Digital Twins in Livestock Farming

Abstract

:Simple Summary

Abstract

1. Introduction

2. The Evolution of Digital Twins

2.1. The First Digital Twin

2.2. Lower Costs Mean Greater Benefits

2.3. Early Publications

2.4. The Following Years

2.5. Real World Digital Twin Examples

3. Implementing Digital Twins

3.1. Key Properties

3.2. Beyond Computer Models and Dealing with Uncertainty

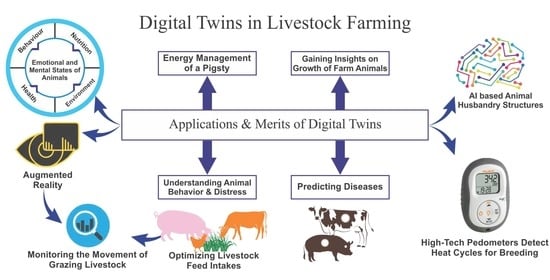

4. Digital Twins in Livestock Farming

4.1. Precision Livestock Farming (PLF) as a Precursor to Digital Twins

- Thermal infrared sensors that can measure animal body temperatures by capturing their infrared radiation levels.

- Respiratory rate sensors that typically consist of a belt around the chest (similar to a halter) to measure its thoracic and abdominal movements.

- Immunosensors that can study the saliva and sweat to provide an assessment of hormones, such as cortisol and lactate, in animal biological fluids. This also results in non-invasive tests.

- Photoplethysmography (PPG) uses infrared lights to detect changes in blood volume in the microvascular bed of tissue. It is a non-invasive and cost-effective way to detect blood volume changes.

- A noseband sensor also known as the Rumi Watch that monitors eating and ruminating activities in dairy cows can help farmers to identify and manage stressed animals.

- Water flow sensors can monitor the drinking behavior of large animal herds. They are considered to provide accurate recommendations.

- Accelerometers use electromechanical signals to measure acceleration forces when an animal moves. They have been proven to be highly accurate in monitoring animal activities and movements.

- Pedometers can objectively measure the total number of steps that each animal takes in a day and calculate the total distance it has covered using an algorithm. They can help identify lameness and stress.

- Wireless intraruminal bolus sensors inserted through the esophagus have been developed to monitor the temperature and pH values of the rumen and reticulum. They can help detect diseases such as ruminal acidosis and hypocalcemia.

- Finally, there is the possibility of using these sensors and several more in combination with each other to sense multiple points of stress, disease or physical pain.

4.2. Emotional and Mental States of Animals

4.3. Energy Management of a Pigsty

4.4. Monitoring the Movement of Grazing Livestock

4.5. Understanding the Growth and Development of Dairy Animals

4.6. AI-Based Computer Vision to Monitor Livestock

4.7. Augmented Reality Compares Anticipated and Actual Animal Behavior

4.8. High-Tech Pedometers Detect Heat Cycles for Breeding

4.9. Potential Application Areas

4.9.1. DATAMATION—Digital Twin Animal Emotions

4.9.2. Gaining Insights on Specific Livestock Conditions

4.9.3. Detecting the Early Onset of Important Livestock Diseases

4.9.4. Optimizing Livestock Feed Intakes

4.10. Limitations of Digital Twins in Livestock Farming

4.10.1. High Switching Costs

4.10.2. Unknown Risks

4.10.3. Lack of Concrete Evidence

4.10.4. Low Return-on-Investment

4.10.5. Sustainability

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Makri, A. Bridging the digital divide in health care. Lancet Digit. Health 2019, 1, e204–e205. [Google Scholar] [CrossRef]

- Ceruzzi, P.E. The Other Side of Moore’s Law: The Apollo Guidance Computer, the Integrated Circuit, and the Microelectronics Revolution, 1962–1975. In NASA Spaceflight; Palgrave Macmillan: Cham, Switzerland, 2018; pp. 89–127. [Google Scholar] [CrossRef]

- Hind, R. The First computer on the Moon. ITNOW 2019, 61, 22–23. [Google Scholar] [CrossRef]

