High-Temperature Atomic Layer Deposition of GaN on 1D Nanostructures

Abstract

:1. Introduction

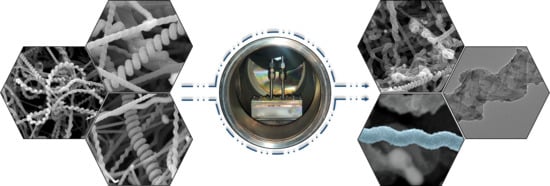

2. High-Temperature Atomic Layer Deposition System Design

3. Growth Details and Characterization

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Krames, M.R.; Shchekin, O.B.; Mueller-Mach, R.; Mueller, G.O.; Zhou, L.; Harbers, G.; Craford, M.G. Status and Future of High-Power Light-Emitting Diodes for Solid-State Lighting. J. Disp. Technol. 2007, 3, 160–175. [Google Scholar] [CrossRef] [Green Version]

- Meyer, J.; Schneidenbach, D.; Winkler, T.; Hamwi, S.; Weimann, T.; Hinze, P.; Ammermann, S.; Johannes, H.-H.; Riedl, T.; Kowalsky, W. Reliable thin film encapsulation for organic light emitting diodes grown by low-temperature atomic layer deposition. Appl. Phys. Lett. 2009, 94, 233305. [Google Scholar] [CrossRef]

- Fernández-Menéndez, L.J.; González, A.S.; Vega, V.; De la Prida, V.M. Electrostatic Supercapacitors by Atomic Layer Deposition on Nanoporous Anodic Alumina Templates for Environmentally Sustainable Energy Storage. Coatings 2018, 8, 403. [Google Scholar] [CrossRef] [Green Version]

- Zheng, L.A.; Ping, E.-X.; Breiner, L.; Doan, T.T. Atomic Layer Deposition of Capacitor Dielectric. U.S. Patent 6,551,893, 22 April 2003. [Google Scholar]

- Hossain, M.d.A.; Khoo, K.T.; Cui, X.; Poduval, G.K.; Zhang, T.; Li, X.; Li, W.M.; Hoex, B. Atomic layer deposition enabling higher efficiency solar cells: A review. Nano Mater. Sci. 2020, 2, 204–226. [Google Scholar] [CrossRef]

- Klahr, B.M.; Martinson, A.B.F.; Hamann, T.W. Photoelectrochemical Investigation of Ultrathin Film Iron Oxide Solar Cells Prepared by Atomic Layer Deposition. Langmuir 2011, 27, 461–468. [Google Scholar] [CrossRef]

- Park, D.G.; Cho, H.J.; Lim, C.; Yeo, I.S.; Roh, J.S.; Kim, C.T.; Hwang, J.M. Characteristics of Al2O3 gate dielectric prepared by atomic layer deposition for giga scale CMOS DRAM devices. In Proceedings of the 2000 Symposium on VLSI Technology. Digest of Technical Papers (Cat. No.00CH37104), Honolulu, HI, USA, 13–15 June 2000; pp. 46–47. [Google Scholar]

- Jeon, W.; Chung, H.-S.; Joo, D.; Kang, S.-W. TiO2 ∕ Al2O3 ∕ TiO2 Nanolaminated Thin Films for DRAM Capacitor Deposited by Plasma-Enhanced Atomic Layer Deposition. Electrochem. Solid State Lett. 2007, 11, H19. [Google Scholar] [CrossRef]

- Weiss, T.; Ebert, W. Atomic Layer Deposition for Coating of Complex 3D Optics. Opt. Photonik 2017, 12, 42–45. [Google Scholar] [CrossRef] [Green Version]

- Pearse, A.J.; Schmitt, T.E.; Fuller, E.J.; El-Gabaly, F.; Lin, C.-F.; Gerasopoulos, K.; Kozen, A.C.; Talin, A.A.; Rubloff, G.; Gregorczyk, K.E. Nanoscale Solid State Batteries Enabled by Thermal Atomic Layer Deposition of a Lithium Polyphosphazene Solid State Electrolyte. Chem. Mater. 2017, 29, 3740–3753. [Google Scholar] [CrossRef] [Green Version]

- Jung, Y.S.; Lu, P.; Cavanagh, A.S.; Ban, C.; Kim, G.-H.; Lee, S.-H.; George, S.M.; Harris, S.J.; Dillon, A.C. Unexpected Improved Performance of ALD Coated LiCoO2/Graphite Li-Ion Batteries. Adv. Energy Mater. 2013, 3, 213–219. [Google Scholar] [CrossRef]

