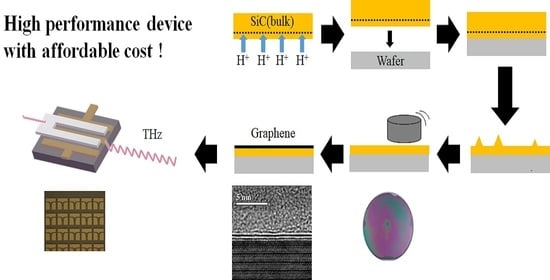

High-Quality Few-Layer Graphene on Single-Crystalline SiC thin Film Grown on Affordable Wafer for Device Applications

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. High Film Quality of the SiC Thin Film in the Hybrid SiC

3.2. High Film-Quality FLG Growth on the Hybrid SiC

3.3. Electronic Structure of FLG on the Hybrid SiC

3.4. Transport Properties of FLG on the Hybrid SiC

3.5. Device Performances of FET Using FLG on the Hybrid SiC

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wallace, P.R. The band theory of graphite. Phys. Rev. 1947, 71, 622–634. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Berger, C.; Song, Z.; Li, T.; Li, X.; Ogbazghi, A.Y.; Feng, R.; Dai, Z.; Marchenkov, A.N.; Conrad, E.H.; First, P.N.; et al. Ultrathin epitaxial graphene: 2D electron gas properties and a route toward graphite-based nanoelectronics. J. Phys. Chem. B 2004, 108, 19912–19916. [Google Scholar] [CrossRef] [Green Version]

- Castro Neto, A.H.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef] [Green Version]

- Someya, T.; Fukidome, H.; Ishida, Y.; Yoshida, R.; Iimori, T.; Yukawa, R.; Akikuno, K.; Yamamoto, S.; Yamamoto, S.; Yamamoto, T.; et al. Observing hot carrier distribution in an n-type epitaxial graphene on a SiC substrate. Appl. Phys. Lett. 2014, 104, 161103. [Google Scholar] [CrossRef]

- Ando, T.; Nakanishi, T.; Saito, R. Berry’s Phase and Absence of Back Scattering in Carbon Nanotubes. J. Phys. Soc. Jpn. 1998, 67, 2857–2862. [Google Scholar] [CrossRef] [Green Version]

- Avouris, P. Graphene: Electronic and Photonic Properties and Devices. Nano Lett. 2010, 10, 4285–4294. [Google Scholar] [CrossRef]

- Schwierz, F. Graphene transistors. Nat. Nanotechnol. 2010, 5, 487–496. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Fal′ko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Sun, Z.; Hasan, T.; Ferrari, A.C. Graphene photonics and optoelectronics. Nat. Photon. 2010, 4, 611–622. [Google Scholar] [CrossRef] [Green Version]

- Boubanga-Tombet, S.; Chan, S.; Watanabe, T.; Satou, A.; Ryzhii, V.; Otsuji, T. Ultrafast carrier dynamics and terahertz emission in optically pumped graphene at room temperature. Phys. Rev. B 2012, 85, 035443. [Google Scholar] [CrossRef]

- Tonouchi, M. Cutting-edge terahertz technology. Nat. Photon. 2010, 1, 97–105. [Google Scholar] [CrossRef]

- Sutter, P.; Sutter, E. Microscopy of Graphene Growth, Processing, and Properties. Adv. Funct. Mater. 2013, 23, 2617–2634. [Google Scholar] [CrossRef]

- Emtsev, K.V.; Bostwick, A.; Horn, K.; Jobst, J.; Kellogg, G.L.; Ley, L.; McChesney, J.L.; Ohta, T.; Reshanov, S.A.; Röhrl, J.; et al. Towards wafer-size graphene layers by atmospheric pressure graphitization of silicon carbide. Nat. Mater. 2009, 8, 203–207. [Google Scholar] [CrossRef]

