Hybrid Carbon Nanotubes–Graphene Nanostructures: Modeling, Formation, Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Method for Modeling the Carbon Nanomaterials Behavior under the Influence of Electromagnetic Field of Laser Radiation

2.2. Method for Creating Carbon Nanomaterials Dispersions and Applying Them to Substrate

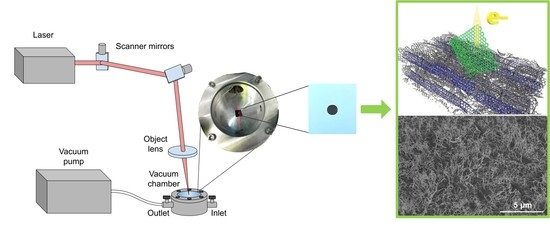

2.3. Method of Laser Formation of Hybrid Nanostructures

2.4. Scanning Electron Microscopy

2.5. Raman Spectroscopy

2.6. Mechanical Characteristics

2.7. Field Emission Characteristics

3. Results

3.1. Modeling of Laser Formation of Hybrid Nanostructures from Carbon Nanomaterials

3.2. Deposition of Carbon Nanomaterials on Si Substrate

3.3. Laser Formation of Hybrid Nanostructures Based on SWCNT and rGO on Si Substrate

3.4. Influence of Laser Radiation on Mechanical Properties of Hybrid Nanostructures

3.5. Effect of Laser Radiation on the Emission Characteristics of Hybrid Nanostructures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Holland, C.E.; Schwoebel, P.R. Cold Cathode Based Microwave Devices for Current and Future Systems. In Proceedings of the 2018 31st International Vacuum Nanoelectronics Conference (IVNC), Kyoto, Japan, 9–13 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–2. [Google Scholar]

- Choi, Y.; Michan, M.; Johnson, J.L.; Naieni, A.K.; Ural, A.; Nojeh, A. Field-emission properties of individual GaN nanowires grown by chemical vapor deposition. J. Appl. Phys. 2012, 111, 044308. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, T.J.; Lyu, S.C.; Zhang, Y.; Ruh, H.; Lee, H.J. Field emission from well-aligned zinc oxide nanowires grown at low temperature. Appl. Phys. Lett. 2002, 81, 3648–3650. [Google Scholar] [CrossRef]

- Giubileo, F.; Di Bartolomeo, A.; Iemmo, L.; Luongo, G.; Passacantando, M.; Koivusalo, E.; Hakkarainen, T.; Guina, M. Field Emission from Self-Catalyzed GaAs Nanowires. Nanomaterials 2017, 7, 275. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Zheng, Z.; Wu, H.; Zhu, L. Field emission properties and growth mechanism of In2O3 nanostructures. Nanoscale Res. Lett. 2014, 9, 111. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Passacantando, M.; Niu, G.; Schlykow, V.; Lupina, G.; Giubileo, F.; Schroeder, T. Observation of field emission from GeSn nanoparticles epitaxially grown on silicon nanopillar arrays. Nanotechnology 2016, 27, 485707. [Google Scholar] [CrossRef] [PubMed]

- Iemmo, L.; Di Bartolomeo, A.; Giubileo, F.; Luongo, G.; Passacantando, M.; Niu, G.; Hatami, F.; Skibitzki, O.; Schroeder, T. Graphene enhanced field emission from InP nanocrystals. Nanotechnology 2017, 28, 495705. [Google Scholar] [CrossRef] [PubMed]

- Lin, P.-H.; Sie, C.-L.; Chen, C.-A.; Chang, H.-C.; Shih, Y.-T.; Chang, H.-Y.; Su, W.-J.; Lee, K.-Y. Field Emission Characteristics of the Structure of Vertically Aligned Carbon Nanotube Bundles. Nanoscale Res. Lett. 2015, 10, 297. [Google Scholar] [CrossRef] [PubMed]

- Giubileo, F.; Bartolomeo, A.D.; Scarfato, A.; Iemmo, L.; Bobba, F.; Passacantando, M.; Santucci, S.; Cucolo, A.M. Local probing of the field emission stability of vertically aligned multi-walled carbon nanotubes. Carbon N. Y. 2009, 47, 1074–1080. [Google Scholar] [CrossRef]

- Wang, M.S.; Peng, L.-M.; Wang, J.Y.; Chen, Q. Electron Field Emission Characteristics and Field Evaporation of a Single Carbon Nanotube. J. Phys. Chem. B 2005, 109, 110–113. [Google Scholar] [CrossRef]

- Di, Y.; Xiao, M.; Zhang, X.; Wang, Q.; Li, C.; Lei, W.; Cui, Y. Large and stable emission current from synthesized carbon nanotube/fiber network. J. Appl. Phys. 2014, 115, 064305. [Google Scholar] [CrossRef]

- Kumar, S.; Duesberg, G.S.; Pratap, R.; Raghavan, S. Graphene field emission devices. Appl. Phys. Lett. 2014, 105, 103107. [Google Scholar] [CrossRef]

