Increased Efficiency of Solar Cells Protected by Hydrophobic and Hydrophilic Anti-Reflecting Nanostructured Glasses

Abstract

:1. Introduction

2. Experimental Process

3. Results and Discussion

3.1. Optical Characterization of Ordered 1D Nanostructures

3.2. Optical Characterization of Disordered 2D Nanostructures

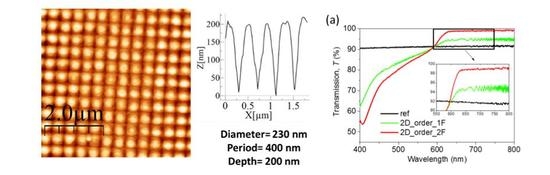

3.3. Optical Characterization of Ordered 2D Nanostructures

3.4. Solar Efficiency

3.5. Wettability

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Timilsina, G.R.; Kurdgelashvili, L.; Narbel, P.A. Solar energy: Markets, economics and policies. Renew. Sustain. Energy Rev. 2012, 16, 449–465. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Solar Energy Perspectives; IEA: Paris, France, 2011. [Google Scholar]

- Macdonald, D.; Cuevas, A.; Kerr, M.J.; Samundsett, C.; Ruby, D.; Winderbaum, S.; Leo, A. Texturing industrial multicrystalline silicon solar cells. Sol. Energy 2004, 76, 277–283. [Google Scholar] [CrossRef]

- Panek, P.; Lipiński, M.; Dutkiewicz, J. Texturization of multicrystalline silicon by wet chemical etching for silicon solar cells. J. Mater. Sci. 2005, 40, 1459–1463. [Google Scholar] [CrossRef]

- Lalanne, P.; Morris, G.M. Antireflection behavior of silicon subwavelength periodic structures for visible light. Nanotechnology 1997, 8, 53. [Google Scholar] [CrossRef]

- Huang, Y.F.; Chattopadhyay, S.; Jen, Y.J.; Peng, C.J.; Liu, T.A.; Hsu, Y.K.; Pan, C.L.; Lo, H.C.; Hsu, C.H.; Chang, Y.H. Improved broadband and quasi-omnidirectional anti-reflection properties with biomimetic silicon nanostructures. Nat. Nanotechnol. 2007, 2, 770–774. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Tao, M.; Chen, L.; Yang, H. Microstructured surface design for omnidirectional antireflection coatings on solar cells. J. Appl. Phys. 2007, 102, 103105. [Google Scholar] [CrossRef]

- Postigo, P.; Kaldirim, M.; Prieto, I.; Martínez, L.; Dotor, L.; Galli, M.; Andreani, L. Enhancement of solar cell efficiency using two-dimensional photonic crystals. In Proceedings of the SPIE Photonics Europe 2010, Brussels, Begium, 12–16 April 2010. [Google Scholar]

- Burrows, K.; Fthenakis, V. Glass needs for a growing photovoltaics industry. Sol. Energy Mater. Sol. Cells 2015, 132, 455–459. [Google Scholar] [CrossRef]

- Powell, D.M.; Winkler, M.T.; Choi, H.; Simmons, C.B.; Needleman, D.B.; Buonassisi, T. Crystalline silicon photovoltaics: A cost analysis framework for determining technology pathways to reach baseload electricity costs. Energy Environ. Sci. 2012, 5, 5874–5883. [Google Scholar] [CrossRef]

- Jorgensen, G.J.; Brunold, S.; Koehl, M.; Nostell, P.; Oversloot, H.; Roos, A. Durability testing of antireflection coatings for solar applications. In SPIE’s International Symposium on Optical Science, Engineering, and Instrumentation; International Society for Optics and Photonics: Bellingham, WA, USA, 1999; pp. 66–76. [Google Scholar]

- Deubener, J.; Helsch, G.; Moiseev, A.; Bornhöft, H. Glasses for solar energy conversion systems. J. Eur. Ceram. Soc. 2009, 29, 1203–1210. [Google Scholar] [CrossRef]

