3.1. Analysis of Sedimentation Coefficient Distributions

Figure 1a shows schematically the basic principle of DCS. A mixture of different nanoparticle populations is physically separated into discrete zones of particles that migrate at velocities

u characteristic to their size, shape, and density. This is achieved within a disk rotating at a constant angular velocity

ω. Throughout the experiment, two quantities are continuously recorded. One of these is the time

t it takes distinct particles to travel up a fluid density gradient from a starting position

R0 until they pass a detector position

RD. Arrival of the particles is monitored by the extinction of light at a wavelength of 405 nm. For non-absorbing materials such as polymer particles, the attenuation of a laser beam resulting from light scattered by particles arriving at specified sedimentation times is monitored.

The sedimentation coefficient

s of a distinct particle population

i is the quotient of the sedimentation velocity (

u = d

R/d

t) and the product

ω2R, where

R is the actual radial position with respect to the axis of rotation.

s is inversely related to the sedimentation time

ti measured in a DCS experiment [

19]:

Run-specific parameters such as

R0,

RD, and

ω can be summarized to one instrumental measurement constant

k. It is recommended to determine this constant by using a particle standard of known sedimentation coefficient. This has turned out to be beneficial if compared with making measurements by quantifying

R0,

RD, and

ω individually [

8].

Polymer particles with spherical shapes are particularly suitable as particle standards because their sedimentation is governed by Stokes’ law [

14]. A narrow size distribution will facilitate the calibration process as the local maximum of the distribution, which should correspond to the Stokes diameter of the non-agglomerated particles, can be readily determined. The current work studies mixtures of supracolloidal assemblies built from spherical constituent particles. Consequently, the latter have the same density as clusters based on them. Moreover, these particles are virtually uniform, which is reflected by their low polydispersity index of 1.001. These two conditions make the polymer nanospheres ideal reference particles to precisely determine the constant

k in Equation (1). To achieve this, the sedimentation coefficient of the particles must be calculated first.

The sedimentation coefficient of a particle

i is defined as the ratio of the effective particle mass

meff and the friction coefficient

f:

where the effective mass results from the difference in the actual particle mass

mp and the mass of the fluid

mf that is displaced by the particle. For spherical particles, the friction coefficient is given by Stokes’ law and reads as follows:

where

η is the viscosity of the fluid and

dh denotes the hydrodynamic diameter of the particles. The effective mass can be expressed by the corresponding volumes of a sphere with diameter

dh and the densities of the particle

ρp = 1.057 g cm

−1 and the density of the displaced fluid

ρf (here: 0.997 g cm

−3) [

21]:

The number-average diameter of the non-agglomerated particles was 142 nm, which was determined by DCS measurement against the commercial polystyrene standard latex. This value is close to the TEM diameter (144 nm) and the hydrodynamic diameter measured by DLS (145 nm).

Due to the small differences related to the low polydispersity of the particles (right peak in

Figure 1c represents the size distribution), the values of any of three methods can be used as a measure for the hydrodynamic particle size. The obvious approach would be to use the DCS value of the non-agglomerated species as an internal reference to calculate the sedimentation coefficients of other species present in the mixture (see below).

Alternatively, one might prefer to calculate the masses in Equation (2) from the TEM radius characteristic for dry particles to account for the fact that the hydrodynamic effective surface layer hardly contributes to the particle mass [

16]. The friction coefficient given in Equation (3) can be calculated from the hydrodynamic diameter as measured by DCS or DLS. In this study, the DLS value was used to allow for a direct comparison with sedimentation coefficients predicted earlier by hydrodynamic bead-shell modeling. In that study, model building was based on the DLS diameter of the cluster constituents [

16].