- Knez, M.; Nielsch, K.; Niinistö, L. Synthesis and Surface Engineering of Complex Nanostructures by Atomic Layer Deposition. Adv. Mater. 2007, 19, 3425–3438. [Google Scholar] [CrossRef]

- Lu, J.; Fu, B.; Kung, M.C.; Xiao, G.; Elam, J.W.; Kung, H.H.; Stair, P.C. Coking-and Sintering-Resistant Palladium Catalysts Achieved Through Atomic Layer Deposition. Science 2012, 335, 1205–1208. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Qi, W.; Li, Y. Coating strategies for atomic layer deposition. Nanotechnol. Rev. 2017, 6, 527–547. [Google Scholar] [CrossRef]

- Wise, A.M.; Ban, C.; Weker, J.N.; Misra, S.; Cavanagh, A.S.; Wu, Z.; Li, Z.; Whittingham, M.S.; Xu, K.; George, S.M.; et al. Effect of Al2O3 Coating on Stabilizing LiNi0.4Mn0.4Co0.2O2 Cathodes. Chem. Mater. 2015, 27, 6146–6154. [Google Scholar] [CrossRef]

- Detavernier, C.; Dendooven, J.; Sree, S.P.; Ludwig, K.F.; Martens, J.A. Tailoring nanoporous materials by atomic layer deposition. Chem. Soc. Rev. 2011, 40, 5242–5253. [Google Scholar] [CrossRef]

- Johnson, R.W.; Hultqvist, A.; Bent, S.F. A brief review of atomic layer deposition: From fundamentals to applications. Mater. Today 2014, 17, 236–246. [Google Scholar] [CrossRef]

- Profijt, H.B.; Potts, S.E.; van de Sanden, M.C.M.; Kessels, W.M.M. Plasma-Assisted Atomic Layer Deposition: Basics, Opportunities, and Challenges. J. Vac. Sci. Technol. Vac. Surf. Films 2011, 29, 050801. [Google Scholar] [CrossRef] [Green Version]

- Oviroh, P.O.; Akbarzadeh, R.; Pan, D.; Coetzee, R.A.M.; Jen, T.-C. New development of atomic layer deposition: Processes, methods and applications. Sci. Technol. Adv. Mater. 2019, 20, 465–496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ylivaara, O.M.E.; Liu, X.; Kilpi, L.; Lyytinen, J.; Schneider, D.; Laitinen, M.; Julin, J.; Ali, S.; Sintonen, S.; Berdova, M.; et al. Aluminum oxide from trimethylaluminum and water by atomic layer deposition: The temperature dependence of residual stress, elastic modulus, hardness and adhesion. Thin Solid Films 2014, 552, 124–135. [Google Scholar] [CrossRef]

- ALD grown nanostructured ZnO thin films: Effect of substrate temperature on thickness and energy band gap. J. King Saud Univ. Sci. 2016, 28, 347–354. [CrossRef] [Green Version]

- Alevli, M.; Gungor, N.; Haider, A.; Kizir, S.; Leghari, S.A.; Biyikli, N. Substrate temperature influence on the properties of GaN thin films grown by hollow-cathode plasma-assisted atomic layer deposition. J. Vac. Sci. Technol. A 2015, 34, 01A125. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Oh, I.-K. Review of plasma-enhanced atomic layer deposition: Technical enabler of nanoscale device fabrication. Jpn. J. Appl. Phys. 2014, 53, 03DA01. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Tsai, F.-Y. Efficient and air-stable plastics-based polymer solar cells enabled by atomic layer deposition. J. Mater. Chem. 2011, 21, 5710–5715. [Google Scholar] [CrossRef]

- Carcia, P.F.; McLean, R.S. Barrier Films for Plastic Substrates Fabricated by Atomic Layer Deposition 2013. U.S. Patent No. 8,445,937, 21 May 2013. [Google Scholar]

- Zhao, D.; Mourey, D.A.; Jackson, T.N. Fast Flexible Plastic Substrate ZnO Circuits. IEEE Electron Device Lett. 2010, 31, 323–325. [Google Scholar] [CrossRef]

- Lei, W.; Li, X.; Chen, Q.; Wang, Z. Plasma-Assisted ALD of an Al2O3 Permeation Barrier Layer on Plastic. Plasma Sci. Technol. 2012, 14, 129–133. [Google Scholar] [CrossRef] [Green Version]

