Reclaimed Water for Vineyard Irrigation in a Mediterranean Context: Life Cycle Environmental Impacts, Life Cycle Costs, and Eco-Efficiency

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site and Data Collection

2.2. Environmental and Cost Assessment Methodology

2.2.1. System Boundaries and Functional Unit

2.2.2. Inventory Data

2.2.3. Life Cycle Impact Assessment

2.2.4. Value and Cost Assessment

2.2.5. Uncertainty and Sensitivity Analysis

3. Results and Discussion

3.1. Results of Environmental Analysis

LCA Results in a Single Index

3.2. Result of Economic Analysis

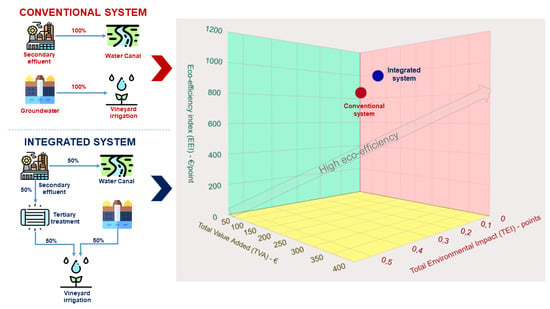

3.3. Eco-Efficiency Performance—Relation between Environment and the Economic Performance

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter | Reliability | Completeness | Temporal Correlation | Geographical Correlation | Further Technological Correlation |

|---|---|---|---|---|---|

| Irrigation water | 1 | 1 | 1 | 1 | 1 |

| Electricity | 2 | 1 | 2 | 2 | 1 |

| N-fertilizer | 2 | 1 | 2 | 2 | 1 |

| P-fertilizer | 2 | 1 | 2 | 2 | 1 |

| K-fertilizer | 2 | 1 | 2 | 2 | 1 |

| Pesticides | 2 | 1 | 2 | 2 | 1 |

| Tractor operations | 2 | 1 | 2 | 2 | 1 |

| Land occupation | 2 | 1 | 2 | 2 | 1 |

| Ammonia volatilization | 3 | 2 | 1 | 2 | 2 |

| Dinitrogen monoxide | 3 | 2 | 1 | 2 | 2 |

| Nitrous oxide | 3 | 2 | 1 | 2 | 2 |

| Nitrates | 3 | 2 | 1 | 2 | 2 |

| Phosphorus | 3 | 2 | 1 | 2 | 2 |

| Phosphates | 3 | 2 | 1 | 2 | 2 |

| Pesticide emissions | 3 | 2 | 1 | 2 | 2 |

| Nutrient emissions | 2 | 1 | 2 | 2 | 1 |

| Impact Categories | Unit | Conventional System | Integrated System | ||

|---|---|---|---|---|---|

| 1 ha | 1 ton | 1 ha | 1 ton | ||

| Acidification | mol H+ eq | 93.1 | 4.03 | 66.2 | 3.15 |

| Climate change | kg CO2 eq | 7206.5 | 311.70 | 5439.1 | 259.01 |

| Ecotoxicity: freshwater | CTUe | 208,592.6 | 9022.17 | 170711.4 | 8129.11 |

| Eutrophication: freshwater | kg P eq | 4.5 | 0.193 | 3.7 | 0.174 |

| Eutrophication: marine | kg N eq | 1964.6 | 84.97 | 949.3 | 45.20 |

| Eutrophication: terrestrial | mol N eq | 440.8 | 19.06 | 247.8 | 11.80 |

| Human toxicity: cancer | CTUh | 1.63 × 10−5 | 7.04 × 10−7 | 1.69 × 10−5 | 8.04 × 10−7 |

| Human toxicity: non-cancer | CTUh | 1.01 × 10−4 | 4.37 × 10−6 | 2.04 × 10−4 | 9.69 × 10−6 |

| Ionising radiation | kBq U235 eq | 765.7 | 33.12 | 598.3 | 28.49 |

| Land use | Pt | 18092.7 | 782.56 | 14384.4 | 684.97 |

| Ozone depletion | kg CFC-11 eq | 1.93 × 10−3 | 8.36 × 10−5 | 1.77 × 10−3 | 8.42 × 10−5 |

