Template-Free Fabrication of Refractive Index Tunable Polysiloxane Coating Using Homogeneous Embedding Strategy: Application in High-Power Laser System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of UV-Curable Polysiloxane Sol

2.3. Preparation of Mesoporous Silica Nanoparticles

2.4. Coating Preparation

2.5. Sample Characterizations

3. Results and Discussion

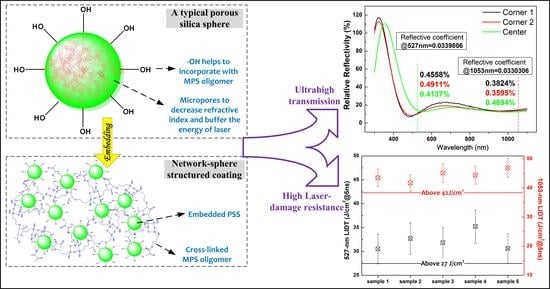

3.1. Structure Design

3.2. Materials Characterizations

3.3. Coating Characterizations

3.4. Coating Application

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Agustin-Saenz, C.; Machado, M.; Tercjak, A. Antireflective mesoporous silica coatings by optimization of water content in acid-catalyzed sol-gel method for application in glass covers of concentrated photovoltaic modules. J. Colloid. Interf. Sci. 2019, 534, 370–380. [Google Scholar] [CrossRef]

- Aminfard, S.; Harrison, R.K.; Ben-Yakar, A. Enhanced optical absorption in ultrathin silicon films using embedded silica-coated silver nanoparticles. Opt. Commun. 2019, 430, 143–150. [Google Scholar] [CrossRef]

- Zhang, F.; Shi, Z.F.; Ma, Z.Z.; Li, Y.; Li, S.; Wu, D.; Xu, T.T.; Li, X.J.; Shan, C.X.; Du, G.T. Silica coating enhances the stability of inorganic perovskite nanocrystals for efficient and stable down-conversion in white light-emitting devices. Nanoscale 2018, 10, 20131–20139. [Google Scholar] [CrossRef] [PubMed]

- Elhadj, S.; Steele, W.A.; VanBlarcom, D.S.; Hawley, R.A.; Schaffers, K.I.; Geraghty, P. Scalable process for mitigation of laser-damaged potassium dihydrogen phosphate crystal optic surfaces with removal of damaged antireflective coating. Appl. Opt. 2017, 56, 2217–2225. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.W.; Kuo, L.C.; Chang, L.A.; Chao, S.; Martin, I.W.; Steinlechner, J.; Fletcher, M. Silicon nitride and silica quarter-wave stacks for low-thermal-noise mirror coatings. Phys. Rev. D 2018, 98, 102001. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Cao, M.H.; Zeng, F.Z.; Qi, J.L.; Liu, H.X.; Hao, H.; Zhou, Z.H. Fine-grained silica-coated barium strontium titanate ceramics with high energy storage. Ceram. Int. 2018, 44, 20239–20244. [Google Scholar] [CrossRef]

- Woo, J.; Yang, S.Y.; Sa, Y.J.; Choi, W.Y.; Lee, M.H.; Lee, H.W.; Shin, T.J.; Kim, T.Y.; Joo, S.H. Promoting oxygen reduction reaction activity of Fe-N/C electrocatalysts by silica-coating-mediated synthesis for anion-exchange membrane fuel cells. Chem. Mater. 2018, 30, 6684–6701. [Google Scholar] [CrossRef]

- Hamrahian, S.A.; Rakhtshah, J.; Davijani, S.M.M.; Salehzadeh, S. Copper Schiff base complex immobilized on silica-coated Fe3O4 nanoparticles: A recoverable and efficient catalyst for synthesis of polysubstituted pyrroles. Appl. Organomet. Chem. 2018, 32, e4501. [Google Scholar] [CrossRef]

- Ye, Y.W.; Liu, Z.Y.; Liu, W.; Zhang, D.W.; Zhao, H.C.; Wang, L.P.; Li, X.G. Superhydrophobic oligoaniline-containing electroactive silica coating as pre-process coating for corrosion protection of carbon steel. Chem. Eng. J. 2018, 348, 940–951. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Deng, X.R.; Yang, W.; Hui, H.H.; Wei, Y.W.; Chen, J.J. Comparative study on cracking behavior of sol-gel silica antireflective coating for high-powered laser system. Eng. Fail. Anal. 2017, 82, 64–71. [Google Scholar] [CrossRef]

- Baisden, P.A.; Atherton, L.J.; Hawley, R.A.; Land, T.A.; Menapace, J.A.; Miller, P.E.; Runkel, M.J.; Spaeth, M.L.; Stolz, C.J.; Suratwala, T.I.; et al. Large optics for the national ignition facility. Fusion Sci. Technol. 2016, 69, 295–351. [Google Scholar] [CrossRef]