- Shih, H.-Y.; Lin, M.-C.; Chen, L.-Y.; Chen, M.-J. Uniform GaN thin films grown on (100) silicon by remote plasma atomic layer deposition. Nanotechnology 2014, 26, 014002. [Google Scholar] [CrossRef]

- Ozgit, C.; Donmez, I.; Alevli, M.; Biyikli, N. Atomic layer deposition of GaN at low temperatures. J. Vac. Sci. Technol. A 2011, 30, 01A124. [Google Scholar] [CrossRef]

- Huang, S.; Jiang, Q.; Yang, S.; Zhou, C.; Chen, K.J. Effective Passivation of AlGaN/GaN HEMTs by ALD-Grown AlN Thin Film. IEEE Electron Device Lett. 2012, 33, 516–518. [Google Scholar] [CrossRef]

- Pansila, P.; Kanomata, K.; Miura, M.; Ahmmad, B.; Kubota, S.; Hirose, F. Growth kinetics for temperature-controlled atomic layer deposition of GaN using trimethylgallium and remote-plasma-excited NH3. Appl. Surf. Sci. 2015, 357, 1920–1927. [Google Scholar] [CrossRef]

- Saini, D.K. Gallium Nitride: Analysis of Physical Properties and Performance in High-Frequency Power Electronic Circuits. Ph.D. Thesis, Wright State Unviersity, Dayton, OH, USA, 2015; p. 1452. [Google Scholar]

- Flack, T.J.; Pushpakaran, B.N.; Bayne, S.B. GaN Technology for Power Electronic Applications: A Review. J. Electron. Mater. 2016, 45, 2673–2682. [Google Scholar] [CrossRef]

- Kim, O.H.; Kim, D.; Anderson, T. Atomic layer deposition of GaN using GaCl3 and NH3. J. Vac. Sci. Technol. A 2009, 27, 6. [Google Scholar] [CrossRef]

- Bastatas, L.D.; Wagle, P.; Echeverria, E.; Austin, A.J.; McIlroy, D.N. The Effect of UV Illumination on the Room Temperature Detection of Vaporized Ammonium Nitrate by a ZnO Coated Nanospring-Based Sensor. Materials 2019, 12, 302. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alayat, A.; Mcllroy, D.N.; McDonald, A.G. Effect of synthesis and activation methods on the catalytic properties of silica nanospring (NS)-supported iron catalyst for Fischer-Tropsch synthesis. Fuel Process. Technol. 2018, 169, 132–141. [Google Scholar] [CrossRef]

- Hass, J.L.; Garrison, E.M.; Wicher, S.A.; Knapp, B.; Bridges, N.; Mcllroy, D.; Arrizabalaga, G. Synthetic osteogenic extracellular matrix formed by coated silicon dioxide nanosprings. J. Nanobiotechnol. 2012, 10, 6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zamir, S.; Meyler, B.; Zolotoyabko, E.; Salzman, J. The effect of AlN buffer layer on GaN grown on (111)-oriented Si substrates by MOCVD. J. Cryst. Growth 2000, 218, 181–190. [Google Scholar] [CrossRef]

- Follstaedt, D.M.; Han, J.; Provencio, P.; Fleming, J.G. Microstructure of GaN Grown on (111) Si by MOCVD. Mater. Res. Soc. Internet J. Nitride Semicond. Res. 1999, 4, 397–402. [Google Scholar] [CrossRef] [Green Version]

- Doverspike, K.; Rowland, L.B.; Gaskill, D.K.; Freitas, J.A. The effect of GaN and ain buffer layers on GaN film properties grown on both C-plane and A-plane sapphire. J. Electron. Mater. 1995, 24, 269–273. [Google Scholar] [CrossRef]

- Crouch, R.K.; Debnam, W.J.; Fripp, A.L. Properties of GaN grown on sapphire substrates. J. Mater. Sci. 1978, 13, 2358–2364. [Google Scholar] [CrossRef]

- Grandjean, N.; Massies, J.; Leroux, M. Nitridation of sapphire. Effect on the optical properties of GaN epitaxial overlayers. Appl. Phys. Lett. 1996, 69, 2071–2073. [Google Scholar] [CrossRef]

- Guangrui, Y.; Guanghan, F.; Shuti, L.; Yong, Z.; Tianmin, Z. Improved optical performance of GaN grown on pattered sapphire substrate. J. Semicond. 2009, 30, 013001. [Google Scholar] [CrossRef]

