Optically-Thin Broadband Graphene-Membrane Photodetector

Abstract

:1. Introduction

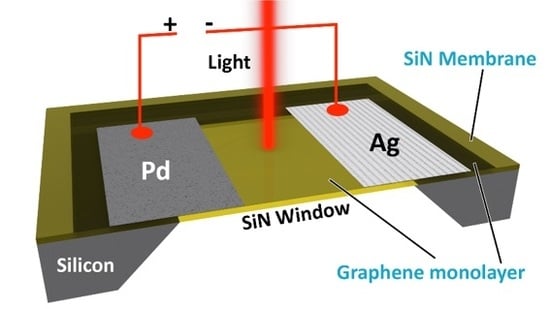

2. Experimental: Samples and Procedures

3. Results

3.1. Large Area Photodetector

3.2. Photodetector for a Small Detection Area

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mak, K.F.; Sfeir, M.Y.; Wu, Y.; Lui, C.H.; Misewich, J.A.; Heinz, T.F. Measurement of the optical conductivity of graphene. Phys. Rev. Lett. 2008, 101, 196405. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Q.; Henriksen, E.A.; Jiang, Z.; Hao, Z.; Martin, M.C.; Kim, P.; Stormer, H.L.; Basov, D.N. Dirac charge dynamics in graphene by infrared spectroscopy. Nat. Phys. 2008, 4, 532–535. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Zhang, Y.; Tian, C.; Girit, C.; Zettl, A.; Crommie, M.; Shen, Y.R. Gate-variable optical transitions in graphene. Science 2008, 320, 206–209. [Google Scholar] [CrossRef] [PubMed]

- Mueller, T.; Xia, F.; Avouris, P. Graphene photodetectors for high-speed optical communications. Nat. Photon. 2010, 4, 297–301. [Google Scholar] [CrossRef] [Green Version]

- Castro Neto, H.; Guinea, F.; Peres, N.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef] [Green Version]

- Bonaccorso, F.; Sun, Z.; Hasan, T.; Ferrari, A.C. Graphene photonics and optoelectronics. Nat. Photon. 2010, 4, 611–622. [Google Scholar] [CrossRef] [Green Version]

- Xia, F.; Mueller, T.; Lin, Y.M.; Valdes-Garcia, A.; Avouris, P. Ultrafast graphene photodetector. Nat. Nanotech. 2009, 4, 839–843. [Google Scholar] [CrossRef] [Green Version]

- Yan, J.; Kim, M.H.; Elle, J.A.; Sushkov, A.B.; Jenkins, G.S.; Milchberg, H.M.; Fuhrer, M.S.; Drew, H.D. Dual-gated bilayer graphene hot-electron bolometer. Nat. Nanotechnol. 2012, 7, 472–478. [Google Scholar] [CrossRef]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.; Geim, A.K. Fine structure constant defines visual transparency of graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Tang, T.T.; Girit, C.; Hao, Z.; Martin, M.C.; Zettl, A.; Crommie, M.F.; Shen, Y.R.; Wang, F. Direct observation of a widely tunable bandgap in bilayer graphene. Nature 2009, 459, 820–823. [Google Scholar] [CrossRef]

- Ryzhii, V.; Mitin, V.; Ryzhii, M.; Ryabova, N.; Otsuji, T. Device model for graphene nanoribbon phototransistor. Appl. Phys. Express 2008, 1, 063002. [Google Scholar] [CrossRef] [Green Version]

- Koppens, F.H.L.; Mueller, T.; Avouris, P.; Ferrari, A.C.; Vitiello, M.S.; Polini, M. Photodetectors based on graphene, other two-dimensional materials and hybrid systems. Nat. Nanotechnol. 2014, 9, 780–793. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.; Balasubramanian, K.; Weitz, R.T.; Burghard, M.; Kern, K. Contact and edge effects in graphene devices. Nat. Nanotechnol. 2008, 3, 486–490. [Google Scholar] [CrossRef] [PubMed]

- Xia, F.; Mueller, T.; Golizadeh-Mojarad, R.; Freitag, M.; Lin, Y.M.; Tsang, J.; Perebeinos, V.; Avouris, P. Photocurrent imaging and efficient photon detection in a graphene transistor. Nano Lett. 2009, 9, 1039–1044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, J.; Ahn, Y.H.; Ruiz-Vargas, C. Imaging of photocurrent generation and collection in single-layer graphene. Nano Lett. 2009, 9, 1742–1746. [Google Scholar] [CrossRef] [PubMed]