| Particulate matter | Disease inc. | 4.82 × 10−4 | 2.08 × 10−5 | 4.3 × 10−4 | 2.05 × 10−5 |

| Photochemical ozone formation | kg NMVOC eq | 26.5 | 1.146 | 23.0 | 1.098 |

| Resource use: fossils | MJ | 81000.8 | 3503.49 | 65156.9 | 3102.71 |

| Resource use: minerals and metals | kg Sb eq | 0.0176 | 7.62 × 10−4 | 0.0137 | 6.53 × 10−4 |

| Water use | m3 water eq | 1,118,816 | 48,391.69 | 826,327 | 39,348.85 |

| Impact Categories | Unit | Conventional System | |||

|---|---|---|---|---|---|

| Mean | 5% | 95% | SD | ||

| Acidification | mol H+ eq | 4.03 | 3.93 | 4.20 | 0.31 |

| Climate change | kg CO2 eq | 311.70 | 298.9 | 325.56 | 12.97 |

| Ecotoxicity: freshwater | CTUe | 9022.17 | 8661.8 | 9375.95 | 245.78 |

| Eutrophication: freshwater | kg P eq | 0.193 | 0.191 | 0.20 | 0.02 |

| Eutrophication: marine | kg N eq | 84.97 | 79.4 | 91.72 | 4.76 |

| Eutrophication: terrestrial | mol N eq | 19.06 | 17.6 | 20.57 | 0.96 |

| Human toxicity: cancer | CTUh | 7.04 × 10−7 | 6.78 × 10−7 | 7.31 × 10−7 | 1.64 × 10−8 |

| Human toxicity: non-cancer | CTUh | 4.37 × 10−6 | 4.19 × 10−6 | 4.54 × 10−6 | 1.21 × 10−7 |

| Ionising radiation | kBq U235 eq | 33.12 | 31.69 | 34.55 | 1.17 |

| Land use | Pt | 782.56 | 745.0 | 820.66 | 29.56 |

| Ozone depletion | kg CFC-11 eq | 8.36 × 10−5 | 7.99 × 10−5 | 8.72 × 10−5 | 3.08 × 10−6 |

| Particulate matter | Disease inc. | 2.08 × 10−5 | 1.94 × 10−5 | 2.22 × 10−5 | 1.03 × 10−6 |

| Photochemical ozone formation | kg NMVOC eq | 1.15 | 1.07 | 1.22 | 0.06 |

| Resource use: fossils | MJ | 3503.49 | 3333.7 | 3668.94 | 157.07 |

| Resource use: minerals and metals | kg Sb eq | 7.62 × 10−4 | 7.33 × 10−4 | 7.91 × 10−4 | 2.06 × 10−5 |

| Water use | m3 water eq | 48,391.69 | 46,556.3 | 50,278.64 | 1195.71 |

| Impact Categories | Unit | Integrated System | |||

|---|---|---|---|---|---|

| Mean | 5% | 95% | SD | ||

| Acidification | mol H+ eq | 3.153 | 2.81 | 3.54 | 1.27 |

| Climate change | kg CO2 eq | 259.01 | 238.1 | 281.88 | 31.21 |

| Ecotoxicity: freshwater | CTUe | 8129.11 | 7790.5 | 8530.30 | 272.45 |

| Eutrophication: freshwater | kg P eq | 0.174 | 0.151 | 0.20 | 0.11 |

| Eutrophication: marine | kg N eq | 45.20 | 41.2 | 49.88 | 8.05 |

| Eutrophication: terrestrial | mol N eq | 11.80 | 10.9 | 12.77 | 0.66 |

| Human toxicity: cancer | CTUh | 8.04 × 10−7 | 7.72 × 10−7 | 8.36 × 10−7 | 2.18 × 10−8 |

| Human toxicity: non-cancer | CTUh | 9.69 × 10−6 | 9.31 × 10−6 | 1.01 × 10−5 | 5.03 × 10−7 |