- Melton, W.A.; Pankove, J.I. GaN growth on sapphire. J. Cryst. Growth 1997, 178, 168–173. [Google Scholar] [CrossRef]

- McIlroy, D.N.; Zhang, D.; Kranov, Y.; Norton, M.G. Nanosprings. Appl. Phys. Lett. 2001, 79, 1540. [Google Scholar] [CrossRef]

- Zhang, D.; Alkhateeb, A.; Han, H.; Mahmood, H.; McIlroy, D.N.; Norton, M.G. Silicon Carbide Nanosprings. Nano Lett. 2003, 3, 983–987. [Google Scholar] [CrossRef]

- McIlroy, D.N.; Alkhateeb, A.; Zhang, D.; Aston, D.E.; Marcy, A.C.; Norton, M.G. Nanospring formation—unexpected catalyst mediated growth. J. Phys. Condens. Matter 2004, 16, R415–R440. [Google Scholar] [CrossRef]

- Wang, L.; Major, D.; Paga, P.; Zhang, D.; Norton, M.G.; McIlroy, D.N. High yield synthesis and lithography of silica-based nanospring mats. Nanotechnology 2006, 17, S298–S303. [Google Scholar] [CrossRef]

- Wojcik, P.M.; Bakharev, P.V.; Corti, G.; McIlroy, D.N. Nucleation, evolution, and growth dynamics of amorphous silica nanosprings. Mater. Res. Express 2017, 4, 015004. [Google Scholar] [CrossRef] [Green Version]

- Kern, W. The Evolution of Silicon Wafer Cleaning Technology. J. Electrochem. Soc. 1990, 137, 1887. [Google Scholar] [CrossRef]

- Bao, K.; Wang, L.; Yan, J.; Sun, H.; Guo, R.; Wu, Y. Synthesis of GaN cauliflowers by ammoniating Ga2O3. J. Alloys Compd. 2013, 552, 26–30. [Google Scholar] [CrossRef]

- Xiao, H.-D.; Ma, H.-L.; Xue, C.-S.; Ma, J.; Zong, F.-J.; Zhang, X.-J.; Ji, F.; Hu, W.-R. Synthesis and structural properties of GaN powders. Mater. Chem. Phys. 2004, 88, 180–184. [Google Scholar] [CrossRef]

- Xue, S.; Zhang, X.; Huang, R.; Zhuang, H. Effects of the sputtering time of ZnO buffer layer on the quality of GaN thin films. Appl. Surf. Sci. 2008, 254, 6766–6769. [Google Scholar] [CrossRef]

- Mishra, M.; Krishna, T.C.S.; Rastogi, P.; Aggarwal, N.; Chauhan, A.K.S.; Goswami, L.; Gupta, G. New Approach to Clean GaN Surfaces. Mater. Focus 2014, 3, 218–223. [Google Scholar] [CrossRef]

- Pozina, G.; Khromov, S.; Hemmingsson, C.; Hultman, L.; Monemar, B. Effect of silicon and oxygen doping on donor bound excitons in bulk GaN. Phys. Rev. B 2011, 84, 165213. [Google Scholar] [CrossRef] [Green Version]

- Al Balushi, Z.Y.; Miyagi, T.; Lin, Y.-C.; Wang, K.; Calderin, L.; Bhimanapati, G.; Redwing, J.M.; Robinson, J.A. The impact of graphene properties on GaN and AlN nucleation. Surf. Sci. 2015, 634, 81–88. [Google Scholar] [CrossRef]

- Ghosh, D.; Hussain, S.; Ghosh, B.; Bhar, R.; Pal, A.K. Stress and Grain Boundary Properties of GaN Films Prepared by Pulsed Laser Deposition Technique. ISRN Mater. Sci. 2014, 2014, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Spruytte, S.G.; Coldren, C.W.; Harris, J.S.; Wampler, W.; Krispin, P.; Ploog, K.; Larson, M.C. Incorporation of nitrogen in nitride-arsenides: Origin of improved luminescence efficiency after anneal. J. Appl. Phys. 2001, 89, 4401–4406. [Google Scholar] [CrossRef]

- Lai, Y.-H.; Yeh, C.-T.; Hwang, J.-M.; Hwang, H.-L.; Chen, C.-T.; Hung, W.-H. Sputtering and Etching of GaN Surfaces. J. Phys. Chem. B 2001, 105, 10029–10036. [Google Scholar] [CrossRef]

