Influence of the Nanoclay Concentration and Oil Viscosity on the Rheological and Tribological Properties of Nanoclay-Based Ecolubricants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design for the Nanoclay-Based Ecolubricants Formulation

2.3. Nanoclay-Based Ecolubricants Preparation

2.4. Nanoclay-Based Ecolubricants Characterization

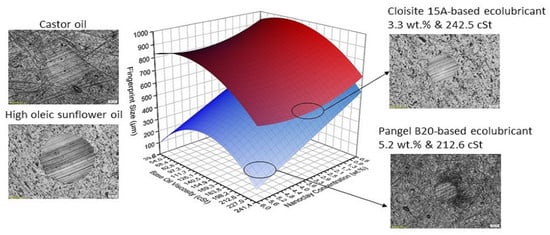

3. Results and Discussion

3.1. Viscous Flow Behaviour of Nanoclay-Based Ecolubricants

3.2. Friction Analysis of Nanoclay-Based Ecolubricants

3.3. Wear Analysis of Nanoclays-Based Ecolubricants

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chan, C.H.; Tang, S.W.; Mohd, N.K.; Lim, W.H.; Yeong, S.K.; Idris, Z. Tribological behavior of biolubricant base stocks and additives. Renew. Sustain. Energy Rev. 2018, 93, 145–157. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, A.; Singla, A. Non-edible vegetable oil–based feedstocks capable of bio-lubricant production for automotive sector applications—A review. Environ. Sci. Pollut. Res. 2019, 26, 14867–14882. [Google Scholar] [CrossRef] [PubMed]

- Darminesh, S.P.; Sidik, N.A.C.; Najafi, G.; Mamat, R.; Ken, T.L.; Asako, Y. Recent development on biodegradable nanolubricant: A review. Int. Commun. Heat Mass Transf. 2017, 86, 159–165. [Google Scholar] [CrossRef]

- Rudnick, L.R. Synthetics, Mineral Oils, and Bio-Based Lubricants: Chemistry and Technology, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2005; ISBN 9781420027181. [Google Scholar]

- Erhan, S.Z.; Asadauskas, S. Lubricant basestocks from vegetable oils. Ind. Crops Prod. 2000, 11, 277–282. [Google Scholar] [CrossRef]

- Ogunniyi, D.S. Castor oil: A vital industrial raw material. Bioresour. Technol. 2006, 97, 1086–1091. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Valencia, C.; Franco, J.M.; Gallegos, C. Viscosity modification of different vegetable oils with EVA copolymer for lubricant applications. Ind. Crops Prod. 2010, 32, 607–612. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Valencia, C.; Franco, J.M.; Gallegos, C. Natural and synthetic antioxidant additives for improving the performance of new biolubricant formulations. J. Agric. Food Chem. 2011, 59, 12917–12924. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, Y.; Cheong, S.; Choi, Y.; Kwon, L.; Lee, J.; Kim, S.H. Understanding the role of nanoparticles in nano-oil lubrication. Tribol. Lett. 2009, 35, 127–131. [Google Scholar] [CrossRef]

- Ghaednia, H.; Jackson, R.L. Fellowship research: The role of nanoparticles in lubricants; Performing lubricated and dry friction tests. Tribol. Lubr. Technol. 2015, 71, 20–24. [Google Scholar]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of nanoparticles in lubricating oil: A critical review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Tarasov, S.; Kolubaev, A.; Belyaev, S.; Lerner, M.; Tepper, F. Study of friction reduction by nanocopper additives to motor oil. Wear 2002, 252, 63–69. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiza, R.; Prosyčevas, I.; Kreivaitis, R. Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribol. Int. 2013, 60, 224–232. [Google Scholar] [CrossRef]

- Hernandez Battez, A.; Fernandez Rico, J.E.; Navas Arias, A.; Viesca Rodriguez, J.L.; Chou Rodriguez, R.; Diaz Fernandez, J.M. The tribological behaviour of ZnO nanoparticles as an additive to PAO6. Wear 2006, 261, 256–263. [Google Scholar] [CrossRef]