| Ionising radiation | kBq U235 eq | 28.49 | 26.27 | 30.94 | 1.44 |

| Land use | Pt | 684.97 | 640.1 | 732.61 | 28.85 |

| Ozone depletion | kg CFC-11 eq | 8.42 × 10−5 | 7.96 × 10−5 | 8.90 × 10−5 | 2.95 × 10−6 |

| Particulate matter | Disease inc. | 2.05 × 10−5 | 1.88 × 10−5 | 2.20 × 10−5 | 1.14 × 10−6 |

| Photochemical ozone formation | kg NMVOC eq | 1.10 | 1.00 | 1.19 | 0.072 |

| Resource use: fossils | MJ | 3102.71 | 2863.4 | 3357.16 | 156.90 |

| Resource use: minerals and metals | kg Sb eq | 6.53 × 10−4 | 6.26 × 10−4 | 6.81 × 10−4 | 1.67 × 10−5 |

| Water use | m3 water eq | 39,348.89 | 36,498.9 | 42,596.22 | 1828.39 |

References

- Mancuso, G.; Lavrnić, S.; Toscano, A. Reclaimed water to face agricultural water scarcity in the Mediterranean area: An overview using Sustainable Development Goals preliminary data. In Wastewater treatment and Reuse—Present and Future Perspectives in Technological Developments and Management Issues; Elsevier: Amsterdam, The Netherlands, 2020; pp. 113–143. [Google Scholar] [CrossRef]

- Lonigro, A.; Montemurro, N.; Rubino, P.; Vergine, P.; Pollice, A. Reuse of treated municipal wastewater for irrigation in Apulia region: The "IN.TE.R.R.A." project. Environ. Eng. Manag. J. 2015, 14, 1665–1674. [Google Scholar] [CrossRef]

- Romeiko, X.X. A Comparative Life Cycle Assessment of Crop Systems Irrigated with the Groundwater and Reclaimed Water in Northern China. Sustainability 2019, 11, 2743. [Google Scholar] [CrossRef] [Green Version]

- Padilla-Rivera, A.; Morgan-Sagastume, J.M.; Güereca-Hernández, L.P. Sustainability Assessment of Wastewater Systems: An Environmental and Economic Approach. J. Environ. Prot. 2019, 10, 241–259. [Google Scholar] [CrossRef] [Green Version]

- Corominas, L.; Foley, J.; Guest, J.; Hospido, A.; Larsen, H.; Morera, S.; Shaw, A. Life cycle assessment applied to wastewater treatment: State of the art. Water Res. 2013, 47, 5480–5492. [Google Scholar] [CrossRef] [PubMed]

- Gallego-Schmid, A.; Tarpani, R.R.Z. Life cycle assessment of wastewater treatment in developing countries: A review. Water Res. 2019, 153, 63–79. [Google Scholar] [CrossRef] [Green Version]

- Arcidiacono, C.; Porto, S.M.C. Life cycle assessment of Arundo donax biomass production in a Mediterranean experimental field using treated wastewater. J. Agric. Eng. 2012, 42, 29. [Google Scholar] [CrossRef]

- Muñoz, I.; Gómez, M.D.M.; Fernández-Alba, A.R. Life Cycle Assessment of biomass production in a Mediterranean greenhouse using different water sources: Groundwater, treated wastewater and desalinated seawater. Agric. Syst. 2010, 103, 1–9. [Google Scholar] [CrossRef]

- Azeb, L.; Hartani, T.; Aitmouheb, N.; Pradeleix, L.; Hajjaji, N.; Aribi, S. Life cycle assessment of cucumber irrigation: Unplanned water reuse versus groundwater resources in Tipaza (Algeria). J. Water Reuse Desalination 2020, 10, 227–238. [Google Scholar] [CrossRef]

- Canaj, K.; Mehmeti, A.; Morrone, D.; Toma, P.; Todorović, M. Life cycle-based evaluation of environmental impacts and external costs of treated wastewater reuse for irrigation: A case study in southern Italy. J. Clean. Prod. 2021, 293, 126142. [Google Scholar] [CrossRef]

