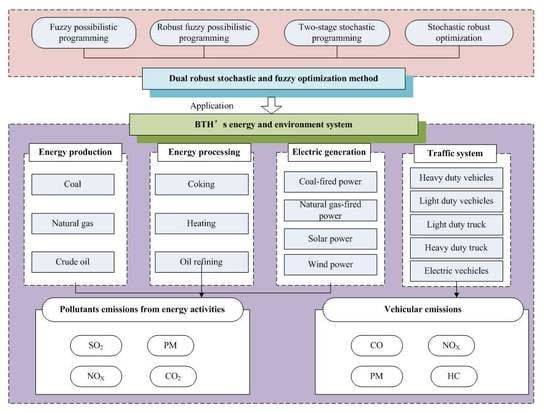

3.3. Development of DRSFO-EES Model

Minimizing the system cost is the objective of DRSFO-EES, which includes costs for coke processing, heat processing, input for coal-based power, oil refining, input for natural gas-based power, imported electricity, first-stage of electricity generation, second-stage of electricity generation, electricity expansion, energy production, subsidy for solar power generation, subsidy for wind power generation, EVs charging piles, EVs charging stations, pollutants treatment, and risk recourse for the stochastic and fuzzy uncertainties. The proposed DRSFO-EES can be solved by Lingo 11.0 software. The schematic diagram of DRAOM-EWNS model is presented in

Figure 2.

In the DRSFO-EES, t denotes the planning periods, period 1 (2020), period 2 (2025), and period 3 (2030); i denotes the primary energy production type, i = 1 is coal, i = 2 is natural gas, and i = 3 is crude oil; k denotes the electric conversion technology, k = 1 is coal-based power, k = 2 is natural gas-based power, k = 3 is solar power, and k = 4 is wind power; h expresses the electricity demand-level, h = 1 (low demand level), h = 2 (medium demand level), h = 3 (high demand level), ; g are the vehicles types, g = 1 is HDVs, g = 2 is LDVs, g = 3 is TDTs, g = 4 is HDTs, and g = 5 is others. The proposed DRSFO-EES is formulated as follows:

Objective:

where

represents the system cost;

denotes the heat processing cost;

denotes oil refining cost;

denotes coke processing cost;

denotes the cost of coal inputs for coal-based power;

denotes the cost of natural gas inputs for natural gas-based power;

denotes importing electricity cost;

denotes the cost of first-stage electricity generation;

denotes the cost of second-stage electricity generation;

denotes electricity expansion cost;

denotes the energy production cost;

denotes the subsidy for solar power;

denotes the subsidy for wind power;

denotes the cost of charging pile;

denotes the cost of changing station;

denotes air-pollutants removal cost;

denotes the risk recourse costs of stochastic and fuzzy uncertainties.

represents the positive deviation between maximum values and worst value of fuzzy parameters.

and

represent their respective weight coefficients, where it is assumed

and

are fixed (i.e.,

=

= 1).

(1) Cost of heat processing. This cost is used for heat processing, and it is calculated based on the unit-price and amount of heat processing.

where

is the cost for unit of heat processing, which is expressed as a triangular fuzzy number;

is the heat processing amount.

(2) Cost for oil refining. This cost is calculated in terms of the unit-price and the amount of oil refining.

where

is the cost for unit of oil refining;

is the crude oil consumption of oil refining. (3) Cost for coke processing. This cost is calculated in terms of the unit-price and the amount of coke processing.

where

is the cost for unit of coke processing; and

is the coke processing amount.

(4) Cost for purchasing coal resources. This cost is used for purchasing coal resources, and it is calculated based on the unit-price and the amount of coal resource.

where

is the price for unit of coal resource; and

is the coal consumption of coal-based power.

(5) Cost for purchasing natural gas resources. This cost is used for purchasing natural gas resources, and it is calculated based on the unit-price and the amount of natural gas resource.

where

is the price for unit of natural gas resource; and

is the natural gas consumption of natural gas-based power.

