Treatment of Poultry Slaughterhouse Wastewater (PSW) Using a Pretreatment Stage, an Expanded Granular Sludge Bed Reactor (EGSB), and a Membrane Bioreactor (MBR)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Poultry Slaughterhouse Wastewater (PSW) Sampling

2.2. EcoflushTM—A Supplementation Agent for the Pretreatment Stage

2.3. Operation of the Pretreatment–EGSB–MBR System

2.4. Pretreatment Tank Preparation

2.5. EGSB Reactor System Used

2.6. Inoculation of the EGSB

2.7. Operating Conditions of the EGSB

2.8. Membrane Bioreactor (MBR) Used

2.9. Inoculation and Operating Conditions of the Membrane Bioreactor (MBR)

2.10. Sample Collection and Analyses for the Lab-Scale Plant

2.11. Analytical Methods for the Lab-Scale Plant Samples

3. Results and Discussion

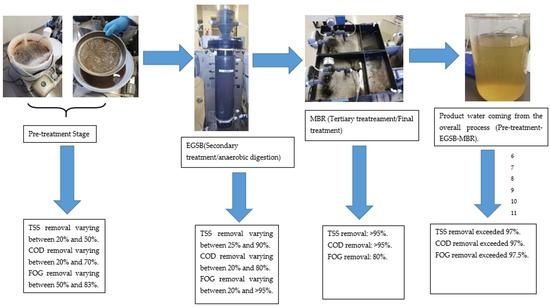

3.1. Pretreatment Stage Performance

3.2. Expanded Granular Sludge Bed Reactor (EGSB) Performance

3.3. Membrane Bioreactor (MBR) Performance

3.4. Overall System Performance of the Pretreatment–EGSB–MBR Lab-Scale System

3.5. MBR Final Effluent Quality Compared to the Wastewater Discharge Standards

4. Conclusions and Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mpentshu, Y. Biosurfactant Producing Biofilms for the Enhancement of Nitrification and Subsequent Aerobic Denitrification. Master’s Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2018. [Google Scholar]

- Kasiri, S.; Mah, F.; Zhang, C.; Haveroen, M.; Ellsworth, S.; Ulrich, A. Anaerobic Processes; Wiley: Hoboken, NJ, USA, 2012; Volume 84. [Google Scholar]

- Bustillo-Lecompte, C.; Mehrvar, M. Slaughterhouse wastewater: Treatment, management and resource recovery. Phys. Chem. Wastewater Treat. Resour. Recover. 2017. [Google Scholar] [CrossRef] [Green Version]

- Rinquest, Z.; Basitere, M.; Ntwampe, S.K.O.; Njoya, M. Poultry slaughterhouse wastewater treatment using a static granular bed reactor coupled with single stage nitrification-denitrification and ultrafiltration systems. J. Water Process Eng. 2019, 29, 100778. [Google Scholar] [CrossRef]

- Njoya, M. Anaerobic Digestion of High Strength Wastewater in High Rate Anaerobic Bioreactor Systems: Case of Poultry Slaughterhouse Wastewater (PSW). Ph.D. Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2019. [Google Scholar]

- Gerardi, M.H. The Microbiology of Anaerobic Digesters; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; ISBN 3175723993. [Google Scholar]

- Njoya, M.; Basitere, M.; Ntwampe, S.K.O. High rate anaerobic treatment of poultry slaughterhouse wastewater (PSW). In New Horizons in Wastewaters Management; Nova Science Publishers, Inc.: New York, NY, USA, 2019; Volume 38. [Google Scholar]

- Del Nery, V.; Damianovic, M.H.Z.; Barros, F.G. The use of upflow anaerobic sludge blanket reactors in the treatment of poultry slaughterhouse wastewater. Water Sci. Technol. 2001, 44, 83–88. [Google Scholar] [CrossRef] [PubMed]

- Avula, R.Y.; Nelson, H.M.; Singh, R.K. Recycling of poultry process wastewater by ultrafiltration. Innov. Food Sci. Emerg. Technol. 2009, 10, 1–8. [Google Scholar] [CrossRef]

