Investigating Polymer–Metal Interfaces by Grazing Incidence Small-Angle X-Ray Scattering from Gradients to Real-Time Studies

Abstract

:1. Introduction

2. Combining Grazing Incidence X-Ray Scattering and Sputter Deposition

2.1. GISAXS: Theoretical Background

2.2. Sputter Deposition

2.3. Measurement and Analysis Strategies

3. Polymer–Metal Interfaces: From Gradients to Real-Time Studies

3.1. Combinatorial Investigations

3.2. In Situ Experiments via the Stop-Sputter Technique

3.3. Real-Time Observations of Metal Layer Growth

3.4. Complex Nanostructure Formation Using Nanostructured Polymer Thin Films

4. Outlook

Acknowledgments

Conflicts of Interest

References

- Faupel, F.; Zaporojtchenko, V.; Strunskus, T.; Elbahri, M. Metal-Polymer Nanocomposites for Functional Applications. Adv. Eng. Mater. 2010, 12, 1177–1190. [Google Scholar] [CrossRef]

- Torrisi, V.; Ruffino, F. Metal-Polymer Nanocomposites: (Co-)Evaporation/(Co)Sputtering Approaches and Electrical Properties. Coatings 2015, 5, 378–424. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, S.; Rieger, J.; Roth, S.V.; Gehrke, R.; Men, Y. Effect of Annealing on the Deformation Mechanism of a Styrene/n-Butyl Acrylate Copolymer Latex Film Investigated by Synchrotron Small-Angle X-ray Scattering. Macromolecules 2008, 41, 4353–4357. [Google Scholar] [CrossRef]

- Pietsch, T.; Metwalli, E.; Roth, S.V.; Gebhardt, R.; Gindy, N.; Müller-Buschbaum, P.; Fahmi, A. Directing the Self-Assembly of Mesostructured Hybrid Materials: Effect of Polymer Concentration and Solvent Type. Macromol. Chem. Phys. 2009, 210, 864–878. [Google Scholar] [CrossRef]

- Faupel, F.; Zaporojtchenko, V.; Strunskus, T.; Erichsen, J.; Dolgner, K.; Kiene, M. Fundamental Aspects of Polymer Metallization. In Metallization of Polymers 2; Sacher, E., Ed.; Springer: Boston, MA, USA, 2002; pp. 73–96. [Google Scholar]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Roth, S.V. A deep look into the spray coating process in real-time—the crucial role of X-rays. J. Phys. Condens. Matter 2016, 28, 403003. [Google Scholar] [CrossRef] [PubMed]

- Karakaya, M.; Zhu, J.; Raghavendra, A.J.; Podila, R.; Parler, S.G.; Kaplan, J.P.; Rao, A.M. Roll-to-roll production of spray coated N-doped carbon nanotube electrodes for supercapacitors. Appl. Phys. Lett. 2014, 105, 263103. [Google Scholar] [CrossRef]

- Izquierdo, A.; Ono, S.S.; Voegel, J.-C.; Schaaf, P.; Decher, G. Dipping versus Spraying: Exploring the Deposition Conditions for Speeding Up Layer-by-Layer Assembly. Langmuir 2005, 21, 7558–7567. [Google Scholar] [CrossRef] [PubMed]

- Seyrek, E.; Decher, G. Layer-by-Layer Assembly of Multifunctional Hybrid Materials and Nanoscale Devices. Polym. Sci. A 2012, 7, 159–185. [Google Scholar]

- Sarkar, K.; Braden, E.V.; Pogorzalek, S.; Yu, S.; Roth, S.V.; Müller-Buschbaum, P. Monitoring Structural Dynamics of In Situ Spray-Deposited Zinc Oxide Films for Application in Dye-Sensitized Solar Cells. ChemSusChem 2014, 7, 2140–2145. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Wang, W.; Körstgens, V.; González, D.M.; Yao, Y.; Minar, N.K.; Feckl, J.M.; Peters, K.; Bein, T.; Fattakhova-Rohlfing, D.; et al. Spray Deposition of Titania Films with Incorporated Crystalline Nanoparticles for All-Solid-State Dye-Sensitized Solar Cells Using P3HT. Adv. Funct. Mater. 2016, 26, 1498–1506. [Google Scholar] [CrossRef]

- Schubert, D. Spin coating as a method for polymer molecular weight determination. Polym. Bull. 1997, 38, 177–184. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Kim, K.; Jung, S.; Kim, C.; Kim, J.; Roth, S.V.; Sprung, M.; Vartanyants, I.A.; Ree, M. Synchrotron X-ray scattering and photon correlation spectroscopy studies on thin film morphology details and structural changes of an amorphous-crystalline brush diblock copolymer. Polymer 2016, 105, 472–486. [Google Scholar] [CrossRef]

- Chou, K.W.; Yan, B.; Li, R.; Li, E.Q.; Zhao, K.; Anjum, D.H.; Alvarez, S.; Gassaway, R.; Biocca, A.; Thoroddsen, S.T.; et al. Spin-Cast Bulk Heterojunction Solar Cells: A Dynamical Investigation. Adv. Mater. 2013, 25, 1923–1929. [Google Scholar] [CrossRef] [PubMed]

- Rudov, A.A.; Patyukova, E.S.; Neratova, I.V.; Khalatur, P.G.; Posselt, D.; Papadakis, C.M.; Potemkin, I.I. Structural Changes in Lamellar Diblock Copolymer Thin Films upon Swelling in Nonselective Solvents. Macromolecules 2013, 46, 5786–5795. [Google Scholar] [CrossRef]

- Al-Hussein, M.; Herzig, E.M.; Schindler, M.; Löhrer, F.; Palumbiny, C.M.; Wang, W.; Roth, S.V.; Müller-Buschbaum, P. Comparative study of the nanomorphology of spray and spin coated PTB7 polymer: Fullerene films. Polym. Eng. Sci. 2016, 56, 889–894. [Google Scholar] [CrossRef]

- Bauer, E.; Maurer, E.; Mehaddene, T.; Roth, S.V.; Müller-Buschbaum, P. Flow in Confined Geometry Introduced by Dewetting of Ultrathin Polystyrene Films. Macromolecules 2006, 39, 5087–5094. [Google Scholar] [CrossRef]

- Thakur, S.; Pandit, P.; Sharma, S.K.; Katyal, S.C.; Singh, M.; Gupta, A. Magnetic ordering in nickel-zinc nanoferrite thin film formed by Langmuir Blodgett technique. Appl. Phys. Lett. 2013, 103, 1–5. [Google Scholar] [CrossRef]

- Pandit, P.; Banerjee, M.; Gupta, A. Growth and morphological analysis of ultra thin PMMA films prepared by Langmuir-Blodgett deposition technique. Colloid. Surf. A 2014, 454, 189–195. [Google Scholar] [CrossRef]

- Aleksandrovic, V.; Greshnykh, D.; Randjelovic, I.; Frömsdorf, A.; Kornowski, A.; Roth, S.V.; Klinke, C.; Weller, H. Preparation and Electrical Properties of Cobalt−Platinum Nanoparticle Monolayers Deposited by the Langmuir−Blodgett Technique. ACS Nano 2008, 2, 1123–1130. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Li, H.; Qiu, Z.; Zhang, S.-L.; Zhang, Z.-B. SMALL-hysteresis thin-film transistors achieved by facile dip-coating of nanotube/polymer composite. Adv. Mater. 2012, 24. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Kim, F.; Tao, A.R.; Connor, S.; Yang, P. Spontaneous formation of nanoparticle stripe patterns through dewetting. Nat. Mater. 2005, 4, 896–900. [Google Scholar] [CrossRef] [PubMed]

- Faustini, M.; Faustini, M.; Louis, B.; Albouy, P.A.; Kuemmel, M.; Grosso, D. Preparation of Sol-Gel Films by Dip-Coating in Extreme Conditions Preparation of Sol-Gel Films by Dip-Coating in Extreme Conditions. J. Phys. Chem. C 2010, 114, 7637–7645. [Google Scholar] [CrossRef]

- Clancy, I.; Amarandei, G.; Nash, C.; Glowacki, B.A. Metal particle compaction during drop-substrate impact for inkjet printing and drop-casting processes. J. Appl. Phys. 2016, 119, 54903. [Google Scholar] [CrossRef]

- Palumbiny, C.M.; Liu, F.; Russell, T.P.; Hexemer, A.; Wang, C.; Müller-Buschbaum, P. The Crystallization of PEDOT : PSS Polymeric Electrodes Probed In Situ during Printing. Adv. Mater. 2015, 27, 3391–3397. [Google Scholar] [CrossRef] [PubMed]

- Stegelmeier, C.; Exner, A.; Hauschild, S.; Filiz, V.; Perlich, J.; Roth, S.V.; Abetz, V.; Förster, S. Evaporation-Induced Block Copolymer Self-Assembly into Membranes Studied by in Situ Synchrotron SAXS. Macromolecules 2015, 48, 1524–1530. [Google Scholar] [CrossRef]

- Metwalli, E.; Moulin, J.-F.; Perlich, J.; Wang, W.; Diethert, A.; Roth, S.V.; Müller-Buschbaum, P. Polymer-Template-Assisted Growth of Gold Nanowires Using a Novel Flow-Stream Technique. Langmuir 2009, 25, 11815–11821. [Google Scholar] [CrossRef] [PubMed]

- Gupta, R.; Rao, K.D.M.; Srivastava, K.; Kumar, A.; Kiruthika, S.; Kulkarni, G.U. Spray Coating of Crack Templates for the Fabrication of Transparent Conductors and Heaters on Flat and Curved Surfaces. ACS Appl. Mater. Interfaces 2014, 6, 13688–13696. [Google Scholar] [CrossRef] [PubMed]

- Schaffer, C.J.; Palumbiny, C.M.; Niedermeier, M.A.; Burger, C.; Santoro, G.; Roth, S.V.; Müller-Buschbaum, P. Morphological Degradation in Low Bandgap Polymer Solar Cells-An In Operando Study. Adv. Energy Mater. 2016, 6, 1600712. [Google Scholar] [CrossRef]