- Hernández Battez, A.; González, R.; Viesca, J.L.; Fernández, J.E.; Díaz Fernández, J.M.; Machado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.; Huang, X.; Huang, L.; Yang, F. Tribological properties of Al2O3 nanoparticles as lubricating oil additives. Ceram. Int. 2014, 40, 7143–7149. [Google Scholar] [CrossRef]

- Shahnazar, S.; Bagheri, S.; Abd Hamid, S.B. Enhancing lubricant properties by nanoparticle additives. Int. J. Hydrogen Energy 2016, 41, 3153–3170. [Google Scholar] [CrossRef]

- Jiao, D.; Zheng, S.; Wang, Y.; Guan, R.; Cao, B. The tribology properties of alumina/silica composite nanoparticles as lubricant additives. Appl. Surf. Sci. 2011, 257, 5720–5725. [Google Scholar] [CrossRef]

- Gupta, R.N.; Harsha, A.P. Antiwear and extreme pressure performance of castor oil with nano-additives. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 1055–1067. [Google Scholar] [CrossRef]

- Gupta, R.N.; Harsha, A.P. Tribological evaluation of calcium-copper-titanate/cerium oxide-based nanolubricants in sliding contact. Lubr. Sci. 2018, 30, 175–187. [Google Scholar] [CrossRef]

- Li, Z.; Xu, C.; Xiao, G.; Zhang, J.; Chen, Z.; Yi, M. Lubrication performance of graphene as lubricant additive in 4-n-pentyl-4′-cyanobiphyl Liquid Crystal (5CB) for Steel/Steel contacts. Materials 2018, 11, 2110. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Li, Y.; He, Y.; Luo, J. In Situ Green Synthesis of the New Sandwichlike Nanostructure of Mn3O4/Graphene as Lubricant Additives. ACS Appl. Mater. Interfaces 2019, 11, 36931–36938. [Google Scholar] [CrossRef] [PubMed]

- Del Ramos-Tejada, M.M.; Rodríguez, J.M.; Delgado, Á.V. Electrorheology of clay particle suspensions. Effects of shape and surface treatment. Rheol. Acta 2018, 57, 405–413. [Google Scholar] [CrossRef]

- Chizhik, P.; Dietzel, D.; Bill, S.; Schirmeisen, A. Tribological properties of a phyllosilicate based microparticle oil additive. Wear 2019, 426–427, 835–844. [Google Scholar] [CrossRef]

- Singh, H.; Bhowmick, H. Influence of nanoclay on the thermophysical properties and lubricity characteristics of mineral oil. In Materials Today, Proceedings of the International Conference on Nanotechnology: Ideas, Innovations & Initiatives-2017 (ICN:3i-2017), Roorkee, India, 6–8 December 2017; Elsevier BV: Amsterdam, The Netherlands, 2019; Volume 18, pp. 1058–1066. [Google Scholar]

- García-López, D.; Fernández, J.F.; Merino, J.C.; Santarén, J.; Pastor, J.M. Effect of organic modification of sepiolite for PA 6 polymer/organoclay nanocomposites. Compos. Sci. Technol. 2010, 70, 1429–1436. [Google Scholar] [CrossRef] [Green Version]

- Cao, Z.; Xia, Y.; Xi, X. Nano-montmorillonite-doped lubricating grease exhibiting excellent insulating and tribological properties. Friction 2017, 5, 219–230. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, G.; Zhang, Z.; Yang, H.; Tan, J. Structures and rheological properties of organo-sepiolite in oil-based drilling fluids. Appl. Clay Sci. 2018, 154, 43–51. [Google Scholar] [CrossRef]

- Liu, P.; Du, M.; Clode, P.; Li, H.; Liu, J.; Leong, Y.K. Surface Chemisty, Microstructure, and Rheology of Thixotropic 1-D Sepiolite Gels. Clays Clay Miner. 2020, 68, 9–22. [Google Scholar] [CrossRef]

- Montgomery, D. Diseño Y Análisis De Experimentos; Limusa Wiley: Mexico City, Mexico, 2004; ISBN 9687270608. [Google Scholar]