- Santandrea, S.; Giubileo, F.; Grossi, V.; Santucci, S.; Passacantando, M.; Schroeder, T.; Lupina, G.; Di Bartolomeo, A. Field emission from single and few-layer graphene flakes. Appl. Phys. Lett. 2011, 98, 163109. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Giubileo, F.; Iemmo, L.; Romeo, F.; Russo, S.; Unal, S.; Passacantando, M.; Grossi, V.; Cucolo, A.M. Leakage and field emission in side-gate graphene field effect transistors. Appl. Phys. Lett. 2016, 109, 023510. [Google Scholar] [CrossRef]

- Urban, F.; Passacantando, M.; Giubileo, F.; Iemmo, L.; Di Bartolomeo, A. Transport and Field Emission Properties of MoS2 Bilayers. Nanomaterials 2018, 8, 151. [Google Scholar] [CrossRef] [PubMed]

- Dwivedi, N.; Dhand, C.; Carey, J.D.; Anderson, E.C.; Kumar, R.; Srivastava, A.K.; Malik, H.K.; Saifullah, M.S.M.; Kumar, S.; Lakshminarayanan, R.; et al. The rise of carbon materials for field emission. J. Mater. Chem. C 2021, 9, 2620–2659. [Google Scholar] [CrossRef]

- Ramalingame, R.; Lakshmanan, A.; Müller, F.; Thomas, U.; Kanoun, O. Highly sensitive capacitive pressure sensors for robotic applications based on carbon nanotubes and PDMS polymer nanocomposite. J. Sens. Sens. Syst. 2019, 8, 87–94. [Google Scholar] [CrossRef]

- Demidenko, N.A.; Kuksin, A.V.; Molodykh, V.V.; Pyankov, E.S.; Ichkitidze, L.P.; Zaborova, V.A.; Tsymbal, A.A.; Tkachenko, S.A.; Shafaei, H.; Diachkova, E.; et al. Flexible Strain-Sensitive Silicone-CNT Sensor for Human Motion Detection. Bioengineering 2022, 9, 36. [Google Scholar] [CrossRef]

- Wang, G.; Liu, J.; Chen, K.; Pathak, R.; Gurung, A.; Qiao, Q. High-performance carbon electrode-based CsPbI2Br inorganic perovskite solar cell based on poly(3-hexylthiophene)-carbon nanotubes composite hole-transporting layer. J. Colloid Interface Sci. 2019, 555, 180–186. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Kurilova, U.E.; Savelyev, M.S.; Murashko, D.T.; Glukhova, O.E. Laser fabrication of composite layers from biopolymers with branched 3D networks of single-walled carbon nanotubes for cardiovascular implants. Compos. Struct. 2021, 260, 113517. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Kitsyuk, E.; Kurilova, U.E.; Suetina, I.A.; Russu, L.; Mezentseva, M.V.; Markov, A.; Narovlyansky, A.N.; Kravchenko, S.; Selishchev, S.V.; et al. Interfaces Based on Laser-Structured Arrays of Carbon Nanotubes with Albumin for Electrical Stimulation of Heart Cell Growth. Polymers 2022, 14, 1866. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Dayyoub, T.; Telyshev, D.V.; Gerasimenko, A.Y. Electroactive Polymer-Based Composites for Artificial Muscle-like Actuators: A Review. Nanomaterials 2022, 12, 2272. [Google Scholar] [CrossRef] [PubMed]

- Putra, N.; Rawi, S.; Amin, M.; Kusrini, E.; Kosasih, E.A.; Indra Mahlia, T.M. Preparation of beeswax/multi-walled carbon nanotubes as novel shape-stable nanocomposite phase-change material for thermal energy storage. J. Energy Storage 2019, 21, 32–39. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, Y.; Cole, M.T.; Yan, Y.; Li, X.; Parmee, R.; Wu, J.; Xu, N.; Milne, W.I.; Deng, S. A truncated-cone carbon nanotube cold-cathode electron gun. Carbon N. Y. 2017, 120, 374–379. [Google Scholar] [CrossRef]

- Perales-Martinez, I.A.; Velásquez-García, L.F. Fully 3D-printed carbon nanotube field emission electron sources with in-plane gate electrode. Nanotechnology 2019, 30, 495303. [Google Scholar] [CrossRef]

- Chen, Q.; Yuan, X.; Xu, X.; Zhang, Y.; Cole, M.T.; Zu, Y.; Chen, Z.; Yin, Y.; Li, H.; Meng, L.; et al. Development of a High-Beam-Transparency Gridded Electron Gun Based on a Carbon Nanotube Cold Cathode. IEEE Electron Device Lett. 2022, 43, 615–618. [Google Scholar] [CrossRef]

- Kuang, H.; Zhang, H.; Liu, X.; Chen, Y.; Zhang, W.; Chen, H.; Ling, Q. Microwave-assisted synthesis of NiCo-LDH/graphene nanoscrolls composite for supercapacitor. Carbon N. Y. 2022, 190, 57–67. [Google Scholar] [CrossRef]