- Pfaff, M.; Müller, P.; Bockstaller, P.; Müller, E.; Subbiah, J.; Wong, W.W.H.; Klein, M.F.G.; Kiersnowski, A.; Puniredd, S.R.; Pisula, W.; et al. Bulk Heterojunction Nanomorphology of Fluorenyl Hexa- peri -hexabenzocoronene–Fullerene Blend Films. ACS Appl. Mater. Interfaces 2013, 5, 11554–11562. [Google Scholar] [CrossRef] [PubMed]

- Park, H.-Y.; Yang, H.; Choi, S.-K.; Jang, S.-Y. Efficient solvent-assisted post-treatment for molecular rearrangement of sprayed polymer field-effect transistors. ACS Appl. Mater. Interfaces 2012, 4, 214–221. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Xiao, Z.; Hanssen, E.; Klein, M.F.G.; Dam, H.H.; Pfaff, M.; Gerthsen, D.; Wong, W.W.H.; Jones, D.J. The role of solvent vapor annealing in highly efficient air-processed small molecule solar cells. J. Mater. Chem. A 2014, 2, 9048–9054. [Google Scholar] [CrossRef]

- Zhang, P.; Huang, H.; Chen, Y.; Yu, S.; Krywka, C.; Vayalil, S.K.; Roth, S.V.; He, T. Preparation of long-range ordered nanostructures in semicrystalline diblock copolymer thin films using micromolding. Chin. J. Polym. Sci. 2014, 32, 1188–1198. [Google Scholar] [CrossRef]

- Martínez-Tong, D.E.; Soccio, M.; García-Gutiérrez, M.C.; Nogales, A.; Rueda, D.R.; Alayo, N.; Pérez-Murano, F.; Ezquerra, T.A. Improving information density in ferroelectric polymer films by using nanoimprinted gratings. Appl. Phys. Lett. 2013, 102, 191601. [Google Scholar] [CrossRef]

- Hamley, I.W. Nanostructure fabrication using block copolymers. Nanotechnology 2003, 14, R39–R54. [Google Scholar] [CrossRef]

- Epps, T.H.; O’Reilly, R.K. Block copolymers: Controlling nanostructure to generate functional materials–synthesis, characterization, and engineering. Chem. Sci. 2016, 7, 1674–1689. [Google Scholar] [CrossRef]

- Ruffino, F.; Grimaldi, M.G.; Bongiorno, C.; Giannazzo, F.; Roccaforte, F.; Raineri, V.; Spinella, C. Normal and abnormal grain growth in nanostructured gold film. J. Appl. Phys. 2009, 105, 54311. [Google Scholar] [CrossRef]

- Amarandei, G.; O’Dwyer, C.; Arshak, A.; Corcoran, D. The stability of thin polymer films as controlled by changes in uniformly sputtered gold. Soft Matter 2013, 9, 2695. [Google Scholar] [CrossRef]

- Hu, S.; Rieger, J.; Lai, Y.; Roth, S.V.; Gehrke, R.; Men, Y. In-Situ Observation of Drying Process of a Latex Droplet by Synchrotron Small-Angle X-ray Scattering. Macromolecules 2008, 41, 5073–5076. [Google Scholar] [CrossRef]

- Wernecke, J.; Okuda, H.; Ogawa, H.; Siewert, F.; Krumrey, M. Depth-Dependent Structural Changes in PS- b -P2VP Thin Films Induced by Annealing. Macromolecules 2014, 47, 5719–5727. [Google Scholar] [CrossRef]

- Singh, J.P.; Chu, H.; Abell, J.; Tripp, R.A.; Zhao, Y. Flexible and mechanical strain resistant large area SERS active substrates. Nanoscale 2012, 4, 3410–3414. [Google Scholar] [CrossRef] [PubMed]

- Kaltenbrunner, M.; White, M.S.; Głowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770. [Google Scholar] [CrossRef] [PubMed]

- Švorčík, V.; Slepička, P.; Švorčíková, J.; Špírková, M.; Zehentner, J.; Hnatowicz, V. Characterization of evaporated and sputtered thin Au layers on poly(ethylene terephtalate). J. Appl. Polym. Sci. 2006, 99, 1698–1704. [Google Scholar] [CrossRef]

- Lamberti, A.; Virga, A.; Rivolo, P.; Angelini, A.; Giorgis, F. Easy Tuning of Surface and Optical Properties of PDMS Decorated by Ag Nanoparticles. J. Phys. Chem. B 2015, 119, 8194–8200. [Google Scholar] [CrossRef] [PubMed]

- Bauer, G.; Hassmann, J.; Walter, H.; Haglmüller, J.; Mayer, C.; Schalkhammer, T. Resonant nanocluster technology—from optical coding and high quality security features to biochips. Nanotechnology 2003, 14, 1289–1311. [Google Scholar] [CrossRef]

- Walter, H.; Bauer, G.; Domnick, R.; Jakopic, G.; Leitner, A. Role of granular structure in metal layers on the optical properties of absorbing mirrors. Opt. Eng. 2006, 45, 103801. [Google Scholar] [CrossRef]

- Bigall, N.C.; Nandan, B.; Gowd, E.B.; Horechyy, A.; Eychmüller, A. High-Resolution Metal Nanopatterning by Means of Switchable Block Copolymer Templates. ACS Appl. Mater. Interfaces 2015, 7, 12559–12569. [Google Scholar] [CrossRef] [PubMed]

- Abul Kashem, M.M.; Perlich, J.; Schulz, L.; Roth, S.V.; Petry, W.; Müller-Buschbaum, P. Maghemite Nanoparticles on Supported Diblock Copolymer Nanostructures. Macromolecules 2007, 40, 5075–5083. [Google Scholar] [CrossRef]

- Cortie, M.B.; McDonagh, A.M. Synthesis and Optical Properties of Hybrid and Alloy Plasmonic Nanoparticles. Chem. Rev. 2011, 111, 3713–3735. [Google Scholar] [CrossRef] [PubMed]

- Prakash, J.; Pivin, J.C.; Swart, H.C. Noble metal nanoparticles embedding into polymeric materials: From fundamentals to applications. Adv. Colloid Interface Sci. 2015, 226, 187–202. [Google Scholar] [CrossRef] [PubMed]

- Al-Badri, Z.M.; Maddikeri, R.R.; Zha, Y.; Thaker, H.D.; Dobriyal, P.; Shunmugam, R.; Russell, T.P.; Tew, G.N. Room temperature magnetic materials from nanostructured diblock copolymers. Nat. Commun. 2011, 2, 482. [Google Scholar] [CrossRef] [PubMed]

- Thurn-Albrecht, T.; Schotter, J.; Kastle, G.A.; Emley, N.; Shibauchi, T.; Krusin-Elbaum, L.; Guarini, K.; Black, C.T.; Tuominen, M.T.; Russell, T.P. Ultrahigh-Density Nanowire Arrays Grown in Self-Assembled Diblock Copolymer Templates. Science 2000, 290, 2126–2129. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Metwalli, E.; Su, B.; Körstgens, V.; Moseguí González, D.; Miasnikova, A.; Laschewsky, A.; Opel, M.; Santoro, G.; Roth, S.V.; et al. Arrangement of Maghemite Nanoparticles via Wet Chemical Self-Assembly in PS-b-PNIPAM Diblock Copolymer Films. ACS Appl. Mater. Interfaces 2015, 7, 13080–13091. [Google Scholar] [CrossRef] [PubMed]

- Perlich, J.; Schulz, L.; Abul Kashem, M.M.; Cheng, Y.-J.; Memesa, M.; Gutmann, J.S.; Roth, S.V.; Müller-Buschbaum, P. Modification of the Morphology of P(S-b-EO) Templated Thin TiO2 Films by Swelling with PS Homopolymer. Langmuir 2007, 23, 10299–10306. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.J.; Kwon, T.; Kim, M.P.; Cho, C.-H.; Jung, H.; Bang, J.; Kim, B.J. Creating opal-templated continuous conducting polymer films with ultralow percolation thresholds using thermally stable nanoparticles. ACS Nano 2011, 5, 9017–9027. [Google Scholar] [CrossRef] [PubMed]

- Fustin, C.-A.; Glasser, G.; Spiess, H.W.; Jonas, U. Site-Selective Growth of Colloidal Crystals with Photonic Properties on Chemically Patterned Surfaces. Adv. Mater. 2003, 15, 1025–1028. [Google Scholar] [CrossRef]

- Sulyanova, E.A.; Shabalin, A.; Zozulya, A.V.; Meijer, J.; Dzhigaev, D.; Gorobtsov, O.; Kurta, R.P.; Lazarev, S.; Lorenz, U.; Singer, A.; et al. Structural Evolution of Colloidal Crystal Films in the Process of Melting Revealed by Bragg Peak Analysis. Langmuir 2015, 31, 5274–5283. [Google Scholar] [CrossRef] [PubMed]

- Frömsdorf, A.; Kornowski, A.; Pütter, S.; Stillrich, H.; Lee, L.-T. Highly Ordered Nanostructured Surfaces Obtained with Silica-Filled Diblock-Copolymer Micelles as Templates. Small 2007, 3, 880–889. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.P.; Kang, D.J.; Jung, D.; Kannan, A.G.; Kim, K.-H.; Ku, K.H.; Jang, S.G.; Chae, W.; Yi, G.; Kim, B.J. Gold-Decorated Block Copolymer Microspheres with Controlled Surface Nanostructures. ACS Nano 2012, 6, 2750–2757. [Google Scholar] [CrossRef] [PubMed]

- Dolatshahi-Pirouz, A.; Jensen, T.; Vorup-Jensen, T.; Bech, R.; Chevallier, J.; Besenbacher, F.; Foss, M.; Sutherland, D.S. Synthesis of Functional Nanomaterials via Colloidal Mask Templating and Glancing Angle Deposition (GLAD). Adv. Eng. Mater. 2010, 12, 899–905. [Google Scholar] [CrossRef]

- Gwinner, M.C.; Koroknay, E.; Fu, L.; Patoka, P.; Kandulski, W.; Giersig, M.; Giessen, H. Periodic Large-Area Metallic Split-Ring Resonator Metamaterial Fabrication Based on Shadow Nanosphere Lithography. Small 2009, 5, 400–406. [Google Scholar] [CrossRef] [PubMed]