An important point to note is that by using the non-agglomerated particles as an internal calibration standard, it is guaranteed that any particles present in the same DCS run, whether those to be studied or those acting as a reference, face the same conditions during their migration through the density gradient. This compensation captured in the constant

k goes beyond the parameters specified in Equation (1). It also considers variations in the density and viscosity of the dispersion medium during sedimentation. This is particularly important when studying sedimentation in a density gradient. In other words, a compensation for fluid densities and viscosities that differ from the actual conditions during the experiment is achieved by using an internal reference. The sedimentation characteristics within the gradient can thus be easily transferred to the sedimentation in other dispersion media. In the following, calculation of the sedimentation coefficient of the reference particles is based on the sedimentation in pure water at 25 °C (

ρf = 0.997 g cm

−3;

η = 0.891 g m

−1 s

−1). The latter is done not only for the sake of simplicity, but also to allow for direct comparison to predicted values from hydrodynamic modeling that have been reported previously [

16]. Consequently, a sedimentation coefficient of

sN=1 = 770 Sv is calculated from Equation (4). The sedimentation time of the nanospheres assigned from the DCS analysis of cluster mixtures is

tN=1 = 401 s, which yields a

k-value of 3.0877 × 10

−8 according to Equation (1). This value is then used to calculate the sedimentation coefficients of any non-spherical species present in the nanoparticle mixture from their respective sedimentation times.

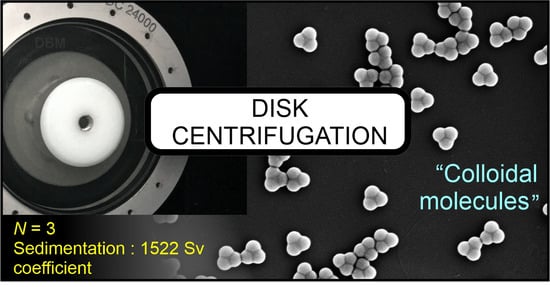

3.2. Particle Clusters as Model Systems for Nanoparticle Mixtures

Thanks to the seminal work by Pine and co-workers [

30], it is known that evaporating emulsion droplets are suitable physical templates to assist the assembly of colloidal particles into an ensemble of stable clusters varying in their number of constituents. A mixture of various species is obtained, resulting from a random distribution of the elementary particles on the droplets [

31]. The gradual increase in cluster mass follows directly from the number of constituent particles

N. A linear correlation does not apply to the increase in surface area and, related to this, friction at the cluster surface. The growth in surface area is largest when going from single particles to dimers, followed by increasingly smaller growth rates with rising

N. The latter is a direct consequence of the packing into dense cluster configurations. It is obvious that the sedimentation coefficients of the clusters gradually increase with rising

N in accordance with Equation (2). Moreover, based on the above, the increments for the rising sedimentation coefficients are becoming increasingly smaller with rising

N. This fact underscores the suitability of particle clusters as model systems to explore the limits of sorting nanoparticle mixtures by centrifugal sedimentation.

The following studies are based on a mixture of particle clusters built from 144 nm-sized polymer nanospheres (Inset of

Figure 2). Most of the clusters consist of up to 12 constituent particles and thus have spatial dimensions within the colloidal domain. Hence, Brownian motion will prevail over sedimentation unless the assemblies are exposed to a centrifugal field [

38]. The morphology of the colloidal clusters in this work and of related supraparticles was discussed in earlier works [

16,

28,

30,

31,

39,

40]. It should be noted that clusters of more than four constituents may occur in different configurations. For example, clusters of five and six particles have two different configurations.

Figure 3 shows common configurations that are observed experimentally and predicted by computer simulations. The cluster mixture contains both isotropic and anisotropic species. Single particles, tetrahedral, octahedral, and icosahedral clusters have isotropic geometries, whereas all other species exhibit anisotropic shapes. The further studies will thus deliberately dispense on any evaluations based on assuming a spherical particle geometry. The basic methodology is thus broadly applicable to particles of arbitrary shapes that do not have to obey Stokes’ law.

3.3. DCS Analysis of Sedimentation Coefficient Distributions

DCS is now applied as an analytical tool to explore the distribution of sedimentation coefficients of the mixture of colloidal clusters. The separation of the particles within the disk centrifuge follows the basic principles of rate-zonal density gradient centrifugation [

15]. The proper design of the density gradient is key for accurate results. The following criteria must be considered when preparing the density gradient:

The density of the particles must exceed the highest density within the gradient.

The density of the sample suspension (particles + dispersion medium; here: 0.997 g cm−3) has to be lower than the lowest density within the gradient.