- Yaakob, M.A.; Radin Mohamed, R.M.S.; Al-Gheethi, A.A.S.; Mohd Kassim, A.H. Characteristics of Chicken Slaughterhouse Wastewater. Chem. Eng. Trans. 2018, 63, 637–642. [Google Scholar] [CrossRef]

- Basitere, M.; Williams, Y.; Sheldon, M.S.; Ntwampe, S.K.O.; De Jager, D.; Dlangamandla, C. Performance of an expanded granular sludge bed (EGSB) reactor coupled with anoxic and aerobic bioreactors for treating poultry slaughterhouse wastewater. Water Pract. Technol. 2016, 11, 86–92. [Google Scholar] [CrossRef]

- Williams, Y. Treatment of Poultry Slaughterhouse Wastewater Using an Expanded Granular Sludge Bed Anaerobic Digester Coupled with Anoxic/Aerobic Hybrid Side Stream Ultrafiltration Membrane Bioreactor. Master’s Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2017. [Google Scholar]

- Sheldon, M.S.; Erdogan, I.G. Multi-stage EGSB/MBR treatment of soft drink industry wastewater. Chem. Eng. J. 2016, 285, 368–377. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, L.; Chi, L.; Long, X.; Mei, Z.; Zhang, Z. Startup and operation of anaerobic EGSB reactor treating palm oil mill effluent. J. Environ. Sci. 2008, 20, 658–663. [Google Scholar] [CrossRef]

- Van Haandel, A.C.; van der Lubbe, J.G.M. Handbook of Biological Wastewater Treatment: Design and Optimisation of Activated Sludge Systems, 2nd ed.; IWA Publishing: London, UK, 2012; ISBN 9781780400808. [Google Scholar]

- Njoya, M.; Basitere, M.; Ntwampe, S.K.O.; Lim, J.W. Performance evaluation and kinetic modeling of down-flow high-rate anaerobic bioreactors for poultry slaughterhouse wastewater treatment. Environ. Sci. Pollut. Res. 2020, 9529–9541. [Google Scholar] [CrossRef] [PubMed]

- Ergofito. Poultry Farming, in Cape Town. 2019, p. 4. Available online: https://www.ergofito.co.za/application/Grease-Fats-Overview (accessed on 30 April 2021).

- Kaskote, E.; Rinquest, Z.; Williams, Y.; Njoya, M. Performance and Statistical Comparison of the Expanded and Static Granular Sludge Bed Reactors Treating Poultry Slaughterhouse Wastewater; IWA Publishing Limited: London, UK, 2019. [Google Scholar] [CrossRef]

- Rinquest, Z.; Basitere, M.; Ngongang, M.M.; Njoya, M.; Ntwampe, S.K.O. Optimization of the COD Removal Efficiency for a Static Granular Bed Reactor Treating Poultry Slaughterhouse Wastewater; MDPI: Basel, Switzerland, 2019. [Google Scholar] [CrossRef] [Green Version]

- Mukandi, M. Modelling of a Bioflocculant Supported Dissolved Air Flotation System for Fats Oil and Grease Laden Wastewater Pretreatment. Master’s Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2017. [Google Scholar]

- APHA. Standard Methods for the Examination of Water and Wastewater Preface to the Twentieth Edition Standard Methods for the Examination of Water and Wastewater; American Public Health Association; American Water Works Association; Water Environment Federation: Washington, DC, USA, 2005; p. 2671. [Google Scholar]

- Cruz-Salomón, A.; Ríos-Valdovinos, E.; Pola-Albores, F.; Lagunas-Rivera, S.; Meza-Gordillo, R.; Ruíz-Valdiviezo, V.M.; Cruz-Salomón, K.C. Expanded granular sludge bed bioreactor in wastewater treatment. Glob. J. Environ. Sci. Manag. 2019, 5, 119–138. [Google Scholar] [CrossRef]

