SVM and ANN Modelling Approach for the Optimization of Membrane Permeability of a Membrane Rotating Biological Contactor for Wastewater Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sludge Inoculation

2.2. Wastewater Preparation

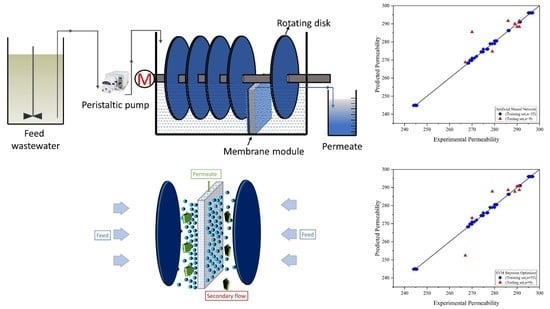

2.3. Bioreactor Set-up and Operation

2.4. Machine Learning Modelling

2.5. Artificial Neural Network

2.6. Support Vector Machine

3. Results and Discussion

3.1. Artificial Neural Networks

3.2. Support Vector Machine

3.3. Performance Comparison of Trained Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tabraiz, S.; Haydar, S.; Hussain, G. Evaluation of a cost-effective and energy-efficient disc material for rotating biological contactors (RBC), and performance evaluation under varying condition of RPM and submergence. Desalination Water Treat. 2016, 57, 20439–20446. [Google Scholar] [CrossRef]

- Waqas, S.; Harun, N.Y.; Bilad, M.R.; Samsuri, T.; Nordin, N.A.H.M.; Shamsuddin, N.; Nandiyanto, A.B.D.; Huda, N.; Roslan, J. Response Surface Methodology for Optimization of Rotating Biological Contactor Combined with External Membrane Filtration for Wastewater Treatment. Membranes 2022, 12, 271. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Performance and Energy Consumption Evaluation of Rotating Biological Contactor for Domestic Wastewater Treatment. Indones. J. Sci. Technol. 2021, 6, 101–112. [Google Scholar] [CrossRef]

- Mohammadi, M.; Mohammadi, P.; Karami, N.; Barzegar, A.; Annuar, M.S.M. Efficient hydrogen gas production from molasses in hybrid anaerobic-activated sludge-rotating biological contactor. Int. J. Hydrogen Energy 2019, 44, 2592–2602. [Google Scholar] [CrossRef]

- Hamedi, S.; Babaeipour, V.; Rouhi, M. Design, construction and optimization a flexible bench-scale rotating biological contactor (RBC) for enhanced production of bacterial cellulose by Acetobacter Xylinium. Bioprocess Biosyst. Eng. 2021, 44, 1071–1080. [Google Scholar]

- Li, N.; Zeng, W.; Yang, Y.; Wang, B.; Li, Z.; Peng, Y. Oxygen mass transfer and post-denitrification in a modified rotating drum biological contactor. Biochem. Eng. J. 2019, 144, 48–56. [Google Scholar] [CrossRef]

- Subhadarsini, L.; Dash, R.R. Treatment of Industrial Waste Water using Single-Stage Rotating Biological Contactor. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Odisha, India, 17–18 September 2020; p. 012025. [Google Scholar]

- Waqas, S.; Bilad, M.R.; Aqsha, A.; Harun, N.Y.; Ayoub, M.; Wirzal, M.D.H.; Jaafar, J.; Mulyati, S.; Elma, M. Effect of membrane properties in a membrane rotating biological contactor for wastewater treatment. J. Environ. Chem. Eng. 2021, 9, 104869. [Google Scholar] [CrossRef]

- Delgado, N.; Navarro, A.; Marino, D.; Peñuela, G.; Ronco, A. Removal of pharmaceuticals and personal care products from domestic wastewater using rotating biological contactors. Int. J. Environ. Sci. Technol. 2019, 16, 1–10. [Google Scholar] [CrossRef]

- Petropoulos, E.; Yu, Y.; Tabraiz, S.; Yakubu, A.; Curtis, T.P.; Dolfing, J. High rate domestic wastewater treatment at 15° C using anaerobic reactors inoculated with cold-adapted sediments/soils–shaping robust methanogenic communities. Sci. Water Res. Technol. 2019, 5, 70–82. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R. A review on rotating biological contactors. Indones. J. Sci. Technol. 2019, 4, 241–256. [Google Scholar] [CrossRef]