- Cossutta, M.; Vretenar, V.; Centeno, T.A.; Kotrusz, P.; McKechnie, J.; Pickering, S.J. A comparative life cycle assessment of graphene and activated carbon in a supercapacitor application. J. Clean. Prod. 2020, 242, 118468. [Google Scholar] [CrossRef]

- Tian, J.; Wu, S.; Yin, X.; Wu, W. Novel preparation of hydrophilic graphene/graphene oxide nanosheets for supercapacitor electrode. Appl. Surf. Sci. 2019, 496, 143696. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Tan, W.K.; Kawamura, G.; Matsuda, A.; Kar, K.K. Microwave-assisted thin reduced graphene oxide-cobalt oxide nanoparticles as hybrids for electrode materials in supercapacitor. J. Energy Storage 2021, 40, 102724. [Google Scholar] [CrossRef]

- Joanni, E.; Kumar, R.; Fernandes, W.P.; Savu, R.; Matsuda, A. In situ growth of laser-induced graphene micro-patterns on arbitrary substrates. Nanoscale 2022, 14, 8914–8918. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, L.; Hu, N.; Yin, D.; Zhu, W.; Chen, S.; Zhu, S.; Yu, W.; Tian, Y. Pillared carbon@tungsten decorated reduced graphene oxide film for pressure sensors with ultra-wide operation range in motion monitoring. Carbon N. Y. 2022, 189, 430–442. [Google Scholar] [CrossRef]

- Liu, W.; Chen, Q.; Huang, Y.; Wang, D.; Li, L.; Liu, Z. In situ laser synthesis of Pt nanoparticles embedded in graphene films for wearable strain sensors with ultra-high sensitivity and stability. Carbon N. Y. 2022, 190, 245–254. [Google Scholar] [CrossRef]

- Chen, R.; Luo, T.; Geng, D.; Shen, Z.; Zhou, W. Facile fabrication of a fast-response flexible temperature sensor via laser reduced graphene oxide for contactless human-machine interface. Carbon N. Y. 2022, 187, 35–46. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Li, T.; Zhang, L.; Meng, F. Recent advances in graphene-based films for electromagnetic interference shielding: Review and future prospects. Carbon N. Y. 2021, 180, 163–184. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuan, Y.; Cao, G.; Han, C.; Li, X.; Wang, X.; Zhang, G.; Geng, L.; Liu, W. A fresh-bias photoresponse of graphene field-effect transistor: An electrical tunable fast dipole moment generation. Carbon N. Y. 2021, 173, 322–328. [Google Scholar] [CrossRef]

- Shen, Z.; Du, J.; Mo, Y.; Chen, A. Nanocomposites of reduced graphene oxide modified with mesoporous carbon layers anchored by hollow carbon spheres for energy storage. Carbon N. Y. 2021, 173, 22–30. [Google Scholar] [CrossRef]

- Kumar, R.; Macedo, W.C.; Singh, R.K.; Tiwari, V.S.; Constantino, C.J.L.; Matsuda, A.; Moshkalev, S.A. Nitrogen–Sulfur Co-Doped Reduced Graphene Oxide-Nickel Oxide Nanoparticle Composites for Electromagnetic Interference Shielding. ACS Appl. Nano Mater. 2019, 2, 4626–4636. [Google Scholar] [CrossRef]

- Pal, K.; Si, A.; El-Sayyad, G.S.; Elkodous, M.A.; Kumar, R.; El-Batal, A.I.; Kralj, S.; Thomas, S. Cutting edge development on graphene derivatives modified by liquid crystal and CdS/TiO2 hybrid matrix: Optoelectronics and biotechnological aspects. Crit. Rev. Solid State Mater. Sci. 2021, 46, 385–449. [Google Scholar] [CrossRef]

- Murakami, K.; Miyaji, J.; Furuya, R.; Adachi, M.; Nagao, M.; Neo, Y.; Takao, Y.; Yamada, Y.; Sasaki, M.; Mimura, H. High-performance planar-type electron source based on a graphene-oxide-semiconductor structure. Appl. Phys. Lett. 2019, 114, 213501. [Google Scholar] [CrossRef]

- Naghdi, S.; Sanchez-Arriaga, G.; Rhee, K.Y. Tuning the work function of graphene toward application as anode and cathode. J. Alloys Compd. 2019, 805, 1117–1134. [Google Scholar] [CrossRef]

- Kaur, G.; Pulagara, N.V.; Kumar, R.; Lahiri, I. Metal foam-carbon nanotube-reduced graphene oxide hierarchical structures for efficient field emission. Diam. Relat. Mater. 2020, 106, 107847. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.; Singh, A.K.; Vaz, A.R.; Rout, C.S.; Moshkalev, S.A. Facile and single step synthesis of three dimensional reduced graphene oxide-NiCoO2 composite using microwave for enhanced electron field emission properties. Appl. Surf. Sci. 2017, 416, 259–265. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Pei, S.; Ren, W.; Tang, D.; Gao, L.; Liu, B.; Li, F.; Liu, C.; Cheng, H.-M. Field Emission of Single-Layer Graphene Films Prepared by Electrophoretic Deposition. Adv. Mater. 2009, 21, 1756–1760. [Google Scholar] [CrossRef]

