|---|---|

| UVC-LED | 0.93 ± 0.20 R2 = 0.950 | 0.021 ± 0.002 R2 = 0.976 | -- * | -- | -- |

| UVC-LED/H2O2—0.147 mM | 0.94 ± 0.25 R2 = 0.948 | 0.020 ± 0.001 R2 = 0.999 | >60/>60 | >7.2/-- | >0.16/-- |

| UVC-LED/H2O2—1.47 mM | 1.5 ± 0.3 R2 = 0.969 | 0.022 ± 0.003 R2 = 0.999 | 20/>60 | 2.4/-- | 0.05/-- |

| UVC-LED/H2O2—2.94 mM | 1.5 ± 0.2 R2 = 0.977 | 0.025 ± 0.001 R2 = 0.999 | 10/>60 | 1.2/-- | 0.03/-- |

| UVC-LED/S2O82−—0.147 mM | 1.3 ± 0.2 R2 = 0.952 | 0.019 ± 0.001 R2 = 0.997 | 20/>60 | 2.4/-- | 0.05/-- |

| UVC-LED/S2O82−—1.47 mM | 1.6 ± 0.3 R2 = 0.950 | 0.044 ± 0.001 R2 = 0.907 | 20/40 | 2.4/4.8 | 0.05/0.11 |

| UVC-LED/S2O82−—2.94 mM | 1.7 ± 0.2 R2 = 0.950 | 0.058 ± 0.001 R2 = 0.997 | 15/25 | 1.8/3.0 | 0.04/0.07 |

| UVC-LED/Fe3+–NTA/ H2O2—0.1 mM/1.47 mM | 0.430 ± 0.007 R2 = 0.928 | 0.081 ± 0.001 R2 = 0.998 | 30/20 | 3.6/2.4 | 0.08/0.05 |

| UVC-LED/Fe3+–NTA/S2O82− —0.1 mM/1.47 mM | 0.450 ± 0.006 R2 = 0.949 | 0.033 ± 0.001 R2 = 0.994 | 30/55 | 3.6/6.6 | 0.08/0.14 |

| Chlorination—0.028 mM | 0.360 ± 0.002 R2 = 0.960 | — | >30 | — | — |

| Chlorination—0.14 mM | 1.7 ± 0.1 R2 = 0.969 | — | 10 | — | — |

| Chlorination—0.28 mM | 3.1 ± 0.6 R2 = 0.989 | — | 5 | — | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miralles-Cuevas, S.; De la Obra, I.; Gualda-Alonso, E.; Soriano-Molina, P.; Casas López, J.L.; Sánchez Pérez, J.A. Simultaneous Disinfection and Organic Microcontaminant Removal by UVC-LED-Driven Advanced Oxidation Processes. Water 2021, 13, 1507. https://doi.org/10.3390/w13111507

Miralles-Cuevas S, De la Obra I, Gualda-Alonso E, Soriano-Molina P, Casas López JL, Sánchez Pérez JA. Simultaneous Disinfection and Organic Microcontaminant Removal by UVC-LED-Driven Advanced Oxidation Processes. Water. 2021; 13(11):1507. https://doi.org/10.3390/w13111507

Chicago/Turabian StyleMiralles-Cuevas, Sara, Irene De la Obra, Elizabeth Gualda-Alonso, Paula Soriano-Molina, José L. Casas López, and José A. Sánchez Pérez. 2021. "Simultaneous Disinfection and Organic Microcontaminant Removal by UVC-LED-Driven Advanced Oxidation Processes" Water 13, no. 11: 1507. https://doi.org/10.3390/w13111507

APA StyleMiralles-Cuevas, S., De la Obra, I., Gualda-Alonso, E., Soriano-Molina, P., Casas López, J. L., & Sánchez Pérez, J. A. (2021). Simultaneous Disinfection and Organic Microcontaminant Removal by UVC-LED-Driven Advanced Oxidation Processes. Water, 13(11), 1507. https://doi.org/10.3390/w13111507