- Elbahri, M.; Hedayati, M.K.; Kiran Chakravadhanula, V.S.; Jamali, M.; Strunkus, T.; Zaporojtchenko, V.; Faupel, F. An Omnidirectional Transparent Conducting-Metal-Based Plasmonic Nanocomposite. Adv. Mater. 2011, 23, 1993–1997. [Google Scholar] [CrossRef] [PubMed]

- Morkved, T.L.; Wiltzius, P.; Jaeger, H.M.; Grier, D.G.; Witten, T.A. Mesoscopic self-assembly of gold islands on diblock-copolymer films. Appl. Phys. Lett. 1994, 64, 422. [Google Scholar] [CrossRef]

- Lin, B.; Morkved, T.L.; Meron, M.; Huang, Z.; Viccaro, P.J.; Jaeger, H.M.; Williams, S.M.; Schlossman, M.L. X-ray studies of polymer/gold nanocomposites. J. Appl. Phys. 1999, 85, 3180. [Google Scholar] [CrossRef]

- Lopes, W.A.; Jaeger, H.M. Hierarchical self-assembly of metal nanostructures on diblock copolymer scaffolds. Nature 2001, 414, 735–738. [Google Scholar] [CrossRef] [PubMed]

- Erb, D.J.; Schlage, K.; Ro hlsberger, R. Uniform metal nanostructures with long-range order via three-step hierarchical self-assembly. Sci. Adv. 2015, 1, e1500751. [Google Scholar] [CrossRef] [PubMed]

- Abul Kashem, M.M.; Patra, D.; Perlich, J.; Rothkirch, A.; Buffet, A.; Roth, S.V.; Rotello, V.M.; Müller-Buschbaum, P. Two- and Three-Dimensional Network of Nanoparticles via Polymer-Mediated Self-Assembly. ACS Macro Lett. 2012, 1, 396–399. [Google Scholar] [CrossRef]

- Yao, Y.; Metwalli, E.; Niedermeier, M.A.; Opel, M.; Lin, C.; Ning, J.; Perlich, J.; Roth, S.V.; Müller-Buschbaum, P. Nano- and Microstructures of Magnetic Field-Guided Maghemite Nanoparticles in Diblock Copolymer Films. ACS Appl. Mater. Interfaces 2014, 6, 5244–5254. [Google Scholar] [CrossRef] [PubMed]

- Röder, J.; Faupel, J.; Krebs, H.-U. Growth of polymer–metal nanocomposites by pulsed laser deposition. Appl. Phys. A 2008, 93, 863–867. [Google Scholar] [CrossRef]

- Sobel, N.; Hess, C.; Lukas, M.; Spende, A.; Stühn, B.; Toimil-Molares, M.E.; Trautmann, C. Conformal SiO2 coating of sub-100 nm diameter channels of polycarbonate etched ion-track channels by atomic layer deposition. Beilstein J. Nanotechnol. 2015, 6, 472–479. [Google Scholar] [CrossRef] [PubMed]

- Mozetič, M.; Ostrikov, K.; Ruzic, D.N.; Curreli, D.; Cvelbar, U.; Vesel, A.; Primc, G.; Leisch, M.; Jousten, K.; Malyshev, O.B.; et al. Recent advances in vacuum sciences and applications. J. Phys. D 2014, 47, 153001. [Google Scholar] [CrossRef]

- Ibrahimkutty, S.; Seiler, A.; Prüßmann, T.; Vitova, T.; Pradip, R.; Bauder, O.; Wochner, P.; Plech, A.; Baumbach, T.; Stankov, S. A portable ultrahigh-vacuum system for advanced synchrotron radiation studies of thin films and nanostructures: EuSi2 nano-islands. J. Synchrotron Rad. 2015, 22, 91–98. [Google Scholar] [CrossRef] [PubMed]

- Beckers, M.; Schell, N.; Martins, R.M.S.; Mücklich, A.; Möller, W. The influence of the growth rate on the preferred orientation of magnetron-sputtered Ti–Al–N thin films studied by in situ X-ray diffraction. J. Appl. Phys. 2005, 98, 044901. [Google Scholar] [CrossRef]

- Hulteen, J.C.; Patrissi, C.J.; Miner, D.L.; Crosthwait, E.R.; Oberhauser, E.B.; Martin, C.R. Changes in the Shape and Optical Properties of Gold Nanoparticles Contained within Alumina Membranes Due to Low-Temperature Annealing. J. Phys. Chem. B 1997, 101, 7727–7731. [Google Scholar] [CrossRef]

- Paci, B.; Generosi, A.; Albertini, V.R.; Spyropoulos, G.D.; Stratakis, E.; Kymakis, E. Enhancement of photo/thermal stability of organic bulk heterojunction photovoltaic devices via gold nanoparticles doping of the active layer. Nanoscale 2012, 4, 7452–7459. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.-L.; Chen, F.-C.; Hsiao, Y.-S.; Chien, F.-C.; Chen, P.; Kuo, C.-H.; Huang, M.H.; Hsu, C.-S. Surface plasmonic effects of metallic nanoparticles on the performance of polymer bulk heterojunction solar cells. ACS Nano 2011, 5, 959–967. [Google Scholar] [CrossRef] [PubMed]

- Müller-Buschbaum, P. The Active Layer Morphology of Organic Solar Cells Probed with Grazing Incidence Scattering Techniques. Adv. Mater. 2014, 26, 7692–7709. [Google Scholar] [CrossRef] [PubMed]

- González, D.M.; Körstgens, V.; Yao, Y.; Song, L.; Santoro, G.; Roth, S.V.; Müller-Buschbaum, P. Improved Power Conversion Efficiency of P3HT:PCBM Organic Solar Cells by Strong Spin-Orbit Coupling-Induced Delayed Fluorescence. Adv. Energy Mater. 2015, 5, 1401770. [Google Scholar] [CrossRef]

- Wang, W.; Pröller, S.; Niedermeier, M.A.; Körstgens, V.; Philipp, M.; Su, B.; Moseguí González, D.; Yu, S.; Roth, S.V.; Müller-Buschbaum, P. Development of the Morphology during Functional Stack Build-up of P3HT:PCBM Bulk Heterojunction Solar Cells with Inverted Geometry. ACS Appl. Mater. Interfaces 2015, 7, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Ning, J.; Körstgens, V.; Yao, Y.; Herzig, E.M.; Roth, S.V.; Müller-Buschbaum, P. The Effect of Fluorination in Manipulating the Nanomorphology in PTB7:PC 71 BM Bulk Heterojunction Systems. Adv. Energy Mater. 2015, 5, 1401315. [Google Scholar] [CrossRef]

- Burroughes, J.; Bradley, D.; Brown, A. Light-emitting diodes based on conjugated polymers. Nature 1990, 347, 539–541. [Google Scholar] [CrossRef]

- Hobson, P.A.; Wedge, S.; Wasey, J.A.E.; Sage, I.; Barnes, W.L. Surface Plasmon Mediated Emission from Organic Light-Emitting Diodes. Adv. Mater. 2002, 14, 1393–1396. [Google Scholar] [CrossRef]

- Huang, W.; Yu, X.; Fan, H.; Yu, J. High performance unipolar inverters by utilizing organic field-effect transistors with ultraviolet/ozone treated polystyrene dielectric. Appl. Phys. Lett. 2014, 105, 93302. [Google Scholar] [CrossRef]

- Yamashita, Y. Organic semiconductors for organic field-effect transistors. Sci. Technol. Adv. Mater. 2009, 10, 24313. [Google Scholar] [CrossRef] [PubMed]

- Adams, S.M.; Campione, S.; Caldwell, J.D.; Bezares, F.J.; Culbertson, J.C.; Capolino, F.; Ragan, R. Non-lithographic SERS Substrates: Tailoring Surface Chemistry for Au Nanoparticle Cluster Assembly. Small 2012, 8, 2239–2249. [Google Scholar] [CrossRef] [PubMed]

- Amarandei, G.; O’Dwyer, C.; Arshak, A.; Corcoran, D. Fractal Patterning of Nanoparticles on Polymer Films and Their SERS Capabilities. ACS Appl. Mater. Interfaces 2013, 5, 8655–8662. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Kaune, G.; Perlich, J.; Papadakis, C.M.; Bivigou Koumba, A.M.; Laschewsky, A.; Schlage, K.; Röhlsberger, R.; Roth, S.V.; Cubitt, R.; et al. Swelling and switching kinetics of gold coated end-capped poly(N-isopropylacrylamide) thin films. Macromolecules 2010, 43, 2444–2452. [Google Scholar] [CrossRef]

- Wolkenhauer, M.; Bumbu, G.; Cheng, Y.; Roth, S.V.; Gutmann, J.S. Investigation of micromechanical cantilever sensors with microfocus grazing incidence small-angle X-ray scattering. Appl. Phys. Lett. 2006, 89, 54101. [Google Scholar] [CrossRef]

- Siffalovic, P.; Chitu, L.; Vegso, K.; Majkova, E.; Jergel, M.; Weis, M.; Luby, S.; Capek, I.; Keckes, J.; Maier, G.A.; et al. Towards strain gauges based on a self-assembled nanoparticle monolayer—SAXS study. Nanotechnology 2010, 21, 385702. [Google Scholar] [CrossRef] [PubMed]

- Zaporojtchenko, V.; Zekonyte, J.; Biswas, A.; Faupel, F. Controlled growth of nano-size metal clusters on polymers by using VPD method. Surf. Sci. 2003, 532–535, 300–305. [Google Scholar] [CrossRef]

- Faupel, F.; Willecke, R.; Thran, A. Diffusion of metals in polymers. Mater. Sci. Eng. 1998, 22, 1–55. [Google Scholar] [CrossRef]

- Martin, P. Ion-based methods for optical thin film deposition. J. Mater. Sci. 1986, 21, 1–25. [Google Scholar] [CrossRef]

- Zaporojtchenko, V.; Strunskus, T.; Behnke, K.; Faupel, F. Controlled Nucleation and Growth of Noble Metals on Polymers. In Interface Controlled Materials; Rühle, M., Gleiter, H., Eds.; Wiley-VCH: Weinheim, Germany, 2000; pp. 24–29. [Google Scholar]

