Tempcore Process Simulator to Analyze Microstructural Evolution of Quenched and Tempered Rebar

Abstract

:Featured Application

Abstract

1. Introduction

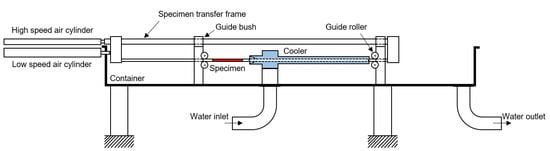

2. Development of Tempcore Process Simulator

3. Results and Discussion

3.1. Test Run of TPS

3.2. Performance Validation of TPS

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Grajcar, A.; Skrzypczyk, P.; Kozłowska, A. Effects of temperature and time of isothermal holding on retained austenite stability in medium-Mn steels. Appl. Sci. 2018, 8, 2156. [Google Scholar] [CrossRef]

- Park, K.S.; Van Tyne, C.J.; Moon, Y.H. Process analysis of multistage forging by using finite element method. J. Mater. Process. Technol. 2007, 187, 586–590. [Google Scholar] [CrossRef]

- Kil, T.D.; Lee, J.M.; Moon, Y.H. Quantitative formability estimation of ring rolling process by using deformation processing map. J. Mater. Process. Technol. 2015, 220, 224–230. [Google Scholar] [CrossRef]

- Nikolaou, J.; Papadimitriou, G.D. Microstructures and mechanical properties after heating of reinforcing 500 MPa class weldable steels produced by various processes (Tempcore, microalloyed with vanadium and work-hardened). Constr. Build. Mater. 2004, 18, 243–254. [Google Scholar] [CrossRef]

- Simon, P.; Economopoulos, M.; Nilles, P. Tempcore: A new process for the production of high-quality reinforcing bars. Iron Steel Eng. 1984, 61, 53–57. [Google Scholar]

- Economopoulos, M.; Restel, Y.; Lessel, G.; Steffes, G. Application of the Tempcore process to the fabrication of high yield strength concrete-reinforcing bars. Metall. Rep. 1975, 45, 1–17. [Google Scholar]

- Movahed, P.; Kolahgar, S.; Marashi, S.P.H.; Pouranvari, M.; Parvin, N. The effect of intercritical heat treatment temperature on the tensile properties and work hardening behavior of ferrite-martensite dual phase steel sheets. Mater. Sci. Eng. A 2009, 518, 1–6. [Google Scholar] [CrossRef]

- El-Mahallawi, I.; Abdel-Aal, U. Accelerated cooling of steel rebars establishment of technological and design parameters of the cooling unit by modelling and experimentation. Metall. Sci. Technol. 1977, 15, 11–24. [Google Scholar]

- Noville, J.F. TEMPCORE®, the most convenient process to produce low cost high strength rebars from 8 to 75 mm. In Proceedings of the METEC and 2nd European Steel Technology and Application Days (ESTAD) Conference, Düsseldorf, Germany, 15–19 June 2015. [Google Scholar]

- Hortigón, B.; Ancio, F.; Nieto-García, E.J.; Herrera, M.A.; Gallardo, J.M. Influence of rebar design on mechanical behaviour of Tempcore steel. Procedia Struct. Integr. 2018, 13, 601–606. [Google Scholar] [CrossRef]

- Bandyopadhyay, K.; Lee, J.; Shim, J.H.; Hwang, B.; Lee, M.G. Modeling and experiment on microstructure evolutions and mechanical properties in grade 600 MPa reinforcing steel rebar subjected to TempCore process. Mater. Sci. Eng. A 2019, 745, 39–52. [Google Scholar] [CrossRef]

- Mohrbacher, H. Metallurgical Effects of Niobium and Molybdenum on Heat-Affected Zone Toughness in Low-Carbon Steel. Appl. Sci. 2019, 9, 1847. [Google Scholar] [CrossRef]

- Jang, J.H.; Lee, J.H.; Joo, B.D.; Moon, Y.H. Flow characteristics of aluminum coated boron steel in hot press forming. Trans. Nonferrous Met. Soc. China 2009, 19, 913–916. [Google Scholar] [CrossRef]

