Anti-Wear and Anti-Erosive Properties of Polymers and Their Hybrid Composites: A Critical Review of Findings and Needs

Abstract

:1. Introduction

- Halting activities;

- Shortening productive service life;

- Decreasing performance;

- Requiring material replacement, including repair and maintenance costs;

- Decreasing productivity and efficiency;

- Reducing revenue;

- Impacting safety (causing explosions, fires, and discharges of toxic products);

- Health impacts (personal injuries and the contamination of the environment due to the escape of toxic products).

1.1. Techniques Utilized for Wear Testing

- Contact methods that involve the testing surface material in common contact with another material, including or not including supplementary media.

- Methods utilizing a flow of coarse erodents or loose solid coarse particles in a liquid or gas.

- Air jet erosion testers;

- Slurry jet erosion testers;

- Water droplet erosion testers;

- Dry erosion testing with loose particles of the erodent;

- Wear testing using solid particle accelerators;

- The Taber method;

- Silica blasting;

- Shot blasting.

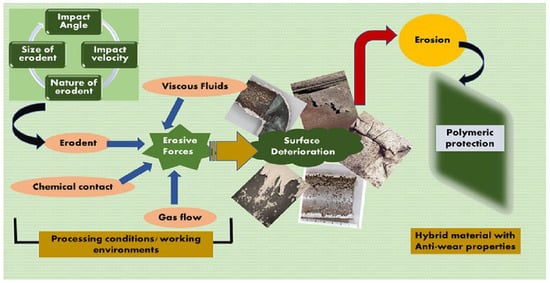

1.2. Factors Affecting Erosion

1.3. Erosion Variables

2. Brief Details on the Historical Utilization of Anti-Erosion/Anti-Wear Materials

Historical Overview of Simulation Techniques for Erosion Studies

3. Research on Erosion Resistance Using Polymers

3.1. Thermoset and Thermoplastic Polymers

3.2. Polymer Composites

| Sr. no | Nomenclature | Material Density (g/cm3) | Hardness Value | Erodent Used | Impingement Velocity (m/s) | Erosion Rate (m3/kg) | Coefficient of Wear | Remarks | Year | Ref |

|---|---|---|---|---|---|---|---|---|---|---|

| Thermoplastic Polymers | ||||||||||

| 1. | PA66 | 1.14 | 11.1 | Quartz | 243 | 2.30 × 10−6 | N.R. | Study of material response in erosive situations in relation to matrix–particle interaction | 1970 | [70] |

| 2. | Polystyrene | 1.16 | 11.9 | Glass beads | 15 | 0.06 × 10−9 | N.R. | Study of erosion behavior of PS | 1981 | [62] |

| 20 | 0.14 × 10−9 | |||||||||

| 40 | 0.16 × 10−9 | |||||||||

| 3. | PA6 | 1.15 | 10.2 | SiO2 | 80 | 9.08 × 10−9 | N.R. | Study of erosive wear of PA | 2001 | [65] |

| 4. | PA66 | 1.14 | 11.1 | -do- | 80 | 7.02 × 10−9 | ||||

| 5. | Aromatic PA | 1.12 | 11.7 | -do- | 80 | 19.64 × 10−9 | ||||

| 6. | TPU-1 | 1.14 | 14.5 | Corundum | 70 | 0.74 × 10−9 | N.R. | Study of erosion process and factors affecting it | 2002 | [3] |

| 7. | PEK | 1.32 | 32.6 | SiO2 | 39 | 4.92 × 10−9 | N.R. | Study of morphology and possible wear mechanism | 2003 | [61] |

| 8. | PEI | 1.27 | 40 | SiO2 | 25 | 4 × 10−8 | 1.26 × 10−2 | Relation of erosion rate and mechanical properties of the neat polymer was studied | 2008 | [24] |

| 9. | PEEK | 1.30 | 28 | 3 × 10−8 | 6.06 × 10−3 | |||||

| 10. | PEK | 1.30 | 34.4 | 5 × 10−8 | 6.88 × 10−3 | |||||

| 11. | PPS | 1.40 | 26.5 | 2 × 10−8 | 4.46 × 10−3 | |||||

| 12. | PES | 1.37 | 24.2 | 3 × 10−8 | 5.12 × 10−3 | |||||

| 13. | PSU | 1.24 | 21.4 | 1 × 10−8 | 4.76 × 10−3 | |||||

| 14. | UHMWPE | 0.93 | N.R. | 4 × 10−9 | N.R. | |||||

| 15. | PEEK | 1.3 | 32.6 | SiC | 34 | 0.25 × 10−8 | 0.25 × 10 −8 | Study of mechanism and wear process | 2017 | [93] |

| Thermoset Polymers | ||||||||||

| 16. | PP | 0.91 | 5.40 | Quartz | 243 | 3.10 × 10−6 | N.R. | Details of material interaction with the particle in erosive conditions | 1970 | [70] |

| 17. | EP | 1.2 | 40.8 | 10.0 × 10−5 | ||||||

| 18. | Bismaleimide | 1.33 | 54.1 | Alumina | 60 | 3.44 × 10−6 | 96 | Study of erosion behavior | 1991 | [71] |

| 19. | PU-1 | 1.26 | 18.1 | Corundum | 70 | 1.11 × 10−9 | N.R. | Study of erosion process and factors affecting it | 2002 | [3] |

| Sr. no | Nomenclature | Material Density (g/cm3) | Hardness Value | Erodent Used | Impingement Velocity (m/s) | Erosion Rate (m3/kg) | Coefficient of Wear | Remarks | Year | Ref |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. | BMI + 20 bisphenol | 1.29 | 53.4 | Alumina | 60 | 6.14 × 10−6 | 193 | Study of erosion behavior | 1991 | [71] |

