Effects of X-rays Radiation on AISI 304 Stainless Steel Weldings with AISI 316L Filler Material: A Study of Resistance and Pitting Corrosion Behavior

Abstract

:1. Introduction

2. Materials Used and Experimental Procedures

2.1. Materials Used

2.2. Experimental Processes

3. Results and Discussion

3.1. Strength Properties

3.2. Microhardness Test Results

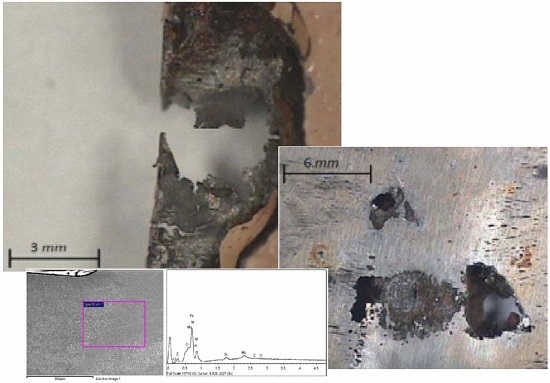

3.3. Characteristics of the Corrosion Pitting

3.4. Analysis of Welded Microstructures

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, D.J.; Byun, J.C.; Sung, J.H.; Lee, H.W. The dependence of crack properties on the Cr/Ni equivalent ratio in AISI 304L austenitic stainless steel weld metals. Mater. Sci. Eng. A. 2009, 513, 154–159. [Google Scholar] [CrossRef]

- Lee, D.J.; Jung, K.H.; Sung, J.H.; Kim, Y.H.; Lee, K.H.; Park, J.U.; Lee, H.W. Pitting corrosion behavior on crack property in AISI 304L weld metals with varying Cr/Ni equivalent ratio. Mater. Des. 2009, 30, 3269–3273. [Google Scholar] [CrossRef]

- Gill, T.P.S.; Shankar, V.; Pujar, M.G.; Rodriguez, P. Effect of composition on the transformation of δ-ferrite TO σ in type 316 stainless steel weld metals. Scr. Metall. Mater. 1995, 32, 1595–1600. [Google Scholar] [CrossRef]

- Lee, E.H.; Byun, T.S.; Hunn, J.D.; Yoo, M.H.; Farrell, K.; Mansur, L.K. On the origin of deformation microstructures in austenitic stainless steel: Part I—Microstructures. Acta Mater. 2001, 49, 3269–3276. [Google Scholar] [CrossRef]

- Lee, E.H.; Byun, T.S.; Hunn, J.D.; Farrell, K.; Mansur, L.K. On the origin of deformation microstructures in austenitic stainless steel: Part II—Mechanisms. Acta Mater. 2001, 49, 3277–3287. [Google Scholar] [CrossRef]

- Lee, E.H.; Byun, T.S.; Hunn, J.D.; Farrell, K.; Mansur, L.K. Origin of hardening and deformation mechanisms in irradiated 316 LN austenitic stainless steel. J. Nucl. Mater. 2001, 296, 183–191. [Google Scholar] [CrossRef]

- Hertzberg, R.W. Deformation and Fracture Mechanics of Engineering Materials, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1983. [Google Scholar]

- Copley, S.M.; Kear, B.H. The dependence of the width of a dissociated dislocation on dislocation velocity. Acta Metall. 1968, 16, 227–231. [Google Scholar] [CrossRef]

- Dai, Y; Egeland, G.W.; Long, B. Tensile properties of ferritic/martensitic steels irradiated in STIP-I. J. Nucl. Mater. 2008, 377, 115–221. [Google Scholar] [CrossRef]

- Farrell, K.; Byun, T.S.; Hashimoto, N. Deformation mode maps for tensile deformation of neutron-irradiated structural alloys. J. Nucl. Mater. 2004, 335, 471–486. [Google Scholar] [CrossRef]

- Wechsler, M.S. The Inhomogeneity of Plastic Deformation, American Society for Metals; Metals Park: Materials Park, OH, USA, 1971; Chapter 2. [Google Scholar]

- Smidt, F.A., Jr. Dislocation Channeling in Irradiated Metals; NRL Report 7078; Naval Research Laboratory: Washington, D.C., USA, 3 June 1970. [Google Scholar]

- Lu, B.T. Pitting and stress corrosion cracking behavior in welded austenitic stainless steel. Electrochim. Acta 2005, 50, 1391–1403. [Google Scholar] [CrossRef]

- Nishimoto, K.; Ogawa, K. Corrosion properties in weldments of stainless steels (1). Metallurgical factors affecting corrosion properties. Weld. Int. 1999, 13, 845–854. [Google Scholar] [CrossRef]

- Gooch, T.G. Corrosion behavior of welded stainless steel. Weld. J. Incl. Weld. Res. Suppl. 1996, 75, 135s–154s. [Google Scholar]

- Brooks, J.A.; Thompson, A.W. Microstructural development and solidification cracking susceptibility of austenitic stainless steel welds. Int. Mater. Rev. 1991, 36, 16–44. [Google Scholar] [CrossRef]