- Motamedi, P.; Dalili, N.; Cadien, K. A route to low temperature growth of single crystal GaN on sapphire. J. Mater. Chem. C 2015, 3, 7428–7436. [Google Scholar] [CrossRef]

- Bilgili, A.K.; Akpinar, Ö.; Kurtulus, G.; Ozturk, M.K.; Ozcelik, S.; Ozbay, E. Structural properties of InGaN/GaN/Al2O3 structure from reciprocal space mapping. J. Mater. Sci. Mater. Electron. 2018, 29, 12373–12380. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Zhang, Y.; Yin, Y. High quality (In) GaN films on homoepitaxial substrates. Superlattices Microstruct. 2017, 102, 166–172. [Google Scholar] [CrossRef]

- Martínez-Ara, L.A.; Aguilar-Hernández, J.R.; Sastré-Hernández, J.; Hernández-Hernández, L.A.; de los, Á.; Maldonado-Altamirano, P.; Mendoza-Pérez, R.; Contreras-Puente, G. Structural and Optical Properties of GaN Thin Films Grown on Si (111) by Pulsed Laser Deposition. Mater. Res. 2019, 22. [Google Scholar] [CrossRef]

- Matoussi, A.; Boufaden, T.; Missaoui, A.; Guermazi, S.; Bessaïs, B.; Mlik, Y.; El Jani, B. Porous silicon as an intermediate buffer layer for GaN growth on (100) Si. Microelectron. J. 2001, 32, 995–998. [Google Scholar] [CrossRef]

- Jana, S.K.; Mukhopadhyay, P.; Ghosh, S.; Kabi, S.; Bag, A.; Kumar, R.; Biswas, D. High-resolution X-ray diffraction analysis of AlxGa1−xN/InxGa1−xN/GaN on sapphire multilayer structures: Theoretical, simulations, and experimental observations. J. Appl. Phys. 2014, 115, 174507. [Google Scholar] [CrossRef]

- Wright, A.F.; Nelson, J.S. Consistent structural properties for AlN, GaN, and InN. Phys. Rev. B 1995, 51, 7866–7869. [Google Scholar] [CrossRef]

- Lemettinen, J. Epitaxy of gallium nitride films on silicon substrates. Master’s Thesis, Aalto University School of Electrical Engineering, 2015. [Google Scholar]

- Bao, K.; Shi, L.; Liu, X.; Chen, C.; Mao, W.; Zhu, L.; Cao, J. Synthesis of GaN Nanorods by a Solid-State Reaction. Available online: https://www.hindawi.com/journals/jnm/2010/271051/ (accessed on 6 July 2020).

- Panda, P.; Mantry, S.; Mohapatra, S.; Singh, S.; Satapathy, A. A study on erosive wear analysis of glass fiber–epoxy–AlN hybrid composites. J. Compos. Mater. 2014, 48, 107–118. [Google Scholar] [CrossRef]

- Liu, W.-S.; Chang, Y.-L.; Chen, H.-Y. Growth of GaN Thin Film on Amorphous Glass Substrate by Direct-Current Pulse Sputtering Deposition Technique. Coatings 2019, 9, 419. [Google Scholar] [CrossRef] [Green Version]

- George, S.M. Atomic Layer Deposition: An Overview. Chem. Rev. 2010, 110, 111–131. [Google Scholar] [CrossRef]

- Mayer, T.M.; Rogers, J.W.; Michalske, T.A. Mechanism of nucleation and atomic layer growth of aluminum nitride on silicon. Chem. Mater. 1991, 3, 641–646. [Google Scholar] [CrossRef]

- Bartram, M.E.; Michalske, T.A.; Rogers, J.W.; Paine, R.T. Nucleation and growth of aluminum nitride: Self-limiting reactions and the regeneration of active sites using sequential exposures of trimethylaluminum and ammonia on silica at 600 K. Chem. Mater. 1993, 5, 1424–1430. [Google Scholar] [CrossRef]

- Banerjee, S.; Kovalgin, A. (Invited) A Comparative Study of Low-Temperature III-V Nitrides ALD in Thermal and Radical-Enhanced Modes. ECS Trans. 2018, 86, 21–29. [Google Scholar] [CrossRef]