| 2. | BMI + 40 bisphenol | 1.23 | 34.9 | 60 | 3.31 × 10−6 | 63 | ||||

| 3. | BMI + 60 bisphenol | 1.29 | 53.4 | 60 | 3.44 × 10−6 | 74 | ||||

| 4. | EP unidirectional + CF 56% | 1.51 | 40.7 | Steel balls | 45 | 0.88 × 10−7 | N.R. | Response in solid particle erosion conditions of unidirectional CF- and GF-reinforced epoxy composites | 2003 | [94] |

| 5. | EP unidirectional + GF 56% | 1.88 | 63.7 | 45 | 1.38 × 10−7 | |||||

| 6. | PEK | 1.32 | 32.6 | SiO2 | 39 | 4.92 × 10−9 | N.R. | Study of morphology and possible wear mechanism | 2003 | [61] |

| 7. | 68 | 1.62 × 10−8 | ||||||||

| 8. | 90 | 4.22 × 10−8 | ||||||||

| 9. | PEK + 10% GF | 1.38 | 35.5 | SiO2 | 39 | 6.23 × 10−9 | ||||

| 10. | PEK + 20% GF | 1.44 | 39.5 | 39 | 0.83 × 10−8 | |||||

| 11. | PEK + 30% GF | 1.53 | 43.7 | 39 | 1.04 × 10−8 | |||||

| 12. | PEEK | 1.31 | 333.5 | 39 | 1.05 × 10−8 | |||||

| 13. | PEEK + 30% CF | 1.36 | 50.6 | 39 | 1.82 × 10−8 | |||||

| 14. | PEI | 1.27 | 41.9 | SiO2 | 30 | 6.69 × 10−9 | N.R. | Mechanical properties and possible wear mechanisms discussed | 2007 | [95] |

| 15. | PEI + 20% GF | 1.42 | 42.1 | 30 | 5.98 × 10−9 | |||||

| 16. | PEI + 30% GF | 1.51 | 46.7 | 30 | 5.63 × 10−9 | |||||

| 17. | PEI + 25% CF | 1.7 | 41.7 | 30 | 0.75 × 10−8 | |||||

| 52 | 1.25 × 10−8 | |||||||||

| 60 | 5.50 × 10−8 | |||||||||

| 88 | 9.51 × 10−8 | |||||||||

| 18. | PEEK | 1.30 | 28 | SiO2 | 25 | 3.0 × 10−8 | 6.06 × 10−3 | Mechanical properties and possible wear mechanisms discussed | 2009 | [96] |

| 19. | CF/PEEK | 1.56 | 60 | 3 × 10−9 | 3.12 × 10−2 | |||||

| 20. | GF/PEEK | 1.99 | 101 | 3 × 10−9 | 7.07 × 10−2 | |||||

| 21. | CF/PEKK | 1.58 | 85 | 1 × 10−9 | 5.30 × 10−2 | |||||

| 22. | GF/PEKK | 2.08 | 112 | 2 × 10−8 | 8.45 × 10−2 | |||||

| 23. | PPS + 20% GF | 1.48 | 35.8 | Silica sand | N.R. | 3 × 10−8 | N.R. | Study of erosion rates | 2009 | [97] |

| 24. | PPS + 30% GF | 1.6 | 37.5 | 3 × 10−8 | ||||||

| 25. | PPS + 40% GF | 1.6 | 110 | 2 × 10−8 | ||||||

| 26. | PEEK | 1.3 | 32.6 | SiC | 34 | 0.25 × 10−8 | N.R. | Study of mechanism and wear process | 2017 | [93] |

| 27. | PEEK + 30% GF | 1.51 | 40.9 | 0.40 × 10−8 | ||||||

| 28. | PEEK + 30% CF | 1.38 | 37.7 | 0.50 × 10−8 |

| Sr. no | Nomenclature | Material Density (g/cm3) | Hardness Value | Erodent Used | Impingement Velocity (m/s) | Erosion Rate (m3/kg) | Coefficient of Wear | Remarks | Year | Ref |

|---|---|---|---|---|---|---|---|---|---|---|

| APS modified TiO2 nanoparticles/in PU | ||||||||||

| 1. | UT-1 (PU with 1% neat nano titania) | N.R. | 167 | N.R. | Only Tg was reported | 2009 | [83] | |||

| 2. | TT-1 (PU with 1% modified nano titania) | N.R. | 185 | N.R. | Only Tg was reported | 2009 | [83] | |||

| 3 | TT-2 (PU with 2% modified nano titania) | N.R. | 187 | N.R. | ||||||

| 4. | TT-3 (PU with 3% modified nano titania) | N.R. | 187 | N.R. | ||||||

| 5. | CNT/epoxy composites | N.R. | Only graphical data for the wear study is available | 2014 | [98] | |||||

| 6. | Epoxy neat resin | N.R. | 0.17 | N.R. | Study of mechanical and anticorrosive properties of surface | 2015 | [99] | |||

| 7. | Resin + 0.1% graphene | 0.19 | N.R. | |||||||

| 8. | Resin + 0.4% graphene | 0.41 | N.R. | |||||||

| 9. | Resin + 0.7% graphene | 0.51 | N.R. | |||||||

| 10. | Graphene Oxide-reinforced silicone-acrylate resin | Study of mechanical stability to be used as a coating for erosion resistance in mechanical corrosion coupling environments | 2015 | [100] | ||||||