Compliance with the two criteria makes the particles settle individually at rates specified by their sedimentation coefficients. In the present case, clusters of a single set of constituent particles were explored at 25 °C. Hence, the various species within the cluster mixture have the same density, which is 1.057 g cm

−3. Their separation during DCS analysis was performed in an aqueous sucrose gradient ranging from 2% (m/m) to 8% (m/m). The minimum density within the gradient equals 1.0052 g cm

−3 and is thus, in accordance with criterion 2, higher than the density of the highly diluted sample suspension (0.02% (m/m),

ρ = 0.997 g cm

−3). This prevents streaming, i.e., a downstream of particle-laden fluid following the centrifugal field [

15]. In addition, the maximum density within the gradient (1.0285 g cm

−3) was kept lower than the actual particle density. This ensures that the particles can travel though the complete gradient fluid and will thus reach the detector position at a characteristic sedimentation time. The gradient design suitable for polystyrene latex particles can be easily adapted for other types of nanoparticles, simply by following the two criteria. The densities of aqueous sucrose solutions as functions of weight fraction and temperature can be found in the literature [

41].

Figure S5 displays densities in the concentration range up to 10% (m/m) sucrose.

The particle clusters do not absorb visible light, but light is scattered by the clusters, as for any other colloidal objects. The colloidal clusters can be thus detected by attenuation of a laser beam. The latter had a wavelength of 405 nm, which provides high sensitivity because violet light is subject to the strongest scattering within the visible region. For this reason, even marginal quantities of particles or particle agglomerates can still be detected.

During the DCS run, the light attenuation of the detector beam is continuously recorded as the function of the sedimentation time. Routines in the device software allow for conversion of the raw data into a particle size distribution. These routines are based on the Mie theory to derive the particle concentration from the measured light extinction [

42]. Moreover, the device software assigns a distinct particle diameter to any given sedimentation time. However, this correlation is only correct if the drag force acting on the particles during sedimentation follows Stokes’ law. The latter applies only to spherical particles and is thus not appropriate for accurately exploring particles with complex shapes. The deviation between the friction coefficients of an anisotropic particle and a spherical particle of the same mass can be at least partially compensated by the introduction of a non-sphericity factor [

12]. However, this can only work if all the particles exhibit the same aspect ratio, which is rarely the case for mixtures of anisotropic particles. Nanoparticle aggregates such as the colloidal clusters in this study have various geometries (

Figure 3), so that the assignment of a single non-sphericity factor that works for all species is not possible.

It is exactly for this reason that the present evaluation explicitly avoids any assumptions of a spherical shape and is thus applicable to particles of arbitrary shapes. The only exception is made when calculating the sedimentation coefficient of the spherical particles used as an internal reference. In this specific case, making use of Equation (3) is justified. Basically, it is also possible to replace the spherical particles by any other type of particles given that their sedimentation coefficient is known. Precise knowledge of the sedimentation coefficient of at least one set of reference particles is required to determine the instrumental measurement constant k in Equation (1). These reference particles can be either measured independently of the sample particles, or, as in the present case, constitute a distinct particle population within the nanoparticle mixture. The latter procedure is advantageous as different particle populations are compared, which are subject to the same experimental conditions. In case of nanoparticle aggregates, it makes sense to use the elementary particles as an internal reference. The k-value calculated from the sedimentation time of the reference particles and their sedimentation coefficient can thus be transferred to any other particle population within the same DCS run. Sedimentation coefficients of the different particle populations are calculated from the respective sedimentation times according to Equation (1).

Together with the profile of light extinction measured during DCS, a distribution of the sedimentation coefficients of the nanoparticle mixture is obtained. This distribution is weighted by the attenuation of light caused by the particle arriving at the detector position and thus differs from the weight distribution

c(

s) obtained from AUC [

43]. In principle, conversion of the two contributions is possible if the scattering cross-sections of the various particle populations are known. According to the authors’ opinion, this issue should be treated in a purist way to allow for a broad application of the methodology.

Figure 2 shows the light extinction-weighted sedimentation coefficient distribution of a mixture of colloidal clusters. As described above, the distribution is solely based on the raw data of the DCS run and knowledge of the sedimentation coefficient of the single particles used as an internal reference. The high resolution of the DCS run is immediately obvious. Single particles and cluster species of 2 to 12 constituents are resolved as discrete bands, which allows for a facile assignment of sedimentation coefficients according to the peak maxima (

Figure 3). Remarkably, species that deviate by less than 1% in their sedimentation coefficients can still be resolved. A more detailed discussion of the resolution of DCS is found in ref. [

12].