- Munirathinam, S. Industry 4.0: Industrial internet of things (IIOT). Adv. Comput. 2020, 117, 129–164. [Google Scholar] [CrossRef]

- El Saddik, A. Digital twins: The convergence of multimedia technologies. IEEE Multimed. 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2019, 58, 3–21. [Google Scholar] [CrossRef]

- Gelernter, D. Mirror Worlds: Or the Day Software Puts the Universe in a Shoebox… How It Will Happen and What It Will Mean; Oxford University Press: Oxford, UK, 1993. [Google Scholar]

- Tao, F.; Qi, Q. Make more digital twins. Nature 2019, 573, 490–491. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boy, G.A. Human-Systems Integration: From Virtual to Tangible; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar] [CrossRef]

- Zhuang, C.; Miao, T.; Liu, J.; Xiong, H. The connotation of digital twin, and the construction and application method of shop-floor digital twin. Robot. Comput. Integr. Manuf. 2021, 68, 1–16. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. Transdisciplinary Perspectives on Complex Systems; Springer: Cham, Switzerland; New York, NY, USA, 2017; pp. 85–113. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and operation of Digital Twins for technical systems and services. CIRP Ann. 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef] [Green Version]

- Ilieva, R.; Ivanova, M.; Peycheva, T.; Nikolov, Y. Modelling in Support of Decision Making in Business Intelligence. In Integration Challenges for Analytics, Business Intelligence, and Data Mining; IGI Global: Hershey, PA, USA, 2021; pp. 115–144. [Google Scholar] [CrossRef]

- Haag, S.; Anderl, R. Digital twin—Proof of concept. Manuf. Lett. 2018, 15, 64–66. [Google Scholar] [CrossRef]

- Shao, G.; Helu, M. Framework for a digital twin in manufacturing: Scope and requirements. Manuf. Lett. 2020, 24, 105–107. [Google Scholar] [CrossRef] [PubMed]

- MarketsandMarkets. Digital Twin Market by Technology, Type (Product, Process, and System), Application (Predictive Maintenance, and Others), Industry (Aerospace & Defense, Automotive & Transportation, Healthcare, and others ), and Geography—Global Forecast to 2026. Available online: https://www.marketsandmarkets.com/Market-Reports/digital-twin-market-225269522.html (accessed on 17 December 2020).

- Ibrion, M.; Paltrinieri, N.; Nejad, A.R. On risk of digital twin implementation in marine industry: Learning from aviation industry. J. Phys. 2019, 1357, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Mayani, M.G.; Svendsen, M.; Oedegaard, S.I. Drilling Digital Twin Success Stories the Last 10 Years. In SPE Norway One Day Seminar; Society of Petroleum Engineers: Richardson, TX, USA, 2018. [Google Scholar] [CrossRef]

- Brenner, B.; Hummel, V. Digital twin as enabler for an innovative digital shopfloor management system in the ESB Logistics Learning Factory at Reutlingen-University. Procedia Manuf. 2017, 9, 198–205. [Google Scholar] [CrossRef]

- Erol, T.; Mendi, A.F.; Doğan, D. Digital Transformation Revolution with Digital Twin Technology. In Proceedings of the 4th International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Istanbul, Turkey, 22–24 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–7. [Google Scholar] [CrossRef]

- 10 Things about Digital Twins in Agriculture, Agrimetrics. Available online: https://agrimetrics.co.uk/2020/04/01/10-things-about-digital-twins-in-agriculture/ (accessed on 18 December 2020).