- Rinzler, A.G.; Hafner, J.H.; Nikolaev, P.; Nordlander, P.; Colbert, D.T.; Smalley, R.E.; Lou, L.; Kim, S.G.; Tománek, D. Unraveling Nanotubes: Field Emission from an Atomic Wire. Science 1995, 269, 1550–1553. [Google Scholar] [CrossRef] [PubMed]

- de Heer, W.A.; Châtelain, A.; Ugarte, D. A Carbon Nanotube Field-Emission Electron Source. Science 1995, 270, 1179–1180. [Google Scholar] [CrossRef]

- Park, S.; Gupta, A.; Yeo, S.; Jung, J.; Paik, S.; Mativenga, M.; Kim, S.; Shin, J.; Ahn, J.; Ryu, J. Carbon Nanotube Field Emitters Synthesized on Metal Alloy Substrate by PECVD for Customized Compact Field Emission Devices to Be Used in X-Ray Source Applications. Nanomaterials 2018, 8, 378. [Google Scholar] [CrossRef]

- Lim, Y.D.; Hu, L.; Xia, X.; Ali, Z.; Wang, S.; Tay, B.K.; Aditya, S.; Miao, J. Field emission properties of SiO2 -wrapped CNT field emitter. Nanotechnology 2018, 29, 015202. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Kitsyuk, E.P.; Kuksin, A.V.; Ryazanov, R.M.; Savitskiy, A.I.; Savelyev, M.S.; Pavlov, A.A. Influence of laser structuring and barium nitrate treatment on morphology and electrophysical characteristics of vertically aligned carbon nanotube arrays. Diam. Relat. Mater. 2019, 96, 104–111. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Yang, W.; Yu, W.; Feng, T.; Li, Q.; Liu, X.; Yang, C. Interaction between carbon nanotubes and substrate and its implication on field emission mechanism. Carbon N. Y. 2006, 44, 418–422. [Google Scholar] [CrossRef]

- Kumar, U.; Sikarwar, S.; Sonker, R.K.; Yadav, B.C. Carbon Nanotube: Synthesis and Application in Solar Cell. J. Inorg. Organomet. Polym. Mater. 2016, 26, 1231–1242. [Google Scholar] [CrossRef]

- Gabdullin, P.; Zhurkin, A.; Osipov, V.; Besedina, N.; Kvashenkina, O.; Arkhipov, A. Thin carbon films: Correlation between morphology and field-emission capability. Diam. Relat. Mater. 2020, 105, 107805. [Google Scholar] [CrossRef]

- Shin, D.H.; Yun, K.N.; Jeon, S.-G.; Kim, J.-I.; Saito, Y.; Milne, W.I.; Lee, C.J. High performance field emission of carbon nanotube film emitters with a triangular shape. Carbon N. Y. 2015, 89, 404–410. [Google Scholar] [CrossRef]

- Jung, S., II; Choi, J.S.; Shim, H.C.; Kim, S.; Jo, S.H.; Lee, C.J. Fabrication of probe-typed carbon nanotube point emitters. Appl. Phys. Lett. 2006, 89, 233108. [Google Scholar] [CrossRef]

- Kawakita, K.; Hata, K.; Sato, H.; Saito, Y. Development of microfocused x-ray source by using carbon nanotube field emitter. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2006, 24, 950. [Google Scholar] [CrossRef]

- Yi, C.; Wu, H.; Li, J.; Song, Y.; Song, Y.; Chen, X.; Ou-Yang, W. Crack-Assisted Field Emission Enhancement of Carbon Nanotube Films for Vacuum Electronics. ACS Appl. Nano Mater. 2019, 2, 7803–7809. [Google Scholar] [CrossRef]

- Qian, M.; Feng, T.; Wang, K.; Ding, H.; Chen, Y.; Li, Q.; Sun, Z. Field emission of carbon nanotube films fabricated by vacuum filtration. Phys. E Low Dimens. Syst. Nanostruct. 2010, 43, 462–465. [Google Scholar] [CrossRef]

- Zhu, L.; Huang, Y.; Yao, Z.; Quan, B.; Zhang, L.; Li, J.; Gu, C.; Xu, X.; Ren, Z. Enhanced polarization-sensitive terahertz emission from vertically grown graphene by a dynamical photon drag effect. Nanoscale 2017, 9, 10301–10311. [Google Scholar] [CrossRef]

- Jayalakshmi, G.; Saravanan, K.; Arun, T.; Suresh, K.; Sundaravel, B.; Panigrahi, B.K.; Kanjilal, D. Structure and electron field emission properties of ion beam reduced graphene oxide sheets. Carbon N. Y. 2017, 119, 172–178. [Google Scholar] [CrossRef]

- Deng, J.-H.; Cheng, G.-A.; Zheng, R.-T.; Yu, B.; Li, G.-Z.; Hou, X.-G.; Zhao, M.-L.; Li, D.-J. Catalyst-free, self-assembly, and controllable synthesis of graphene flake–carbon nanotube composites for high-performance field emission. Carbon N. Y. 2014, 67, 525–533. [Google Scholar] [CrossRef]