- Zhang, Q.; Wei, Y.; Yang, W.; Hui, H.; Deng, X.; Wang, J.; Xu, Q.; Shen, J. Improvement on contamination resistance to volatile organics and moisture of sol–gel silica antireflective coating for 351 nm laser system by structural modulation with fluorinated compounds. RSC Adv. 2015, 5, 4529–4536. [Google Scholar] [CrossRef]

- Deng, X.R.; Yang, W.; Zhang, Q.H.; Hui, H.H.; Wei, Y.W.; Wang, J.; Xu, Q.; Lei, X.Y.; Chen, J.J.; Zhu, J.L. Fabrication of UV-curable silicone coating with high transmittance and laser-induced damage threshold for high-power laser system. J. Sol.-Gel Sci. Technol. 2018, 88, 249–254. [Google Scholar] [CrossRef]

- Elzaabalawy, A.; Pieter, V.; Meguid, S.A. Multifunctional silica-silicone nanocomposite with regenerative superhydrophobic capabilities. ACS Appl. Mater. Inter. 2019, 11, 42827–42837. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhang, C.; Sun, J.; Ding, R.; Zhang, Q.; Xu, Y. A double-layer moisture barrier & antireflective film based on bridged polysilsesquioxane and porous silica. RSC Adv. 2015, 5, 56998–57005. [Google Scholar]

- Parsaee, A.; Shokrieh, M.M. Hydrophobic properties of a vulcanized silicone-based nanocomposite coating exposed to heat, sulfuric acid and the ultraviolet radiation. Mater. Res. Express 2019, 6, 015014. [Google Scholar] [CrossRef]

- Bernsmeier, D.; Polte, J.; Ortel, E.; Krahl, T.; Kemnitz, E.; Kraehnert, R. Antireflective coatings with adjustable refractive index and porosity synthesized by Micelle-templated deposition of MgF2 sol particles. ACS Appl. Mater. Inter. 2014, 6, 19559–19565. [Google Scholar] [CrossRef]

- Liu, C.C.; Li, J.G.; Kuo, S.W. Co-template method provides hierarchical mesoporous silicas with exceptionally ultra-low refractive indices. RSC Adv. 2014, 4, 20262–20272. [Google Scholar] [CrossRef]

- Hsueh, H.Y.; Chen, H.Y.; She, M.S.; Chen, C.K.; Ho, R.M.; Gwo, S.; Hasegawa, H.; Thomas, E.L. Inorganic gyroid with exceptionally low refractive index from block copolymer templating. Nano. Lett. 2010, 10, 4994–5000. [Google Scholar] [CrossRef]

- Hulkkonen, H.H.; Salminen, T.; Niemi, T. Block copolymer patterning for creating porous silicon thin films with tunable refractive indices. ACS Appl. Mater. Inter. 2017, 9, 31260–31265. [Google Scholar] [CrossRef]

- Landwehr, J.; Fader, R.; Rumler, M.; Rommel, M.; Bauer, A.J.; Frey, L.; Simon, B.; Fodor, B.; Petrik, P.; Schiener, A.; et al. Optical polymers with tunable refractive index for nanoimprint technologies. Nanotechnology 2014, 25, 505301. [Google Scholar] [CrossRef] [PubMed]

- Tsai, C.L.; Liou, G.S. Highly transparent and flexible polyimide/ZrO2 nanocomposite optical films with a tunable refractive index and Abbe number. Chem. Commun. 2015, 51, 13523–13526. [Google Scholar] [CrossRef] [PubMed]

- Mohamed-Noriega, N.; Hinojosa, M.; Gonzalez, V.; Rodil, S.E. Polymer-based composite with outstanding mechanically tunable refractive index. Opt. Mater. 2016, 58, 18–23. [Google Scholar] [CrossRef]

- Seo, Y.; Cho, S.; Kim, S.; Choi, S.; Kim, H. Synthesis of refractive index tunable silazane networks for transparent glass fiber reinforced composite. Ceram. Int. 2017, 43, 7895–7900. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, G.Y.; Liang, X.; Zhang, W.S.; Zhou, L.; He, B.F.; Song, P.; Yuan, X.; Zhang, C.H.; Zhang, L.Y.; et al. Thermally stable transparent sol-gel based active siloxane-oligomer materials with tunable high refractive index and dual reactive groups. RSC Adv. 2016, 6, 70825–70831. [Google Scholar] [CrossRef]