- Maheswaran, R.; Sunil, J. Effect of nano sized garnet particles dispersion on the viscous behavior of extreme pressure lubricant oil. J. Mol. Liq. 2016, 223, 643–651. [Google Scholar] [CrossRef]

- Heyer, P.; Läuger, J. Correlation between friction and flow of lubricating greases in a new tribometer device. Lubr. Sci. 2009, 21, 253–268. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Martín-Alfonso, M.J.; Franco, J.M. Tunable rheological-tribological performance of “green” gel-like dispersions based on sepiolite and castor oil for lubricant applications. Appl. Clay Sci. 2020, 192. [Google Scholar] [CrossRef]

- Kuznetsov, N.M.; Stolyarova, D.Y.; Belousov, S.I.; Kamyshinsky, R.A.; Orekhov, A.S.; Vasiliev, A.L.; Chvalun, S.N. Halloysite nanotubes: Prospects in electrorheology. Express Polym. Lett. 2018, 12, 958–965. [Google Scholar] [CrossRef]

- Balan, C.; Franco, J.M. Influence of the geometry on the transient and steady flow of lubricating greases. Tribol. Trans. 2001, 44, 53–58. [Google Scholar] [CrossRef]

- Hou, K.; Ouyang, J.; Zheng, C.; Zhang, J.; Yang, H. Surface-modified sepiolite fibers for reinforcing resin brake composites. Mater. Express 2017, 7, 104–112. [Google Scholar] [CrossRef]

- Papenhuijzen, J.M.P. The role of particle interactions in the rheology of dispersed systems. Rheol. Acta 1972, 11, 73–88. [Google Scholar] [CrossRef]

- Delgado, M.A.; Valencia, C.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Influence of soap concentration and oil viscosity on the rheology and microstructure of lubricating greases. Ind. Eng. Chem. Res. 2006, 45, 1902–1910. [Google Scholar] [CrossRef]

- Delgado, M.A.; Franco, J.M.; Valencia, C.; Kuhn, E.; Gallegos, C. Transient shear flow of model lithium lubricating greases. Mech. Time-Depend. Mater. 2009, 13, 63–80. [Google Scholar] [CrossRef]

- Gonçalves, D.; Graça, B.; Campos, A.V.; Seabra, J. On the friction behaviour of polymer greases. Tribol. Int. 2016, 93, 399–410. [Google Scholar] [CrossRef]

- Yu, H.L.; Xu, Y.; Shi, P.J.; Wang, H.M.; Zhao, Y.; Xu, B.S.; Bai, Z.M. Tribological behaviors of surface-coated serpentine ultrafine powders as lubricant additive. Tribol. Int. 2010, 43, 667–675. [Google Scholar] [CrossRef]

- García-Morales, M.; Fernández-Silva, S.D.; Roman, C.; Delgado, M.A. Electro-active control of the viscous flow and tribological performance of ecolubricants based on phyllosilicate clay minerals and castor oil. Appl. Clay Sci. 2020, 198, 1058302. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Maldonado-Cortés, D.; García, P.; Irigoyen, M.; Taha-Tijerina, J.; Guerra, J. Tribological performance of halloysite clay nanotubes as green lubricant additives. Wear 2017, 376–377, 885–892. [Google Scholar] [CrossRef]

- Kalin, M.; Kogovšek, J.; Remškar, M. Mechanisms and improvements in the friction and wear behavior using MoS 2 nanotubes as potential oil additives. Wear 2012, 280–281, 36–45. [Google Scholar] [CrossRef]