- Núñez, L.A.; Martínez, B. Anaerobic treatment of slaughterhouse wastewater in an expanded granular sludge bed (EGSB) reactor. Water Sci. Technol. 1999, 40, 99–106. [Google Scholar] [CrossRef]

- Fuchs, W.; Binder, H.; Mavrias, G.; Braun, R. Anaerobic treatment of wastewater with high organic content using a stirred tank reactor coupled with a membrane filtration unit. Water Res. 2003, 37, 902–908. [Google Scholar] [CrossRef]

- Chu, L.B.; Yang, F.L.; Zhang, X.W. Anaerobic treatment of domestic wastewater in a membrane-coupled expended granular sludge bed (EGSB) reactor under moderate to low temperature. Process Biochem. 2005, 40, 1063–1070. [Google Scholar] [CrossRef]

| Parameters | Units | MBR Outlet | CoCT Bylaws | DWA (2010) | SANS 241:2015 |

|---|---|---|---|---|---|

| pH | n/a | 7.7 | 5.5–9.5 | 5.5–9.5 | 5.5–9.5 |

| Temperature | °C | 22 | ≤40 | ||

| Conductivity | µs/cm | 350 | ≤500 | ≤200 | ≤170 |

| TDS | ppm | 1000 | 4000 | ||

| tCOD | mg/L | 110 | ≤5000 | ≤5000 | 1000–2400 |

| TSS | mg/L | 8 | 1000 | ||

| FOG | mg/L | 27 | 400 |

| References | Technology Used | Type of Wastewater | Results |

|---|---|---|---|

| [12] | EGSB | PSW | 69% tCOD removal; 98% TSS removal; 92% FOG removal |

| [12] | Ultrafiltration membrane bioreactor (UFMBR) | PSW | 47% TSS removal; 62% tCOD removal |

| [12] | EGSB–UFMBR | PSW | 92% tCOD removal; 99% TSS removal |

| [11] | EGSB | PSW | 65% total COD removal |

| [23] | EGSB | Slaughterhouse wastewater | 54–80% COD removal |

| [24] | MBR | Wastewater with high organic content | 97% COD removal |

| [25] | Hollow fiber membrane filtration–EGSB | Domestic wastewater | 85–96% COD removal |

| [13] | EGSB–MBR | Soft-drink industry wastewater | 95% total COD removal |

| [14] | EGSB | Palm-oil mill effluent | 91% tCOD removal |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meyo, H.B.; Njoya, M.; Basitere, M.; Ntwampe, S.K.O.; Kaskote, E. Treatment of Poultry Slaughterhouse Wastewater (PSW) Using a Pretreatment Stage, an Expanded Granular Sludge Bed Reactor (EGSB), and a Membrane Bioreactor (MBR). Membranes 2021, 11, 345. https://doi.org/10.3390/membranes11050345

Meyo HB, Njoya M, Basitere M, Ntwampe SKO, Kaskote E. Treatment of Poultry Slaughterhouse Wastewater (PSW) Using a Pretreatment Stage, an Expanded Granular Sludge Bed Reactor (EGSB), and a Membrane Bioreactor (MBR). Membranes. 2021; 11(5):345. https://doi.org/10.3390/membranes11050345

Chicago/Turabian StyleMeyo, Honeil Basile, Mahomet Njoya, Moses Basitere, Seteno Karabo Obed Ntwampe, and Ephraim Kaskote. 2021. "Treatment of Poultry Slaughterhouse Wastewater (PSW) Using a Pretreatment Stage, an Expanded Granular Sludge Bed Reactor (EGSB), and a Membrane Bioreactor (MBR)" Membranes 11, no. 5: 345. https://doi.org/10.3390/membranes11050345

APA StyleMeyo, H. B., Njoya, M., Basitere, M., Ntwampe, S. K. O., & Kaskote, E. (2021). Treatment of Poultry Slaughterhouse Wastewater (PSW) Using a Pretreatment Stage, an Expanded Granular Sludge Bed Reactor (EGSB), and a Membrane Bioreactor (MBR). Membranes, 11(5), 345. https://doi.org/10.3390/membranes11050345