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP-JMST 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Miled, Z.; French, M.O. Towards a Reasoning Framework for Digital Clones Using the Digital Thread. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; AIAA: Reston, VA, USA, 2017; p. 0873. [Google Scholar] [CrossRef]

- Hu, L.; Nguyen, N.T.; Tao, W.; Leu, M.C.; Liu, X.F.; Shahriar, M.R.; Al Sunny, S.N. Modeling of cloud-based digital twins for smart manufacturing with MT connect. Procedia Manuf. 2018, 26, 1193–1203. [Google Scholar] [CrossRef]

- Damjanovic-Behrendt, V. A Digital Twin-Based Privacy Enhancement Mechanism for the Automotive Industry. In Proceedings of the 2018 International Conference on Intelligent Systems (IS), Funchal-Madeira, Portugal, 25–27 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 272–279. [Google Scholar] [CrossRef]

- Talkhestani, B.A.; Jazdi, N.; Schloegl, W.; Weyrich, M. Consistency check to synchronize the Digital Twin of manufacturing automation based on anchor points. Procedia CIRP 2018, 72, 159–164. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Cheng, Y.; Zhang, Y.; Ji, P.; Xu, W.; Zhou, Z.; Tao, F. Cyber-physical integration for moving digital factories forward towards smart manufacturing: A survey. Int. J. Adv. Manuf. Technol. 2018, 97, 1209–1221. [Google Scholar] [CrossRef]

- Ayani, M.; Ganebäck, M.; Ng, A.H. Digital Twin: Applying emulation for machine reconditioning. Procedia CIRP 2018, 72, 243–248. [Google Scholar] [CrossRef]

- Macchi, M.; Roda, I.; Negri, E.; Fumagalli, L. Exploring the role of digital twin for asset lifecycle management. IFAC-PapersOnLine 2018, 51, 790–795. [Google Scholar] [CrossRef]

- Bitton, R.; Gluck, T.; Stan, O.; Inokuchi, M.; Ohta, Y.; Yamada, Y.; Yagyu, T.; Elovici, Y.; Shabtai, A. Deriving a Cost-Effective Digital Twin of an ICS to Facilitate Security Evaluation. In Proceedings of the European Symposium on Research in Computer Security, Barcelona, Spain, 3–7 September 2018; Springer: Berlin/Heidelberg, Germany; pp. 533–554. [Google Scholar] [CrossRef]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for real-time geometry assurance in individualized production. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Zuo, Y.; Zhao, D. Digital twin service towards smart manufacturing. Procedia CIRP 2018, 72, 237–242. [Google Scholar] [CrossRef]

- Botkina, D.; Hedlind, M.; Olsson, B.; Henser, J.; Lundholm, T. Digital twin of a cutting tool. Procedia CIRP 2018, 72, 215–218. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient. Intell. Humaniz. Comput. 2018, 10, 1–13. [Google Scholar] [CrossRef]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital twins in smart farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- MarketsandMarkets. Precision Livestock Farming Market with COVID-19 Impact Analysis by System Type, Application, Offering, Farm Type, Farm Size and Geography—Global Forecast to 2025. 2020. Available online: https://www.reportlinker.com/p05812010/Precision-Livestock-Farming-Market-by-Functional-Process-Hardware-Application-And-Geography-Analysis-Forecast-to.html (accessed on 18 December 2020).

- Neethirajan, S. Recent advances in wearable sensors for animal health management. Sens. Bio Sens. Res. 2017, 12, 15–29. [Google Scholar] [CrossRef] [Green Version]

- Neethirajan, S. The role of sensors, big data and machine learning in modern animal farming. Sens. Bio Sens. Res. 2020, 29, 100367. [Google Scholar] [CrossRef]

- Neethirajan, S. Transforming the adaptation physiology of farm animals through sensors. Animals 2020, 10, 1512. [Google Scholar] [CrossRef]

- Neethirajan, S.; Ragavan, K.V.; Weng, X. Agro-defense: Biosensors for food from healthy crops and animals. Trends Food Sci. Technol. 2018, 73, 25–54. [Google Scholar] [CrossRef]

- Jo, S.K.; Park, D.H.; Park, H.; Kwak, Y.; Kim, S.H. Energy Planning of Pigsty Using Digital Twin. In Proceedings of the 2019 International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Korea, 16–18 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 723–725. [Google Scholar] [CrossRef]

- Park, J.K.; Park, E.Y. Animal Monitoring Scheme in Smart Farm using Cloud-Based System. ECTI CIT 2020, 15, 24–33. [Google Scholar] [CrossRef]