- Sprinkle, M.; Siegel, D.; Hu, Y.; Hicks, J.; Tejeda, A.; Taleb-Ibrahimi, A.; Le Fèvre, P.; Bertran, F.; Vizzini, S.; Enriquez, H.; et al. First direct observation of a nearly ideal graphene band structure. Phys. Rev. Lett. 2009, 103, 226803. [Google Scholar] [CrossRef] [Green Version]

- Fukidome, H.; Kawai, Y.; Fromm, F.; Kotsugi, M.; Handa, H.; Ide, T.; Ohkouchi, T.; Miyashita, H.; Enta, Y.; Kinoshita, T.; et al. Precise control of epitaxy of graphene by microfabricating SiC substrate. Appl. Phys. Lett. 2012, 101, 041605. [Google Scholar] [CrossRef] [Green Version]

- Lauffer, P.; Emtsev, K.V.; Graupner, R.; Seyller, T.; Ley, L.; Reshanov, S.A.; Weber, H.B. Atomic and electronic structure of few-layer graphene on SiC(0001) studied with scanning tunnelling microscopy and spectroscopy. Phys. Rev. B 2008, 77, 155426. [Google Scholar] [CrossRef]

- Ohta, T.; Bostwick, A.; Seyller, T.; Horn, K.; Rotenberg, E. Controlling the electronic structure of bilayer graphene. Science 2006, 313, 951–954. [Google Scholar] [CrossRef] [Green Version]

- Michetti, P.; Cheli, M.; Iannaccone, G. Model of tunneling transistors based on graphene on SiC. Appl. Phys. Lett. 2012, 96, 133508. [Google Scholar] [CrossRef] [Green Version]

- Miyamoto, Y.; Handa, H.; Saito, E.; Konno, A.; Narita, Y.; Suemitsu, M.; Fukidome, H.; Ito, T.; Yasui, K.; Nakazawa, H.; et al. Raman-scattering spectroscopy of epitaxial graphene formed on Si substrate. e-J. Surf. Sci. Nanotechnol. 2009, 7, 107–109. [Google Scholar] [CrossRef] [Green Version]

- Fukidome, H.; Miyamoto, Y.; Handa, H.; Suemitsu, M. Epitaxial growth processes of graphene on silicon substrates. Jpn. J. Appl. Phys. 2010, 49, 01AH03. [Google Scholar] [CrossRef]

- Fukidome, H.; Abe, S.; Takahashi, R.; Imaizumi, K.; Inomata, S.; Handa, H.; Saito, E.; Enta, Y.; Yoshigoe, A.; Teraoka, Y. Controls over structural and electronic properties of epitaxial graphene on silicon using surface termination of 3C-SiC(111)/Si. Appl. Phys. Exp. 2011, 4, 115104. [Google Scholar] [CrossRef]

- Fukidome, H.; Takahashi, R.; Abe, S.; Imaizumi, K.; Handa, H.; Kang, H.-C.; Karasawa, H.; Suemitsu, T.; Otsuji, T.; Enta, Y.; et al. Control of epitaxy of graphene by crystallographic orientation of a Si substrate toward device applications. J. Mater. Chem. 2011, 21, 17242–17248. [Google Scholar] [CrossRef]

- Fukidome, H.; Kawai, Y.; Handa, H.; Hibino, H.; Miyashita, H.; Kotsugi, M.; Ohkochi, T.; Jung, M.-H.; Suemitsu, T.; Kinoshita, T.; et al. Site-selective epitaxy of graphene on Si wafers. Proc. IEEE 2013, 101, 1557–1566. [Google Scholar] [CrossRef]

- Fukidome, H.; Ide, T.; Kawai, T.; Shinohara, T.; Nagamura, N.; Horiba, K.; Kotsugi, M.; Ohkochi, T.; Kinoshita, T.; Kumighashira, H.; et al. Microscopically-Tuned Band Structure of Epitaxial Graphene through Interface and Stacking Variations Using Si Substrate Microfabrication. Sci. Rep. 2014, 4, 5173. [Google Scholar] [CrossRef] [Green Version]