Zone widths in a DCS experiment are governed by several factors. Because DCS detects particles arrive at a fixed position over time, the actual zone width of a given particle population is captured as a time interval within which all particles of this population arrive at the detector position. A broad zone is thus reflected by a larger time interval. This becomes apparent when the light extinction is plotted against the sedimentation time (

Figure S1). The peak-width at half-height is largest for the non-agglomerated particles (25.2 s) and decrease systematically for the clusters with rising numbers of constituent particles

N (13.0 s for dimers; 9.2 s for trimers; 7.3 s for tetramers; 6.0 s for pentamers; 5.4 s for hexamers). The polydispersity of the cluster constituents (1.001) and, consequently, of the clusters is rather low and virtually negligible compared to the broadening due to Brownian motion. Band broadening due to diffusion is an important aspect. Translational diffusion coefficients decrease with the number of constituent spheres [

16,

38] and, consequently, facilitate band narrowing with rising numbers of constituent particles

N (

Figure S1). The density gradient influences the band width as well. A steep gradient profile results in lower sedimentation velocities in the leading edge of the zone, whereas the velocities are higher at the trailing edge. The density gradient thus keeps the zone of a distinct particle population together. The density gradient equally affects all particle populations because the detector position is fixed in DCS measurement. This constitutes a difference from preparative centrifugal separations, where different particle populations are harvested from different sections of the density gradient (

Figure 4).

According to Equation [

2], there is an inverse relationship between sedimentation time and sedimentation coefficient. This must be considered when comparing actual zone widths during the DCS run with the widths of the individual peaks in the sedimentation coefficient distribution (

Figure 2). It follows that the non-agglomerated particles which form the broadest zone (peak-width at half-height: 25.2 s) during the DCS run are presented by the narrowest peak in the sedimentation coefficient distribution (peak-width at half-height: 48 Sv). In comparison, the tetramers form narrower zones (peak-width at half-height: 7.3 s) but are represented by a broader peak in the sedimentation coefficient profile (peak-width at half-height: 81 Sv).

Accurate assessment of the sedimentation coefficients obtained from the DCS strategy can be based on a comparison with values obtained from theoretical modeling. García de la Torre and co-workers have established model building and calculation routines, which can be applied to rigid particles of arbitrary shapes. Recently, we reported on sedimentation coefficients of colloidal clusters calculated along these lines [

16]. The clusters studied are identical to those in the present studies but limited to a maximum of six constituent particles. Nonetheless, a direct comparison can be made (

Figure 3). The sedimentation coefficients obtained by DCS are in excellent correlation to the values predicted for clusters with the same spatial dimensions and geometries. Deviations are negligible for single particles and even for dimers, which are the geometries with the highest aspect ratio. Although the deviations increase with the number of constituents, they are less than 6% for six-particle clusters with octahedral symmetry. This underscores the suitability of DCS to directly measure sedimentation coefficient distributions of complex nanoparticle mixtures.

3.4. Application for Preparative Nanoparticle Separations

The separation quality accomplished during the DCS analysis should now serve as a basis to optimize preparative centrifugal separations. To this end, separations according to the sedimentation coefficients were carried out in a swinging-bucket rotor. The buckets host clear centrifuge tubes with a capacity of 38.5 mL. Compared to a fixed-angle centrifuge rotor, swing-out rotors significantly reduce collisions of the particles with the wall of the tube and help to reduce wall effects on sedimentation (see below). More importantly, the fluid layers and the particle zones follow the centrifugal field throughout the whole run, including acceleration and deceleration intervals, which is the prerequisite for excellent selectivity during fractionation. The orientation of the layers with respect to the axis of rotation is a feature which DCS analysis and separations carried out in a swing-out rotor have in common. In this context, the spinning hollow disk in DCS can be considered as an extension of the centrifuge tube in a swing-out rotor by 360 °C (

Figure 1).

Nevertheless, there are two important differences that should be kept in mind. The first one is related to the geometry of the disk, which has some similarities to a zonal rotor used for preparative separations at larger scales [

32]. A density gradient linear in volume will be also linear along the sedimentation path if placed in a centrifuge tube. However, if prepared within the rotating hollow disk, a concave profile of the density gradient is obtained across the sedimentation path. The second difference to be considered relates to the substantial difference between an analytical technique and a preparative method. DCS probes the different particle populations after having reached a fixed position. This means that all particles have migrated along the same path, but they have reached their destination at different times according to their sedimentation coefficient. In preparative separations, the principle of operation is reversed. The centrifugal run and thus the sedimentation are terminated for all particle populations at the same time. At precisely this time, they have traveled different distances, which are determined by their sedimentation coefficients. Hence, the two methods offer the opportunity to complement each other if aligned at the same experimental problem.