- Hwang, T.W.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Functionally graded properties in directed-energy-deposition titanium parts. Opt. Laser Technol. 2018, 105, 80–88. [Google Scholar] [CrossRef]

- Jang, J.H.; Joo, B.D.; Van Tyne, C.J.; Moon, Y.H. Characterization of deposited layer fabricated by direct laser melting process. Met. Mater. Int. 2013, 19, 497–506. [Google Scholar] [CrossRef]

- Jeon, C.H.; Han, S.W.; Joo, B.D.; Van Tyne, C.J.; Moon, Y.H. Deformation analysis for cold rolling of Al-Cu double layered sheet by the physical modeling and finite element method. Met. Mater. Int. 2013, 19, 1069–1076. [Google Scholar] [CrossRef]

- Gordon, W.A.; Van Tyne, C.J.; Moon, Y.H. Axisymmetric extrusion through adaptable dies—Part 1: Flexible velocity fields and power terms. Int. J. Mech. Sci. 2007, 49, 86–95. [Google Scholar] [CrossRef]

- Gordon, W.A.; Van Tyne, C.J.; Moon, Y.H. Axisymmetric extrusion through adaptable dies—Part 3: Minimum pressure streamlined die shapes. Int. J. Mech. Sci. 2007, 49, 104–115. [Google Scholar] [CrossRef]

- Kim, D.K.; Woo, Y.Y.; Park, K.S.; Sim, W.J.; Moon, Y.H. Advanced induction heating system for hot stamping. Int. J. Adv. Manuf. Technol. 2018, 99, 583–593. [Google Scholar] [CrossRef]

- Winczek, J.; Gawronska, E.; Gucwa, M.; Sczygiol, N. Theoretical and Experimental Investigation of Temperature and Phase Transformation during SAW Overlaying. Appl. Sci. 2019, 9, 1472. [Google Scholar] [CrossRef]

- Song, M.C.; Moon, Y.H. Coupled electromagnetic and thermal analysis of induction heating for the forging of marine crankshafts. Appl. Therm. Eng. 2016, 98, 98–109. [Google Scholar] [CrossRef]

- Kim, B.J.; Van Tyne, C.J.; Lee, M.Y.; Moon, Y.H. Finite element analysis and experimental confirmation of warm hydroforming process for aluminum alloy. J. Mater. Process. Technol. 2007, 187, 296–299. [Google Scholar] [CrossRef]

- Seo, D.M.; Hwang, T.W.; Moon, Y.H. Carbonitriding of Ti-6Al-4V alloy via laser irradiation of pure graphite powder in nitrogen environment. Surf. Coat. Technol. 2019, 363, 224–254. [Google Scholar] [CrossRef]

- Lee, R.S.; Lin, Y.K.; Chien, T.W. Experimental and theoretical studies on formability of 22MnB5 at elevated temperatures by Gleeble simulator. Procedia Eng. 2014, 81, 1682–1688. [Google Scholar] [CrossRef]

- Xiong, Z.P.; Kostryzhev, A.G.; Chen, L.; Pereloma, E.V. Microstructure and mechanical properties of, strip cast TRIP steel subjected to thermo-mechanical simulation. Mater. Sci. Eng. A 2016, 677, 356–366. [Google Scholar] [CrossRef]

- Nikolaou, J.; Papadimitriou, G.D. Impact toughness of reinforcing steels produced by (i) the Tempcore process and (ii) microalloying with vanadium. Int. J. Impact Eng. 2005, 31, 1065–1080. [Google Scholar] [CrossRef]

- Zheng, H.; Abel, A.A. Fatigue properties of reinforcing steel produced by TEMPCORE process. J. Mater. Civ. Eng. 1999, 11, 158–165. [Google Scholar] [CrossRef]

- Riva, P.; Franchi, A.; Tabeni, D. Welded Tempcore reinforcement behaviour for seismic applications. Mater. Struct. 2001, 34, 240–247. [Google Scholar] [CrossRef]