- Kawai, M.; Kubota, Y. The Method for Producing Nanocarbon Film and Nanocarbon Film; International patent publication number: WO 2014/061337 A1; International Patent Publication Date: 24.04.2014; ShinEtsu Chemical Co., Ltd.: Tokyo, Japan, 2014. [Google Scholar]

- Fukidome, H.; Kotsugi, M.; Nagashio, K.; Sato, R.; Ohkouchi, T.; Itoh, T.; Toriumi, A.; Suemitsu, M.; Kinoshita, T. Orbital-Specific Tunability of Man-Body Effects in Bilayer Graphene by Gate Bias and Metal Contact. Sci. Rep. 2014, 4, 3713. [Google Scholar] [CrossRef] [Green Version]

- Hasegawa, M.; Tashima, K.; Kotsugi, M.; Ohkochi, T.; Suemitsu, M.; Fukidome, H. Inhomogeneous Longitudinal Distribution of Ni Atoms on Graphene Induced by Layer-Dependent Internal Diffusion. Appl. Phys. Lett. 2016, 109, 111604. [Google Scholar] [CrossRef]

- Hibino, H.; Kageshima, H.; Maeda, F.; Nagase, M.; Kobayashi, Y.; Yamaguchi, H. Microscopic thickness determination of thin graphite films formed on SiC from quantized oscillation in reflectivity of low-energy electrons. Phys. Rev. B 2008, 77, 075413. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.-S.; Park, G.-H.; Fukidome, H.; Someya, T.; Iimori, T.; Fumio, K.; Matsuda, I.; Suemitsu, M. A table-top formation of bilayer quasi-free-standing epitaxialgraphene on SiC(0001) by microwave annealing in air. Carbon 2018, 130, 792–798. [Google Scholar] [CrossRef] [Green Version]

- Handa, H.; Takahashi, R.; Abe, S.; Imaizumi, K.; Saito, E.; Jung, M.-H.; Ito, S.; Fukidome, H.; Suemitsu, M. Transmission Electron Microscopy and Raman-Scattering Spectroscopy Observation on the Interface Structure of Graphene Formed on Si Substrates with Various Orientations. Jpn. J. Appl. Phys. 2011, 50, 04DH02. [Google Scholar] [CrossRef]

- Emstev, K.V.; Speck, F.; Seyller, T.; Ley, L. Interaction, growth, and ordering of epitaxial graphene on SiC{0001} surfaces: A comparative photoelectron spectroscopy study. Phys. Rev. B 2008, 77, 155303. [Google Scholar] [CrossRef] [Green Version]

- Riedl, C.; Coletti, C.; Starke, U. Structural and electronic properties of epitaxial graphene on SiC(0001): A review of growth, characterization, transfer doping and hydrogen intercalation. J. Phys. D Appl. Phys. 2010, 43, 374009. [Google Scholar] [CrossRef] [Green Version]

- Norimatsu, W.; Kusunoki, M. Transitional structures of the interface between graphene and 6H–SiC (0001). Chem. Phys. Lett. 2009, 468, 52–56. [Google Scholar] [CrossRef]

- Norimatsu, W.; Kusunoki, M. Epitaxial graphene on SiC{0001}: Advances and perspectives. Phys. Chem. Chem. Phys. 2014, 16, 3501–3511. [Google Scholar] [CrossRef] [PubMed]

- Cançado, L.G.; Takai, K.; Enoki, T.; Takai, K.; Enoki, T. General equation for the determination of the crystallite size La of nanographite by Raman spectroscopy. Appl. Phys. Lett. 2006, 88, 163106. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef] [Green Version]

- Caldwell, J.D.; Anderson, T.J.; Culbertson, J.C.; Jernigan, G.G.; Hobart, K.D.; Kub, F.J.; Tadjer, M.J.; Teesco, J.L.; Hite, J.K.; Mastro, M.A.; et al. Technique for the Dry Transfer of Epitaxial Graphene onto Arbitrary Substrates. ACS Nano 2010, 4, 1108–1114. [Google Scholar] [CrossRef] [Green Version]