- Tabraiz, S.; Ahmad, S.; Shehzadi, I.; Asif, M.B. Study of physio-psychological effects on traffic wardens due to traffic noise pollution; exposure-effect relation. J. Environ. Health sci. 2015, 13, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Irfan, M.; Waqas, S.; Arshad, U.; Khan, J.A.; Legutko, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Rahman, S.; Skrzypczak, A. Response Surface Methodology and Artificial Neural Network Modelling of Membrane Rotating Biological Contactors for Wastewater Treatment. Materials 2022, 15, 1932. [Google Scholar] [CrossRef]

- Irfan, M.; Waqas, S.; Khan, J.A.; Rahman, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Legutko, S.; Ochowiak, M.; Włodarczak, S.; Czernek, K. Effect of Operating Parameters and Energy Expenditure on the Biological Performance of Rotating Biological Contactor for Wastewater Treatment. Energies 2022, 15, 3523. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.; Wibisono, Y.; Jaafar, J.; Mahlia, T.M.I.; Khan, A.L.; Aslam, M. Recent progress in integrated fixed-film activated sludge process for wastewater treatment: A review. J. Environ. Manag. 2020, 268, 110718. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Huda, N.; Harun, N.Y.; Md Nordin, N.A.H.; Shamsuddin, N.; Wibisono, Y.; Khan, A.L.; Roslan, J. Membrane Filtration as Post-Treatment of Rotating Biological Contactor for Wastewater Treatment. Sustainability 2021, 13, 7287. [Google Scholar]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Suleman, H.; Nordin, N.A.H.; Jaafar, J.; Othman, M.H.D.; Elma, M. An energy-efficient membrane rotating biological contactor for wastewater treatment. J. Cleaner Prod. 2021, 282, 124544. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Klaysom, C.; Jaafar, J.; Khan, A.L. An integrated rotating biological contactor and membrane separation process for domestic wastewater treatment. Alexandria Eng. J. 2020, 59, 4257–4265. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Effect of organic and nitrogen loading rate in a rotating biological contactor for wastewater treatment. J. Phys. Conf. Ser. 2021, 1793, 012063. [Google Scholar] [CrossRef]

- Tabraiz, S.; Shamurad, B.; Petropoulos, E.; Quintela-Baluja, M.; Charlton, A.; Dolfing, J.; Sallis, P.J. Mitigation of membrane biofouling in membrane bioreactor treating sewage by novel quorum quenching strain of Acinetobacter originating from a full-scale membrane bioreactor. Bioresour. Technol. 2021, 334, 125242. [Google Scholar] [CrossRef]

- Corbatón-Báguena, M.-J.; Vincent-Vela, M.-C.; Gozálvez-Zafrilla, J.-M.; Álvarez-Blanco, S.; Lora-García, J.; Catalán-Martínez, D. Comparison between artificial neural networks and Hermia’s models to assess ultrafiltration performance. Sep. Purif. Technol. 2016, 170, 434–444. [Google Scholar] [CrossRef] [Green Version]

- Mirbagheri, S.A.; Bagheri, M.; Bagheri, Z.; Kamarkhani, A.M. Evaluation and prediction of membrane fouling in a submerged membrane bioreactor with simultaneous upward and downward aeration using artificial neural network-genetic algorithm. Process Saf. Environ. Prot. 2015, 96, 111–124. [Google Scholar] [CrossRef]

- Zhao, Z.; Lou, Y.; Chen, Y.; Lin, H.; Li, R.; Yu, G. Prediction of interfacial interactions related with membrane fouling in a membrane bioreactor based on radial basis function artificial neural network (ANN). Bioresour. Technol. 2019, 282, 262–268. [Google Scholar] [CrossRef]

- Schmitt, F.; Banu, R.; Yeom, I.-T.; Do, K.-U. Development of artificial neural networks to predict membrane fouling in an anoxic-aerobic membrane bioreactor treating domestic wastewater. Biochem. Eng. J. 2018, 133, 47–58. [Google Scholar] [CrossRef]