- Hexemer, A.; Müller-Buschbaum, P. Advanced grazing-incidence techniques for modern soft-matter materials analysis. IUCrJ 2015, 2, 106–125. [Google Scholar] [CrossRef] [PubMed]

- Kohn, P.; Rong, Z.; Scherer, K.H.; Sepe, A.; Sommer, M.; Müller-Buschbaum, P.; Friend, R.H.; Steiner, U.; Hüttner, S. Crystallization-induced 10-nm structure formation in P3HT/PCBM blends. Macromolecules 2013, 46, 4002–4013. [Google Scholar] [CrossRef]

- Kim, E.; Vaynzof, Y.; Sepe, A.; Guldin, S.; Scherer, M.; Cunha, P.; Roth, S.V.; Steiner, U. Gyroid-structured 3D ZnO networks made by atomic layer deposition. Adv. Funct. Mater. 2014, 24, 863–872. [Google Scholar] [CrossRef]

- Jiang, Z.; Lee, D.R.; Narayanan, S.; Wang, J.; Sinha, S.K. Waveguide-enhanced grazing-incidence small-angle X-ray scattering of buried nanostructures in thin films. Phys. Rev. B 2011, 84, 75440. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P. A Basic Introduction to Grazing Incidence Small-Angle X-Ray Scattering. In Applications of Synchrotron Light to Scattering and Diffraction in Materials and Life Sciences; Lecture Notes in Physics; Gomez, M., Nogales, A., Garcia-Gutierrez, M.C., Ezquerra, T.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 776, pp. 61–89. [Google Scholar]

- Ruffino, F.; Torrisi, V.; Marletta, G.; Grimaldi, M.G. Growth morphology of nanoscale sputter-deposited Au films on amorphous soft polymeric substrates. Appl. Phys. A 2011, 103, 939–949. [Google Scholar] [CrossRef]

- Amarandei, G.; O’Dwyer, C.; Arshak, A.; Thiele, U.; Steiner, U.; Corcoran, D. Effect of Au Nanoparticle Spatial Distribution on the Stability of Thin Polymer Films. Langmuir 2013, 29, 6706–6714. [Google Scholar] [CrossRef] [PubMed]

- Amarandei, G.; Clancy, I.; O’Dwyer, C.; Arshak, A.; Corcoran, D. Stability of ultrathin nanocomposite polymer films controlled by the embedding of gold nanoparticles. ACS Appl. Mater. Interfaces 2014, 6, 20758–20767. [Google Scholar] [CrossRef] [PubMed]

- Daillant, J. Recent developments and applications of grazing incidence scattering. Curr. Opin. Colloid Interface Sci. 2009, 14, 396–401. [Google Scholar] [CrossRef]

- Daillant, J.; Gibaud, A. X-ray and Neutron Reflectivity; Lecture Notes in Physics; Daillant, J., Gibaud, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 770. [Google Scholar]

- Müller-Buschbaum, P. Grazing incidence small-angle X-ray scattering: An advanced scattering technique for the investigation of nanostructured polymer films. Anal. Bioanal. Chem. 2003, 376, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Renaud, G.; Lazzari, R.; Leroy, F. Probing surface and interface morphology with Grazing Incidence Small Angle X-Ray Scattering. Surf. Sci. Rep. 2009, 64, 255–380. [Google Scholar] [CrossRef]

- Lim, T.; McCarthy, D.; Hendy, S.; Stevens, K.J.; Brown, S.A.; Tilley, R.D. Real-Time TEM and Kinetic Monte Carlo Studies of the Coalescence of Decahedral Gold Nanoparticles. ACS Nano 2009, 3, 3809–3813. [Google Scholar] [CrossRef] [PubMed]

- Métois, J.J.; Heinemann, K.; Poppa, H. In situ investigation of the mobility of small gold clusters on cleaved MgO surfaces. Appl. Phys. Lett. 1976, 29, 134. [Google Scholar] [CrossRef]

- Zan, R.; Bangert, U.; Ramasse, Q.; Novoselov, K.S. Evolution of Gold Nanostructures on Graphene. Small 2011, 7, 2868–2872. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.W.; Palmer, R.E. Direct atomic imaging and dynamical fluctuations of the tetrahedral Au(20) cluster. Nanoscale 2012, 4, 4947–4949. [Google Scholar] [CrossRef] [PubMed]

- Ehrlich, G. Direct observations of the surface diffusion of atoms and clusters. Surf. Sci. 1991, 246, 1–12. [Google Scholar] [CrossRef]

- Ruffino, F.; Torrisi, V.; Marletta, G.; Grimaldi, M.G. Effects of the embedding kinetics on the surface nano-morphology of nano-grained Au and Ag films on PS and PMMA layers annealed above the glass transition temperature. Appl. Phys. A 2012, 107, 669–683. [Google Scholar] [CrossRef]

- Levine, J.R.; Cohen, J.B.; Chung, Y.W.; Georgopoulos, P. Grazing-incidence small-angle X-ray scattering: New tool for studying thin film growth. J. Appl. Crystallogr. 1989, 22, 528–532. [Google Scholar] [CrossRef]

- Levine, J.R.; Cohen, J.B.; Chung, Y.W. Thin film island growth kinetics : A grazing incidence small angle X-ray scattering study of gold on glass. Surf. Sci. 1991, 248, 215–224. [Google Scholar] [CrossRef]

- Stearns, D.G. The scattering of X-rays from nonideal multilayer structures. J. Appl. Phys. 1989, 65, 491. [Google Scholar] [CrossRef]

- Holý, V.; Baumbach, T. Nonspecular X-ray reflection from rough multilayers. Phys. Rev. B 1994, 49, 10668–10676. [Google Scholar] [CrossRef]

- Salditt, T.; Metzger, T.H.; Brandt, C.; Klemradt, U.; Peisl, J. Determination of the static scaling exponent of self-affine interfaces by nonspecular X-ray scattering. Phys. Rev. B 1995, 51, 5617–5627. [Google Scholar] [CrossRef]

- Vineyard, G.H. Grazing-incidence diffraction and the distorted-wave approximation for the study of surfaces. Phys. Rev. B 1982, 26, 4146–4159. [Google Scholar] [CrossRef]

- Busch, P.; Rauscher, M.; Smilgies, D.-M.; Posselt, D.; Papadakis, C.M. Grazing-incidence small-angle X-ray scattering from thin polymer films with lamellar structures–the scattering cross section in the distorted-wave Born approximation. J. Appl. Crystallogr. 2006, 39, 433–442. [Google Scholar] [CrossRef]

- Hu, S.; Rieger, J.; Roth, S.V.; Gehrke, R.; Leyrer, R.J.; Men, Y. GIUSAXS and AFM studies on surface reconstruction of latex thin films during thermal treatment. Langmuir 2009, 25, 4230–4234. [Google Scholar] [CrossRef] [PubMed]

- Perlich, J.; Rubeck, J.; Botta, S.; Gehrke, R.; Roth, S.V.; Ruderer, M.A.; Prams, S.M.; Rawolle, M.; Zhong, Q.; Körstgens, V.; et al. Grazing incidence wide angle X-ray scattering at the wiggler beamline BW4 of HASYLAB. Rev. Sci. Instrum. 2010, 81, 105105. [Google Scholar] [CrossRef] [PubMed]

- Okuda, H.; Takeshita, K.; Ochiai, S.; Sakurai, S.; Kitajima, Y. Near-surface relaxation structure of annealed block copolymer film on Si substrates examined by grazing-incidence small-angle scattering utilizing soft X-rays. J. Appl. Crystallogr. 2011, 44, 380–384. [Google Scholar] [CrossRef] [Green Version]

- Yoneda, Y. Anomalous Surface Reflection of X Rays. Phys. Rev. 1963, 131, 2010–2013. [Google Scholar] [CrossRef]

- Andreazza, P.; Khelfane, H.; Lyon, O.; Andreazza-Vignolle, C.; Ramos, A.Y.; Samah, M. Trends in anomalous small-angle X-ray scattering in grazing incidence for supported nanoalloyed and core-shell metallic nanoparticles. Eur. Phys. J. Spec. Top. 2012, 208, 231–244. [Google Scholar] [CrossRef]

- Simon, J.-P.; Babonneau, D.; Drouet, M.; Lyon, O. Anomalous grazing incidence small-angle X-ray scattering of carbon-encapsulated Au and Cu clusters. J. Appl. Crystallogr. 2009, 42, 312–322. [Google Scholar] [CrossRef]

- Santoro, G.; Buffet, A.; Döhrmann, R.; Yu, S.; Körstgens, V.; Müller-Buschbaum, P.; Gedde, U.; Hedenqvist, M.; Roth, S.V. Use of intermediate focus for grazing incidence small and wide angle X-ray scattering experiments at the beamline P03 of PETRA III, DESY. Rev. Sci. Instrum. 2014, 85, 43901. [Google Scholar] [CrossRef] [PubMed]

- Roth, S.V.; Burghammer, M.; Riekel, C.; Müller-Buschbaum, P.; Diethert, A.; Panagiotou, P.; Walter, H. Self-assembled gradient nanoparticle-polymer multilayers investigated by an advanced characterization method: Microbeam grazing incidence X-ray scattering. Appl. Phys. Lett. 2003, 82, 1935–1937. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Roth, S.V.; Burghammer, M.; Diethert, A.; Panagiotou, P.; Riekel, C. Multiple-scaled polymer surfaces investigated with micro-focus grazing-incidence small-angle X-ray scattering. Europhys. Lett. 2003, 61, 639–645. [Google Scholar] [CrossRef]

- Roth, S.V.; Autenrieth, T.; Grübel, G.; Riekel, C.; Burghammer, M.; Hengstler, R.; Schulz, L.; Müller-Buschbaum, P. In situ observation of nanoparticle ordering at the air-water-substrate boundary in colloidal solutions using X-ray nanobeams. Appl. Phys. Lett. 2007, 91, 91915. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Bauer, E.; Pfister, S.; Roth, S.V.; Burghammer, M.; Riekel, C.; David, C.; Thiele, U. Creation of multi-scale stripe-like patterns in thin polymer blend films. Europhys. Lett. 2006, 73, 35–41. [Google Scholar] [CrossRef]