- Guo, Z.; Huang, H.-D.; Zhong, L.; Lv, R.; Huang, Z.-H.; Li, J.; Perea-Lopez, N.; Yang, P.; Terrones, M.; Ruoff, R.S.; et al. Hollow “graphene” microtubes using polyacrylonitrile nanofiber template and potential applications of field emission. Carbon N. Y. 2020, 167, 439–445. [Google Scholar] [CrossRef]

- Lee, D.H.; Lee, J.A.; Lee, W.J.; Kim, S.O. Flexible Field Emission of Nitrogen-Doped Carbon Nanotubes/Reduced Graphene Hybrid Films. Small 2011, 7, 95–100. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Ahmed, Z.; Wang, Q.; Yu, C.; Feng, Z.; Li, G.; Zhang, M.; Zhou, C.; Senegor, R.; Yang, C.Y. Structures, properties, and applications of CNT-graphene heterostructures. 2D Mater. 2019, 6, 042005. [Google Scholar] [CrossRef]

- Yan, Z.; Ma, L.; Zhu, Y.; Lahiri, I.; Hahm, M.G.; Liu, Z.; Yang, S.; Xiang, C.; Lu, W.; Peng, Z.; et al. Three-Dimensional Metal–Graphene–Nanotube Multifunctional Hybrid Materials. ACS Nano 2013, 7, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.H.; Kim, J.E.; Han, T.H.; Hwang, J.W.; Jeon, S.; Choi, S.-Y.; Hong, S.H.; Lee, W.J.; Ruoff, R.S.; Kim, S.O. Versatile Carbon Hybrid Films Composed of Vertical Carbon Nanotubes Grown on Mechanically Compliant Graphene Films. Adv. Mater. 2010, 22, 1247–1252. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Lee, D.H.; Lee, W.J.; Kim, S.O. Tailored Assembly of Carbon Nanotubes and Graphene. Adv. Funct. Mater. 2011, 21, 1338–1354. [Google Scholar] [CrossRef]

- Hong, X.; Shi, W.; Zheng, H.; Liang, D. Effective carbon nanotubes/graphene hybrid films for electron field emission application. Vacuum 2019, 169, 108917. [Google Scholar] [CrossRef]

- Deng, J.; Zheng, R.; Yang, Y.; Zhao, Y.; Cheng, G. Excellent field emission characteristics from few-layer graphene–carbon nanotube hybrids synthesized using radio frequency hydrogen plasma sputtering deposition. Carbon N. Y. 2012, 50, 4732–4737. [Google Scholar] [CrossRef]

- Wang, K.; Pang, J.; Li, L.; Zhou, S.; Li, Y.; Zhang, T. Synthesis of hydrophobic carbon nanotubes/reduced graphene oxide composite films by flash light irradiation. Front. Chem. Sci. Eng. 2018, 12, 376–382. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Lai, Y.-T.; Tai, N.-H. Enhanced field emission properties of a reduced graphene oxide/carbon nanotube hybrid film. Diam. Relat. Mater. 2014, 47, 1–6. [Google Scholar] [CrossRef]

- Song, M.; Xu, P.; Song, Y.; Wang, X.; Li, Z.; Shang, X.; Wu, H.; Zhao, P.; Wang, M. Water-processed carbon nanotube/graphene hybrids with enhanced field emission properties. AIP Adv. 2015, 5, 097130. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Morozova, E.A.; Ryabkin, D.I.; Fayzullin, A.; Tarasenko, S.V.; Molodykh, V.V.; Pyankov, E.S.; Savelyev, M.S.; Sorokina, E.A.; Rogalsky, A.Y.; et al. Reconstruction of Soft Biological Tissues Using Laser Soldering Technology with Temperature Control and Biopolymer Nanocomposites. Bioengineering 2022, 9, 238. [Google Scholar] [CrossRef]

- Li, C.; Zhou, X.; Zhai, F.; Li, Z.; Yao, F.; Qiao, R.; Chen, K.; Cole, M.T.; Yu, D.; Sun, Z.; et al. Carbon Nanotubes as an Ultrafast Emitter with a Narrow Energy Spread at Optical Frequency. Adv. Mater. 2017, 29, 1701580. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Chen, K.; Guan, M.; Wang, X.; Zhou, X.; Zhai, F.; Dai, J.; Li, Z.; Sun, Z.; Meng, S.; et al. Extreme nonlinear strong-field photoemission from carbon nanotubes. Nat. Commun. 2019, 10, 4891. [Google Scholar] [CrossRef] [PubMed]

- Cho, W.-S.; Lee, Y.D.; Kim, Y.C.; Son, Y.C.; Heo, J.N.; Han, I.T.; Park, J.-H.; Ju, B.-K. Fabrication and Field Emission Properties of Spray-Deposited RNA–Carbon Nanotube Films. Electrochem. Solid State Lett. 2009, 12, J83. [Google Scholar] [CrossRef]

- Jung, H.; An, S.Y.; Jang, D.M.; Kim, J.M.; Park, J.Y.; Kim, D. A multi-wall carbon nanotube/polymethyl methacrylate composite for use in field emitters on flexible substrates. Carbon N. Y. 2012, 50, 987–993. [Google Scholar] [CrossRef]