- Gunsel, S.; Smeeth, M.; Spikes, H. Friction and wear reduction by boundary film-forming viscosity index improvers. SAE Tech. Pap. Ser. 1996. [Google Scholar] [CrossRef]

| Sample | Nanoclay Concentration (wt.%) | Base Oil Viscosity (cSt) | Cloisite 15A | Pangel B20 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| RB * | K (Pa·sn) | n | µ∞ (Pa·s) | RB * | K (Pa·sn) | n | µ∞ (Pa·s) | |||

| 0, 0A | 3.3 | 140.5 | P | 1.287 | 0.428 | 0.346 | P | 33.572 | 0.111 | 0.529 |

| 0, 0B | 3.3 | 140.5 | P | 1.215 | 0.516 | 0.299 | P | 29.523 | 0.095 | 0.650 |

| +1.414, 0 | 6.0 | 140.5 | P | 9.548 | 0.115 | 0.559 | P | 88.232 | 0.124 | 0.224 |

| −1.414, 0 | 0.5 | 140.5 | N | 0.314 | 1 | - | P | 0.171 | 0.560 | 0.280 |

| 0, +1.414 | 3.3 | 242.5 | P | 0.756 | 0.727 | 0.656 | P | 31.252 | 0.136 | 0.772 |

| 0, −1.414 | 3.3 | 38.5 | P | 1.361 | 0.206 | 0.106 | P | 28.246 | 0.054 | 0.126 |

| +1, +1 | 5.2 | 212.6 | P | 2.049 | 0.418 | 0.745 | P | 63.299 | 0.124 | 0.853 |

| +1, −1 | 5.2 | 68.4 | P | 4.187 | 0.166 | 0.217 | P | 47.638 | 0.056 | 0.295 |

| −1, +1 | 1.3 | 212.6 | N | 0.638 | 1 | - | P | 1.976 | 0.212 | 0.602 |

| −1, −1 | 1.3 | 68.4 | N | 0.186 | 1 | - | P | 2.834 | 0.222 | 0.146 |

| Sample | Nanoclay Concentration (wt.%) | Oil Viscosity (cSt) | Cloisite 15A D (µm) | Pangel B20 D (µm) |

|---|---|---|---|---|

| 0, 0A | 3.3 | 140.5 | 790 ± 60 | 505 ± 25 |

| 0, 0B | 3.3 | 140.5 | 857 ± 28 | 669 ± 26 |

| +1.414, 0 | 6.0 | 140.5 | 642 ± 37 | 285 ± 10 |

| −1.414, 0 | 0.5 | 140.5 | 1024 ± 57 | 893 ± 51 |

| 0, +1.414 | 3.3 | 242.5 | 347 ± 55 | 315 ± 19 |

| 0, −1.414 | 3.3 | 38.5 | 839 ± 43 | 378 ± 18 |

| +1, +1 | 5.2 | 212.6 | 953 ± 66 | 338 ± 50 |

| +1, −1 | 5.2 | 68.4 | 893 ± 72 | 298 ± 10 |

| −1, +1 | 1.3 | 212.6 | 747 ± 64 | 607 ± 66 |

| −1, −1 | 1.3 | 68.4 | 848 ± 86 | 445 ± 19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Silva, S.D.; García-Morales, M.; Ruffel, C.; Delgado, M.A. Influence of the Nanoclay Concentration and Oil Viscosity on the Rheological and Tribological Properties of Nanoclay-Based Ecolubricants. Lubricants 2021, 9, 8. https://doi.org/10.3390/lubricants9010008

Fernández-Silva SD, García-Morales M, Ruffel C, Delgado MA. Influence of the Nanoclay Concentration and Oil Viscosity on the Rheological and Tribological Properties of Nanoclay-Based Ecolubricants. Lubricants. 2021; 9(1):8. https://doi.org/10.3390/lubricants9010008

Chicago/Turabian StyleFernández-Silva, Samuel D., Moisés García-Morales, Charlène Ruffel, and Miguel A. Delgado. 2021. "Influence of the Nanoclay Concentration and Oil Viscosity on the Rheological and Tribological Properties of Nanoclay-Based Ecolubricants" Lubricants 9, no. 1: 8. https://doi.org/10.3390/lubricants9010008

APA StyleFernández-Silva, S. D., García-Morales, M., Ruffel, C., & Delgado, M. A. (2021). Influence of the Nanoclay Concentration and Oil Viscosity on the Rheological and Tribological Properties of Nanoclay-Based Ecolubricants. Lubricants, 9(1), 8. https://doi.org/10.3390/lubricants9010008