- Thompson, J.D.; Zwickl, B.M.; Jayich, A.M.; Marquardt, F.; Girvin, S.M.; Harris, J. Strong dispersive coupling of a high-finesse cavity to a micromechanical membrane. Nature 2008, 452, 72–75. [Google Scholar] [CrossRef] [Green Version]

- Kippenberg, T.J.; Vahala, K.J. Cavity Opto-Mechanics. Opt. Express 2007, 15, 17172–17205. [Google Scholar] [CrossRef]

- Schmid, S.; Bagci, T.; Zeuthen, E.; Taylor, J.M.; Herring, P.K.; Cassidy, M.C.; Marcus, C.M.; Villanueva, L.G.; Amato, B.; Boisen, A.; et al. Single-layer graphene on silicon nitride micromembrane resonators. J. Appl. Phys. 2014, 115, 054513. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; John, S. Broadband light-trapping enhancement of graphene absorptivity. Phys. Rev. B 2019, 99, 035417. [Google Scholar] [CrossRef] [Green Version]

- Kohli, P.; Chatterton, J.; Stieler, D.; Tuttle, G.; Li, M.; Hu, X.; Ye, Z.; Ho, K.M. Fine tuning resonant frequencies for a single cavity defect in three-dimensional layer-by-layer photonic crystal. Optics Express 2008, 16, 19844. [Google Scholar] [CrossRef]

- Stieler, D.; Barsic, A.; Biswas, R.; Tuttle, G.; Ho, K.M. A Four-port Channel Drop Filter in The Three-dimensional Woodpile Photonic Crystal. Chin. J. Luminescence 2018, 39, 1036–1041. [Google Scholar] [CrossRef] [PubMed]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast laser processing of materials: From science to industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Campbell, J.; Stein, O.; Jiang, L.; Hund, J.; Lu, Y. Deformation Behavior of Foam Laser Targets Fabricated by Two-Photon Polymerization. Nanomaterials 2018, 8, 498. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moon, D.I.; Kim, B.; Peterson, R.; Badokas, K.; Seol, M.L.; Senesky, D.G.; Han, J.W.; Meyyappan, M. A Single Input Multiple Output (SIMO) Variation-Tolerant Nanosensor. ACS Sens. 2018, 3, 1782–1788. [Google Scholar] [CrossRef]

- Gailevičius, D.; Hayran, Z.; Turduev, M.; Kurt, H.; Juodkazis, S.; Malinauskas, M.; Mizeikis, V.; Staliunas, K. Nanostructures for highly efficient infrared detection. In Advanced Fabrication Technologies for Micro/Nano Optics and Photonics XI; von Freymann, G., Schoenfeld, W.V., Rumpf, R.C., Eds.; SPIE Proc: Bellingham, WA, USA, 2017; Volume 10115, p. 101150Z. [Google Scholar]

- Hayran, Z.; Kurt, H.; Staliunas, K. Rainbow trapping in a chirped three-dimensional photonic crystal. Sci. Rep. 2017, 7, 3046. [Google Scholar] [CrossRef] [Green Version]

- Suk, M.E.; Aluru, N. Water transport through ultrathin graphene. J. Phys. Chem. Lett. 2010, 1, 1590–1594. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Z.; Chen, Z.; Xu, J.B.; Tsang, H.K.; Shu, C. Graphene photodetector integrated on silicon nitride waveguide. J. Appl. Phys. 2015, 117, 144504. [Google Scholar] [CrossRef]

- Gao, Y.; Tao, L.; Tsang, H.K.; Shu, C. Graphene-on-silicon nitride waveguide photodetector with interdigital contacts. Appl. Phys. Lett. 2018, 112, 211107. [Google Scholar] [CrossRef]

- Maniscalco, B.; Kaminski, P.; Walls, J. Thin film thickness measurements using Scanning White Light Interferometry. Thin Solid Films 2014, 550, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Juodkazis, S.; Nishi, Y.; Misawa, H.; Mizeikis, V.; Schecker, O.; Waitz, R.; Leiderer, P.; Scheer, E. Optical transmission and laser structuring of silicon membranes. Opt. Express 2009, 17, 15308–15317. [Google Scholar] [CrossRef]