- Al-Hussein, M.; Ruderer, M.A.; Metwalli, E.; Korstgens, V.; Vainio, U.; Roth, S.V.; Dohrmann, R.; Gehrke, R.; Gebhardt, R.; Burghammer, M.; et al. Determination of the Ordered Structure in Conjugated-Coil Diblock Copolymers Films from a Thickness Gradient Prepared by Spin-Coated Drop Technique. Macromolecules 2009, 42, 4230–4236. [Google Scholar] [CrossRef]

- Roth, S.V.; Döhrmann, R.; Gehrke, R.; Röhlsberger, R.; Schlage, K.; Metwalli, E.; Körstgens, V.; Burghammer, M.; Riekel, C.; David, C.; et al. Mapping the morphological changes of deposited gold nanoparticles across an imprinted groove. J. Appl. Crystallogr. 2015, 48, 1827–1833. [Google Scholar] [CrossRef]

- Schwartzkopf, M.; Buffet, A.; Körstgens, V.; Metwalli, E.; Schlage, K.; Benecke, G.; Perlich, J.; Rawolle, M.; Rothkirch, A.; Heidmann, B.; et al. From atoms to layers: In situ gold cluster growth kinetics during sputter deposition. Nanoscale 2013, 5, 5053–5062. [Google Scholar] [CrossRef] [PubMed]

- Herzog, G.; Abul Kashem, M.M.; Benecke, G.; Buffet, A.; Gehrke, R.; Perlich, J.; Schwartzkopf, M.; Körstgens, V.; Meier, R.; Niedermeier, M.A.; et al. Influence of Nanoparticle Surface Functionalization on the Thermal Stability of Colloidal Polystyrene Films. Langmuir 2012, 28, 8230–8237. [Google Scholar] [CrossRef] [PubMed]

- Perlich, J.; Schwartzkopf, M.; Körstgens, V.; Roth, S.V.; Gehrke, R.; München, T.U.; Materialien, F.; Physik-department, E. Pattern Formation of Colloidal Suspensions by Dip-Coating : An In-Situ Grazing Incidence X-ray Scattering Study. Phot. Sci. Annu. Rep. 2010, 6, 253–255. [Google Scholar] [CrossRef]

- Herzog, G.; Benecke, G.; Buffet, A.; Heidmann, B.; Perlich, J.; Risch, J.F.H.; Santoro, G.; Schwartzkopf, M.; Yu, S.; Wurth, W.; et al. In Situ Grazing Incidence Small-Angle X-ray Scattering Investigation of Polystyrene Nanoparticle Spray Deposition onto Silicon. Langmuir 2013, 29, 11260–11266. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Santoro, G.; Yu, S.; Vayalil, S.K.; Bommel, S.; Roth, S.V. Manipulating the Assembly of Spray-Deposited Nanocolloids: In Situ Study and Monolayer Film Preparation. Langmuir 2016, 32, 4251–4258. [Google Scholar] [CrossRef] [PubMed]

- Al-Hussein, M.; Schindler, M.; Ruderer, M.A.; Perlich, J.; Schwartzkopf, M.; Herzog, G.; Heidmann, B.; Buffet, A.; Roth, S.V.; Müller-Buschbaum, P. In situ X-ray study of the structural evolution of gold nano-domains by spray deposition on thin conductive P3HT films. Langmuir 2013, 29, 2490–2497. [Google Scholar] [CrossRef] [PubMed]

- Roth, S.V.; Herzog, G.; Körstgens, V.; Buffet, A.; Schwartzkopf, M.; Perlich, J.; Abul Kashem, M.M.; Döhrmann, R.; Gehrke, R.; Rothkirch, A.; et al. In situ observation of cluster formation during nanoparticle solution casting on a colloidal film. J. Phys. Condens. Matter 2011, 23, 254208. [Google Scholar] [CrossRef] [PubMed]

- Moulin, J.-F.; Roth, S.V.; Müller-Buschbaum, P. Flow at interfaces: A new device for X-ray surface scattering investigations. Rev. Sci. Instrum. 2008, 79, 15109. [Google Scholar] [CrossRef] [PubMed]

- Körstgens, V.; Philipp, M.; Magerl, D.; Niedermeier, M.A.; Santoro, G.; Roth, S.V.; Müller-Buschbaum, P. Following initial changes in nanoparticle films under laminar flow conditions with in situ GISAXS microfluidics. RSC Adv. 2014, 4, 1476–1479. [Google Scholar] [CrossRef]

- Philipp, M.; Körstgens, V.; Magerl, D.; Heller, C.; Yao, Y.; Wang, W.; Santoro, G.; Roth, S.V.; Müller-Buschbaum, P. Sorption of Water and Initial Stages of Swelling of Thin PNIPAM Films Using in Situ GISAXS Microfluidics. Langmuir 2015, 31, 9619–9627. [Google Scholar] [CrossRef] [PubMed]

- Buffet, A.; Rothkirch, A.; Döhrmann, R.; Körstgens, V.; Abul Kashem, M.M.; Perlich, J.; Herzog, G.; Schwartzkopf, M.; Gehrke, R.; Müller-Buschbaum, P.; et al. P03, the microfocus and nanofocus X-ray scattering (MiNaXS) beamline of the PETRA III storage ring: The microfocus endstation. J. Synchrotron Radiat. 2012, 19, 647–653. [Google Scholar] [CrossRef] [PubMed]

- Schwartzkopf, M.; Santoro, G.; Brett, C.J.; Rothkirch, A.; Polonskyi, O.; Hinz, A.; Metwalli, E.; Yao, Y.; Strunskus, T.; Faupel, F.; et al. Real-Time Monitoring of Morphology and Optical Properties during Sputter Deposition for Tailoring Metal–Polymer Interfaces. ACS Appl. Mater. Interfaces 2015, 7, 13547–13556. [Google Scholar] [CrossRef] [PubMed]

- Slobodskyy, T.; Zozulya, A.; Tholapi, R.; Sprung, M. Versatile AFM setup combined with micro-focused X-ray beam. Rev. Sci. Instrum. 2015, 86, 65104. [Google Scholar] [CrossRef] [PubMed]

- Müller-Buschbaum, P.; Bauer, E.; Maurer, E.; Roth, S.V.; Gehrke, R.; Burghammer, M.; Riekel, C. Large-scale and local-scale structures in polymer-blend films: A grazing-incidence ultra-small-angle X-ray scattering and sub-microbeam grazing-incidence small-angle X-ray scattering investigation. J. Appl. Crystallogr. 2006, 40, s341–s345. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Bauer, E.; Maurer, E.; Schlögl, K.; Roth, S.V.; Gehrke, R. Route to create large-area ordered polymeric nanochannel arrays. Appl. Phys. Lett. 2006, 88, 83114. [Google Scholar] [CrossRef]

- Roth, S.V.; Döhrmann, R.; Dommach, M.; Kuhlmann, M.; Kröger, I.; Gehrke, R.; Walter, H.; Schroer, C.; Lengeler, B.; Müller-Buschbaum, P. Small-angle options of the upgraded ultrasmall-angle X-ray scattering beamline BW4 at HASYLAB. Rev. Sci. Instrum. 2006, 77, 85106. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Casagrande, M.; Gutmann, J.; Kuhlmann, T.; Stamm, M.; Von Krosigk, G.; Lode, U.; Cunis, S.; Gehrke, R. Determination of micrometer length scales with an X-ray reflection ultra small-angle scattering set-up. Europhys. Lett. 2007, 42, 517–522. [Google Scholar] [CrossRef]

- Roth, S.V.; Walter, H.; Burghammer, M.; Riekel, C.; Lengeler, B.; Schroer, C.; Kuhlmann, M.; Walther, T.; Sehrbrock, A.; Domnick, R.; et al. Combinatorial investigation of the isolated nanoparticle to coalescent layer transition in a gradient sputtered gold nanoparticle layer on top of polystyrene. Appl. Phys. Lett. 2006, 88, 21910. [Google Scholar] [CrossRef]

- Sanandaji, N.; Ovaskainen, L.; Klein Gunnewiek, M.; Vancso, G.J.; Hedenqvist, M.S.; Yu, S.; Eriksson, L.; Roth, S.V.; Gedde, U.W. Unusual crystals of poly(ε-caprolactone) by unusual crystallisation: The effects of rapid cooling and fast solvent loss on the morphology, crystal structure and melting. Polymer 2013, 54, 1497–1503. [Google Scholar] [CrossRef]

- Krause, B.; Miljevic, B.; Aschenbrenner, T.; Piskorska-Hommel, E.; Tessarek, C.; Barchuk, M.; Buth, G.; Donfeu Tchana, R.; Figge, S.; Gutowski, J.; et al. Influence of a low-temperature capping on the crystalline structure and morphology of InGaN quantum dot structures. J. Alloys Compd. 2014, 585, 572–579. [Google Scholar] [CrossRef]

- Darko, C.; Botiz, I.; Reiter, G.; Breiby, D.W.; Andreasen, J.W.; Roth, S.V.; Smilgies, D.-M.; Metwalli, E.; Papadakis, C.M. Crystallization in diblock copolymer thin films at different degrees of supercooling. Phys. Rev. E 2009, 79, 41802. [Google Scholar] [CrossRef] [PubMed]

- Willmott, P. Deposition of complex multielemental thin films. Prog. Surf. Sci. 2004, 76, 163–217. [Google Scholar] [CrossRef]

- Meille, V. Review on methods to deposit catalysts on structured surfaces. Appl. Catal. A 2006, 315, 1–17. [Google Scholar] [CrossRef]

- Schürmann, U.; Takele, H.; Zaporojtchenko, V.; Faupel, F. Optical and electrical properties of polymer metal nanocomposites prepared by magnetron co-sputtering. Thin Solid Films 2006, 515, 801–804. [Google Scholar] [CrossRef]

- Matz, W.; Schell, N.; Neumann, W.; Bøttiger, J.; Chevallier, J. A two magnetron sputter deposition chamber for in situ observation of thin film growth by synchrotron radiation scattering. Rev. Sci. Instrum. 2001, 72, 3344. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of substrate temperature and deposition rate on structure of thick sputtered Cu coatings. J. Vac. Sci. Technol. 1975, 12, 830. [Google Scholar] [CrossRef]