- Xin, H.; Woolley, A.T. Directional Orientation of Carbon Nanotubes on Surfaces Using a Gas Flow Cell. Nano Lett. 2004, 4, 1481–1484. [Google Scholar] [CrossRef]

- Vad, T.; Wulfhorst, J.; Pan, T.-T.; Steinmann, W.; Dabringhaus, S.; Beckers, M.; Seide, G.; Gries, T.; Sager, W.F.C.; Heidelmann, M.; et al. Orientation of Well-Dispersed Multiwalled Carbon Nanotubes in Melt-Spun Polymer Fibers and Its Impact on the Formation of the Semicrystalline Polymer Structure: A Combined Wide-Angle X-ray Scattering and Electron Tomography Study. Macromolecules 2013, 46, 5604–5613. [Google Scholar] [CrossRef]

- Suryavanshi, U.; Baskar, A.V.; Balasubramanian, V.V.; Al-Deyab, S.S.; Al-Enizi, A.; Vinu, A. Growth and physico-chemical properties of interconnected carbon nanotubes in FeSBA-15 mesoporous molecular sieves. Arab. J. Chem. 2016, 9, 171–178. [Google Scholar] [CrossRef]

- Bocharov, G.; Eletskii, A. Theory of Carbon Nanotube (CNT)-Based Electron Field Emitters. Nanomaterials 2013, 3, 393–442. [Google Scholar] [CrossRef]

- Xin, H.; Li, B. Optical orientation and shifting of a single multiwalled carbon nanotube. Light Sci. Appl. 2014, 3, e205. [Google Scholar] [CrossRef]

- Lee, B.H.; Cho, J.W.; Kim, K.H. Crystallization, orientation, and mechanical properties of laser-heated photothermally drawn polypropylene/multi-walled carbon nanotube fibers. Eur. Polym. J. 2017, 91, 70–80. [Google Scholar] [CrossRef]

- Hur, J.W.; Yoo, H.J.; Cho, J.W.; Kim, K.H. Orientation and mechanical properties of laser-induced photothermally drawn fibers composed of multiwalled carbon nanotubes and poly(ethylene terephthalate). J. Polym. Sci. Part B Polym. Phys. 2016, 54, 603–609. [Google Scholar] [CrossRef]

- Spellauge, M.; Loghin, F.-C.; Sotrop, J.; Domke, M.; Bobinger, M.; Abdellah, A.; Becherer, M.; Lugli, P.; Huber, H.P. Ultra-short-pulse laser ablation and modification of fully sprayed single walled carbon nanotube networks. Carbon N. Y. 2018, 138, 234–242. [Google Scholar] [CrossRef]

- Dang, M.N.; Nguyen, M.D.; Hiep, N.K.; Hong, P.N.; Baek, I.H.; Hong, N.T. Improved Field Emission Properties of Carbon Nanostructures by Laser Surface Engineering. Nanomaterials 2020, 10, 1931. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Li, Z.; Cole, M.T.; Wang, A.; Guo, X.; Liu, X.; Lyu, W.; Teng, H.; Qv, Y.; Liu, G.; et al. Nanocone-Shaped Carbon Nanotubes Field-Emitter Array Fabricated by Laser Ablation. Nanomaterials 2021, 11, 3244. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Kuksin, A.V.; Shaman, Y.P.; Kitsyuk, E.P.; Fedorova, Y.O.; Sysa, A.V.; Pavlov, A.A.; Glukhova, O.E. Electrically Conductive Networks from Hybrids of Carbon Nanotubes and Graphene Created by Laser Radiation. Nanomaterials 2021, 11, 1875. [Google Scholar] [CrossRef]

- Jiang, R.; Liu, J.; Yang, K.; Zhao, J.; Zeng, B. Enhanced Field Emission of Single-Wall Carbon Nanotube Cathode Prepared by Screen Printing with a Silver Paste Buffer Layer. Nanomaterials 2022, 12, 165. [Google Scholar] [CrossRef]

- Lee, H.R.; Lee, S.W.; Shikili, C.; Kang, J.S.; Lee, J.; Park, K.C. Enhanced Electron Emission of Paste CNT Emitters with Nickel Buffer Layer and Its X-ray Application. J. Nanosci. Nanotechnol. 2016, 16, 12053–12058. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, G.; Zhang, Q.; Lan, P.; Zhu, B.; Yu, T.; Lin, Z. Large current carbon nanotube emitter growth using nickel as a buffer layer. Nanotechnology 2007, 18, 095604. [Google Scholar] [CrossRef]

- Srividya, S.; Gautam, S.; Jha, P.; Kumar, P.; Kumar, A.; Ojha, U.S.; Rawat, J.S.B.S.; Pal, S.; Chaudhary, P.K.; Harsh; et al. Titanium buffer layer for improved field emission of CNT based cold cathode. Appl. Surf. Sci. 2010, 256, 3563–3566. [Google Scholar] [CrossRef]