| 11. | Epoxy/clay nanocomposite with organically modified montmorillonite | Study of mechanical strength, electrical conductivity, flammability, and thermal stability for applications in aerospace, adhesives, and coating industries | 2016 | [101] | ||||||

| Silica-filled epoxy nanocomposite | Effect of pyrogenic silica on epoxy resin for use as anti-cavitation painting | 2017 | [82] | |||||||

| 12. | H (Neat) | 1.11 | 75 | SiO2 | N.R. | |||||

| H3SiO2 (3 wt%) | 1.12 | 61 | ||||||||

| H5SiO2 (5 wt%) | 1.13 | 60 | ||||||||

| 13. | Epoxy/graphene-reinforced composites | Composites were qualitatively and quantitatively evaluated in terms of contact angle, surface roughness, adhesion to the substrate, corrosion resistance, and abrasion resistance for oil and gas pipelines | 2018 | [102] | ||||||

| 14. | Ni-P-nano-NiTi composites | Only scratch test and indentation test were performed | 2019 | [103] | ||||||

| 15. | Mechanical characterization of wood apple- and coconut shell-reinforced hybrid composites | Fabrication of coconut and wood apple shell powder-reinforced epoxy composites and experimental investigation of mechanical properties | 2020 | [104] | ||||||

| 16. | Characterization of carbon fiber-reinforced polyphenylene sulfide composites prepared with compatibilizers | Interfacial adhesion was studied using SEM and DMA (dynamic mechanical analysis) with the addition of Joncryl between carbon fiber and polyphenylene sulfide | 2020 | [105] | ||||||

3.3. The Role of Filler

4. Drawbacks and Future Needs

5. Conclusions

- Epoxy is a versatile coating with certain disadvantages, including brittleness and rigidity, that can be efficiently reduced by using hybrid polymers, i.e., its modification with polyurethane for surface protection.

- Nano–Al2O3 has the ability to benefit from hydrogen bonding with polymer chains; because of its low cost, it can be considered a promising nanoparticle for increasing wear resistivity.

- Carbon-based materials, such as MWCNT, graphene, and graphite, can have covalent bonding within their matrix; thus, they can improve the modulus and tensile strength of the polymer matrix. However, graphite can exhibit Van der Walls bonding among its layers, so it may reduce the shear stress of the composite. Comparing graphene with MWCNT, we observe its better dispersion in the matrix in comparison with MWCNT.

- Replacing carbon fiber with aligned CNT films as the reinforcement material can lead to a change in erosive wear behavior from brittle to ductile. CNTs can absorb more energy upon fracture or bending, and it is possible to further functionalize CNTs to increase their erosive wear.

- The erosive wear of composites with glass fibers as a filler is greater than that of carbon fiber composites. The change in erosive rate is due to fiber/matrix interfacial bonding and the different properties of the fibers.

- Due to its minimal cost, nano-silica is recognized as the most widely used NP for manufacturing erosive endurance composites. It can develop effective bonding with the matrix because of its self-lubricating characteristics.

- Polymer hybrids containing nano–TiO2 can alter mechanical characteristics and erosive properties by effectively transmitting the cracks and developing a strong bridge between the filler and the polymer resin during the erosion process.

- ZnO nanoparticles have the major advantage of favorable mechanical properties in polymer hybrid materials; with a phase disruption mechanism, its surface functionalization can develop strong covalent bonds between polymer chains.

- The addition of nano-clay to a polymer matrix results in a phase disruption mechanism that can enhance the mechanical characteristics of the polymer composite to some extent by utilizing its Van der Wall interactions.

- For wear applications, the filler plays a key role in optimizing the polymer; important factors include its composition, the polymer–filler interaction, and the homogeneous distribution of filler in the matrix. The erosion of the matrix surface varies depending on the nature of the erodent and the impingement conditions.

- At perpendicular angles, erosion was found to be lower; at inclined ranges, it varied due to the slicing of fiber material.

- Higher hardness values of composites do not indicate a higher wear resistance value. Lower Tg values suggest that the nanocomposites plasticize more effectively with the neat resin and convey better erosion resistance. The observed plasticization is in harmony with the greater strength and augmented ductility.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ryzhenkov, V.A.; Lebedeva, A.I.; Mednikov, A. Erosion wear of the blades of wet-steam turbine stages: Present state of the problem and methods for solving it. Therm. Eng. 2011, 58, 713–718. [Google Scholar] [CrossRef]

- Korostelyov, D.A.; Dergachyov, K.V. Application of Computer Simulation to Identify Erosion Resistance of Materials of Wet-steam Turbine Blades. IOP Conf. Ser. Earth Environ. Sci. 2017, 87, 082026. [Google Scholar] [CrossRef]

- Barkoula, N.-M.; Karger-Kocsis, J. Review Processes and influencing parameters of the solid particle erosion of polymers and their composites. J. Mater. Sci. 2002, 37, 3807–3820. [Google Scholar] [CrossRef]

- Babu, A.; Perumal, G.; Arora, H.; Grewal, H. Enhanced slurry and cavitation erosion resistance of deep cryogenically treated thermal spray coatings for hydroturbine applications. Renew. Energy 2021, 180, 1044–1055. [Google Scholar] [CrossRef]

- Rothammer, B.; Marian, M.; Neusser, K.; Bartz, M.; Böhm, T.; Krauß, S.; Schroeder, S.; Uhler, M.; Thiele, S.; Merle, B.; et al. Amorphous Carbon Coatings for Total Knee Replacements—Part II: Tribological Behavior. Polymers 2021, 13, 1880. [Google Scholar] [CrossRef] [PubMed]

