Flexible Textile-Based Organic Transistors Using Graphene/Ag Nanoparticle Electrode

Abstract

:1. Introduction

2. Results

2.1. Prepratation of Graphene/Ag Nanoparticle Electrode on PET Textile

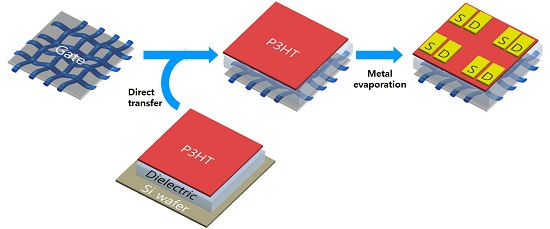

2.2. Prepratation of Transistor Devices Using Graphene/AgNP Textile Composites

3. Materials and Methods

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, H.M.; Kang, H.W.; Hwang, D.K.; Lim, H.S.; Ju, B.K.; Lim, J.A. Metal–Insulator–Semiconductor Coaxial Microfibers Based on Self-Organization of Organic Semiconductor: Polymer Blend for Weavable, Fibriform Organic Field-Effect Transistors. Adv. Funct. Mater. 2016, 26, 2706–2714. [Google Scholar] [CrossRef]

- Ryu, G.S.; Jeong, S.H.; Park, B.C.; Park, B.; Song, C.K. Fabrication of organic thin film transistors on Polyethylene Terephthalate (PET) fabric substrates. Org. Electron. 2014, 15, 1672–1677. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Tee, B.C.K.; Vosgueritchian, M.; Bao, Z. Stretchable Organic Solar Cells. Adv. Mater. 2011, 23, 1771–1775. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.H.; Kim, J.S.; Noh, J.; Lee, I.; Kim, H.J.; Choi, S.; Seo, J.; Jeon, S.; Kim, T.S.; Lee, J.Y.; et al. Wearable Textile Battery Rechargeable by Solar Energy. Nano Lett. 2013, 13, 5753–5761. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Kwon, S.S.; Lee, M.; Kim, J.Y.; Han, Y.; Kim, E.; Choi, K.C.; Park, S.; Park, B.C. Soft fabric-based flexible organic light-emitting diodes. Org. Electron. 2013, 14, 3007–3013. [Google Scholar] [CrossRef]

- Hamedi, M.; Herlogsson, L.; Crispin, X.; Marcilla, R.; Berggren, M.; Inganas, O. Fiber-Embedded Electrolyte-Gated Field-Effect Transistors for e-Textiles. Adv. Mater. 2009, 21, 573–577. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.; Hong, J.; Lee, E.K.; Yu, H.; Kim, H.; Lee, J.U.; Lee, W.; Oh, J.H. Highly Flexible Organic Nanofiber Phototransistors Fabricated on a Textile Composite for Wearable Photosensors. Adv. Funct. Mater. 2016, 26, 1445–1453. [Google Scholar] [CrossRef]

- Kong, B.S.; Jung, D.H.; Oh, S.K.; Han, C.S.; Jung, H.T. Single-Walled Carbon Nanotube Gold Nanohybrids: Application in Highly Effective Transparent and Conductive Films. J. Phys. Chem. C 2007, 111, 8377–8382. [Google Scholar] [CrossRef]

- Park, M.; Im, J.; Shin, M.; Min, Y.; Park, J.; Cho, H.; Park, S.; Shim, M.B.; Jeon, S.; Chung, D.Y.; et al. Highly stretchable electric circuits from a composite material of silver nanoparticles and elastomeric fibres. Nat. Nanotechnol. 2012, 7, 803–809. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.J.; Lee, J.U.; Jo, W.H. Multi-walled carbon nanotubes covalently attached with poly(3-hexylthiophene) for enhancement of field-effect mobility of poly(3-hexylthiophene)/multi-walled carbon nanotube composites. Carbon 2010, 48, 389–395. [Google Scholar] [CrossRef]