- George, S.M.; Ott, A.W.; Klaus, J.W. Surface Chemistry for Atomic Layer Growth. J. Phys. Chem. 1996, 100, 13121–13131. [Google Scholar] [CrossRef]

- Fenwick, W.E.; Li, N.; Xu, T.; Melton, A.; Wang, S.; Yu, H.; Summers, C.; Jamil, M.; Ferguson, I.T. MOCVD growth of GaN on Si(111) substrates using an ALD-grown Al2O3 interlayer. J. Cryst. Growth 2009, 311, 4306–4310. [Google Scholar] [CrossRef]

- Bläsing, J.; Reiher, A.; Dadgar, A.; Diez, A.; Krost, A. The origin of stress reduction by low-temperature AlN interlayers. Appl. Phys. Lett. 2002, 81, 2722–2724. [Google Scholar] [CrossRef]

- Ueno, K.; Fudetani, T.; Arakawa, Y.; Kobayashi, A.; Ohta, J.; Fujioka, H. Electron transport properties of degenerate n-type GaN prepared by pulsed sputtering. APL Mater. 2017, 5, 126102. [Google Scholar] [CrossRef]

- Ueno, K.; Taiga, F.; Kobayashi, A.; Fujioka, H. Optical characteristics of highly conductive n-type GaN prepared by pulsed sputtering deposition. Sci. Rep. 2019, 9, 20242. [Google Scholar] [CrossRef]

- Ebert, P.; Ivanova, L.; Borisova, S.; Eisele, H.; Laubsch, A.; Dähne, M. Electronic properties of dislocations in GaN investigated by scanning tunneling microscopy. Appl. Phys. Lett. 2009, 94, 062104. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.; Yang, J.W.; Osinsky, A.; Gangopadhyay, S.; Lim, B.; Anwar, M.Z.; Asif Khan, M.; Kuksenkov, D.; Temkin, H. Schottky barrier detectors on GaN for visible–blind ultraviolet detection. Appl. Phys. Lett. 1997, 70, 2277–2279. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, J.; Zhou, H.; Zhang, Y.; Chen, T.; Zhang, K.; Wang, Y.; Dang, K.; Bian, Z.; Duan, X.; et al. High-performance lateral GaN Schottky barrier diode on silicon substrate with low turn-on voltage of 0.31 V, high breakdown voltage of 2.65 kV and high-power figure-of-merit of 2.65 GW cm −2. Appl. Phys. Express 2019, 12, 046502. [Google Scholar] [CrossRef]

- Bastatas, L.D.; Wagle, P.; Echeverria, E.; Slinker, J.D.; McIlroy, D.N. Electrical characterization of ZnO-coated nanospring ensemble by impedance spectroscopy: Probing the effect of thermal annealing. Nanotechnology 2019, 30, 234006. [Google Scholar] [CrossRef]

- Baumann, E.; Giorgetta, F.R.; Hofstetter, D.; Lu, H.; Chen, X.; Schaff, W.J.; Eastman, L.F.; Golka, S.; Schrenk, W.; Strasser, G. Intersubband photoconductivity at 1.6μm using a strain-compensated AlN∕GaN superlattice. Appl. Phys. Lett. 2005, 87, 191102. [Google Scholar] [CrossRef] [Green Version]

- Hofstetter, D.; Schad, S.-S.; Wu, H.; Schaff, W.J.; Eastman, L.F. GaN/AlN-based quantum-well infrared photodetector for 1.55 μm. Appl. Phys. Lett. 2003, 83, 572–574. [Google Scholar] [CrossRef]

- Maeda, N.; Hiroki, M.; Watanabe, N.; Oda, Y.; Yokoyama, H.; Yagi, T.; Makimoto, T.; Enoki, T.; Kobayashi, T. Systematic Study of Insulator Deposition Effect (Si3N4, SiO2, AlN, and Al2O3) on Electrical Properties in AlGaN/GaN Heterostructures. Jpn. J. Appl. Phys. 2007, 46, 547–554. [Google Scholar] [CrossRef]

- Binet, F.; Duboz, J.Y.; Rosencher, E.; Scholz, F.; Härle, V. Mechanisms of recombination in GaN photodetectors. Appl. Phys. Lett. 1996, 69, 1202–1204. [Google Scholar] [CrossRef]

- Muret, P.; Philippe, A.; Monroy, E.; Muñoz, E.; Beaumont, B.; Omnès, F.; Gibart, P. Properties of a hole trap in n-type hexagonal GaN. J. Appl. Phys. 2002, 91, 2998–3001. [Google Scholar] [CrossRef]