- LiuJie, X.; Davim, J.P.; Cardoso, R. Prediction on tribological behaviour of composite PEEK-CF30 using artificial neural networks. J. Mater. Process. Technol. 2007, 189, 374–378. [Google Scholar] [CrossRef]

- Li, Q.-H.; Yin, X.; Huang, B.-T.; Luo, A.-M.; Lyu, Y.; Sun, C.-J.; Xu, S.-L. Shear interfacial fracture of strain-hardening fiber-reinforced cementitious composites and concrete: A novel approach. Eng. Fract. Mech. 2021, 253, 107849. [Google Scholar] [CrossRef]

- Myalski, J.; Śleziona, J. Glassy carbon particles as component to modification of tribological properties. J. Mater. Process. Technol. 2006, 175, 291–298. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S. Current Trends and Applications of Machine Learning in Tribology—A Review. Lubricants 2021, 9, 86. [Google Scholar] [CrossRef]

- Rymsza, Z.J.W. Tribology of Sliping Polymers; Emerald Publishing Limited: Bingley, UK, 1986. [Google Scholar]

- Kennedy, D.; Hashmi, M. Methods of wear testing for advanced surface coatings and bulk materials. J. Mater. Process. Technol. 1998, 77, 246–253. [Google Scholar] [CrossRef]

- Paktin, H.; Gulzar, S. Tribology of Polymers and Polymer-Modified Asphalt Binders Considering Linear Viscoelasticity. In Tribology of Polymer and Polymer Composites for Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2021; pp. 71–87. [Google Scholar]

- Sahoo, P.; Das, S.K. Tribology—A Tool for Mechanical and Industrial Engineering. In Mechanical and Industrial Engineering; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–37. [Google Scholar]

- Islam, M.A.; Farhat, Z.N. Effect of impact angle and velocity on erosion of API X42 pipeline steel under high abrasive feed rate. Wear 2014, 311, 180–190. [Google Scholar] [CrossRef]

- Arjula, S.; Harsha, A. Study of erosion efficiency of polymers and polymer composites. Polym. Test. 2006, 25, 188–196. [Google Scholar] [CrossRef]

- Oka, Y.; Ohnogi, H.; Hosokawa, T.; Matsumura, M. The impact angle dependence of erosion damage caused by solid particle impact. Wear 1997, 203–204, 573–579. [Google Scholar] [CrossRef]

- Mitramajumdar, D.; Aglan, H. Behaviour of advanced polymer composites in erosive/corrosive environments. Polymer 1992, 33, 1855–1859. [Google Scholar] [CrossRef]

- Shipway, P.; Hutchings, I. A method for optimizing the particle flux in erosion testing with a gas-blast apparatus. Wear 1994, 174, 169–175. [Google Scholar] [CrossRef]

- McKeen, L.W. The Effect of Temperature and Other Factors on Plastics and Elastomers; William Andrew: Norwich, NY, USA, 2014. [Google Scholar] [CrossRef]

- Matsushita, A.; Gonzalez, D.; Wang, M.; Doan, J.; Qiao, Y.; McKittrick, J. Beyond density: Mesostructural features of impact resistant wood. Mater. Today Commun. 2019, 22, 100697. [Google Scholar] [CrossRef]

- Mondel, D.; Das, S.; Prasad, B. Study of erosive-corrosive wear characteristics of an aluminium alloy composite through factorial design of experiments. Wear 1998, 217, 1–6. [Google Scholar] [CrossRef]

- Mahapatra, S.; Patnaik, A. Study on mechanical and erosion wear behavior of hybrid composites using Taguchi experimental design. Mater. Des. 2009, 30, 2791–2801. [Google Scholar] [CrossRef]

- Tarodiya, R.; Levy, A. Erosion of polymers and polymer composites surfaces by particles. Adv. Powder Technol. 2021, 32, 3149–3159. [Google Scholar] [CrossRef]

- Arjula, S.; Harsha, A.P.; Ghosh, M.K. Solid-particle erosion behavior of high-performance thermoplastic polymers. J. Mater. Sci. 2008, 43, 1757–1768. [Google Scholar] [CrossRef]

- Liu, B.; Bao, L.; Xu, A. Effect of fabric orientation and impact angle on the erosion behavior of high-performance thermoplastic composites reinforced with ductile fabric. Wear 2016, 352–353, 24–30. [Google Scholar] [CrossRef]

- Ayub, S.; Guan, B.H.; Ahmad, F.; Nisa, Z.U. A Shear Mixing approach in Polymer Composite Formation. In Proceedings of the 2021 Third International Sustainability and Resilience Conference: Climate Change, Online Conference, 15–16 November 2021; pp. 205–210. [Google Scholar]

- Harsha, A.P.; Nagesh, D.S. Prediction of weight loss of various polyaryletherketones and their composites in three-body abrasive wear situation using artificial neural networks. J. Reinf. Plast. Compos. 2007, 26, 1367–1377. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, F.; Li, L.; Shen, C.; Castro, J.; Lee, L.J. Thickness effect on particle erosion resistance of thermoplastic polyurethane coating on steel substrate. Wear 2013, 303, 49–55. [Google Scholar] [CrossRef]

- Balaji, E.; Moorthy, R.S. Investigation on Mechanical and Wear Properties of ZE43 Magnesium Composites Reinforced with Silicon Nitride by Friction Stir Processing. Silicon 2022, in press. [Google Scholar] [CrossRef]

- Pool, K.; Dharan, C.; Finnie, I. Erosive wear of composite materials. Wear 1986, 107, 1–12. [Google Scholar] [CrossRef]