- Hibino, H.; Kageshima, H.; Maeda, F.; Nagase, M.; Kobayashi, Y.; Kobayashi, Y.; Yamaguchi, H. Thickness Determination of Graphene Layers Formed on SiC Using Low-Energy Electron Microscopy. e-J. Surf. Sci. Nanotech. 2008, 6, 107–110. [Google Scholar] [CrossRef] [Green Version]

- Hass, J.; de Heer, W.A.; Conrad, E.H. The growth and morphology of epitaxial multilayer graphene. J. Phys. Condens. Matter. 2008, 20, 323202. [Google Scholar] [CrossRef]

- Rotenberg, E.; Bostwick, A.; Ohta, T.; McChesney, J.L.; Seyller, T.; Horn, K. Origin of the energy gap in epitaxial graphene. Nat. Mater. 2008, 7, 258–259. [Google Scholar] [CrossRef] [Green Version]

- McCann, E.; Fal’ko, V.I. Landau-Level Degeneracy and Quantum Hall Effect in a Graphite Bilayer. Phys. Rev. Lett. 2006, 96, 086805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tedesco, J.L.; VanMil, B.L.; Myers-Ward, R.L.; McCrate, J.M.; Kitt, S.A.; Campbell, P.M.; Jernigan, G.G.; Culbertson, J.C.; Eddy, C.R., Jr.; Gaskill, D.K. Hall effect mobility of epitaxial graphene grown on silicon carbide. Appl. Phys. Lett. 2009, 95, 122102. [Google Scholar] [CrossRef]

- Ray, N.; Shallcoress, S.; Hensel, S.; Pankratov, O. Buffer layer limited conductivity in epitaxial graphene on the Si face of SiC. Phys. Rev. B 2012, 86, 125426. [Google Scholar] [CrossRef]

- Minamitani, E.; Arafune, R.; Frederiksen, T.; Suzuki, T.; Shahed, S.M.F.; Kobayashi, T.; Endo, N.; Fukidome, H.; Watanabe, S.; Komeda, T. Atomic-scale characterization, of the interfacial phonon in graphene/SiC. Phys. Rev. B 2017, 96, 155431. [Google Scholar] [CrossRef]

- Fratini, S.; Guinea, F. Substrate-limited electron dynamics in graphene. Phys. Rev. B 2008, 77, 195415. [Google Scholar] [CrossRef] [Green Version]

- Brown, M.A.; Crosser, M.S.; Leyden, M.R.; Qi, Y.; Minot, E.D. Measurement of high carrier mobility in graphene in an aqueous electrolyte environment. Appl. Phys. Lett. 2016, 109, 093104. [Google Scholar] [CrossRef] [Green Version]

- Schwierz, F. Graphene Transistors: Status, Prospects, and Problems. Proc. IEEE 2013, 101, 1567–1584. [Google Scholar] [CrossRef]

- Wang, X.; Ouyang, Y.; Li, X.; Wang, H.; Guo, J.; Dai, H. Room-Temperature All-Semiconducting Sub-10-nm Graphene Nanoribbon Field-Effect Transistors. Phys. Rev. Lett. 2008, 100, 206803. [Google Scholar] [CrossRef] [Green Version]

- Han, S.J.; Reddy, D.; Carpenter, G.D.; Franklin, A.D.; Jenkins, K.A. Current Saturation in Submicrometer Graphene Transistors with Thin Gate Dielectric; Experiment, Simulation, and Theory. ACS Nano 2012, 6, 5220–5226. [Google Scholar] [CrossRef]

- Moon, J.S.; Curtis, D.; Bui, S.; Hu, M.; Gaskill, D.K.; Tedesco, J.L.; Asbeck, P.; Jernigan, G.G.; VanMil, B.L.; Myers-Ward, R.L.; et al. Top-gated Epitaxial Graphene FETs on Si-Face SiC Wafers with a Peak Transconductance of 600 mS/mm. IEEE Electron Device Lett. 2010, 31, 260–262. [Google Scholar] [CrossRef]