- Verdoux, C.N.; Kruize, J.W. Digital Twins in Farm Management: Illustrations from the FIWARE Accelerators Smart Agri Food and Fractals. In Proceedings of the 7th Asian-Australasian Conference on Precision Agriculture Digital, Hamilton, New Zealand, 16–18 October 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Barni, A.; Alessandro Fontana, S.M.; Sorlini, M.; Canetta, L. Exploiting the Digital Twin in the Assessment and Optimization of Sustainability Performances. In Proceedings of the 2018 International Conference on Intelligent Systems (IS), Funchal, Portugal, 25–27 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 706–713. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Xu, N. Digital twin for sustainability evaluation of railway station buildings. Front. Built Environ. 2018, 4, 77. [Google Scholar] [CrossRef] [Green Version]

| Industry | Sector | Digital Twin Types and Advantages | Reference |

|---|---|---|---|

| Boeing | Aero Manufacturing | The digital twin asset development model has shown a 40% quality improvement in first-time parts/systems to deliver enhanced productivity gains. | [18] |

| Halliburton | Oil Field Service | Using different sensors to capture different dimensions of data while drilling oil wells. Uses this with virtual models to make drilling more efficient. | [19] |

| Dassault | Software | Using digital twins for various parts of the human body, thus, helping people benefit from less invasive and more personalized medical interventions. | [20] |

| Unilever | Fast Moving Consumer Goods | Creating virtual models of its factories to track and improve key factory performance parameters and production variables. Helped save USD 2.8 million. | [21] |

| Royal Dutch Shell | Oil and Gas | Using digital twins to design and recreate realistic real-time models of valuable assets. As a result, are able to reduce maintenance costs, as well as downtime. | [21] |

| Bridgestone | Tire Manufacturer | Experimenting with real-time data from tire sensors to improve precision safety systems. | [21] |

| Key Terms | Description |

|---|---|

| Physical Environment | Environment where the physical asset exists. Often not easily accessible. |

| Virtual Simulation | Environment where the virtual digital twin exists. Easily accessible. |

| Sensory States | Different possible states representing changes in the physical asset. |

| Changes in State | Switching between various states in the physical asset or digital twin. |

| Twinning | Synchronization of states between the physical asset and digital twin. |

| Twinning Rate | The rate at which this synchronization occurs. As close to real-time. |

| System Processes | Various processes that cause state changes to the asset or twin. |

| A Digital Twin Needs to Be | |

|---|---|

| Individual | It must represent a specific thing, e.g., “Daisy the cow” rather than a generic cow. |

| Near real-time | This also means that the digital twin should be “always on,” available for as long as its real-world counterpart exists. |

| Data informed | It must be updated via a digital measurement of the real-world thing, e.g., a soil moisture meter or a regular satellite observation. |

| Realistic | The twin must be a sufficiently realistic surrogate for the real-world thing. |

| Actionable | Information from the real-world twin must have the potential to lead to an action. |

| Perceived Benefits of Digital Twins—From Characterizing the Digital Twin Research | |

|---|---|

| Reduces Costs | [24,25,26,27] |

| Reduces Risks | [27] |

| Reduces complexity | [28] |

| Improves after-sales service | [29,30] |

| Improves efficiency | [31] |

| Improves maintenance decisions | [32] |

| Improves security | [33] |

| Improves safety and reliability | [34] |

| Improves manufacturing processes | [35,36] |

| Enhances flexibility and competitiveness | [37] |

| Fosters innovation | [24] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neethirajan, S.; Kemp, B. Digital Twins in Livestock Farming. Animals 2021, 11, 1008. https://doi.org/10.3390/ani11041008

Neethirajan S, Kemp B. Digital Twins in Livestock Farming. Animals. 2021; 11(4):1008. https://doi.org/10.3390/ani11041008

Chicago/Turabian StyleNeethirajan, Suresh, and Bas Kemp. 2021. "Digital Twins in Livestock Farming" Animals 11, no. 4: 1008. https://doi.org/10.3390/ani11041008

APA StyleNeethirajan, S., & Kemp, B. (2021). Digital Twins in Livestock Farming. Animals, 11(4), 1008. https://doi.org/10.3390/ani11041008