- Reifsnider, K.; Sendeckyj, G.; Wang, S.; Johnson, W.; Stinchcomb, W.; Pagano, N.; Tsiang, T.-H. Survey of Sand and Rain Erosion of Composite Materials. J. Compos. Technol. Res. 1986, 8, 154. [Google Scholar] [CrossRef]

- Reyna, J.L.; Chester, M.V.; Ahn, S.; Fraser, A.M. Improving the Accuracy of Vehicle Emissions Profiles for Urban Transportation Greenhouse Gas and Air Pollution Inventories. Environ. Sci. Technol. 2014, 49, 369–376. [Google Scholar] [CrossRef]

- Jing, W.; Zhang, F.; Chen, H. Comparative tribological performance and erosion resistance of epoxy resin composite coatings reinforced with aramid fiber and carbon fiber. Colloid. Surf. A 2021, 648, 129354. [Google Scholar] [CrossRef]

- Muboyadzhyan, S.; Pomelov, Y.A. Erosion resistance of coatings deposited by high-energy plasmochemistry. Vopr. Aviats. Nauki Tekhn. 1992, 114, 58–66. [Google Scholar]

- Muboyadzhyan, S.A. Erosion-resistant coatings for gas turbine compressor blades. Russ. Met. 2009, 2009, 183–196. [Google Scholar] [CrossRef]

- Kablov, E.N.; Muboyadzhyan, S.A. Erosion-resistant coatings for gas turbine engine compressor blades. Russ. Met. 2017, 2017, 494–504. [Google Scholar] [CrossRef]

- Bartczak, Z.; Grala, M.; Richaud, E.; Gadzinowska, K. Erosion of the molecular network in the amorphous layers of polyethylene upon high- strain deformation. Polymer 2016, 99, 552–565. [Google Scholar] [CrossRef]

- Li, C.; Li, Y.; Shi, J.; Li, B.; Gao, Y.; Goei, R.; Li, Y.; Shah, I.A.; Wu, K.; Zhao, S.; et al. Interfacial characterization and erosive wear performance of zirconia toughened alumina ceramics particles reinforced high chromium white cast irons composites. Tribol. Int. 2021, 165, 107262. [Google Scholar] [CrossRef]

- Barkoula, N.-M. Solid Particle Erosion Behaviour of Polymers and Polymeric Composites. Ph.D. Thesis, University of Kaiserslautern, Kaiserslautern, Germany, 2002. [Google Scholar]

- Myshkin, N.K.; Grigoriev, F.A. Green Tribology for Sustainable Development Goals. In International Workshop IFToMM for Sustainable Development Goals; Springer: Berlin/Heidelberg, Germany, 2021; pp. 421–428. [Google Scholar]

- Suresh, A.; Harsha, A.; Ghosh, M. Erosion Studies of Short Glass Fiber-reinforced Thermoplastic Composites and Prediction of Erosion Rate Using ANNs. J. Reinf. Plast. Compos. 2009, 29, 1641–1652. [Google Scholar] [CrossRef]

- Rout, A.; Satapathy, A.; Mantry, S.; Sahoo, A.; Mohanty, T. Erosion wear performance analysis of polyester-GF-granite hybrid composites using the Taguchi method. Procedia Eng. 2012, 38, 1863–1882. [Google Scholar] [CrossRef] [Green Version]

- Wee, S.K.; Yap, Y.J. CFD study of sand erosion in pipeline. J. Pet. Sci. Eng. 2019, 176, 269–278. [Google Scholar] [CrossRef]

- Liu, Z.; Wan, S.; Nguyen, V.; Zhang, Y.-W. A numerical study on the effect of particle shape on the erosion of ductile materials. Wear 2014, 313, 135–142. [Google Scholar] [CrossRef]

- Seward, O.; Cepero-Mejías, F.; Fairclough, J.P.A.; Kerrigan, K. Development of a Novel Friction Model for Machining Simulations in Unidirectional Composite Materials. Polymers 2022, 14, 847. [Google Scholar] [CrossRef]

- Zhang, W.; Brinn, C.; Cook, A.; Pascual-Marquez, F. Ice-Release and Erosion Resistant Materials for Wind Turbines. J. Physics Conf. Ser. 2017, 926, 012002. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, M.A.; Çamur, H.; Savaş, M.A.; Abba, S. Multi-Response Optimization and Prediction of Tribological Behaviours of Filled Polytetrafluoroethylene Composites Using Taguchi-Deng and Evolutionary Harris Hawk’s Optimization Methodologies. Research Square 2022. [Google Scholar] [CrossRef]

- Zahavi, J.; Schmitt, G.F. Solid particle erosion of reinforced composite materials. Wear 1981, 71, 179–190. [Google Scholar] [CrossRef]

- Zahavi, J.; Schmitt, G.F. Solid particle erosion of polymeric coatings. Wear 1981, 71, 191–210. [Google Scholar] [CrossRef]

- Un Nisa, Z.; Chuan, L.K.; Ayub, S.; Guan, B.H.; Ahmad, F. Thermal and Morphological Characterization of Coagula-tion-Processed Nanocomposite of Polypropylene and Bio-nanocarbon obtained from Bamboo. In Proceedings of the 2021 Third International Sustainability and Resilience Conference: Climate Change, Online Conference, 15–16 November 2021; pp. 436–439. [Google Scholar]

- Guo, J.; Song, H.; Liu, H.; Luo, C.; Ren, Y.; Ding, T.; Khan, M.A.; Young, D.P.; Liu, X.; Zhang, X.; et al. Polypyrrole-interface-functionalized nano-magnetite epoxy nanocomposites as electromagnetic wave absorbers with enhanced flame retardancy. J. Mater. Chem. C 2017, 5, 5334–5344. [Google Scholar] [CrossRef]