- Chew, C.M.; Aroua, M.K.; Hussain, M.A. Advanced process control for ultrafiltration membrane water treatment system. J. Cleaner Prod. 2018, 179, 63–80. [Google Scholar] [CrossRef]

- Chakraborty, S.; Dasgupta, J.; Farooq, U.; Sikder, J.; Drioli, E.; Curcio, S. Experimental analysis, modeling and optimization of chromium (VI) removal from aqueous solutions by polymer-enhanced ultrafiltration. J. Membr. Sci. 2014, 456, 139–154. [Google Scholar] [CrossRef]

- Soleimani, R.; Shoushtari, N.A.; Mirza, B.; Salahi, A. Experimental investigation, modeling and optimization of membrane separation using artificial neural network and multi-objective optimization using genetic algorithm. Chem. Eng. Res. Des. 2013, 91, 883–903. [Google Scholar] [CrossRef]

- Rahmanian, B.; Pakizeh, M.; Mansoori, S.A.A.; Abedini, R. Application of experimental design approach and artificial neural network (ANN) for the determination of potential micellar-enhanced ultrafiltration process. J. Hazard. Mater. 2011, 187, 67–74. [Google Scholar] [CrossRef]

- Meng, X.; Wang, F.; Meng, S.; Wang, R.; Mao, Z.; Li, Y.; Yu, M.; Wang, X.; Zhao, Q.; Yang, L. Novel Surrogates for Membrane Fouling and the Application of Support Vector Machine in Analyzing Fouling Mechanism. Membranes 2021, 11, 990. [Google Scholar] [CrossRef]

- Bagheri, M.; Akbari, A.; Mirbagheri, S.A. Advanced control of membrane fouling in filtration systems using artificial intelligence and machine learning techniques: A critical review. Process Saf. Environ. Prot. 2019, 123, 229–252. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, F.; Yang, Z. Comparative analysis of ANN and SVM models combined with wavelet preprocess for groundwater depth prediction. Water 2017, 9, 781. [Google Scholar] [CrossRef] [Green Version]

- Arshad, U.; Taqvi, S.A.A.; Buang, A. Experimental analysis and data-driven machine learning modelling of the minimum ignition temperature (MIT) of aluminium dust. Fuel 2022, 324, 124569. [Google Scholar] [CrossRef]

- Arshad, U.; Taqvi, S.A.A.; Buang, A.; Awad, A. SVM, ANN, and PSF modelling approaches for prediction of iron dust minimum ignition temperature (MIT) based on the synergistic effect of dispersion pressure and concentration. Process Saf. Environ. Prot. 2021, 152, 375–390. [Google Scholar] [CrossRef]

- Arshad, U.; Taqvi, S.A.A.; Buang, A. Modelling of the minimum ignition temperature (MIT) of corn dust using statistical analysis and artificial neural networks based on the synergistic effect of concentration and dispersion pressure. Process Saf. Environ. Prot. 2021, 147, 742–755. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, L.; Xu, K.; Wang, Q. Prediction of minimum ignition energy from molecular structure using quantitative structure–property relationship (QSPR) models. Ind. Eng. Chem. Res. 2017, 56, 47–51. [Google Scholar] [CrossRef]

- Safavi, H.R.; Esmikhani, M. Conjunctive use of surface water and groundwater: Application of support vector machines (SVMs) and genetic algorithms. Water Resour. Manag. 2013, 27, 2623–2644. [Google Scholar] [CrossRef]

- Bafitlhile, T.M.; Li, Z. Applicability of ε-Support Vector Machine and Artificial Neural Network for Flood Forecasting in Humid, Semi-Humid and Semi-Arid Basins in China. Water 2019, 11, 85. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.-C.; Lin, G.-F. An hourly streamflow forecasting model coupled with an enforced learning strategy. Water 2015, 7, 5876–5895. [Google Scholar] [CrossRef] [Green Version]

- Nabipour, M.; Keshavarz, P. Modélisation de la tension superficielle de frigorigènes purs au moyen de réseaux neuronaux à rétropropagation non récurrents. Int. J. Refrig 2017, 75, 217–227. [Google Scholar] [CrossRef]