- Yuan, Y.; Chen, J. Nano-Welding of Multi-Walled Carbon Nanotubes on Silicon and Silica Surface by Laser Irradiation. Nanomaterials 2016, 6, 36. [Google Scholar] [CrossRef] [PubMed]

- Bonafé, F.P.; Aradi, B.; Hourahine, B.; Medrano, C.R.; Hernández, F.J.; Frauenheim, T.; Sánchez, C.G. A Real-Time Time-Dependent Density Functional Tight-Binding Implementation for Semiclassical Excited State Electron–Nuclear Dynamics and Pump–Probe Spectroscopy Simulations. J. Chem. Theory Comput. 2020, 16, 4454–4469. [Google Scholar] [CrossRef] [PubMed]

- Grochowski, P.; Lesyng, B. Extended Hellmann–Feynman forces, canonical representations, and exponential propagators in the mixed quantum-classical molecular dynamics. J. Chem. Phys. 2003, 119, 11541–11555. [Google Scholar] [CrossRef]

- Andrade, X.; Castro, A.; Zueco, D.; Alonso, J.L.; Echenique, P.; Falceto, F.; Rubio, Á. Modified Ehrenfest Formalism for Efficient Large-Scale ab initio Molecular Dynamics. J. Chem. Theory Comput. 2009, 5, 728–742. [Google Scholar] [CrossRef] [PubMed]

- Labunov, V.A.; Tabulina, L.V.; Komissarov, I.V.; Grapov, D.V.; Prudnikova, E.L.; Shaman, Y.P.; Basaev, S.A.; Pavlov, A.A. Features of the reduction of graphene from graphene oxide. Russ. J. Phys. Chem. A 2017, 91, 1088–1092. [Google Scholar] [CrossRef]

- Tereshchenko, S.A.; Savelyev, M.S.; Podgaetsky, V.M.; Gerasimenko, A.Y.; Selishchev, S.V. Nonlinear threshold effect in the Z-scan method of characterizing limiters for high-intensity laser light. J. Appl. Phys. 2016, 120, 093109. [Google Scholar] [CrossRef]

- Savelyev, M.S.; Gerasimenko, A.Y.; Podgaetskii, V.M.; Tereshchenko, S.A.; Selishchev, S.V.; Tolbin, A.Y. Conjugates of thermally stable phthalocyanine J-type dimers with single-walled carbon nanotubes for enhanced optical limiting applications. Opt. Laser Technol. 2019, 117, 272–279. [Google Scholar] [CrossRef]

- Kumar, R.; Pérez del Pino, A.; Sahoo, S.; Singh, R.K.; Tan, W.K.; Kar, K.K.; Matsuda, A.; Joanni, E. Laser processing of graphene and related materials for energy storage: State of the art and future prospects. Prog. Energy Combust. Sci. 2022, 91, 100981. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, Y.; Shang, Y.; Han, W. Structural changes and electrical properties of nanowelded multiwalled carbon nanotube junctions. Appl. Opt. 2018, 57, 7435. [Google Scholar] [CrossRef]

- Merlen, A.; Buijnsters, J.G.; Pardanaud, C. Chapter 13. Raman Spectroscopy Characterization of Carbon Materials: From Graphene to All-carbon Heterostructures. In All-carbon Composites and Hybrids; Royal Society of Chemistry: Cambridge, UK, 2021; pp. 317–346. [Google Scholar]

- Ten, G.; Gerasimenko, A.; Savelyev, M.; Kuksin, A.; Vasilevsky, P.; Kitsyuk, E.; Baranov, V. Influence of edge defects on Raman spectra of graphene. Lett. Mater. 2020, 10, 89–93. [Google Scholar] [CrossRef]

- Puech, P.; Kandara, M.; Paredes, G.; Moulin, L.; Weiss-Hortala, E.; Kundu, A.; Ratel-Ramond, N.; Plewa, J.-M.; Pellenq, R.; Monthioux, M. Analyzing the Raman Spectra of Graphenic Carbon Materials from Kerogens to Nanotubes: What Type of Information Can Be Extracted from Defect Bands? C J. Carbon Res. 2019, 5, 69. [Google Scholar] [CrossRef]

- Khanna, V.; Kumar, V.; Bansal, S.A. Mechanical properties of aluminium-graphene/carbon nanotubes (CNTs) metal matrix composites: Advancement, opportunities and perspective. Mater. Res. Bull. 2021, 138, 111224. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Li, Z.; Liu, M.; Kinloch, I.A.; Young, R.J. Mechanisms of mechanical reinforcement by graphene and carbon nanotubes in polymer nanocomposites. Nanoscale 2020, 12, 2228–2267. [Google Scholar] [CrossRef] [PubMed]

- Jorio, A.; Saito, R. Raman spectroscopy for carbon nanotube applications. J. Appl. Phys. 2021, 129, 021102. [Google Scholar] [CrossRef]

- Scardaci, V.; Compagnini, G. Raman Spectroscopy Investigation of Graphene Oxide Reduction by Laser Scribing. C J. Carbon Res. 2021, 7, 48. [Google Scholar] [CrossRef]