- Al Rashid, A.; Ahmed, W.; Khalid, M.Y.; Koç, M. Vat photopolymerization of polymers and polymer composites: Processes and applications. Addit. Manuf. 2021, 47, 102279. [Google Scholar] [CrossRef]

- Ayub, S.; Guan, B.H.; Ahmad, F. Graphene and Iron based composites as EMI shielding: A Systematic Review. In Proceedings of the 2020 Second International Sustainability and Resilience Conference: Technology and Innovation in Building Designs, Sakheer, Bahrain, 11–12 November 2020; pp. 1–5. [Google Scholar]

- Rattan, R.; Bijwe, J. Influence of impingement angle on solid particle erosion of carbon fabric reinforced polyeth-erimide composite. Wear 2007, 262, 568–574. [Google Scholar] [CrossRef]

- Gong, Y.; Cui, C.; Wu, M.; Miao, X. The water droplet erosion resistance of Ni-based composite coating through laser cladding. Mater. Res. Express 2021, 8, 096524. [Google Scholar] [CrossRef]

- Kim, A.; Kim, I. Solid particle erosion of CFRP composite with different laminate orientations. Wear 2009, 267, 1922–1926. [Google Scholar] [CrossRef]

- Barkoula, N.-M.; Karger-Kocsis, J. Effects of fibre content and relative fibre-orientation on the solid particle erosion of GF/PP composites. Wear 2002, 252, 80–87. [Google Scholar] [CrossRef]

- Quaranta, E.; Davies, P. Emerging and Innovative Materials for Hydropower Engineering Applications: Turbines, Bearings, Sealing, Dams and Waterways, and Ocean Power. Engineering 2021, 8, 148–158. [Google Scholar] [CrossRef]

- Miyazaki, N.; Takeda, N. Solid Particle Erosion of Fiber Reinforced Plastics. J. Compos. Mater. 1993, 27, 21–31. [Google Scholar] [CrossRef]

- Roy, M.; Vishwanathan, B.; Sundararajan, G. The solid particle erosion of polymer matrix composites. Wear 1994, 171, 149–161. [Google Scholar] [CrossRef]

- Harsha, A.; Tewari, U.; Venkatraman, B. Solid particle erosion behaviour of various polyaryletherketone composites. Wear 2003, 254, 693–712. [Google Scholar] [CrossRef]

- Horstman, R.; Peters, K.; Schindler, B.; Meltzer, R.; Vieth, M.; Thai, C.; Tsuda, K.; Hojo, H. Erosion Behavior of Polystyrene. J. Test. Eval. 1981, 9, 359. [Google Scholar] [CrossRef]

- Walley, S.; Field, J.; Yennadhiou, P. Single solid particle impact erosion damage on polypropylene. Wear 1984, 100, 263–280. [Google Scholar] [CrossRef]

- Friedrich, K. Erosive wear of polymer surfaces by steel ball blasting. J. Mater. Sci. 1986, 21, 3317–3332. [Google Scholar] [CrossRef]

- Rajesh, J.; Bijwe, J.; Tewari, U.; Venkataraman, B. Erosive wear behavior of various polyamides. Wear 2001, 249, 702–714. [Google Scholar] [CrossRef]

- Walley, S.M.; Field, J.E. The erosion and deformation of polyethylene by solid-particle impact. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Sci. 1987, 321, 277–303. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, L.; Liu, W.; Li, J. The blast erosion behaviour of ultrahigh molecular weight polyethylene. Wear 1998, 218, 128–133. [Google Scholar] [CrossRef]

- Walley, S.; Field, J.; Greengrass, M. An impact and erosion study of polyetheretherketone. Wear 1987, 114, 59–72. [Google Scholar] [CrossRef]

- Rao, P.V.; Buckley, D.H. Angular Particle Impingement Studies of Thermoplastic Materials at Normal Incidence. ASLE Trans. 1986, 29, 283–298. [Google Scholar] [CrossRef]

- Tilly, G.; Sage, W. The interaction of particle and material behaviour in erosion processes. Wear 1970, 16, 447–465. [Google Scholar] [CrossRef]

- Brandstädter, A.; Goretta, K.; Routbort, J.; Groppi, D.; Karasek, K. Solid-particle erosion of bismaleimide polymers. Wear 1991, 147, 155–164. [Google Scholar] [CrossRef]

- Arani, N.H.; Eghbal, M.; Papini, M. Modeling the solid particle erosion of rubber particulate-reinforced epoxy. Tribol. Int. 2020, 153, 106656. [Google Scholar] [CrossRef]

- Tarodiya, R.; Levy, A. Surface erosion due to particle-surface interactions—A review. Powder Technol. 2021, 387, 527–559. [Google Scholar] [CrossRef]

- Cui, X.; Zhu, G.; Pan, Y.; Shao, Q.; Zhao, C.; Dong, M.; Zhang, Y.; Guo, Z. Polydimethylsiloxane-titania nanocomposite coating: Fabrication and corrosion resistance. Polymer 2018, 138, 203–210. [Google Scholar] [CrossRef]

- Virk, A.S.; Hall, W.; Summerscales, J. Failure strain as the key design criterion for fracture of natural fibre composites. Compos. Sci. Technol. 2010, 70, 995–999. [Google Scholar] [CrossRef]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, J.; Yang, H.; Wang, X.; Cai, Z.; Zhu, M. Effect of modulation of interfacial properties on the tribo-logical properties of viscoelastic epoxy resin damping coatings. Polym. Test. 2021, 100, 107229. [Google Scholar] [CrossRef]