- Abraham, J.W.; Strunskus, T.; Faupel, F.; Bonitz, M. Molecular dynamics simulation of gold cluster growth during sputter deposition. J. Appl. Sci. 2016, 119, 185301. [Google Scholar] [CrossRef]

- Robins, J.L. Thin film nucleation and growth kinetics. Appl. Surf. Sci. 1988, 33–34, 379–394. [Google Scholar] [CrossRef]

- Franz, H.; Leupold, O.; Röhlsberger, R.; Roth, S.V.; Seeck, O.H.; Spengler, J.; Strempfer, J.; Tischer, M.; Viefhaus, J.; Weckert, E.; et al. PETRA III : DESY’ s New High Brilliance Third Generation Synchrotron Radiation Source. J. Synchrotron Radiation 2006, 19, 25–29. [Google Scholar] [CrossRef]

- Eikenberry, E.; Brönnimann, C.; Hülsen, G.; Toyokawa, H.; Horisberger, R.; Schmitt, B.; Schulze-Briese, C.; Tomizaki, T. PILATUS: A two-dimensional X-ray detector for macromolecular crystallography. Nucl. Instrum. Meth. Phys. Res. Sect. A 2003, 501, 260–266. [Google Scholar] [CrossRef]

- Rawolle, M.; Körstgens, V.; Ruderer, M.A.; Metwalli, E.; Guo, S.; Herzog, G.; Benecke, G.; Schwartzkopf, M.; Buffet, A.; Perlich, J.; et al. Note: Comparison of grazing incidence small angle X-ray scattering of a titania sponge structure at the beamlines BW4 (DORIS III) and P03 (PETRA III). Rev. Sci. Instrum. 2012, 83, 106104. [Google Scholar] [CrossRef] [PubMed]

- Dürr, A.C.; Schreiber, F.; Kelsch, M.; Carstanjen, H.D.; Dosch, H.; Seeck, O.H. Morphology and interdiffusion behavior of evaporated metal films on crystalline diindenoperylene thin films. J. Appl. Phys. 2003, 93, 5201–5209. [Google Scholar] [CrossRef]

- Bommel, S.; Kleppmann, N.; Weber, C.; Spranger, H.; Schäfer, P.; Novak, J.; Roth, S.V.; Schreiber, F.; Klapp, S.H.L.; Kowarik, S. Unravelling the multilayer growth of the fullerene C60 in real time. Nat. Commun. 2014, 5, 5388. [Google Scholar] [CrossRef] [PubMed]

- Frank, C.; Banerjee, R.; Oettel, M.; Gerlach, A.; Novák, J.; Santoro, G.; Schreiber, F. Analysis of island shape evolution from diffuse X-ray scattering of organic thin films and implications for growth. Phys. Rev. B 2014, 90, 41–44. [Google Scholar] [CrossRef]

- Benecke, G.; Wagermaier, W.; Li, C.; Schwartzkopf, M.; Flucke, G.; Hoerth, R.; Zizak, I.; Burghammer, M.; Metwalli, E.; Müller-Buschbaum, P.; et al. A customizable software for fast reduction and analysis of large X-ray scattering data sets: Applications of the new DPDAK package to small-angle X-ray scattering and grazing-incidence small-angle X-ray scattering. J. Appl. Crystallogr. 2014, 47, 1797–1803. [Google Scholar] [CrossRef] [PubMed]

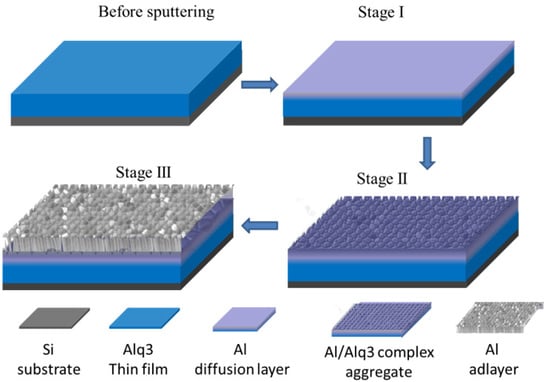

- Yu, S.; Santoro, G.; Sarkar, K.; Dicke, B.; Wessels, P.; Bommel, S.; Döhrmann, R.; Perlich, J.; Kuhlmann, M.; Metwalli, E.; et al. Formation of Al Nanostructures on Alq3: An in Situ Grazing Incidence Small Angle X-Ray Scattering Study during RF Sputter Deposition. J. Phys. Chem. Lett. 2013, 4, 3170–3175. [Google Scholar] [CrossRef]

- Santoro, G.; Yu, S.; Schwartzkopf, M.; Zhang, P.; Koyiloth Vayalil, S.; Risch, J.F.H.; Rübhausen, M.A.; Hernández, M.; Domingo, C.; Roth, S.V. Silver substrates for surface enhanced Raman scattering: Correlation between nanostructure and Raman scattering enhancement. Appl. Phys. Lett. 2014, 104, 243107. [Google Scholar] [CrossRef]

- Roth, S.V.; Santoro, G.; Risch, J.F.H.; Yu, S.; Schwartzkopf, M.; Boese, T.; Döhrmann, R.; Zhang, P.; Besner, B.; Bremer, P.; et al. Patterned Diblock Co-Polymer Thin Films as Templates for Advanced Anisotropic Metal Nanostructures. ACS Appl. Mater. Interfaces 2015, 7, 12470–12477. [Google Scholar] [CrossRef] [PubMed]

- Lazzari, R. IsGISAXS : A program for grazing-incidence small-angle X-ray scattering analysis of supported islands. J. Appl. Crystallogr. 2002, 35, 406–421. [Google Scholar] [CrossRef]

- Busch, P.; Posselt, D.; Smilgies, D.-M.; Rauscher, M.; Papadakis, C.M. Inner Structure of Thin Films of Lamellar Poly(styrene-b-butadiene) Diblock Copolymers As Revealed by Grazing-Incidence Small-Angle Scattering. Macromolecules 2007, 40, 630–640. [Google Scholar] [CrossRef]

- Gonzalez-garcfa, L.; Barranco, A.; Paez, M.; Hernandez, J.; Rueda, D.R.; Ezquerra, A.; Babonneau, D. Structure of Glancing Incidence Deposited TiO2 Thin Films as Revealed by Grazing Incidence Small-Angle X-ray Scattering. ChemPhysChem 2010, 11, 2205–2208. [Google Scholar] [CrossRef] [PubMed]

- Leroy, F.; Revenant, C.; Renaud, G.; Lazzari, R. In situ GISAXS study of the growth of Pd on MgO(001). Appl. Surf. Sci. 2004, 238, 233–237. [Google Scholar] [CrossRef]

- Revenant, C.; Leroy, F.; Lazzari, R.; Renaud, G.; Henry, C. Quantitative analysis of grazing incidence small-angle X-ray scattering: Pd/MgO(001) growth. Phys. Rev. B 2004, 69, 35411. [Google Scholar] [CrossRef]

- Leroy, F.; Renaud, G.; Létoublon, A.; Lazzari, R. Growth of Co on Au(111) studied by multiwavelength anomalous grazing-incidence small-angle X-ray scattering: From ordered nanostructures to percolated thin films and nanopillars. Phys. Rev. B 2008, 77, 235429. [Google Scholar] [CrossRef]

- Renaud, G.; Lazzari, R.; Revenant, C.; Barbier, A.; Noblet, M.; Ulrich, O.; Leroy, F.; Jupille, J.; Borensztein, Y.; Henry, C.R.; et al. Real-time monitoring of growing nanoparticles. Science 2003, 300, 1416–1419. [Google Scholar] [CrossRef] [PubMed]

- Maret, M.; Liscio, F.; Makarov, D.; Doisneau-Cottignies, B.; Ganss, F.; Missiaen, J.-M.; Albrecht, M. Growth temperature effect on the structure of CoPt islands on NaCl(001) studied by grazing-incidence small-angle X-ray scattering. J. Appl. Crystallogr. 2013, 47, 102–109. [Google Scholar] [CrossRef]

- Portale, G.; Sciortino, L.; Albonetti, C.; Giannici, F.; Martorana, A.; Bras, W.; Biscarini, F.; Longo, A. Influence of metal-support interaction on the surface structure of gold nanoclusters deposited on native SiOx/Si substrates. Phys. Chem. Chem. Phys. 2014, 16, 6649–6656. [Google Scholar] [CrossRef] [PubMed]

- Couet, S.; Diederich, T.; Schlage, K.; Röhlsberger, R. A compact UHV deposition system for in situ study of ultrathin films via hard X-ray scattering and spectroscopy. Rev. Sci. Instrum. 2008, 79, 93908. [Google Scholar] [CrossRef] [PubMed]

- Döhrmann, R.; Botta, S.; Buffet, A.; Santoro, G.; Schlage, K.; Schwartzkopf, M.; Bommel, S.; Risch, J.F.H.; Mannweiler, R.; Brunner, S.; et al. A new highly automated sputter equipment for in situ investigation of deposition processes with synchrotron radiation. Rev. Sci. Instrum. 2013, 84, 43901. [Google Scholar] [CrossRef] [PubMed]

- Robbie, K.; Brett, M.J. Sculptured thin films and glancing angle deposition: Growth mechanics and applications. J. Vac. Sci. Technol. A 1997, 15, 1460–1465. [Google Scholar] [CrossRef]

- Alvarez, R.; García-Martín, J.M.; Macías-Montero, M.; Gonzalez-Garcia, L.; González, J.C.; Rico, V.; Perlich, J.; Cotrino, J.; González-Elipe, A.R.; Palmero, A. Growth regimes of porous gold thin films deposited by magnetron sputtering at oblique incidence: From compact to columnar microstructures. Nanotechnology 2013, 24, 45604. [Google Scholar] [CrossRef] [PubMed]

- Roth, S.V.; Kuhlmann, M.; Walter, H.; Snigirev, A.; Snigireva, I.; Lengeler, B.; Schroer, C.G.; Burghammer, M.; Riekel, C.; Müller-Buschbaum, P. Colloidal silver nanoparticle gradient layer prepared by drying between two walls of different wettability. J. Phys. Condens. Matter 2009, 21, 264012. [Google Scholar] [CrossRef] [PubMed]