- Late, D.J.; Maitra, U.; Panchakarla, L.S.; Waghmare, U.V.; Rao, C.N.R. Temperature effects on the Raman spectra of graphenes: Dependence on the number of layers and doping. J. Phys. Condens. Matter 2011, 23, 055303. [Google Scholar] [CrossRef]

- Sharma, M.; Rani, S.; Pathak, D.K.; Bhatia, R.; Kumar, R.; Sameera, I. Temperature dependent Raman modes of reduced graphene oxide: Effect of anharmonicity, crystallite size and defects. Carbon N. Y. 2021, 184, 437–444. [Google Scholar] [CrossRef]

- Khisamov, R.; Nazarov, K.; Trinh, P.; Nazarov, A.; Phuong, D.; Mulyukov, R. Field electron emission from a copper-based composite reinforced with carbon nanotubes. Lett. Mater. 2019, 9, 566–570. [Google Scholar] [CrossRef]

- Kim, J.-W.; Jeong, J.-W.; Kang, J.-T.; Choi, S.; Park, S.; Shin, M.-S.; Ahn, S.; Song, Y.-H. Great improvement in adhesion and uniformity of carbon nanotube field emitters through reactive nanometer-scale SiC fillers. Carbon N. Y. 2015, 82, 245–253. [Google Scholar] [CrossRef]

- Slepchenkov, M.M.; Shmygin, D.S.; Zhang, G.; Glukhova, O.E. Controlling anisotropic electrical conductivity in porous graphene-nanotube thin films. Carbon N. Y. 2020, 165, 139–149. [Google Scholar] [CrossRef]

| Dispersion Number | Composition | Concentration (mg/mL) |

|---|---|---|

| 1 | SWCNT | 0.1 |

| 2 | rGO | 0.1 |

| 3 | rGO + SWCNT | 0.05/0.05 |

| Sample | Laser Energy Density, J/cm2 | ID/IG | ν (G Band), cm−1 | ν (D Band), cm−1 |

|---|---|---|---|---|

| 1. SWCNT | 0 | 0.036 | 1595 | 1343 |

| 0.3 | 0.083 | 1592 | 1338 | |

| 0.5 | 0.112 | 1590 | 1338 | |

| 0.8 | 0.269 | 1589 | 1339 | |

| 2. rGO | 0 | 0.439 | 1596 | 1352 |

| 0.3 | 0.425 | 1597 | 1354 | |

| 0.5 | 0.421 | 1597 | 1353 | |

| 0.8 | 0.407 | 1596 | 1353 | |

| 3. rGO/SWCNT | 0 | 0.032 | 1595 | 1343 |

| 0.3 | 0.033 | 1593 | 1341 | |

| 0.5 | 0.038 | 1593 | 1340 | |

| 0.8 | 0.054 | 1591 | 1339 | |

| 4. rGO(bl)-SWCNT | 0 | 0.092 | 1594 | 1340 |

| 0.3 | 0.113 | 1595 | 1339 | |

| 0.5 | 0.136 | 1589 | 1341 | |

| 0.8 | 0.181 | 1592 | 1342 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gerasimenko, A.Y.; Kuksin, A.V.; Shaman, Y.P.; Kitsyuk, E.P.; Fedorova, Y.O.; Murashko, D.T.; Shamanaev, A.A.; Eganova, E.M.; Sysa, A.V.; Savelyev, M.S.; et al. Hybrid Carbon Nanotubes–Graphene Nanostructures: Modeling, Formation, Characterization. Nanomaterials 2022, 12, 2812. https://doi.org/10.3390/nano12162812

Gerasimenko AY, Kuksin AV, Shaman YP, Kitsyuk EP, Fedorova YO, Murashko DT, Shamanaev AA, Eganova EM, Sysa AV, Savelyev MS, et al. Hybrid Carbon Nanotubes–Graphene Nanostructures: Modeling, Formation, Characterization. Nanomaterials. 2022; 12(16):2812. https://doi.org/10.3390/nano12162812

Chicago/Turabian StyleGerasimenko, Alexander Yu., Artem V. Kuksin, Yury P. Shaman, Evgeny P. Kitsyuk, Yulia O. Fedorova, Denis T. Murashko, Artemiy A. Shamanaev, Elena M. Eganova, Artem V. Sysa, Mikhail S. Savelyev, and et al. 2022. "Hybrid Carbon Nanotubes–Graphene Nanostructures: Modeling, Formation, Characterization" Nanomaterials 12, no. 16: 2812. https://doi.org/10.3390/nano12162812

APA StyleGerasimenko, A. Y., Kuksin, A. V., Shaman, Y. P., Kitsyuk, E. P., Fedorova, Y. O., Murashko, D. T., Shamanaev, A. A., Eganova, E. M., Sysa, A. V., Savelyev, M. S., Telyshev, D. V., Pavlov, A. A., & Glukhova, O. E. (2022). Hybrid Carbon Nanotubes–Graphene Nanostructures: Modeling, Formation, Characterization. Nanomaterials, 12(16), 2812. https://doi.org/10.3390/nano12162812