- Wong, Y.-Y.; Chang, E.Y.; Yang, T.-H.; Chang, J.-R.; Ku, J.-T.; Hudait, M.K.; Chou, W.-C.; Chen, M.; Lin, K.-L. The Roles of Threading Dislocations on Electrical Properties of AlGaN/GaN Heterostructure Grown by MBE. J. Electrochem. Soc. 2010, 157, H746. [Google Scholar] [CrossRef]

- Gurusinghe, M.N.; Andersson, T.G. Mobility in epitaxial GaN: Limitations of free-electron concentration due to dislocations and compensation. Phys. Rev. B 2003, 67, 235208. [Google Scholar] [CrossRef]

- Zhu, T.; Oliver, A.R. Unintentional doping in GaN. Phys. Chem. Chem. Phys. 2012, 14, 9558–9573. [Google Scholar] [CrossRef]

- Leys, M.; Cheng, K.; Derluyn, J.; Degroote, S.; Germain, M.; Borghs, G.; Taylor, C.A.; Dawson, P. Growth and characterization of unintentionally doped GaN grown on silicon(111) substrates. J. Cryst. Growth 2008, 310, 4888–4890. [Google Scholar] [CrossRef]

- Oliver, R.A. Application of highly silicon-doped marker layers in the investigation of unintentional doping in GaN on sapphire. Ultramicroscopy 2010, 111, 73–78. [Google Scholar] [CrossRef]

- Fichtenbaum, N.A.; Mates, T.E.; Keller, S.; DenBaars, S.P.; Mishra, U.K. Impurity incorporation in heteroepitaxial N-face and Ga-face GaN films grown by metalorganic chemical vapor deposition. J. Cryst. Growth 2008, 310, 1124–1131. [Google Scholar] [CrossRef]

- Cruz, S.C.; Keller, S.; Mates, T.E.; Mishra, U.K.; DenBaars, S.P. Crystallographic orientation dependence of dopant and impurity incorporation in GaN films grown by metalorganic chemical vapor deposition. J. Cryst. Growth 2009, 311, 3817–3823. [Google Scholar] [CrossRef]

- Saarinen, K.; Hautakangas, S.; Tuomisto, F. Dominant intrinsic acceptors in GaN and ZnO. Phys. Scr. 2006, T126, 105–109. [Google Scholar] [CrossRef]

- Slack, G.A.; Schowalter, L.J.; Morelli, D.; Freitas, J.A. Some effects of oxygen impurities on AlN and GaN. J. Cryst. Growth 2002, 246, 287–298. [Google Scholar] [CrossRef]

- Mishra, M.; C, S.K.T.; Aggarwal, N.; Kaur, M.; Singh, S.; Gupta, G. Pit assisted oxygen chemisorption on GaN surfaces. Phys. Chem. Chem. Phys. 2015, 17, 15201–15208. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Austin, A.J.; Echeverria, E.; Wagle, P.; Mainali, P.; Meyers, D.; Gupta, A.K.; Sachan, R.; Prassana, S.; McIlroy, D.N. High-Temperature Atomic Layer Deposition of GaN on 1D Nanostructures. Nanomaterials 2020, 10, 2434. https://doi.org/10.3390/nano10122434

Austin AJ, Echeverria E, Wagle P, Mainali P, Meyers D, Gupta AK, Sachan R, Prassana S, McIlroy DN. High-Temperature Atomic Layer Deposition of GaN on 1D Nanostructures. Nanomaterials. 2020; 10(12):2434. https://doi.org/10.3390/nano10122434

Chicago/Turabian StyleAustin, Aaron J., Elena Echeverria, Phadindra Wagle, Punya Mainali, Derek Meyers, Ashish Kumar Gupta, Ritesh Sachan, S. Prassana, and David N. McIlroy. 2020. "High-Temperature Atomic Layer Deposition of GaN on 1D Nanostructures" Nanomaterials 10, no. 12: 2434. https://doi.org/10.3390/nano10122434

APA StyleAustin, A. J., Echeverria, E., Wagle, P., Mainali, P., Meyers, D., Gupta, A. K., Sachan, R., Prassana, S., & McIlroy, D. N. (2020). High-Temperature Atomic Layer Deposition of GaN on 1D Nanostructures. Nanomaterials, 10(12), 2434. https://doi.org/10.3390/nano10122434