- Moretti, M.; Van Passel, S.; Camposeo, S.; Pedrero, F.; Dogot, T.; Lebailly, P.; Vivaldi, G. Modelling environmental impacts of treated municipal wastewater reuse for tree crops irrigation in the Mediterranean coastal region. Sci. Total. Environ. 2019, 660, 1513–1521. [Google Scholar] [CrossRef]

- Giungato, P.; Guinée, J.B. LCA of an urban wastewater tertiary treatment plant. In Proceedings of the 7th International Conference on Life Cycle Assessment in the Agri-Food Sector (LCA Food 2010), Bari, Italy, 22–24 September 2010. [Google Scholar]

- Arborea, S.; Giannoccaro, G.; De Gennaro, B.C.; Iacobellis, V.; Piccinni, A.F. Cost–Benefit Analysis of Wastewater Reuse in Puglia, Southern Italy. Water 2017, 9, 175. [Google Scholar] [CrossRef] [Green Version]

- Arena, C.; Genco, M.; Mazzola, M.R. Environmental Benefits and Economical Sustainability of Urban Wastewater Reuse for Irrigation—A Cost-Benefit Analysis of an Existing Reuse Project in Puglia, Italy. Water 2020, 12, 2926. [Google Scholar] [CrossRef]

- Giannoccaro, G.; Arborea, S.; De Gennaro, B.C.; Iacobellis, V.; Piccinni, A.F. Assessing Reclaimed Urban Wastewater for Reuse in Agriculture: Technical and Economic Concerns for Mediterranean Regions. Water 2019, 11, 1511. [Google Scholar] [CrossRef] [Green Version]

- Mizyed, N.R. Challenges to treated wastewater reuse in arid and semi-arid areas. Environ. Sci. Policy 2013, 25, 186–195. [Google Scholar] [CrossRef]

- Sgroi, M.; Vagliasindi, F.G.; Roccaro, P. Feasibility, sustainability and circular economy concepts in water reuse. Curr. Opin. Environ. Sci. Health 2018, 2, 20–25. [Google Scholar] [CrossRef]

- Todorovic, M.; Mehmeti, A.; Scardigno, A. Eco-efficiency of agricultural water systems: Methodological approach and assessment at meso-level scale. J. Environ. Manag. 2016, 165, 62–71. [Google Scholar] [CrossRef] [PubMed]

- Saab, M.T.A.; Jomaa, I.; Skaf, S.; Fahed, S.; Todorovic, M. Assessment of a Smartphone Application for Real-Time Irrigation Scheduling in Mediterranean Environments. Water 2019, 11, 252. [Google Scholar] [CrossRef] [Green Version]

- Koeble, R. The Global Nitrous Oxide Calculator—GNOC—Online Tool Manual. Jt. Res. Cent. Eur. Comm. 2014, 1.2.4, 40. [Google Scholar]

- Nemecek, T.; Kagi, T. Life Cycle Inventories of Agricultural Production Systems; Ecoinvent report No. 15. Final Rep. Ecoinvent V2.0; Agroscope Reckenholz-Tanikon Research Station: Zürich, Switzerland; Dübendorf, Switzerland, 2007; pp. 1–360. Available online: https://db.ecoinvent.org/reports/15_Agriculture.pdf (accessed on 14 August 2021).

- Green Delta Open LCA Version 1.10., Green Delta GmbH, Germany. Available online: https://www.openlca.org/download/ (accessed on 20 May 2021).

- Ecoinvent Database Version 3.1 Swiss Centre for Life Cycle Inventories, Switzerland. Available online: https://www.ecoinvent.org/database/ecoinvent-371/ecoinvent-371.html (accessed on 20 May 2021).