- Xie, G.; Sun, X.H.; Gong, H.J.; Ren, Y.L.; Chen, H.; Li, M.Y.; Li, Y.B.; Zhang, L.; Ji, Z.J.; Si, L.N. Tribology of Polymer Composites with Green Nano-Materials. In Green Tribology; CRC Press: Boca Raton, FL, USA, 2021; p. 129. [Google Scholar]

- Tsuda, K.; Kubouchi, M.; Sakai, T.; Saputra, A.H.; Mitomo, N. General method for predicting the sand erosion rate of GFRP. Wear 2006, 260, 1045–1052. [Google Scholar] [CrossRef]

- Harsha, A.; Jha, S.K. Erosive wear studies of epoxy-based composites at normal incidence. Wear 2008, 265, 1129–1135. [Google Scholar] [CrossRef]

- Manders, P.W.; Bader, M.G. The strength of hybrid glass/carbon fibre composites. J. Mater. Sci. 1981, 16, 2246–2256. [Google Scholar] [CrossRef]

- Abenojar, J.; Tutor, J.; Ballesteros, Y.; del Real, J.; Martinez, M.A. Erosion-wear, mechanical and thermal properties of silica filled epoxy nanocomposites. Compos. Part B Eng. 2017, 120, 42–53. [Google Scholar] [CrossRef]

- Sabzi, M.; Mirabedini, S.; Zohuriaan-Mehr, J.; Atai, M. Surface modification of TiO2 nano-particles with silane coupling agent and investigation of its effect on the properties of polyurethane composite coating. Prog. Org. Coat. 2009, 65, 222–228. [Google Scholar] [CrossRef]

- Burnside, S.D.; Giannelis, E.P. Synthesis and properties of new poly(dimethylsiloxane) nanocomposites. Chem. Mater. 1995, 7, 1597–1600. [Google Scholar] [CrossRef]

- De Oliveira, A.D.; Beatrice, C.A.G. Polymer nanocomposites with different types of nanofiller. In Nanocomposites-Recent Evolutions; IntechOpen: London, UK, 2018; pp. 103–104. [Google Scholar]

- Abdollahi, M.; Alboofetileh, M.; Rezaei, M.; Behrooz, R. Comparing physico-mechanical and thermal properties of alginate nanocomposite films reinforced with organic and/or inorganic nanofillers. Food Hydrocoll. 2013, 32, 416–424. [Google Scholar] [CrossRef]

- Balasubramanian, K.B.N.; Ramesh, T. Role, effect, and influences of micro and nano-fillers on various properties of polymer matrix composites for microelectronics: A review. Polym. Adv. Technol. 2018, 29, 1568–1585. [Google Scholar] [CrossRef]

- Saba, N.; Md Tahir, P.; Jawaid, M. A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Zhang, L.; Wan, W.; Jiang, X.; Wang, B.; Yin, L.; Agathopoulos, S.; Xie, J.; Zhang, L.; Lu, H.; Deng, L. Enhancement of oxidation and corrosion resistance of flaky carbonyl-iron powder via SiO2/KH560/PDMS coating applied with sol-gel. Surf. Coat. Technol. 2022, 437, 128346. [Google Scholar] [CrossRef]

- Kumar, S.; Satapathy, B.K.; Patnaik, A. Thermo-mechanical correlations to erosion performance of short glass/carbon fiber reinforced vinyl ester resin hybrid composites. Comput. Mater. Sci. 2012, 60, 250–260. [Google Scholar] [CrossRef]

- Bahramnia, H.; Mohammadian Semnani, H.; Habibolahzadeh, A.; Abdoos, H. Epoxy/polyurethane nano-composite coatings for anti-erosion/wear applications: A review. J. Compos. Mater. 2020, 54, 3189–3203. [Google Scholar] [CrossRef]

- Chellaganesh, D.; Khan, M.A.; Ashif, A.M.; Selvan, T.R.; Nachiappan, S.; Jappes, J.T.W. Hybrid Composite Material and Solid Particle Erosion Studies. IOP Conf. Ser. Mater. Sci. Eng. 2018, 346, 012014. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, M.; Li, J.; Yu, J.; Sun, S.; Ge, S.; Guo, X.; Xie, F.; Jiang, B.; Wujcik, E.K.; et al. Silver nanoparticles/graphene oxide decorated carbon fiber synergistic reinforcement in epoxy-based compo-sites. Polymer 2017, 131, 263–271. [Google Scholar] [CrossRef]

- Tewari, U.S.; Harsha, A.P.; Häger, A.M.; Friedrich, K. Solid particle erosion of carbon fibre–and glass fibre–epoxy composites. Compos. Sci. Technol. 2003, 63, 549–557. [Google Scholar] [CrossRef]

- Harsha, A.; Thakre, A. Investigation on solid particle erosion behaviour of polyetherimide and its composites. Wear 2007, 262, 807–818. [Google Scholar] [CrossRef]

- Suresh, A.; Harsha, A.; Ghosh, M. Solid particle erosion of unidirectional fibre reinforced thermoplastic composites. Wear 2009, 267, 1516–1524. [Google Scholar] [CrossRef]

- Suresh, A.; Harsha, A.; Ghosh, M. Solid particle erosion studies on polyphenylene sulfide composites and prediction on erosion data using artificial neural networks. Wear 2009, 266, 184–193. [Google Scholar] [CrossRef]