(6) Cost for importing electricity. This cost is calculated in terms of the unit-price and the amount of importing electricity.

where

is the price for unit of imported electricity;

is the amount of imported electricity.

(7) Operation cost for first-stage electricity generation. The cost represents the operation cost of first-stage electricity generation facilities (i.e., coal-based power, gas-based power, wind power and solar power) during the planning periods. It is calculated in terms of the operation costs and the amount of electricity generation for each of the electricity generation facilities. Furthermore, the first-stage is given by

, where

denotes the decision variables,

.

where

denotes the operation cost of different power conversion technologies;

is the first-stage electricity generation amount, which is determined by decision variables

(

and

).

(8) Penalty cost for second-stage electricity generation amounts (i.e., shortage electricity amount of first-stage). It is calculated in terms of the penalty costs and the amount of second-stage electricity generation by each electricity generation technology.

where

is the operating cost for the second-stage electricity generation amount (

).

is the second-stage electricity generation amount.

(9) Fixed and variable costs for electric capacity expansion. These costs include the fixed and variable electric capacity expansion costs of four electricity generation technologies in the planning horizon.

where

denote fixed-charge cost for different electric capacity expansion.

are binary variables for identifying whether or not the capacity expansion needs to be undertaken by power conversion technology

k.

denote the variable cost of capacity expansion.

denotes the continuous variable of the capacity expansion amount.

(10) Generation costs for primary energy resources. This cost is calculated in terms of the unit-price of primary energy (i.e., coal, natural gas, and crude oil) and the amount of primary generation.

where

is the production cost per unit of energy resource; and

is the production amount.

(11) Subsidy for solar power. The government provides a subsidy for units of electricity generated by solar power, and it is calculated in terms of the unit-subsidy of solar power and the amount of electricity generation amount of solar power.

where

is the solar subsidy provided by government for unit of electricity generated by solar power.

(12) Subsidy for wind power. The government provides a subsidy for units of electricity generated by wind power, and it is calculated in terms of the unit-subsidy of wind power and the amount of electricity generation amount of wind power.

where

is the wind subsidy provided by government for unit of electricity generated by wind power.

(13) Costs for battery charging piles. It is calculated in terms of the average charging pile amount for unit of electric vehicle, the EVs population, as well as the investment cost per EV charging pile.

where

is the EVs population;

is the average charging pile amount for unit of electric vehicle;

is the investment cost per EV charging pile.

(14) Costs for battery changing station. It is calculated in terms of the average changing station amount for unit of electric vehicle, the EVs population, as well as the investment cost per EV changing station.

where

is the average changing station amount for unit of electric vehicles;

is the investment cost per

EV changing station.

(15) Costs for pollutant reduction. These costs include reduction costs for three pollutants, i.e., SO

2, NO

X, and PM emissions.

where

is the cost of desulfurization;

is the SO

2 emissions from coking processing;

is the SO

2 emissions from coal-based power;

is the SO

2 emissions from natural gas-based power;

is the SO

2 emissions from heating processing;

is the SO

2 emissions from oil refining;

is the desulfurization cost of per unit of SO

2 emission;

is the desulfurization efficiency.

(15a) Costs for SO

2 emissions reduction. The cost is calculated in terms of the total SO

2 emissions, the desulfurization cost per unit of SO

2 emission, and the desulfurization efficiency.

where

is the cost of desulfurization;

is the SO

2 emissions from coking processing;

is the SO

2 emissions from coal-based power;

is the SO

2 emissions from natural gas-based power;

is the SO

2 emissions from heating processing;

is the SO

2 emissions from oil refining;

is the desulfurization cost per unit of SO

2 emission;

is the desulfurization efficiency.