- Lee, K.H.; Kang, S.K.; Zhang, S.; Gu, Y.; Lodge, T.P.; Frisbie, C.D. “Cut and Stick” rubbery ion gels as high capacitance gate dielectrics. Adv. Mater. 2012, 24, 4457–4462. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.S.; Lee, K.E.; Cha, H.J.; Seong, D.G.; Um, M.K.; Byun, J.H.; Oh, Y.; Oh, J.H.; Lee, W.; Lee, J.U. Highly Conductive Graphene/Ag Hybrid Fibers for Flexible Fiber-Type Transistors. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Ong, B.S.; Wu, Y.; Liu, P.; Gardner, S. High-performance semiconducting polythiophenes for organic thin-film transistors. J. Am. Chem. Soc. 2004, 126, 3378–3379. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.W.; Lee, H.J.; Choi, J.H.; Koh, W.G.; Myoung, J.M.; Hur, J.H.; Park, J.J.; Cho, J.H.; Jeong, U. Periodic array of polyelectrolyte-gated organic transistors from electrospun poly(3-hexylthiophene) nanofibers. Nano Lett. 2010, 10, 347–351. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Cho, J.H.; Lee, J.; Ruden, P.P.; Frisbie, C.D. Comparison of the mobility-carrier density relation in polymer and single-crystal organic transistors employing vacuum and liquid gate dielectrics. Adv. Mater. 2009, 21, 2174–2179. [Google Scholar] [CrossRef]

- Bittle, E.G.; Basham, J.I.; Jackson, T.N.; Jurchescu, O.D.; Gundlach, D.J. Mobility overestimation due to gated contacts in organic field-effect transistors. Nat. Commun. 2016, 7. [Google Scholar] [CrossRef] [PubMed]

- Thomschke, M.; Hofmann, S.; Olthof, S.; Anderson, M.; Kleemann, H.; Schober, M.; Lüssem, B.; Leo, K. Improvement of voltage and charge balance in inverted top-emitting organic electroluminescent diodes comprising doped transport layers by thermal annealing. Appl. Phys. Lett. 2011, 98. [Google Scholar] [CrossRef]

- Ma, W.; Yang, C.; Gong, X.; Lee, K.; Heeger, A.J. Thermally Stable, Efficient Polymer Solar Cells with Nanoscale Control of the Interpenetrating Network Morphology. Adv. Funct. Mater. 2005, 15, 1617–1622. [Google Scholar] [CrossRef]

- Zhao, J.; Swinnen, A.; Assche, G.V.; Manca, J.; Vanderzande, D.; Mele, B.V. Phase Diagram of P3HT/PCBM Blends and Its Implication for the Stability of Morphology. J. Phys. Chem. B 2009, 113, 1587–1591. [Google Scholar] [CrossRef] [PubMed]

- Fragiadakis, D.; Pissis, P.; Bokobza, L. Glass transition and molecular dynamics in poly(dimethylsiloxane)/silica nanocomposites. Polymer 2005, 46, 6001–6008. [Google Scholar] [CrossRef]

- Arora, N. MOSFET Models for VLSI Circuit Simulation Theory and Practic; Springer: New York, NY, USA, 1993. [Google Scholar]

| Treatment | μh (cm2·V−1·s−1) | Ion/Ioff | VT (V) |

|---|---|---|---|

| Without annealing | 2.7 | 4.5 × 104 | −1.5 |

| With annealing | 7.2 | 4 × 105 | −1.1 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Kwon, Y.J.; Lee, K.E.; Oh, Y.; Um, M.-K.; Seong, D.G.; Lee, J.U. Flexible Textile-Based Organic Transistors Using Graphene/Ag Nanoparticle Electrode. Nanomaterials 2016, 6, 147. https://doi.org/10.3390/nano6080147

Kim Y, Kwon YJ, Lee KE, Oh Y, Um M-K, Seong DG, Lee JU. Flexible Textile-Based Organic Transistors Using Graphene/Ag Nanoparticle Electrode. Nanomaterials. 2016; 6(8):147. https://doi.org/10.3390/nano6080147

Chicago/Turabian StyleKim, Youn, Yeon Ju Kwon, Kang Eun Lee, Youngseok Oh, Moon-Kwang Um, Dong Gi Seong, and Jea Uk Lee. 2016. "Flexible Textile-Based Organic Transistors Using Graphene/Ag Nanoparticle Electrode" Nanomaterials 6, no. 8: 147. https://doi.org/10.3390/nano6080147

APA StyleKim, Y., Kwon, Y. J., Lee, K. E., Oh, Y., Um, M. -K., Seong, D. G., & Lee, J. U. (2016). Flexible Textile-Based Organic Transistors Using Graphene/Ag Nanoparticle Electrode. Nanomaterials, 6(8), 147. https://doi.org/10.3390/nano6080147