Transitioning from Si to SiGe Nanowires as Thermoelectric Material in Silicon-Based Microgenerators

Abstract

:1. Introduction

2. Materials and Methods

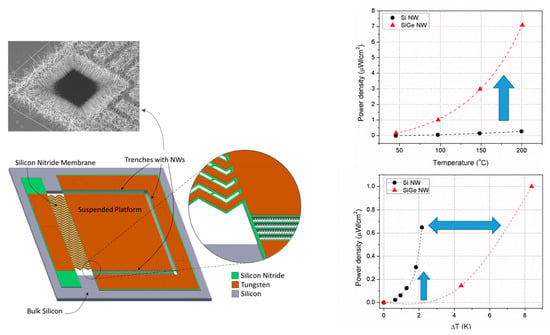

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ashton, K. That ‘internet of things’ thing. RFID J. 2009. Available online: https://www.rfidjournal.com/that-internet-of-things-thing (accessed on 19 December 2020).

- Newman, P. The Internet of Things 2020 Report, BI Intelligence (Preview). Available online: https://www.businessinsider.com/internet-of-things-report?IR=T (accessed on 19 December 2020).

- Whalley, S. TSensors and Exponential Abundance. Available online: https://www.aps.org/units/fiap/meetings/conference/upload/2-1-Whalley-Trillion-sensors.pdf (accessed on 19 December 2020).

- Brycek, J. The Trillion Sensors (TSensors) Foundation for the IoT. Available online: http://www.iot-inc.com/wp-content/uploads/2015/11/2-Janusz.pdf (accessed on 19 December 2020).

- Vullers, R.J.M.; van Schaijk, R.; Doms, I.; van Hoof, C.; Mertens, R. Micropower energy harvesting. Solid State Electron. 2009, 53, 684–693. [Google Scholar] [CrossRef]

- Rowe, D.M. Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manage. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Xi, X.-L.; Chen, Z.-G. Advanced thermoelectric design: From materials and structures to devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef]

- Haras, M.; Skotnicki, T. Thermoelectricity for IoT–A review. Nano Energy 2018, 54, 461–476. [Google Scholar] [CrossRef]

- Narducci, D. Thermoelectric harvesters and the internet of things: Technological and economic drivers. J. Phys. Energy 2019, 1, 024001. [Google Scholar] [CrossRef]

- Tarancon, A. Powering the IoT revolution with heat. Nat. Electron. 2019, 2, 270–271. [Google Scholar] [CrossRef]

- Hicks, L.D.; Dresselhaus, M.S. Thermoelectric figure of merit of a one-dimensional conductor. Phys. Rev. B Condens. Matter 1993, 47, 16631–16634. [Google Scholar] [CrossRef]

- Chen, R.; Lee, J.; Lee, W.; Li, D. Thermoelectrics of nanowires. Chem. Rev. 2019, 119, 9260–9302. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, L.; Santos, J.D.; Roncaglia, A.; Narducci, D.; Calaza, C.; Salleras, M.; Donmez, I.; Tarancon, A.; Morata, A.; Gadea, G.; et al. Smart integration of silicon nanowire arrays in all-silicon thermoelectric micro-nanogenerators. Semicond. Sci. Technol. 2016, 31, 084001. [Google Scholar] [CrossRef] [Green Version]

- Ziouche, K.; Yuan, Z.; Lejeune, P.; Lasri, T.; Leclercq, D.; Bougrioua, Z. Silicon-based monolithic planar micro thermoelectric generator using bonding technology. J. Microelectromech. Syst. 2017, 26, 45–47. [Google Scholar] [CrossRef]

- Dávila, D.; Tarancón, A.; Kendig, D.; Fernández-Regúlez, M.; Sabaté, N.; Salleras, M.; Calaza, C.; Cané, C.; Gràcia, I.; Figueras, E.; et al. Planar thermoelectric microgenerators based on silicon nanowires. J. Electron. Mater. 2011, 40, 851–855. [Google Scholar] [CrossRef]

- Davila, D.; Tarancon, A.; Fernandez-Regulez, M.; Calaza, C.; Salleras, M.; San Paulo, A.; Fonseca, L. Silicon nanowire arrays as thermoelectric material for a power microgenerator. J. Micromech. Microeng. 2011, 21, 104007. [Google Scholar] [CrossRef]

- Davila, D.; Tarancon, A.; Calaza, C.; Salleras, M.; Fernandez-Regulez, M.; San Paulo, A.; Fonseca, L. Monolithically integrated thermoelectric energy harvester based on silicon nanowire arrays for powering micro/nanodevices. Nano Energy 2012, 1, 812–819. [Google Scholar] [CrossRef]

- Donmez-Noyan, I.; Gadea, G.; Salleras, M.; Pacios, M.; Calaza, C.; Stranz, A.; Dolcet, M.; Morata, A.; Tarancon, A.; Fonseca, L. SiGe nanowire arrays based thermoelectric microgenerator. Nano Energy 2019, 57, 492–499. [Google Scholar] [CrossRef]