Parallel to the above-mentioned DCS analysis, sucrose density gradients ranging also from 2% (m/m) to 8% (m/m) were prepared in centrifuge tubes. In line with the DCS analysis, the centrifugation was performed at 24,000 rpm. Centrifugation times were chosen based on the sedimentation coefficients measured by DCS. In doing so, the time required to maximize the sedimentation path of a 12-particle cluster was estimated. This ensured maximum separation of the cluster populations.

Figure 4 shows the separation achieved in the centrifugal run. A total of twelve discrete zones, each of them corresponding to a particle population settling at the same rate, are observed. Classification of the zones to specific clusters follows the number of constituent particles

N. This is in full accord with the sequence of sedimentation coefficients obtained from DCS (

Figure 3). Verification of zone allocation was achieved by FESEM after extraction of the cluster fractions (

Figure 4).

The separation of the cluster mixture into discrete zones within the centrifuge tube paved the way for a quantitative evaluation. There are a number of reports in the literature on the calculation of sedimentation coefficients from separations of biomacromolecules performed in a centrifuge tube [

15,

44,

45]. According to Equation (1), it is possible to calculate sedimentation coefficients from the radial locations of the various zones once the centrifugal run is terminated. To this end, a centrifugal separation of the cluster mixture was carried out in a graduated test tube. The

RD values in Equation (1) are taken from the center of mass of the zones. The initial position

R0 is assumed as the interface between sample zone and density gradient (

Figure S3). The effective time of centrifugation was determined along the lines given by Schumaker [

15]. To this end, the course of the rpm values during the entire centrifugal run was recorded. Periods of acceleration and deceleration are considered by plotting the angular velocity-squared ω

2 with the course of the centrifugation time (

Figure S2). Integration of

ω2 over the entire time span and division by the maximum value of

gave an effective centrifugation time of 470.4 s at maximum angular velocity

ωmax (here: 2513.4 s

−1).

The calculation according to Equation (1) will yield the actual sedimentation coefficients of the different nanoparticle populations within the density gradient. The latter can be considered as dispersion medium with a gradual change not only in density but also in viscosity. In DCS, the impact of the medium is considered by the measurement constant

k. Hence, sedimentation coefficients determined by DCS reflect experimental conditions identical to those assumed for the particles used as a calibration standard. The data gathered in

Figure 3 refer to the sedimentation in pure water at 25 °C. To allow for a comparison with the DCS values, it is necessary to correct the values determined from preparative separations by the mean viscosities and densities, which the particles experience during their sedimentation. This correction can be made by using the following expression [

44]:

where

sPC and

sG denote the sedimentation coefficients of a given particle population at 25 °C in pure water and in the gradient.

ρW = 0.997 g cm

−3 and

ηw = 0.891 g m s

−1 are the density and viscosity of water at 25 °C.

The mean density and viscosity of the gradient,

ρG and

ηG, were determined as follows: first, the sucrose concentrations at the zone centers were calculated based on the linear profile of the gradient (

Figure S3). Densities and viscosities of aqueous sucrose solutions given in ref. [

41] were plotted against the weight proportion of sucrose and subjected to a polynomial fitting (

Figures S4 and S5). The fitting functions were integrated from the minimal concentration of sucrose in the gradient (2% (m/m)) to the concentration of sucrose at the zone center (

Figure S3). Division by the difference in the two sucrose concentrations yields the mean density and viscosity during the sedimentation of a given particle population. In the concentration range considered, the densities and viscosities increase virtually on a linear scale (

Figures S4 and S5). Hence, the derivation of the quantities

ρG and

ηG could be also simplified by averaging the respective quantities at the beginning and at the end of the sedimentation path.