- Chen, J.; Trevarthen, J.A.; Deng, T.; Bradley, M.S.; Rahatekar, S.S.; Koziol, K. Aligned carbon nanotube reinforced high performance polymer composites with low erosive wear. Compos. Part A Appl. Sci. Manuf. 2014, 67, 86–95. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Li, D.; Sun, Y.; Wang, Z.; Hou, C.; Chen, L.; Cao, Y.; Liu, Y. Mechanical and Anticorrosive Properties of Graphene/Epoxy Resin Composites Coating Prepared by in-Situ Method. Int. J. Mol. Sci. 2015, 16, 2239–2251. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y.; Tian, X.; Wang, Y.; Sun, Y.; Yu, H.; Li, D.-S.; Liu, Y. In Situ Synthesis of Reduced Graphene Oxide-Reinforced Silicone-Acrylate Resin Composite Films Applied in Erosion Resistance. J. Nanomater. 2015, 2015, 405087. [Google Scholar] [CrossRef]

- Gul, S.; Kausar, A.; Muhammad, B.; Jabeen, S. Technical Relevance of Epoxy/Clay Nanocomposite with Organically Modified Montmorillonite: A Review. Polym. Technol. Eng. 2016, 55, 1393–1415. [Google Scholar] [CrossRef]

- Wang, X.; Qi, X.; Lin, Z.; Battocchi, D. Graphene Reinforced Composites as Protective Coatings for Oil and Gas Pipelines. Nanomaterials 2018, 8, 1005. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- MacLean, M.; Farhat, Z.; Jarjoura, G.; Fayyad, E.; Abdullah, A.; Hassan, M. Fabrication and investigation of the scratch and indentation behaviour of new generation Ni-P-nano-NiTi composite coating for oil and gas pipelines. Wear 2019, 426, 265–276. [Google Scholar] [CrossRef]

- Rampur, V.; Banagar, A.R.; Ganesh, U.L.; Srinivas, C.V.; Reur, S.C. Mechanical characterization of wood apple and coconut shell reinforced hybrid composites. AIP Conf. Proc. 2020, 2247, 040001. [Google Scholar] [CrossRef]

- Durmaz, B.; Aytac, A. Characterization of carbon fiber-reinforced poly(phenylene sulfide) composites prepared with various compatibilizers. J. Compos. Mater. 2019, 54, 89–100. [Google Scholar] [CrossRef]

- Dong, M.; Li, Q.; Liu, H.; Liu, C.; Wujcik, E.K.; Shao, Q.; Ding, T.; Mai, X.; Shen, C.; Guo, Z. Thermoplastic polyurethane-carbon black nanocomposite coating: Fabrication and solid particle erosion resistance. Polymer 2018, 158, 381–390. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, Z.; Chen, J.; Fan, B.; Qi, X.; Ma, J.; Gu, D.; Yang, Y.; Song, L. Effects of Surface-Modified Graphite on Tribological Properties and Thermal Conductivity of Fabric Self-Lubricating Liner. Asian J. Chem. 2014, 26, 5712–5716. [Google Scholar] [CrossRef]

- Mohammad, F.; Sharif, M.A.; Ahmed, A.; Suhail, M. Development and characterization of Silicon Carbide Coating on Graphite Substrate. Res. Sq. 2021, preprint. [Google Scholar]

- Ayub, S.; Guan, B.; Ahmad, F.; Oluwatobi, Y.; Nisa, Z.; Javed, M.; Mosavi, A. Graphene and Iron Reinforced Polymer Composite Electromagnetic Shielding Applications: A Review. Polymers 2021, 13, 2580. [Google Scholar] [CrossRef]

- Arjula, S.; Harsha, A.; Ghosh, M. Erosive wear of unidirectional carbon fibre reinforced polyetherimide composite. Mater. Lett. 2008, 62, 3246–3249. [Google Scholar] [CrossRef]

- Fouad, Y.; El-Meniawi, M.; Afifi, A. Erosion behaviour of epoxy based unidirectionl (GFRP) composite materials. Alex. Eng. J. 2011, 50, 29–34. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Satapathy, B.K.; Patnaik, A. Thermo-mechanical correlations to erosion performance of short carbon fibre reinforced vinyl ester resin composites. Mater. Des. 2011, 32, 2260–2268. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nisa, Z.U.; Chuan, L.K.; Guan, B.H.; Ayub, S.; Ahmad, F. Anti-Wear and Anti-Erosive Properties of Polymers and Their Hybrid Composites: A Critical Review of Findings and Needs. Nanomaterials 2022, 12, 2194. https://doi.org/10.3390/nano12132194

Nisa ZU, Chuan LK, Guan BH, Ayub S, Ahmad F. Anti-Wear and Anti-Erosive Properties of Polymers and Their Hybrid Composites: A Critical Review of Findings and Needs. Nanomaterials. 2022; 12(13):2194. https://doi.org/10.3390/nano12132194

Chicago/Turabian StyleNisa, Zaib Un, Lee Kean Chuan, Beh Hoe Guan, Saba Ayub, and Faiz Ahmad. 2022. "Anti-Wear and Anti-Erosive Properties of Polymers and Their Hybrid Composites: A Critical Review of Findings and Needs" Nanomaterials 12, no. 13: 2194. https://doi.org/10.3390/nano12132194

APA StyleNisa, Z. U., Chuan, L. K., Guan, B. H., Ayub, S., & Ahmad, F. (2022). Anti-Wear and Anti-Erosive Properties of Polymers and Their Hybrid Composites: A Critical Review of Findings and Needs. Nanomaterials, 12(13), 2194. https://doi.org/10.3390/nano12132194