(15b) Costs for NO

X emissions reduction. The cost is calculated in terms of the total NOx emissions, the desulfurization cost per unit of NOx emission, and the desulfurization efficiency.

where

is the cost of denitration;

is the NO

x emissions from coking processing;

is the NO

x emissions from coal-based power;

is the NO

x emissions from natural gas-based power;

is the NO

x emissions from heat processing;

is the NO

x emissions from oil refining;

is the denitration cost per unit of NO

x emission;

is the denitration efficiency.

(15c) Costs for PM emissions reduction. The cost is calculated in terms of the total PM emissions, the desulfurization cost per unit of PM emission, and the desulfurization efficiency.

where

is the PM removal cost;

is the PM emissions from coking processing;

is the PM emissions from coal-based power;

is the PM emissions from natural gas-based power;

is the PM emissions from heating processing;

is the NO

X emissions from oil refining;

is the treatment cost per unit of PM emission;

is the PM removal efficiency.

(16) Costs for risk recourse of stochastic and fuzzy uncertainties.

where

denotes the risk recourse cost for stochastic uncertainties;

denotes the risk recourse cost of fuzzy uncertainties, with capturing the difference between the extreme values of fuzzy parameters. The nonnegative factors

ρ1 and

ρ2 represent robust levels (its range from 0 to 1), which can help managers make trade-offs between system economy and reliability.

Constraints:

The constraints of the proposed DRSFO-EES model include traffic sector, heat processing, coke processing, oil refining, electricity generation, energy production, air-pollutants treatment, and risk recourse cost for stochastic uncertainties and risk recourse for fuzzy uncertainties.

(1) Constraints for traffic sector.

This constraint represents that the optimized vehicles population must be not less than the lower bounds of vehicle population.

means the credibility of the

is higher than or equal to confidence-level

α.

where

is the optimized solutions of vehicles population;

is the lower bounds of vehicle population, which is expressed as a triangular fuzzy number.

Constraints for vehicle-emissions, including CO, NOx, HC, and PM emissions. These constraints represent that the vehicle-emissions are calculated in terms of the annual average mileage, the proportion of electric vehicles and the emission factors of CO, NOx, HC and PM emissions.

where

is CO emissions from vehicle

g in period

t;

is the annual average mileage;

is the proportion of electric vehicles;

the emission factor of CO;

the emission factor of NO

X;

the emission factor of HC;

the emission factor of PM.

Constraints of the electricity demands of EVs. This constraint is calculated in terms of the electricity consumption amounts per hundred kilometers of EVs and the amount of EVs.

where

is the electricity consumption amounts of EVs;

is the electricity consumption amounts per hundred kilometers of EVs.

(2) Constraints of heat processing. Constraint (52) depicts that the heat generation amounts must not be less than the heat demands, and

means the credibility of the

is higher than or equal to confidence-level

α. Constraints (53) and (54) represent the consumption amounts of natural gas and coal for heat processing.

where

is the heat demand;

denotes the energy consumption for the unit of kerosene processing.

denotes the coal consumption of heat processing;

is the natural gas consumption of heat processing;

denotes the ratio of coal consumption of heat processing;

denotes the ratio of natural gas consumption of heat processing.

(3) Constraints of oil refining. The constraint depicts the input amounts of crude oil for oil refining.

where

is the diesel processing amount;

denotes the crude oil consumption for unit of diesel processing;

is the processing amount of gasoline;

denote the crude oil consumption for unit of gasoline processing;

is the processing amount of kerosene;

denotes the crude oil consumption for unit of kerosene processing;

is the fuel oil processing amount;

is the crude consumption for unit of fuel oil processing;

is the processing amount for naphtha;

denotes the crude oil consumption for unit of naphtha processing;

is the processing amount of asphaltic pyrobitumen;

denotes the crude oil consumption for unit of asphaltic pyrobitumen processing;

is the processing amount of LPG;

denotes the crude consumption for unit of LPG processing;

denotes the crude oil consumption of other oil products.