Figure 5 shows a comparison of the sedimentation coefficients

sPC calculated from the radial positions of the zone centers within the centrifuge tube with the quantities determined by DCS. Notably, the sedimentation coefficients obtained by the two strategies deviate by less than 8%. This is remarkable, inasmuch as there are a number of uncertainties in the calculation of accurate sedimentation coefficients from the results of rate-zonal separations carried out in centrifuge tubes [

46]. The following issues must be considered:

uncertainty in the particle density;

uncertainties in the profile of the density gradient;

uncertainties in the positions of the zones;

temperature variations inside the rotor chamber;

wall effects.

This study has shown that deviations in comparison to other methods can be kept low. It is briefly outlined how this was achieved despite the uncertainties listed above.

This study is centered on the determination of the sedimentation of solid nanoparticles. In contrast to most biological particles or synthetic micro- or nanogels, solid particles do not vary their density while migrating through a density gradient. Uncertainty in particle density is thus limited to experimental errors in the determination of particle densities. The latter can be precisely measured with an uncertainty of less than 0.005 g cm−3.

Considerable uncertainties in the density gradient profile shown in

Figure S3 are to be expected in the top layer of the gradient underneath the sample zone. Diffusion of gradient material (here: sucrose) into the sample zone may cause strong deviations from the expected gradient profile [

32,

46]. However, it turned out that this phenomenon had little effect on the calculated values of the sedimentation coefficients. This was achieved by setting an effective sedimentation time, allowing the zones of migrating particles to reach positions far from the first layers of the gradient (

Figure S3).

Uncertainties in radial positions relate to both the starting zone and the final positions of the zones of banded particles. Precise allocation of the beginning of the sedimentation path is challenging inasmuch as the profile of density gradient is not well known at the interface between the sample zone and the top layer of the gradient. It may thus be justified to define the starting position either by the interface itself or as the center of mass within the sample zone. In the present case, the two positions differed by 2.1 mm. This value can be reduced by smaller sample volumes at the expense of the number of particles that can be separated in a single run. In this work, the nanoparticles were dispersed in pure water. For this reason, streaming is to be expected within the sample zone. This is why the diverse nanoparticle populations rapidly accumulate near the interface of sample and gradient during acceleration of the centrifuge. It is exactly for this reason that the radial position of the beginning of the gradient (R = 70.14 mm) was chosen as the beginning of the sedimentation path for all nanoparticle populations. This definition was corroborated by the agreement with the values from DCS and hydrodynamic modeling.

The sedimentation coefficients were calculated from the radial positions of the centers of mass of the zones, which are affected by the centrifugal field. As a result, the particle distributions deviate from Gaussian profiles. In the present case, uncertainty of the zone position had little effect because of the low bandwidths resulting from the narrow size distributions of the particle populations. Nonetheless, further refinement could be achieved by taking into account the interplay of sedimentation and diffusion along the lines given by Schumaker [

15].

Variation in the temperature inside the rotor chamber may have a marked effect on the sedimentation of the particles. An uncertainty of 1 °C will cause an error of over 2.5% in the determination of sedimentation coefficients [

46]. Variations in temperature affect both the density and viscosity of the gradient and can become a major problem when calculating sedimentation coefficients from centrifugal separations. In the DCS measurements shown above, this problem was circumvented by using an internal calibration standard of known sedimentation coefficient. It is also possible to use the same strategy in preparative centrifugal separations. Alternatively, values obtained from preparative separations can be corrected by DCS analysis of at least one component. In the present case, this was not done to identify deviations among the methods.

Collisions of nanoparticles with the walls of cylindrically shaped centrifuge tubes may occur. Particles that hit the wall may stick to it or accumulate near the wall and then settle down as an ensemble at modified sedimentation velocities [

15,

47]. Only those particles that escape from collision with the side wall, exhibit ideal sedimentation behavior. The latter fraction is larger if the centrifuge tube is placed in a swinging bucket following the direction of the centrifugal field. Further improvement can be achieved by using either radially shaped centrifuge tubes [

15] or zonal rotors that avoid wall effects by allowing the sedimentation to proceed within a bowl-shaped chamber [

32].

Notwithstanding these uncertainties, the present results have shown that close agreement with sedimentation coefficients, either experimentally measured by DCS or predicted by theoretical modeling, can be achieved. Consequently, the three rather different approaches in determining sedimentation coefficients complement each other very well. Sedimentation coefficient distributions, which are readily accessible by DCS, have proven a valuable tool to optimize the centrifugal separation of nanoparticle mixtures.