- Dotreppe, J.C. Mechanical properties of quenched and self-tempered reinforcing steel at elevated temperatures compared with recommendations of Eurocode 2—Part 1-2. Mater. Struct. 1997, 30, 430–438. [Google Scholar] [CrossRef]

- Felicetti, R.; Gambarova, P.G.; Meda, A. Residual behavior of steel rebars and R/C sections after a fire. Constr. Build. Mater. 2009, 23, 3546–3555. [Google Scholar] [CrossRef]

- Khalifa, H.; Megahed, G.M.; Hamouda, R.M.; Taha, M.A. Experimental investigation and simulation of structure and tensile properties of Tempcore treated rebar. J. Mater. Process. Technol. 2016, 230, 244–253. [Google Scholar] [CrossRef]

- Mukherjee, M.; Dutta, C.; Haldar, A. Prediction of hardness of the tempered martensitic rim of TMT rebars. Mater. Sci. Eng. A 2012, 543, 35–43. [Google Scholar] [CrossRef]

| Air cylinder stroke (mm) | 800 |

| Cooling time (sec) | 1~2.5 |

| Water flow rate (m3/h) | Max 65 |

| Water pressure (bar) | 0~15 |

| Specimen length (mm) | 360 |

| Control valve | 80A × JIS20K (Globe Type) |

| Container material | 316 Stainless steel |

| Parameter | Shop Floor Operation | TPS |

|---|---|---|

| Water flow rate (m3/h) | 500 | 45 |

| Cooler quantity | 10 | 1 |

| Cooling length (m) | 14 | 0.72 |

| Rolling speed (m/s) | 6.65 | - |

| Cylinder speed (m/s) | - | 0.36 |

| Cooling time (sec) | 2.1 | 2.0 |

| Heating temperature (°C) | 1.000 | |

| Water flow rate (m3/h) | 36 | |

| Water pressure (bar) | 11~12 | |

| Cooling time (sec) | 1.0, 1.5, 2.0 | |

| Specimen diameter (mm) | 25 | |

| Chemical composition of specimen (wt%) | C | 0.29 |

| Si | 0.21 | |

| Mn | 0.52 | |

| P | < 0.040 | |

| S | < 0.040 | |

| Cooling time (sec) | 1.5 | ||

| Alloy type | Type 1 | Type 2 | |

| Chemical composition (wt%) | C | 0.28 | 0.27 |

| Si | 0.24 | 0.22 | |

| Mn | 1.43 | 1.22 | |

| V | 0.031 | 0.020 | |

| P | <0.040 | <0.040 | |

| S | <0.040 | <0.040 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, C.S.; Yi, H.J.; Kim, Y.-T.; Han, S.W.; Lee, T.; Moon, Y.H. Tempcore Process Simulator to Analyze Microstructural Evolution of Quenched and Tempered Rebar. Appl. Sci. 2019, 9, 2938. https://doi.org/10.3390/app9142938

Park CS, Yi HJ, Kim Y-T, Han SW, Lee T, Moon YH. Tempcore Process Simulator to Analyze Microstructural Evolution of Quenched and Tempered Rebar. Applied Sciences. 2019; 9(14):2938. https://doi.org/10.3390/app9142938

Chicago/Turabian StylePark, Chun Su, Hyang Jun Yi, Yong-Tae Kim, Sang Wook Han, Taekyung Lee, and Young Hoon Moon. 2019. "Tempcore Process Simulator to Analyze Microstructural Evolution of Quenched and Tempered Rebar" Applied Sciences 9, no. 14: 2938. https://doi.org/10.3390/app9142938

APA StylePark, C. S., Yi, H. J., Kim, Y. -T., Han, S. W., Lee, T., & Moon, Y. H. (2019). Tempcore Process Simulator to Analyze Microstructural Evolution of Quenched and Tempered Rebar. Applied Sciences, 9(14), 2938. https://doi.org/10.3390/app9142938