- Roth, S.V.; Müller-Buschbaum, P.; Timmann, A.; Perlich, J.; Gehrke, R. Structural changes in gradient colloidal thin gold films deposited from aqueous solution. J. Appl. Crystallogr. 2007, 40, s346–s349. [Google Scholar] [CrossRef]

- Roth, S.V.; Rothkirch, A.; Autenrieth, T.; Gehrke, R.; Wroblewski, T.; Burghammer, M.C.; Riekel, C.; Schulz, L.; Hengstler, R.; Müller-Buschbaum, P. Spatially Resolved Investigation of Solution Cast Nanoparticle Films by X-ray Scattering and Multidimensional Data Set Classification. Langmuir 2010, 26, 1496–1500. [Google Scholar] [CrossRef] [PubMed]

- Knopfmacher, O.; Hammock, M.L.; Appleton, A.L.; Schwartz, G.; Mei, J.; Lei, T.; Pei, J.; Bao, Z. Highly stable organic polymer field-effect transistor sensor for selective detection in the marine environment. Nat. Commun. 2014, 5, 2954. [Google Scholar] [CrossRef] [PubMed]

- Yokota, T.; Kuribara, K.; Tokuhara, T.; Zschieschang, U.; Klauk, H.; Takimiya, K.; Sadamitsu, Y.; Hamada, M.; Sekitani, T.; Someya, T. Flexible low-voltage organic transistors with high thermal stability at 250 °C. Adv. Mater. 2013, 25. [Google Scholar] [CrossRef] [PubMed]

- Ruderer, M.A.; Körstgens, V.; Metwalli, E.; Al-Hussein, M.; Vainio, U.; Roth, S.V.; Döhrmann, R.; Gehrke, R.; Gebhardt, R.; Burghammer, M.; et al. Determination of the local gold contact morphology on a photoactive polymer film using nanobeam GISAXS. Nucl. Instrum. Meth. Phys. Res. Sect. B 2010, 268, 403–410. [Google Scholar] [CrossRef]

- Zhao, Y.; Sugunan, A.; Rihtnesberg, D.B.; Wang, Q.; Toprak, M.S.; Muhammed, M. Size-tuneable synthesis of photoconducting poly-(3-hexylthiophene) nanofibres and nanocomposites. Phys. Status Solidi 2012, 9, 1546–1550. [Google Scholar] [CrossRef]

- Metwalli, E.; Couet, S.; Schlage, K.; Röhlsberger, R.; Körstgens, V.; Ruderer, M.; Wang, W.; Kaune, G.; Roth, S.V.; Müller-Buschbaum, P. In situ GISAXS Investigation of Gold Sputtering onto a Polymer Template. Langmuir 2008, 24, 4265–4272. [Google Scholar] [CrossRef] [PubMed]

- Metwalli, E.; Körstgens, V.; Schlage, K.; Meier, R.; Kaune, G.; Buffet, A.; Couet, S.; Roth, S.V.; Röhlsberger, R.; Müller-Buschbaum, P. Cobalt Nanoparticles Growth on a Block Copolymer Thin Film: A Time-Resolved GISAXS Study. Langmuir 2013, 29, 6331–6340. [Google Scholar] [CrossRef] [PubMed]

- Schlage, K.; Couet, S.; Roth, S.V.; Vainio, U.; Rüffer, R.; Abul Kashem, M.M.; Müller-Buschbaum, P.; Röhlsberger, R. The formation and magnetism of iron nanostructures on ordered polymer templates. New J. Phys. 2012, 14, 43007. [Google Scholar] [CrossRef]

- Shelton, C.K.; Epps, T.H. Block copolymer thin films: Characterizing nanostructure evolution with in situ X-ray and neutron scattering. Polymer 2016, 105, 545–561. [Google Scholar] [CrossRef]

- Schaffer, C.J.; Palumbiny, C.M.; Niedermeier, M.A.; Jendrzejewski, C.; Santoro, G.; Roth, S.V.; Müller-Buschbaum, P. A Direct Evidence of Morphological Degradation on a Nanometer Scale in Polymer Solar Cells. Adv. Mater. 2013, 25, 6760–6764. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Ruderer, M.A.; Rawolle, M.; Körstgens, V.; Birkenstock, C.; Perlich, J.; Müller-Buschbaum, P. Evolution of Lateral Structures during the Functional Stack Build-up of P3HT:PCBM-Based Bulk Heterojunction Solar Cells. ACS Appl. Mater. Interfaces 2013, 5, 8581–8590. [Google Scholar] [CrossRef] [PubMed]

- Kaune, G.; Metwalli, E.; Meier, R.; Körstgens, V.; Schlage, K.; Couet, S.; Röhlsberger, R.; Roth, S.V.; Müller-Buschbaum, P. Growth and Morphology of Sputtered Aluminum Thin Films on P3HT Surfaces. ACS Appl. Mater. Interfaces 2011, 3, 1055–1062. [Google Scholar] [CrossRef] [PubMed]

- Kaune, G.; Ruderer, M.A.; Metwalli, E.; Wang, W.; Couet, S.; Schlage, K.; Röhlsberger, R.; Roth, S.V.; Müller-Buschbaum, P. In Situ GISAXS Study of Gold Film Growth on Conducting Polymer Films. ACS Appl. Mater. Interfaces 2009, 1, 353–360. [Google Scholar] [CrossRef] [PubMed]

- Zaporojtchenko, V.; Behnke, K.; Thran, A.; Strunskus, T.; Faupel, F. Condensation coefficients and initial stages of growth for noble metals deposited onto chemically different polymer surfaces. Appl. Surf. Sci. 1999, 144–145, 355–359. [Google Scholar] [CrossRef]

- Guler, U.; Turan, R. Effect of particle properties and light polarization on the plasmonic resonances in metallic nanoparticles. Opt. Express 2010, 18, 17322–17338. [Google Scholar] [CrossRef] [PubMed]

- Krpetić, Z.; Guerrini, L.; Larmour, I.A.; Reglinski, J.; Faulds, K.; Graham, D. Importance of nanoparticle size in colorimetric and SERS-based multimodal trace detection of Ni(II) ions with functional gold nanoparticles. Small 2012, 8, 707–714. [Google Scholar] [CrossRef] [PubMed]

- Valden, M.; Lai, X.; Goodman, D.W. Onset of Catalytic Activity of Gold Clusters on Titania with the Appearance of Nonmetallic Properties. Science 1998, 281, 1647–1650. [Google Scholar] [CrossRef] [PubMed]

- Toderas, F.; Baia, M.; Baia, L.; Astilean, S. Controlling gold nanoparticle assemblies for efficient surface-enhanced Raman scattering and localized surface plasmon resonance sensors. Nanotechnology 2007, 18, 255702. [Google Scholar] [CrossRef]

- Hövel, M.; Gompf, B.; Dressel, M. Electrodynamics of ultrathin gold films at the insulator-to-metal transition. Thin Solid Films 2011, 519, 2955–2958. [Google Scholar] [CrossRef]

- Siegel, J.; Lyutakov, O.; Rybka, V.; Kolská, Z.; Svorčík, V. Properties of gold nanostructures sputtered on glass. Nanoscale Res. Lett. 2011, 6, 96. [Google Scholar] [CrossRef] [PubMed]

- Hövel, M.; Gompf, B.; Dressel, M. Dielectric properties of ultrathin metal films around the percolation threshold. Phys. Rev. B 2010, 1–7. [Google Scholar] [CrossRef]

- Han, Y.; Ferrando, R.; Li, Z.Y. Atomic Details of Interfacial Interaction in Gold Nanoparticles Supported on MgO(001). J. Phys. Chem. Lett. 2014, 5, 131–137. [Google Scholar] [CrossRef] [PubMed]

- Schwartzkopf, M. In situ µGISAXS Untersuchungen der Wachstumskinetik von Goldclustern. Dissertation, Fachbereich Chemie, University of Hamburg, Hamburg, Germany, 2014. [Google Scholar]

- Owens, D.; Wendt, R. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Xu, H.; Aizpurua, J.; Kall, M.; Apell, P. Electromagnetic contributions to single-molecule sensitivity in surface-enhanced raman scattering. Phys. Rev. E 2000, 62, 4318–4324. [Google Scholar] [CrossRef]

- Xu, H.; Bjerneld, E. Interparticle coupling effects in surface-enhanced Raman scattering. Proc. SPIE, Micro- Nanotechnol. Sens. Syst. Appl. II 2001, 4258, 35–42. [Google Scholar]

- Xu, J.; Zhang, L.; Gong, H. Tailoring Plasmonic Nanostructures for Optimal SERS Sensing of Small Molecules and Large Microorganisms. Small 2011, 371–376. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Santoro, G.; Yao, Y.; Babonneau, D.; Schwartzkopf, M.; Zhang, P.; Vayalil, S.K.; Wessels, P.; Döhrmann, R.; Drescher, M.; et al. Following the Island Growth in Real Time: Ag Nanocluster Layer on Alq3 Thin Film. J. Phys. Chem. C 2015, 119, 4406–4413. [Google Scholar] [CrossRef]

- DeMasi, A.; Piper, L.F.J.; Zhang, Y.; Reid, I.; Wang, S.; Smith, K.E.; Downes, J.E.; Peltekis, N.; McGuinness, C.; Matsuura, A. Electronic structure of the organic semiconductor Alq[sub 3] (aluminum tris-8-hydroxyquinoline) from soft X-ray spectroscopies and density functional theory calculations. J. Chem. Phys. 2008, 129, 224705. [Google Scholar] [CrossRef] [PubMed]

- Simonot, L.; Babonneau, D.; Camelio, S.; Lantiat, D.; Guérin, P.; Lamongie, B.; Antad, V. In situ optical spectroscopy during deposition of Ag:Si3N4 nanocomposite films by magnetron sputtering. Thin Solid Films 2010, 518, 2637–2643. [Google Scholar] [CrossRef]

- Lazzari, R.; Renaud, G.; Revenant, C.; Jupille, J.; Borensztein, Y. Adhesion of growing nanoparticles at a glance: Surface differential reflectivity spectroscopy and grazing incidence small angle X-ray scattering. Phys. Rev. B 2009, 79, 125428. [Google Scholar] [CrossRef]