- Hoekstra, A.Y.; Mekonnen, M.; Chapagain, A.K.; Mathews, R.E.; Richter, B.D. Global Monthly Water Scarcity: Blue Water Footprints versus Blue Water Availability. PLoS ONE 2012, 7, e32688. [Google Scholar] [CrossRef]

- FAO Food and Agriculture Organization of the United Nations, Crops and Drops: Making the Best Use of Water for Agriculture. World Food Day. Rome, Italy. 2002, p. 28. Available online: www.fao.org/DOCREP/005/Y3918E/Y3918E00.htm (accessed on 14 August 2021).

- Deng, L.; Chen, L.; Zhao, J.; Wang, R. Comparative analysis on environmental and economic performance of agricultural cooperatives and smallholder farmers: The case of grape production in Hebei, China. PLoS ONE 2021, 16, e0245981. [Google Scholar] [CrossRef]

- Russo, V.; Strever, A.E.; Ponstein, H.J. Exploring sustainability potentials in vineyards through LCA? Evidence from farming practices in South Africa. Int. J. Life Cycle Assess. 2021, 26, 1–17. [Google Scholar] [CrossRef]

- Falcone, G.; De Luca, A.I.; Stillitano, T.; Strano, A.; Romeo, G.; Gulisano, G. Assessment of Environmental and Economic Impacts of Vine-Growing Combining Life Cycle Assessment, Life Cycle Costing and Multicriterial Analysis. Sustainability 2016, 8, 793. [Google Scholar] [CrossRef] [Green Version]

- Roselli, L.; Casieri, A.; De Gennaro, B.C.; Sardaro, R.; Russo, G. Environmental and Economic Sustainability of Table Grape Production in Italy. Sustainability 2020, 12, 3670. [Google Scholar] [CrossRef]

- Ng, R.; Yeo, Z.; Low, J.S.C.; Song, B. A method for relative eco-efficiency analysis and improvement: Case study of bonding technologies. J. Clean. Prod. 2015, 99, 320–332. [Google Scholar] [CrossRef]

- Arampatzis, G.; Angelis-Dimakis, A.; Blind, M.; Assimacopoulos, D. A web-based Toolbox to support the systemic eco-efficiency assessment in water use systems. J. Clean. Prod. 2016, 138, 181–194. [Google Scholar] [CrossRef]

- Meneses, M.; Pasqualino, J.; Castells, F. Environmental assessment of urban wastewater reuse: Treatment alternatives and applications. Chemosphere 2010, 81, 266–272. [Google Scholar] [CrossRef]

- Sieverding, H.; Kebreab, E.; Johnson, J.M.F.; Xu, H.; Wang, M.; Del Grosso, S.J.; Bruggeman, S.; Stewart, C.E.; Westhoff, S.; Ristau, J.; et al. A life cycle analysis (LCA) primer for the agricultural community. Agron. J. 2020, 112, 3788–3807. [Google Scholar] [CrossRef]

- Xue, X.; Cashman, S.; Gaglione, A.; Mosley, J.; Weiss, L.; Ma, X.C.; Cashdollar, J.; Garland, J. Holistic analysis of urban water systems in the Greater Cincinnati region: (1) life cycle assessment and cost implications. Water Res. X 2019, 2, 100015. [Google Scholar] [CrossRef]

- Gargiulo, A.; Carvalho, M.L.; Girardi, P. Life Cycle Assessment of Italian Electricity Scenarios to 2030. Energies 2020, 13, 3852. [Google Scholar] [CrossRef]

- Fotia, K.; Mehmeti, A.; Tsirogiannis, I.; Nanos, G.; Mamolos, A.; Malamos, N.; Barouchas, P.; Todorovic, M. LCA-Based Environmental Performance of Olive Cultivation in Northwestern Greece: From Rainfed to Irrigated through Conventional and Smart Crop Management Practices. Water 2021, 13, 1954. [Google Scholar] [CrossRef]