- Donmez-Noyan, I.; Dolcet, M.; Salleras, M.; Stranz, A.; Calaza, C.; Gadea, G.; Pacios, M.; Morata, A.; Tarancon, A.; Fonseca, L. All-silicon thermoelectric micro/nanogenerator including a heat exchanger for harvesting applications. J. Power Sources 2019, 413, 125–133. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Chen, R.; Diaz Delgado, R.; Liang, W.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P. Enhanced thermoelectric performance of rough silicon nanowires. Nature 2008, 451, 163–167. [Google Scholar] [CrossRef]

- Boukai, A.I.; Bunimovich, Y.; Tahir-Kheli, J.; Yu, J.-K.; Goddard III, W.A.; Heath, J.R. Silicon nanowires as efficient thermoelectric materials. Nature 2008, 451, 168–171. [Google Scholar] [CrossRef]

- Totaro, M.; Bruschi, P.; Pennelli, G. Top down fabricated silicon nanowire networks for thermoelectric applications. Microelectron. Eng. 2012, 97, 157–161. [Google Scholar] [CrossRef]

- Li, Y.; Buddharaju, K.; Singh, N.; Lee, S.J. Top-Down Silicon Nanowire-Based Thermoelectric Generator: Design and Characterization. J. Electron. Mater. 2012, 41, 989–992. [Google Scholar] [CrossRef]

- Tomita, M.; Oba, S.; Himeda, Y.; Yamato, R.; Shima, K.; Kumada, T.; Xu, M.; Takezawa, H.; Mesaki, K.; Tsuda, K.; et al. Modeling, Simulation, Fabrication, and Characterization of a 10-μW/cm² Class Si-Nanowire Thermoelectric Generator for IoT Applications. IEEE Trans. Electron Devices 2018, 65, 5180–5188. [Google Scholar] [CrossRef]

- Hu, G.; Edwards, H.; Lee, M. Silicon integrated circuit thermoelectric generators with a high specific power generation capacity. Nat. Electron. 2019, 2, 300–306. [Google Scholar] [CrossRef]

- Elyamny, S.; Dimaggio, E.; Magagna, S.; Narducci, D.; Pennelli, G. High Power Thermoelectric Generator Based on Vertical Silicon Nanowires. Nano Lett. 2020, 20, 4748–4753. [Google Scholar] [CrossRef] [PubMed]

- Gadea, G.; Morata, A.; Santos, J.D.; Davila, D.; Calaza, C.; Salleras, M.; Fonseca, L.; Tarancon, A. Towards a full integration of vertically aligned silicon nanowires in MEMS using silane as a precursor. Nanotechnology 2015, 26, 195302. [Google Scholar] [CrossRef] [Green Version]

- Gadea, G.; Sojo, J.M.; Pacios, M.; Salleras, M.; Fonseca, L.; Morata, A.; Tarancon, A. Enhanced thermoelectric figure of merit of individual Si nanowires with ultralow contact resistances. Nano Energy 2020, 57, 104191. [Google Scholar] [CrossRef]

- Fonseca, L.; Donmez, I.; Salleras, M.; Calaza, C.; Gadea, G.; Santos, J.D.; Morata, A.; Tarancon, A. Improved thermal isolation of silicon suspended platforms for an all-silicon thermoelectric microgenerator based on large scale integration of Si nanowires as thermoelectric material. J. Phys. Conf. Ser. 2015, 660, 012113. [Google Scholar] [CrossRef] [Green Version]

- Calaza, C.; Fonseca, L.; Salleras, M.; Donmez, I.; Tarancon, A.; Morata, A.; Santos, J.D.; Gadea, G. Thermal test of an improved platform for silicon nanowire-based thermoelectric micro-generators. J. Electron. Mater. 2016, 45, 1689–1694. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Xiang, Q.; Ze, R.; Ma, M.; Wang, S.; Xie, Q.; Xian, Y. Thermal and electrical analysis of SiGe thermoelectric unicouple filled with thermal insulation materials. Appl. Therm. Eng. 2018, 134, 266–274. [Google Scholar] [CrossRef]

- Pérez-Taborda, J.A.; Caballero-Calero, O.; Martín-González, M. Silicon-Germanium (SiGe) Nanostructures for Thermoelectric Devices: Recent Advances and New Approaches to High Thermoelectric Efficiency-Chapter 8. In New Research on Silicon-Structure, Properties, Technology; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef] [Green Version]

- Amato, M.; Palummo, M.; Rurali, R.; Ossicini, S. Silicon−Germanium Nanowires: Chemistry and Physics in Play, from Basic Principles to Advanced Applications. Chem. Rev. 2014, 114, 1371–1412. [Google Scholar] [CrossRef] [PubMed]

- Gadea, G.; Pacios, M.; Morata, A.; Tarancon, A. Silicon-based nanostructures for integrated thermoelectric generators. J. Phys. D Appl. Phys. 2018, 51, 423001. [Google Scholar] [CrossRef]

- Maycock, P.D. Thermal conductivity of silicon, germanium, III-V compounds and III-V alloys. Solid State Electron. 1967, 10, 161–168. [Google Scholar] [CrossRef]