- Rustam, Z.; Arfiani, A.; Pandelaki, J. Cerebral infarction classification using multiple support vector machine with information gain feature selection. Bull. Electr. Eng. Inform. 2020, 9, 1578–1584. [Google Scholar] [CrossRef]

- Meng, X.; Meng, S.; Liu, Y. The Limitations in Current Studies of Organic Fouling and Future Prospects. Membranes 2021, 11, 922. [Google Scholar] [CrossRef]

- Hamedi, H.; Ehteshami, M.; Mirbagheri, S.A.; Zendehboudi, S. New deterministic tools to systematically investigate fouling occurrence in membrane bioreactors. Chem. Eng. Res. Des. 2019, 144, 334–353. [Google Scholar] [CrossRef]

- Cai, Y.-D.; Ricardo, P.-W.; Jen, C.-H.; Chou, K.-C. Application of SVM to predict membrane protein types. J. Theor. Biol. 2004, 226, 373–376. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Wei, D.; Liu, T.; Liu, Y.; Yan, L.; Wei, Q.; Du, B.; Xu, W. EDTA functionalized magnetic biochar for Pb (II) removal: Adsorption performance, mechanism and SVM model prediction. Sep. Purif. Technol. 2019, 227, 115696. [Google Scholar] [CrossRef]

| Contaminant | Influent |

|---|---|

| COD (mg/L) | 281 ± 8.5 |

| TN (mg/L) | 2.5 ± 0.19 |

| Ammonia (mg/L) | 0.66 ± 0.03 |

| Nitrate (mg/L) | 0.49 ± 0.04 |

| Turbidity (NTU) | 14.6 ± 0.55 |

| pH | 6.28 ± 0.21 |

| Run # | Sr # | (A) Disk Rotational Speed (rpm) | (B) HRT (h) | (C) SRT (d) | Permeability (L/m2 h bar) |