| Input/Output | Unit | Conventional System (CS) | Integrated System (IS) |

|---|---|---|---|

| Crop yield | ton/ha | 23.12 | 21.00 |

| Water withdrawals | m3/ton | 136.80 | 143.60 |

| Water consumption | m3/ton | 68.34 | 17.10 |

| Irrigation energy | kWh/ton | 202.50 | 161.00 |

| N-based fertilizers | kg/ton | 5.69 | 3.82 |

| P-based fertilizers | kg/ton | 3.03 | 3.10 |

| K-based fertilizers | kg/ton | 3.03 | 2.60 |

| Pesticides | kg/ton | 2.76 | 3.05 |

| Diesel Fuel | MJ/ton | 399.10 | 439.30 |

| Treatment system | unit/ha | - | 1 |

| Impact Categories | Normalization Factor | Weighting Factor |

|---|---|---|

| Acidification | 55.556 | 0.062 |

| Climate change | 8097.166 | 0.2106 |

| Ecotoxicity: freshwater | 42,680.324 | 0.0192 |

| Eutrophication: freshwater | 1.607 | 0.028 |

| Eutrophication: marine | 19.547 | 0.0296 |

| Eutrophication: terrestrial | 176.741 | 0.0371 |

| Human toxicity: cancer | 0.000 | 0.0213 |

| Human toxicity: non-cancer | 0.000 | 0.0184 |

| Ionising radiation | 4219.409 | 0.0501 |

| Land use | 819,672.131 | 0.0794 |

| Ozone depletion | 0.054 | 0.0631 |

| Particulate matter | 0.001 | 0.0896 |

| Photochemical ozone formation | 40.601 | 0.0478 |

| Resource use: fossils | 65,019.506 | 0.0832 |

| Resource use: minerals and metals | 0.064 | 0.0755 |

| Water use | 11,469.205 | 0.0851 |

| Inputs | Unit | Value |

|---|---|---|

| Crop market price | €/kg | 0.70 |

| Cost groundwater | €/m3 | 0.62 |

| Cost of reclaimed water | €/m3 | 0.44 |

| Biovegetal | €/kg | 0.07 |

| Ammonium sulfate | €/kg | 0.36 |

| Calcium nitrate | €/kg | 0.25 |

| Fuel | €/kg | 1.00 |

| Pesticides | €/kg | 32.5 |

| Parameters | Unit | Conventional System | Integrated System |

|---|---|---|---|

| Gross production value | €/ha | 16,184 | 14,700 |

| Variable cost | €/ha | 7099 | 6870 |

| Variable cost | €/ton | 307.1 | 328.7 |

| Returns over operating costs (gross returns) | €/ha | 11,288 | 9962 |

| Returns over operating costs (gross returns) | €/ton | 488.2 | 474.3 |

| Total Value Added (TVA) | €/ha | 9084 | 7830 |

| Total Value Added (TVA) | €/ton | 393 | 371.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canaj, K.; Morrone, D.; Roma, R.; Boari, F.; Cantore, V.; Todorovic, M. Reclaimed Water for Vineyard Irrigation in a Mediterranean Context: Life Cycle Environmental Impacts, Life Cycle Costs, and Eco-Efficiency. Water 2021, 13, 2242. https://doi.org/10.3390/w13162242

Canaj K, Morrone D, Roma R, Boari F, Cantore V, Todorovic M. Reclaimed Water for Vineyard Irrigation in a Mediterranean Context: Life Cycle Environmental Impacts, Life Cycle Costs, and Eco-Efficiency. Water. 2021; 13(16):2242. https://doi.org/10.3390/w13162242

Chicago/Turabian StyleCanaj, Kledja, Domenico Morrone, Rocco Roma, Francesca Boari, Vito Cantore, and Mladen Todorovic. 2021. "Reclaimed Water for Vineyard Irrigation in a Mediterranean Context: Life Cycle Environmental Impacts, Life Cycle Costs, and Eco-Efficiency" Water 13, no. 16: 2242. https://doi.org/10.3390/w13162242

APA StyleCanaj, K., Morrone, D., Roma, R., Boari, F., Cantore, V., & Todorovic, M. (2021). Reclaimed Water for Vineyard Irrigation in a Mediterranean Context: Life Cycle Environmental Impacts, Life Cycle Costs, and Eco-Efficiency. Water, 13(16), 2242. https://doi.org/10.3390/w13162242