- Babonneau, D.; Camelio, S.; Simonot, L.; Pailloux, F.; Guérin, P.; Lamongie, B.; Lyon, O. Tunable plasmonic dichroism of Au nanoparticles self-aligned on rippled Al2O3 thin films. Europhys. Lett. 2011, 93, 26005. [Google Scholar] [CrossRef]

- Grachev, S.; De Grazia, M.; Barthel, E.; Søndergård, E.; Lazzari, R. Real-time monitoring of nanoparticle film growth at high deposition rate with optical spectroscopy of plasmon resonances. J. Phys. D 2013, 46, 375305. [Google Scholar] [CrossRef]

- Roth, S.V.; Müller-Buschbaum, P.; Burghammer, M.; Walter, H.; Panagiotou, P.; Diethert, A.; Riekel, C. Microbeam grazing incidence small angle X-ray scattering—a new method to investigate heterogeneous thin films and multilayers. Spectrochim. Acta B 2004, 59, 1765–1773. [Google Scholar] [CrossRef]

- Atwater, H.A.; Polman, A. Plasmonics for improved photovoltaic devices. Nat. Mater. 2010, 9, 205–213. [Google Scholar] [CrossRef] [PubMed]

- Stratakis, E.; Kymakis, E. Nanoparticle-based plasmonic organic photovoltaic devices. Mater. Today 2013, 16, 133–146. [Google Scholar] [CrossRef]

- Jeffers, G.; Dubson, M.A.; Duxbury, P.M. Island-to-percolation transition during growth of metal films. J. Appl. Phys. 1994, 75, 5016–5020. [Google Scholar] [CrossRef]

- Russell, T.P.; Coulon, G.; Deline, V.R.; Miller, D.C. Characteristics of the surface-induced orientation for symmetric diblock PS/PMMA copolymers. Macromolecules 1989, 22, 4600–4606. [Google Scholar] [CrossRef]

- Hawkeye, M.M.; Brett, M.J. Glancing angle deposition: Fabrication, properties, and applications of micro- and nanostructured thin films. J. Vac. Sci. Technol. A 2007, 25, 1317–1335. [Google Scholar] [CrossRef]

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–153. [Google Scholar] [CrossRef]

- Buffet, A.; Abul Kashem, M.M.; Schlage, K.; Couet, S.; Röhlsberger, R.; Rothkirch, A.; Herzog, G.; Metwalli, E.; Meier, R.; Kaune, G.; et al. Time-resolved ultrathin cobalt film growth on a colloidal polymer template. Langmuir 2011, 27, 343–346. [Google Scholar] [CrossRef] [PubMed]

- Paul, N.; Metwalli, E.; Yao, Y.; Schwartzkopf, M.; Yu, S.; Roth, S.V.; Müller-Buschbaum, P.; Paul, A. Templating growth of gold nanostructures with a CdSe quantum dot array. Nanoscale 2015, 7, 9703–9714. [Google Scholar] [CrossRef] [PubMed]

- Kawabata, K.; Tanaka, T.; Kitabatake, A.; Yamada, K.; Mikami, Y.; Kajioka, H.; Toiyama, K. High rate sputtering for Ni films by an rf-dc coupled magnetron sputtering system with multipolar magnetic plasma confinement. J. Vac. Sci. Technol. A 2001, 19, 1438. [Google Scholar] [CrossRef]

- Liang, L.Y.; Cao, H.T.; Liu, Q.; Jiang, K.M.; Liu, Z.M.; Zhuge, F.; Deng, F.L. Substrate Biasing Effect on the Physical Properties of Reactive RF-Magnetron-Sputtered Aluminum Oxide Dielectric Films on ITO Glasses. ACS Appl. Mater. Interfaces 2014, 6, 2255–2261. [Google Scholar] [CrossRef] [PubMed]

- Maissel, L.I.; Schaible, P.M. Thin films deposited by bias sputtering. J. Appl. Phys. 1965, 36, 237–242. [Google Scholar] [CrossRef]

- Lim, J.W.; Ishikawa, Y.; Miyake, K.; Yamashita, M.; Isshiki, M. Influence of substrate bias voltage on the impurity concentrations in Hf films deposited by ion beam deposition method. Mater. Trans. 2002, 43, 1403–1408. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Gebhardt, R.; Roth, S.V.; Metwalli, E.; Doster, W. Effect of Calcium Concentration on the Structure of Casein Micelles in Thin Films. Biophys. J. 2007, 93, 960–968. [Google Scholar] [CrossRef] [PubMed]

- Müller-Buschbaum, P.; Gebhardt, R.; Maurer, E.; Bauer, E.; Gehrke, R.; Doster, W. Thin Casein Films as Prepared by Spin-Coating: Influence of Film Thickness and of pH. Biomacromolecules 2006, 7, 1773–1780. [Google Scholar] [CrossRef] [PubMed]

- Pechkova, E.; Roth, S.V.; Burghammer, M.; Fontani, D.; Riekel, C.; Nicolini, C. µGISAXS and protein nanotemplate crystallization: Methods and instrumentation. J. Synchrotron Radiat. 2005, 12, 713–716. [Google Scholar] [CrossRef] [PubMed]

- Håkansson, K.M.O. Online determination of anisotropy during cellulose nanofibril assembly in a flow focusing device. RSC Adv. 2015, 5, 18601–18608. [Google Scholar] [CrossRef]

- Yu, S.; Chen, F.; Wu, Q.; Roth, S.V.; Brüning, K.; Schneider, K.; Kuktaite, R.; Hedenqvist, M.S. Structural Changes of Gluten/Glycerol Plastics under Dry and Moist Conditions and during Tensile Tests. ACS Sustain. Chem. Eng. 2016, 4, 3388–3397. [Google Scholar] [CrossRef]

- Wu, Q.; Yu, S.; Kollert, M.; Mtimet, M.; Roth, S.V.; Gedde, U.W.; Johansson, E.; Olsson, R.T.; Hedenqvist, M.S. Highly Absorbing Antimicrobial Biofoams Based on Wheat Gluten and Its Biohybrids. ACS Sustain. Chem. Eng. 2016, 4, 2395–2404. [Google Scholar] [CrossRef]

- Roth, S.V.; Artus, G.R.J.; Rankl, M.; Seeger, S.; Burghammer, M.; Riekel, C.; Müller-Buschbaum, P. Lateral structural variations in thin cellulose layers investigated by microbeam grazing incidence small-angle X-ray scattering. Phys. B 2005, 357, 190–192. [Google Scholar] [CrossRef]

- Gebhardt, R.; Vendrely, C.; Burghammer, M.; Riekel, C. Characterization of the boundary zone of a cast protein drop: Fibroin beta-sheet and nanofibril formation. Langmuir 2009, 25, 6307–6311. [Google Scholar] [CrossRef] [PubMed]

- Hamedi, M.M.; Hajian, A.; Fall, A.B.; Håkansson, K.; Salajkova, M.; Lundell, F.; Wågberg, L.; Berglund, L.A. Highly Conducting, Strong Nanocomposites Based on Nanocellulose-Assisted Aqueous Dispersions of Single-Wall Carbon Nanotubes. ACS Nano 2014, 8, 2467–2476. [Google Scholar] [CrossRef] [PubMed]

- Keckes, J.; Burgert, I.; Frühmann, K.; Müller, M.; Kölln, K.; Hamilton, M.; Burghammer, M.; Roth, S.V.; Stanzl-tschegg, S.; Fratzl, P. Cell-wall recovery after irreversible deformation of wood. Nat. Mater. 2003, 2, 810–813. [Google Scholar] [CrossRef] [PubMed]

- Kölln, K.; Grotkopp, I.; Burghammer, M.; Roth, S.V.; Funari, S.S.; Dommach, M.; Müller, M. Mechanical properties of cellulose fibres and wood. Orientational aspects in situ investigated with synchrotron radiation. J. Synchrotron Radiat. 2005, 12, 739–744. [Google Scholar] [CrossRef] [PubMed]

- Håkansson, K.M.O.; Fall, A.B.; Lundell, F.; Yu, S.; Krywka, C.; Roth, S.V.; Santoro, G.; Kvick, M.; Prahl Wittberg, L.; Wågberg, L.; et al. Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments. Nat. Commun. 2014, 5, 4018. [Google Scholar] [CrossRef] [PubMed]

- Beyene, H.T.; Chakravadhanula, V.S.K.; Hanisch, C.; Elbahri, M.; Strunskus, T.; Zaporojtchenko, V.; Kienle, L.; Faupel, F. Preparation and plasmonic properties of polymer-based composites containing Ag-Au alloy nanoparticles produced by vapor phase co-deposition. J. Mater. Sci. 2010, 45, 5865–5871. [Google Scholar] [CrossRef]

- Beyene, H.T.; Chakravadhanula, V.S.K.; Hanisch, C.; Strunskus, T.; Zaporojtchenko, V.; Elbahri, M.; Faupel, F. Vapor Phase Deposition, Structure, and Plasmonic Properties of Polymer-Based Composites Containing Ag-Cu Bimetallic Nanoparticles. Plasmonics 2012, 7, 107–114. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schwartzkopf, M.; Roth, S.V. Investigating Polymer–Metal Interfaces by Grazing Incidence Small-Angle X-Ray Scattering from Gradients to Real-Time Studies. Nanomaterials 2016, 6, 239. https://doi.org/10.3390/nano6120239

Schwartzkopf M, Roth SV. Investigating Polymer–Metal Interfaces by Grazing Incidence Small-Angle X-Ray Scattering from Gradients to Real-Time Studies. Nanomaterials. 2016; 6(12):239. https://doi.org/10.3390/nano6120239

Chicago/Turabian StyleSchwartzkopf, Matthias, and Stephan V. Roth. 2016. "Investigating Polymer–Metal Interfaces by Grazing Incidence Small-Angle X-Ray Scattering from Gradients to Real-Time Studies" Nanomaterials 6, no. 12: 239. https://doi.org/10.3390/nano6120239

APA StyleSchwartzkopf, M., & Roth, S. V. (2016). Investigating Polymer–Metal Interfaces by Grazing Incidence Small-Angle X-Ray Scattering from Gradients to Real-Time Studies. Nanomaterials, 6(12), 239. https://doi.org/10.3390/nano6120239