(4) Constraints of coke processing. Constraint (56) means that the amount of coke processing is not less than the coke demands, and

means the credibility of the

is higher than or equal to confidence-level

α. Constraint (57) depicts the coal consumption amount for coke processing.

where

is the coke demand expressed as a triangular fuzzy number.

denotes the coal consumption for unit of coke processing;

is the coal consumption of coke processing.

(5) Constraints of electricity generation.

Constraints for mass balance of coal and natural gas resources. These constraints are established to calculate the consumption amounts of coal and natural gas for electricity generation.

where

is the coal (

i = 1) and natural gas (

i = 2) consumption for a unit of electricity generation.

Constraints of electricity demand and supply balance. Constraint (60) is established to ensure the electricity demand be satisfied by domestic electricity generation and importation. And

means the credibility of the

is higher than or equal to confidence-level

α. For constraint (61), the optimized amount of electricity generated in the first-stage is given by

, where

denotes the decision variables, and

.

where

is the electricity demand under various electricity demand levels, which show the characteristics of stochastic and fuzzy sets.

denotes the decision variable of first-stage electricity generation.

Constraints for electricity capacities. These constraints mainly depict that the amount of generated electricity must not exceed its existing and expanded capacities, which are established to ensure that the available electricity-generation capacity is greater than the generated electricity.

where

is the operating hours of electricity conversion technology

k;

is the original capacity;

is the lower bound of load demands;

is the upper bound of load demands.

(6) Constraints of energy production. The constraint is established to ensure the primary energy production amount must be less than the lower bound and higher than the upper bound.

where

is the upper bound of amount of primary energy production.

is the lower bound of amount of primary energy production.

(7) Constraints for air-pollutants management.

SO

2 emissions. Constraints (69) to (74) represent the SO

2 emissions from energy activities (i.e., coke processing, heat processing, electricity generation, and oil refining). Constraints (74) are used for ensuring that the SO

2-emissions are satisfied by the pollutant-emission permits.

where

is the SO

2 emission factor of coal;

is the SO

2 emission factor of natural gas;

is the SO

2 emission factor of crude oil;

is the desulfurization efficiency;

is the upper bounds of SO

2 emission.

NO

X emissions. Constraints (75) to (79) represent the NOx emissions from energy activities (i.e., coke processing, heat processing, electricity generation, and oil refining). Constraints (80) are used for ensuring that the NOx-emissions are satisfied by the pollutant-emission permits.

where

is the NO

x emission factor of coal;

is the NO

x emission factor of natural gas;

is the NO

x emission factor of crude oil;

is the denitration efficiency;

is the upper bounds of NO

x emission.

PM emissions. Constraints (81) to (85) represent the PM emissions from energy activities (i.e., coke processing, heat processing, electricity generation, and oil refining). Constraints (86) are used for ensuring that the PM-emissions are satisfied by the pollutant-emission permits.

where

is the PM emission factor of coal;

is the PM emission factor of natural gas;

is the PM emission factor of crude oil;

is the PM removal efficiency;

is the upper bound of PM emission.

CO

2 emissions. Constraints (81) to (85) represent the CO

2- emissions from energy activities (i.e., coke processing, heat processing, electricity generation, and oil refining).

where

is the CO

2 emission factor of coal;

is the CO

2 emission factor of natural gas;

is the CO

2 emission factor of crude oil.

(8) The expected deviations for stochastic uncertainties. These constraints are used for capturing the risk from stochastic uncertainties.

where

are slack variables that can achieve looser constraints;

and

are the weighted values of the expected deviations from stochastic uncertainties.

(9) The expected deviations for fuzzy uncertainties. These constraints are used for capturing the risk from fuzzy uncertainties.

where

represents the positive deviation between maximum values and worst value of fuzzy parameters of right-side of constraints.

,

,

, and

are the maximum values of all potential values, i.e.,

,

is the inverse of

.

,

,

, and

represent the possible worst values of fuzzy numbers

,

,

, and

, respectively.

(10) Non-negative constraints. This constraint assures that only positive variables are considered in the solutions, eliminating infeasibility while calculating the solution.