1. Introduction

Loop heat pipes (LHP) are widely used for thermal management and cooling in electronics [

1,

2,

3] because of their high capacity to transmit heat over long distances with only small drops in temperature. The primary wick [

4] is central to these devices, because it provides the necessary capillary force to pump the working fluid around the device from the heat source to the heat sink [

5,

6,

7].

Porous wicks for LHP are mainly manufactured by powder sintering technology [

8,

9,

10], which is a very well-known technology. Nevertheless, two other techniques are also used for LHP: meshes and foams. With the advent of three-dimensional (3D) printing, the production industry may be on the eve of a manufacturing revolution. The potential of wick manufacturing by 3D printing to improve LHP performance has already been experimentally assessed [

11,

12,

13].

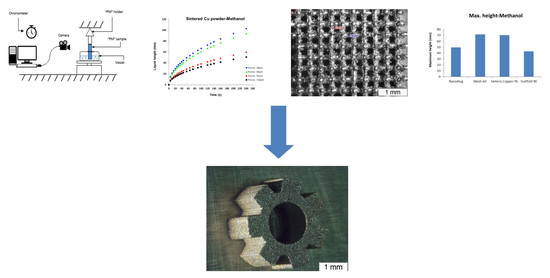

Selective laser melting (SLM) is a technology for the rapid manufacture of complex geometries (

Figure 1), which would not otherwise be possible. It also controls the specific pore size, distribution, and connection.

The type of material, its porosity, internal structure, geometry, and wettability are among the key determinants of the porous media performance [

14,

15,

16]. Precisely how such parameters affect the capillary action and the permeability of the medium is essential to the design of an LHP device, (both high permeability and high capillary actions are required) [

17]. Aiming at performance optimization, these two effects need different pore sizes: small for capillary action and pumping, and larger for permeability [

18,

19].

The capillary pumping should be sufficient to ensure the correct supply of fluid to the LHP evaporation zone, preventing any dry spots from appearing at the wick’s liquid-vapor interface, which means that liquid velocity through the wick

must be larger than the liquid evaporation rate at the liquid-vapor interface

[

20].

It is known that the Washburn equation determines the capacity of capillary pumping or pumping height (

y) of a bundle of parallel cylindrical tubes as a function of time (

t) and some fluid properties (surface tension (

σ), contact angle (

ϕ), viscosity (

µ)), and the tube radius (

reff).

Its use, although with reservations, has also been extended to the imbibitions into a porous medium. These reservations are: uniform pore distribution, constant pore size, and gravitational forces negligible compared with the capillaries, but these conditions rarely occur in real cases. In

Section 3.1, an error analysis was performed between the predictions of the Washburn equation and the experimental [

21] values in order to confirm the law’s adequacy. In this article, the Washburn equation is not considered since the biexponential expression best fits the experimental data. Working fluid wettability is another influencing parameter already studied in many works [

22].

For an 80 W loop heat pipe application with a primary wick of 30 mm in height, the fluid flow rate at the top of the wick (liquid-vapor interface) must be higher than or equal to 0.031 mm/s.

The permeability of the wick, therefore, depends greatly on its internal structure (pore size and pore connection). Theoretical permeability as a function of the internal structure of the porous medium has been widely studied [

23]; however, these permeability-internal structure relations are valid for specific internal arrangements [

24] that are not always present in nature. Darcy’s law is a simple proportional relationship between the instantaneous flow rate through a porous medium of permeability (κ), the dynamic viscosity of the fluid, and the pressure drop over a given distance in a homogeneously permeable medium. In this work, it is used to obtain the permeability of different porous media working with the same fluid (methanol) by measuring pressure drop and flow rate through them. In the above-mentioned application, the pressure drop in the wick must be less than or equal to 100 Pa to arrive at the proper flow rate into the LHP [

22]. The wick permeability must, therefore, be greater than 4 × 10

−12 m

2.

2. Aims and Methodology

The main objective of this research is to experimentally determine the capillary action and permeability of a SLM wick for a loop heat pipe [

25,

26,

27] and to compare both results with those of other similar wicks made of conventional manufacturing techniques (sintering, mesh, etc.) in order to evaluate the wick performance.

Experimentation is presented as an efficient means of obtaining the flow velocity through a porous media, the capillary action curve, which will be obtained by measuring liquid height versus time for several materials and techniques: (i) sintering, (ii) meshing, and (iii) SLM. The experimental method is also the most accurate way of determining the permeability of a medium as porous as an LHP wick with a complex internal structure. In this case, samples with different pore sizes (D) were built through two different technologies, sintering and SLM, and were finally tested.

The working liquid used throughout all the experiments was methanol, the thermophysical parameters of which are: density ρ = 786.47 (kg/m3), enthalpy of vaporization hfv = 1,169.2 (kJ/kg), surface tension σlv = 22.16 (N/m), and viscosity µ = 544.61 (µPas).

5. Conclusions

SLM technology is being widely used in different sectors as an interesting manufacturing technique to create prototypes and/or small productions of complex products. Hence, it appears to be an appropriate technique for the “ad-hoc” manufacture of porous media, particularly wicks for the heat pipe and loop heat pipe industry, where outstanding capillarity as well as high permeability is required. This technology generates fully controlled internal passages inside the wick’s body, with the desired geometry and pore size according to detailed specifications. A new SLM wick was manufactured and both the capillary action and permeability were addressed through different tests. The results have been compared to those obtained for wicks manufactured with conventional techniques: sintered powder and meshes (widely used nowadays in LHP manufacturing).

The first test was performed to measure the liquid pumping capacity and capillary action of wicks created by different techniques (sintering, mesh, SLM). The wick specifications were a speed of advance of 0.031 mm/s at a height of 30 mm imposed by a particular 80 W LHP application. It was concluded that the faster the ascent of the fluid, the better the wick performance. With regard to capillary action, the SLM wick (scaffold) presented a 23% faster response than the sintered powder, although the stainless-steel mesh offered the fastest response.

Regarding permeability, scaffold samples presented values of two orders of magnitude higher than that of the sintered powder, showing its lower resistance to fluid flow. In this study, the hydraulic behavior of the scaffold design was superior to the behavior of sintering copper, suggesting that it is more suitable for implementation in the 80 W LHP application.

Finally, it has been concluded that SLM technology can easily and precisely create the wick structure that best fits the heat pipe requirements in terms of fluid pumping, capillary action, and permeability.