- Bai, J.W.; Liao, L.; Zhou, H.; Cheng, R.; Liu, L.; Huang, Y.; Duan, X.F. Top-Gated Chemical Vapor Deposition Grown Graphene Transistors with Current Saturation. Nano Lett. 2011, 11, 2555–2559. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meric, I.; Dean, C.R.; Young, A.F.; Balitskaya, N.; Trembly, N.J.; Nuckolls, C.; Kim, P.; Shepard, K.L. Channel Length Scaling in Graphene Field-Effect Transistors Studied with Pulsed Current-Voltage Measurements. Nano Lett. 2011, 11, 1093–1097. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Xu, H.; Zhang, Z.; Wang, S.; Ding, L.; Zeng, Q.; Yang, L.; Pei, T.; Liang, X.; Gao, M.; et al. Growth and Performance of Yttrium Oxide as an Ideal High-κ Gate Dielectric for Carbon-Based Electronics. Nano Lett. 2010, 10, 2024–2030. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Nah, J.; Jo, I.; Shahrjerdi, D.; Colombo, L.; Yao, Z.; Tutuc, E.; Banerjee, S.K. Realization of a high mobility dual-gated graphene field-effect transistor with Al2O3 dielectric. Appl. Phys. Lett. 2009, 94, 062107. [Google Scholar] [CrossRef] [Green Version]

- Yu, C.; He, Z.; Song, B.; Liu, Q.B.; Han, T.T.; Dun, S.B.; Wang, J.J.; Zhou, C.J.; Guo, J.C.; Lv, Y.J.; et al. Improvement of the Frequency Characteristics of Graphene Field-Effect Transistors on SiC substrate. IEEE. Electron Dev. Lett. 2017, 38, 1339–1342. [Google Scholar] [CrossRef]

- Jung, M.-H.; Park, G.-H.; Yoshida, T.; Fukidome, H.; Suemitsu, T.; Otsuji, T.; Suemitsu, M. High-Performance Graphene Field-Effect Transistors with Extremely Small Access Length Using Self-Aligned Source and Drain Technique. Proc. IEEE 2013, 101, 1603–1608. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Endoh, N.; Akiyama, S.; Tashima, K.; Suwa, K.; Kamogawa, T.; Kohama, R.; Funakubo, K.; Konishi, S.; Mogi, H.; Kawahara, M.; et al. High-Quality Few-Layer Graphene on Single-Crystalline SiC thin Film Grown on Affordable Wafer for Device Applications. Nanomaterials 2021, 11, 392. https://doi.org/10.3390/nano11020392

Endoh N, Akiyama S, Tashima K, Suwa K, Kamogawa T, Kohama R, Funakubo K, Konishi S, Mogi H, Kawahara M, et al. High-Quality Few-Layer Graphene on Single-Crystalline SiC thin Film Grown on Affordable Wafer for Device Applications. Nanomaterials. 2021; 11(2):392. https://doi.org/10.3390/nano11020392

Chicago/Turabian StyleEndoh, Norifumi, Shoji Akiyama, Keiichiro Tashima, Kento Suwa, Takamasa Kamogawa, Roki Kohama, Kazutoshi Funakubo, Shigeru Konishi, Hiroshi Mogi, Minoru Kawahara, and et al. 2021. "High-Quality Few-Layer Graphene on Single-Crystalline SiC thin Film Grown on Affordable Wafer for Device Applications" Nanomaterials 11, no. 2: 392. https://doi.org/10.3390/nano11020392

APA StyleEndoh, N., Akiyama, S., Tashima, K., Suwa, K., Kamogawa, T., Kohama, R., Funakubo, K., Konishi, S., Mogi, H., Kawahara, M., Kawai, M., Kubota, Y., Ohkochi, T., Kotsugi, M., Horiba, K., Kumigashira, H., Suemitsu, M., Watanabe, I., & Fukidome, H. (2021). High-Quality Few-Layer Graphene on Single-Crystalline SiC thin Film Grown on Affordable Wafer for Device Applications. Nanomaterials, 11(2), 392. https://doi.org/10.3390/nano11020392