- Wang, S.; Chen, K.; Wang, Q. Ytterbium triflate immobilized on sulfo-functionalized SBA-15 catalyzed conversion of cellulose to lactic acid. J. Porous Mat. 2018, 25, 1531–1539. [Google Scholar] [CrossRef]

- Ataollahi, N.; Cappelletto, E.; Vezzu, K.; Di Noto, V.; Cavinato, G.; Callone, E.; Dire, S.; Scardi, P.; Di Maggio, R. Properties of anion exchange membrane based on polyamine: Effect of functionalized silica particles prepared by sol-gel method. Solid State Ionics 2018, 322, 85–92. [Google Scholar] [CrossRef]

- Meyer-ter-Vehn, J. Prospects of inertial confinement fusion. Plasma Phys. Contr. F 1997, 39, B39–B45. [Google Scholar] [CrossRef]

- Miller, G.H.; Moses, E.I.; Wuest, C.R. The national ignition facility. Opt. Eng. 2004, 43, 2841–2853. [Google Scholar] [CrossRef]

- Moses, E.I.; Wuest, C.R. The national ignition facility: Laser performance and first experiments. Fusion Sci. Technol. 2005, 47, 314–322. [Google Scholar] [CrossRef]

- Deng, X.R.; Yang, W.; Hui, H.H.; Zhang, Q.H.; Xu, Q.; Chen, J.J.; Zhu, J.L.; Lei, X.Y. Silica-Based Sol-Gel Coating with high transmission at 1053 and 527 nm and absorption at 351 nm for frequency-converting crystals in high-power laser system. Appl. Sci. 2019, 9, 5038. [Google Scholar] [CrossRef] [Green Version]

- Hu, D.; Liu, D.; Zhang, J.; Wu, L.; Li, W. Preparation and stability study of broadband anti-reflection coatings and application research for CdTe solar cell. Opt. Mater. 2018, 77, 132–139. [Google Scholar] [CrossRef]

- Khan, S.B.; Irfan, S.; Zheng, Z.; Lee, S.L. Influence of refractive index on antireflectance efficiency of thin films. Materials 2019, 12, 1483. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ye, L.; Ge, X.; Wang, X.; Hui, Z.; Zhang, Y. Design and preparation of durable double-layer non-quarter-wave antireflective coatings. Ceram. Int. 2019, 45, 8504–8509. [Google Scholar] [CrossRef]

- Ristau, D.; Jupe, M.; Starke, K. Laser damage thresholds of optical coatings. Thin Solid Films 2009, 518, 1607–1613. [Google Scholar] [CrossRef]

- Krupta, R.; Giesen, A. Photothermal study of optical components at 10.6 µm: Finite element calculations and experiments. Proc. SPIE 1996, 2714, 156–165. [Google Scholar]

- Zhao, Q.; Wu, Z.; Thomsen, M.; Han, Y.; Fan, Z. Interfacial effects on the transient temperature rise of multilayer coatings induced by a short-pulse laser irradiation. Proc. SPIE 1998, 3244, 491–498. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, X.-R.; Lei, X.-Y.; Yang, W.; Hui, H.-H.; Wang, T.-Y.; Chen, J.-J.; Zhu, J.-L.; Zhang, Q.-H. Template-Free Fabrication of Refractive Index Tunable Polysiloxane Coating Using Homogeneous Embedding Strategy: Application in High-Power Laser System. Nanomaterials 2020, 10, 381. https://doi.org/10.3390/nano10020381

Deng X-R, Lei X-Y, Yang W, Hui H-H, Wang T-Y, Chen J-J, Zhu J-L, Zhang Q-H. Template-Free Fabrication of Refractive Index Tunable Polysiloxane Coating Using Homogeneous Embedding Strategy: Application in High-Power Laser System. Nanomaterials. 2020; 10(2):381. https://doi.org/10.3390/nano10020381

Chicago/Turabian StyleDeng, Xue-Ran, Xiang-Yang Lei, Wei Yang, Hao-Hao Hui, Tian-Yu Wang, Jin-Ju Chen, Ji-Liang Zhu, and Qing-Hua Zhang. 2020. "Template-Free Fabrication of Refractive Index Tunable Polysiloxane Coating Using Homogeneous Embedding Strategy: Application in High-Power Laser System" Nanomaterials 10, no. 2: 381. https://doi.org/10.3390/nano10020381

APA StyleDeng, X. -R., Lei, X. -Y., Yang, W., Hui, H. -H., Wang, T. -Y., Chen, J. -J., Zhu, J. -L., & Zhang, Q. -H. (2020). Template-Free Fabrication of Refractive Index Tunable Polysiloxane Coating Using Homogeneous Embedding Strategy: Application in High-Power Laser System. Nanomaterials, 10(2), 381. https://doi.org/10.3390/nano10020381