- Moein, T.; Gailevičius, D.; Katkus, T.; Ng, S.H.; Moss, D.J.; Malinauskas, M.; Juodkazis, S. Graphene bolometer for vis-IR spectral range made on nano-SiN membrane. In Advanced Fabrication Technologies for Micro/Nano Optics and Photonics XI; von Freymann, G., Schoenfeld, W.V., Rumpf, R.C., Eds.; SPIE, Proc: Bellingham, WA, USA, 2018; Volume 10544, p. 105440H. [Google Scholar]

- Cai, X.; Sushkov, A.B.; Suess, R.J.; Jadidi, M.M.; Jenkins, G.S.; Nyakiti, L.O.; Myers-Ward, R.L.; Li, S.; Yan, J.; Gaskill, D.K.; et al. Sensitive room-temperature terahertz detection via the photothermoelectric effect in graphene. Nat. Nanotechnol. 2014, 9, 814–819. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Scagliotti, M.; Salvato, M.; Crescenzi, M.; Boscardin, M.; Castrucci, P. Infuence of the contact geometry on single-walled carbon nanotube/Si photodetector response. Appl. Nanosci. 2018, 8, 780–793. [Google Scholar] [CrossRef]

- Gan, Z.; Wang, C.; Chen, Z. Material Structure and Mechanical Properties of Silicon Nitride and Silicon Oxynitride Thin Films Deposited by Plasma Enhanced Chemical Vapor Deposition. Surfaces 2018, 1, 59–72. [Google Scholar] [CrossRef] [Green Version]

- Gopalan, K.K.; Janner, D.; Nanot, S.; Parret, R.; Lundeberg, M.B.; Koppens, F.; Pruneri, V. Mid-Infrared Pyroresistive Graphene Detector on LiNbO3. Adv. Opt. Mater. 2017, 5. [Google Scholar] [CrossRef] [Green Version]

- Cougnon, F.G.; Depla, D. The Seebeck Coefficient of Sputter Deposited Metallic Thin Films: The Role of Process Conditions. Coatings 2019, 9, 299. [Google Scholar] [CrossRef] [Green Version]

- Kockert, M.; Mitdank, R.; Zykov, A.; Kowarik, S.; Fischer, S.F. Absolute Seebeck coefficient of thin platinum films. J. Appl. Phys. 2019, 129, 105106. [Google Scholar] [CrossRef] [Green Version]

- Balčytis, A.; Ryu, M.; Juodkazis, S.; Morikawa, J. Micro-thermocouple on nano-membrane: thermometer for nanoscale measurements. Sci. Rep. 2018, 8, 6324. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moein, T.; Gailevičius, D.; Katkus, T.; Ng, S.H.; Lundgaard, S.; Moss, D.J.; Kurt, H.; Mizeikis, V.; Staliūnas, K.; Malinauskas, M.; et al. Optically-Thin Broadband Graphene-Membrane Photodetector. Nanomaterials 2020, 10, 407. https://doi.org/10.3390/nano10030407

Moein T, Gailevičius D, Katkus T, Ng SH, Lundgaard S, Moss DJ, Kurt H, Mizeikis V, Staliūnas K, Malinauskas M, et al. Optically-Thin Broadband Graphene-Membrane Photodetector. Nanomaterials. 2020; 10(3):407. https://doi.org/10.3390/nano10030407

Chicago/Turabian StyleMoein, Tania, Darius Gailevičius, Tomas Katkus, Soon Hock Ng, Stefan Lundgaard, David J. Moss, Hamza Kurt, Vygantas Mizeikis, Kȩstutis Staliūnas, Mangirdas Malinauskas, and et al. 2020. "Optically-Thin Broadband Graphene-Membrane Photodetector" Nanomaterials 10, no. 3: 407. https://doi.org/10.3390/nano10030407

APA StyleMoein, T., Gailevičius, D., Katkus, T., Ng, S. H., Lundgaard, S., Moss, D. J., Kurt, H., Mizeikis, V., Staliūnas, K., Malinauskas, M., & Juodkazis, S. (2020). Optically-Thin Broadband Graphene-Membrane Photodetector. Nanomaterials, 10(3), 407. https://doi.org/10.3390/nano10030407