- Bilmes, P.; Gonzalez, A.; Llorente, C.; Solari, M. Effect of δ ferrite solidification morphology of austenitic stainless steel weld metal on properties of welded joints. Weld. Int. 1996, 10, 797–808. [Google Scholar] [CrossRef]

- Allen, D.J. Solidification sequences in austenitic steel weld metal deposited on ferritic base material. Met. Technol. 1983, 10, 24–27. [Google Scholar] [CrossRef]

- Pascual, M.; Salas, F.; Carcel, F.J.; Perales, M.; Sánchez, A. TIG AISI-316 welds using an inert gas welding chamber and different filler metals: Changes in mechanical properties and microstructure. Rev. Met. 2010, 46, 493–498. [Google Scholar] [CrossRef]

- Carcel-Carrasco, J.; Pascual-Guillamon, M.; Perez-Puig, M. Microstructural characteristics and resistance to corrosion in welds of steel AISI 304 with inconel 625 exposed to ionizing radiation (radiation x). DYNA Septiembre 2014, 89, 542–551. [Google Scholar] [CrossRef]

| ASTM | EN10088-2 | %C | %Cr | %Ni | %Mn | %Si | %Mo |

|---|---|---|---|---|---|---|---|

| 304 (SS) | X5CrNi18-10 | 0.07 | 18 | 9.5 | 1.90 | 1.00 | - |

| 316L (WF) | X2CrNiMo17-12-2 | 0.04 | 17–20 | 11–14 | 2.50 | 0.90 | 2.0–2.5 |

| Irradiated Doses | Conventional Atmosphere | Argon Chamber | Conventional Atmosphere | Argon Chamber |

|---|---|---|---|---|

| Dose (Gy) | Yield Strength (MPa) | Tensile Strength (MPa) | ||

| 0 | 378 ± 20 | 415 ± 14 | 569 ± 28 | 623 ± 21 |

| 200 | 376 ± 13 | 392 ± 19 | 551 ± 22 | 587 ± 29 |

| 700 | 372 ± 8 | 389 ± 9 | 544 ± 31 | 583 ± 14 |

| 1000 | 407 ± 10 | 411 ± 17 | 620 ± 30 | 616 ± 26 |

| Dose (Gy) | Break Strain (%) | Break Energy (J) | ||

| 0 | 33 ± 7 | 51 ± 11 | 367 ± 23 | 673 ± 170 |

| 200 | 29 ± 6 | 38 ± 5 | 350 ± 53 | 475 ± 59 |

| 700 | 24 ± 10 | 32 ± 3 | 360 ± 90 | 388 ± 45 |

| 1000 | 30 ± 5 | 33 ± 5 | 401 ± 95 | 398 ± 60 |

| Dose (Gy) | Conventional Atmosphere | Argon Chamber | Conventional Atmosphere | Argon Chamber | Conventional Atmosphere | Argon Chamber |

|---|---|---|---|---|---|---|

| TAZ Metal Base Zone | TAZ Interfac with Weld Zone | Weld Zone | ||||

| 0 | 220 ± 5 | 220 ± 6 | 195 ± 9 | 202 ± 8 | 200 ± 9 | 203 ± 8 |

| 200 | 215 ± 8 | 218 ± 9 | 221 ± 9 | 190 ± 7 | 204 ± 9 | 202 ± 7 |

| 700 | 210 ± 10 | 214 ± 9 | 213 ± 8 | 189 ± 9 | 194 ± 8 | 200 ± 9 |

| 1000 | 230 ±9 | 223 ± 10 | 225 ± 10 | 215 ± 9 | 202 ± 10 | 230 ± 9 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cárcel-Carrasco, F.J.; Pascual-Guillamón, M.; Pérez-Puig, M.A. Effects of X-rays Radiation on AISI 304 Stainless Steel Weldings with AISI 316L Filler Material: A Study of Resistance and Pitting Corrosion Behavior. Metals 2016, 6, 102. https://doi.org/10.3390/met6050102

Cárcel-Carrasco FJ, Pascual-Guillamón M, Pérez-Puig MA. Effects of X-rays Radiation on AISI 304 Stainless Steel Weldings with AISI 316L Filler Material: A Study of Resistance and Pitting Corrosion Behavior. Metals. 2016; 6(5):102. https://doi.org/10.3390/met6050102

Chicago/Turabian StyleCárcel-Carrasco, Francisco Javier, Manuel Pascual-Guillamón, and Miguel Angel Pérez-Puig. 2016. "Effects of X-rays Radiation on AISI 304 Stainless Steel Weldings with AISI 316L Filler Material: A Study of Resistance and Pitting Corrosion Behavior" Metals 6, no. 5: 102. https://doi.org/10.3390/met6050102

APA StyleCárcel-Carrasco, F. J., Pascual-Guillamón, M., & Pérez-Puig, M. A. (2016). Effects of X-rays Radiation on AISI 304 Stainless Steel Weldings with AISI 316L Filler Material: A Study of Resistance and Pitting Corrosion Behavior. Metals, 6(5), 102. https://doi.org/10.3390/met6050102