|---|---|---|---|---|---|

| 49 | 1 | 40 | 15 | 10 | 296 |

| 16 | 2 | 50 | 12 | 15 | 275 |

| 25 | 3 | 23.2 | 15 | 10 | 245 |

| 34 | 4 | 40 | 20 | 10 | 302 |

| 8 | 5 | 30 | 18 | 5 | 272 |

| 51 | 6 | 40 | 15 | 10 | 296 |

| 43 | 7 | 40 | 15 | 10 | 295 |

| 18 | 8 | 50 | 12 | 15 | 274 |

| 44 | 9 | 40 | 15 | 10 | 296.5 |

| 33 | 10 | 40 | 9.95 | 10 | 291 |

| 5 | 11 | 50 | 12 | 5 | 269 |

| 36 | 12 | 40 | 20 | 10 | 303 |

| 38 | 13 | 40 | 15 | 1.6 | 286 |

| 35 | 14 | 40 | 20 | 10 | 302 |

| 10 | 15 | 50 | 18 | 5 | 277 |

| 19 | 16 | 30 | 18 | 15 | 278 |

| 48 | 17 | 40 | 15 | 10 | 296 |

| 41 | 18 | 40 | 15 | 18.4 | 304 |

| 39 | 19 | 40 | 15 | 1.6 | 286 |

| 14 | 20 | 30 | 12 | 15 | 270 |

| 30 | 21 | 56.8 | 15 | 10 | 245 |

| 47 | 22 | 40 | 15 | 10 | 295 |

| 24 | 23 | 50 | 18 | 15 | 281 |

| 23 | 24 | 50 | 18 | 15 | 280.5 |

| 28 | 25 | 56.8 | 15 | 10 | 244 |

| 9 | 26 | 30 | 18 | 5 | 272 |

| 53 | 27 | 40 | 15 | 10 | 296.5 |

| 11 | 28 | 50 | 18 | 5 | 276.5 |

| 1 | 29 | 30 | 12 | 5 | 268 |

| 26 | 30 | 23.2 | 15 | 10 | 244.5 |

| 32 | 31 | 40 | 9.95 | 10 | 291.5 |

| 6 | 32 | 50 | 12 | 5 | 270 |

| 20 | 33 | 30 | 18 | 15 | 279 |

| 46 | 34 | 40 | 15 | 10 | 297 |

| 15 | 35 | 30 | 12 | 15 | 271 |

| 55 | 36 | 40 | 15 | 10 | 296 |

| 50 | 37 | 40 | 15 | 10 | 296.5 |

| 22 | 38 | 50 | 18 | 15 | 280 |

| 4 | 39 | 50 | 12 | 5 | 269.5 |

| 3 | 40 | 30 | 12 | 5 | 268.5 |

| 2 | 41 | 30 | 12 | 5 | 268 |

| 45 | 42 | 40 | 15 | 10 | 296 |

| 17 | 43 | 50 | 12 | 15 | 274.5 |

| 42 | 44 | 40 | 15 | 18.4 | 304.5 |

| 29 | 45 | 56.8 | 15 | 10 | 245.5 |

| 12 | 46 | 50 | 18 | 5 | 275 |

| 40 | 47 | 40 | 15 | 18.4 | 304 |

| 54 | 48 | 40 | 15 | 10 | 296 |

| 31 | 49 | 40 | 9.95 | 10 | 291 |

| 27 | 50 | 23.2 | 15 | 10 | 245 |

| 13 | 51 | 30 | 12 | 15 | 271 |

| 37 | 52 | 40 | 15 | 1.6 | 286.5 |

| 52 | 53 | 40 | 15 | 10 | 295.5 |

| 21 | 54 | 30 | 18 | 15 | 280 |

| 7 | 55 | 30 | 18 | 5 | 272 |

| Error Index | ANN 13 | SVM Bayesian Optimizer | SVM Grid Search | SVM Random Search | ||||

|---|---|---|---|---|---|---|---|---|

| Train Data | Unseen Data | Train Data | Unseen Data | Train Data | Unseen Data | Train Data | Unseen Data | |

| RMSE | 0.514 | 5.80 | 2.141 | 6.014 | 2.343 | 5.883 | 1.803 | 6.602 |

| MBE | 0.044 | 1.636 | −0.152 | −0.75 | −0.013 | −0.58 | 0.258 | −0.284 |

| MAE | 0.367 | 3.77 | 2 | 4.124 | 2.189 | 4.15 | 1.618 | 4.456 |

| NSE | 0.999 | 0.713 | 0.984 | 0.7 | 0.981 | 0.706 | 0.989 | 0.63 |

| R2 | 0.999 | 0.74 | 0.992 | 0.798 | 0.983 | 0.793 | 0.989 | 0.805 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waqas, S.; Harun, N.Y.; Sambudi, N.S.; Arshad, U.; Nordin, N.A.H.M.; Bilad, M.R.; Saeed, A.A.H.; Malik, A.A. SVM and ANN Modelling Approach for the Optimization of Membrane Permeability of a Membrane Rotating Biological Contactor for Wastewater Treatment. Membranes 2022, 12, 821. https://doi.org/10.3390/membranes12090821

Waqas S, Harun NY, Sambudi NS, Arshad U, Nordin NAHM, Bilad MR, Saeed AAH, Malik AA. SVM and ANN Modelling Approach for the Optimization of Membrane Permeability of a Membrane Rotating Biological Contactor for Wastewater Treatment. Membranes. 2022; 12(9):821. https://doi.org/10.3390/membranes12090821

Chicago/Turabian StyleWaqas, Sharjeel, Noorfidza Yub Harun, Nonni Soraya Sambudi, Ushtar Arshad, Nik Abdul Hadi Md Nordin, Muhammad Roil Bilad, Anwar Ameen Hezam Saeed, and Asher Ahmed Malik. 2022. "SVM and ANN Modelling Approach for the Optimization of Membrane Permeability of a Membrane Rotating Biological Contactor for Wastewater Treatment" Membranes 12, no. 9: 821. https://doi.org/10.3390/membranes12090821

APA StyleWaqas, S., Harun, N. Y., Sambudi, N. S., Arshad, U., Nordin, N. A. H. M., Bilad, M. R., Saeed, A. A. H., & Malik, A. A. (2022). SVM and ANN Modelling Approach for the Optimization of Membrane Permeability of a Membrane Rotating Biological Contactor for Wastewater Treatment. Membranes, 12(9), 821. https://doi.org/10.3390/membranes12090821