- Dismukes, J.P.; Ekstrom, L.; Steigmeier, E.F.; Kudman, I.; Beers, D.S. Thermal and electrical properties of heavily doped Ge-Si alloys up to 1300 °K. J. Appl. Phys. 1964, 35, 2899–2907. [Google Scholar] [CrossRef]

- Sadhu, J.; Tian, H.; Ma, J.; Azeredo, B.; Kim, J.; Balasundaram, K.; Zhang, C.; Li, X.; Ferreira, P.M.; Sinha, S. Quenched phonon drag in silicon nanowires reveals significant effect in the bulk at room temperature. Nano Lett. 2015, 15, 3159–3165. [Google Scholar] [CrossRef]

- Ohishi, Y.; Xie, J.; Miyazaki, Y.; Aikebaier, Y.; Muta, H.; Kurosaki, K.; Yamanaka, S.; Uchida, N.; Tada, T. Thermoelectric properties of heavily boron- and phosphorus-doped silicon. Jpn. J. Appl. Phys. 2015, 54, 071301. [Google Scholar] [CrossRef]

- van Herwaarden, A.W.W. The Seebeck effect in silicon ICs. Sens. Actuators 1984, 6, 245–254. [Google Scholar] [CrossRef]

- Stranz, A.; Kahler, J.; Waag, A.; Peiner, E. Thermoelectric properties of high-doped silicon from room temperature to 900 K. J. Electron. Mater. 2013, 42, 2381–2387. [Google Scholar] [CrossRef]

- Wang, Z.; Mingo, N. Diameter dependence of SiGe nanowire thermal conductivity. Appl. Phys. Lett. 2010, 97, 101903. [Google Scholar] [CrossRef] [Green Version]

- Santos, J.D.; Salleras, M.; Donmez, I.; Gadea, G.; Calaza, C.; Morata, A.; Tarancón, A.; Fonseca, L. Power Response of a Planar Thermoelectric Microgenerator Based on Silicon Nanowires at Different Convection Regimes. Energy Harvest. Syst. 2016, 3, 335–342. [Google Scholar] [CrossRef]

- Ji, S.; Liao, X. Researches on MEMS thermoelectric-photoelectric integrated energy harvester with metal heat sink. Microelectron. J. 2020, 96, 104702. [Google Scholar] [CrossRef]

| Parameter | Si NWs | SiGe NWs |

|---|---|---|

| Temperature | 630 °C | 650 °C |

| Pressure | 2.5 Torr | 2.5 Torr |

| HCl | 30 sccm | 30 sccm |

| H2 | 1000 sccm | 1000 sccm |

| SiH4—H2 (10%) | 150 sccm | 200 sccm |

| GeH4—H2 (10%) | - | 8 sccm |

| B2H6—H2 (750 ppm) | 50 sccm | 50 sccm |

| Property | Si NWs | SiGe NWs |

|---|---|---|

| NW diameter | 112 ± 31 nm | 64 ± 11 nm |

| NW density | 3.9 NWs/µm2 | 4.9 NWs/µm2 |

| Property | Si NWs | SiGe NWs |

|---|---|---|

| Rdevice (Ω) | 15.06 | 19.50 |

| Voc (mV) | 0.52 | 3.37 |

| ∆T (°C) | 1.54 | 14.4 |

| Max. Power Density (μW/cm2) | 0.23 | 7.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fonseca, L.; Donmez-Noyan, I.; Dolcet, M.; Estrada-Wiese, D.; Santander, J.; Salleras, M.; Gadea, G.; Pacios, M.; Sojo, J.-M.; Morata, A.; et al. Transitioning from Si to SiGe Nanowires as Thermoelectric Material in Silicon-Based Microgenerators. Nanomaterials 2021, 11, 517. https://doi.org/10.3390/nano11020517

Fonseca L, Donmez-Noyan I, Dolcet M, Estrada-Wiese D, Santander J, Salleras M, Gadea G, Pacios M, Sojo J-M, Morata A, et al. Transitioning from Si to SiGe Nanowires as Thermoelectric Material in Silicon-Based Microgenerators. Nanomaterials. 2021; 11(2):517. https://doi.org/10.3390/nano11020517

Chicago/Turabian StyleFonseca, Luis, Inci Donmez-Noyan, Marc Dolcet, Denise Estrada-Wiese, Joaquin Santander, Marc Salleras, Gerard Gadea, Mercè Pacios, Jose-Manuel Sojo, Alex Morata, and et al. 2021. "Transitioning from Si to SiGe Nanowires as Thermoelectric Material in Silicon-Based Microgenerators" Nanomaterials 11, no. 2: 517. https://doi.org/10.3390/nano11020517

APA StyleFonseca, L., Donmez-Noyan, I., Dolcet, M., Estrada-Wiese, D., Santander, J., Salleras, M., Gadea, G., Pacios, M., Sojo, J. -M., Morata, A., & Tarancon, A. (2021). Transitioning from Si to SiGe Nanowires as Thermoelectric Material in Silicon-Based Microgenerators. Nanomaterials, 11(2), 517. https://doi.org/10.3390/nano11020517