- Verita, M.; Geotti-Bianchini, F.; Falcone, R.; Zangiacomi, G.; Chabas, A.; Lombardo, T.; Daveau, S.; Ausset, P.; Cachier, H.; Oikonomou, K. Analysis of self-cleaning and float glass: A comparative study of pollution on the glass surfaces under real life conditions. Glass Technol. 2007, 48, 183–190. [Google Scholar]

- Mellott, N.; Durucan, C.; Pantano, C.; Guglielmi, M. Commercial and laboratory prepared titanium dioxide thin films for self-cleaning glasses: Photocatalytic performance and chemical durability. Thin Solid Films 2006, 502, 112–120. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Salvaggio, M.G.; Passalacqua, R.; Perathoner, S.; Centi, G.; Lanza, M.; Stassi, A. Functional nano-textured titania-coatings with self-cleaning and antireflective properties for photovoltaic surfaces. Sol. Energy 2016, 125, 227–242. [Google Scholar] [CrossRef]

- Son, J.; Kundu, S.; Verma, L.K.; Sakhuja, M.; Danner, A.J.; Bhatia, C.S.; Yang, H. A practical superhydrophilic self cleaning and antireflective surface for outdoor photovoltaic applications. Sol. Energy Mater. Sol. Cells 2012, 98, 46–51. [Google Scholar] [CrossRef]

- Lin, S.H.; Wu, Y.N.; Lin, Y.C.; Yang, Y.M. Design and fabrication of antireflective nanoparticulate thin films with superhydrophilic self-cleaning properties on glass substrate. J. Taiwan Inst. Chem. Eng. 2011, 42, 852–859. [Google Scholar] [CrossRef]

- Yang, C.; Tartaglino, U.; Persson, B. Influence of surface roughness on superhydrophobicity. Phys. Rev. Lett. 2006, 97, 116103. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Verho, T.; Ras, R.H. Moving superhydrophobic surfaces toward real-world applications. Science 2016, 352, 142–143. [Google Scholar] [CrossRef] [PubMed]

- Verma, L.K.; Sakhuja, M.; Son, J.; Danner, A.; Yang, H.; Zeng, H.; Bhatia, C. Self-cleaning and antireflective packaging glass for solar modules. Renew. Energy 2011, 36, 2489–2493. [Google Scholar] [CrossRef]

- Brongersma, M.L.; Cui, Y.; Fan, S. Light management for photovoltaics using high-index nanostructures. Nat. Mater. 2017, 13, 451–460. [Google Scholar] [CrossRef] [PubMed]

- Faÿ, S.; Kroll, U.; Bucher, C.; Vallat-Sauvain, E.; Shah, A. Low pressure chemical vapour deposition of ZnO layers for thin-film solar cells: Temperature-induced morphological changes. Sol. Energy Mater. Sol. Cells 2005, 86, 385–397. [Google Scholar] [CrossRef]

- Berginski, M.; Hüpkes, J.; Schulte, M.; Schöpe, G.; Stiebig, H.; Rech, B.; Wuttig, M. The effect of front ZnO: Al surface texture and optical transparency on efficient light trapping in silicon thin-film solar cells. J. Appl. Phys. 2007, 101, 074903. [Google Scholar] [CrossRef]

- Tan, H.; Santbergen, R.; Smets, A.H.; Zeman, M. Plasmonic light trapping in thin-film silicon solar cells with improved self-assembled silver nanoparticles. Nano Lett. 2012, 12, 4070–4076. [Google Scholar] [CrossRef] [PubMed]

- Morawiec, S.; Mendes, M.J.; Mirabella, S.; Simone, F.; Priolo, F.; Crupi, I. Self-assembled silver nanoparticles for plasmon-enhanced solar cell back reflectors: Correlation between structural and optical properties. Nanotechnology 2013, 24, 265601. [Google Scholar] [CrossRef] [PubMed]

- Bozzola, A.; Liscidini, M.; Andreani, L.C. Photonic light-trapping versus Lambertian limits in thin film silicon solar cells with 1D and 2D periodic patterns. Opt. Express 2012, 20, A224–A244. [Google Scholar] [CrossRef] [PubMed]

- Buencuerpo, J.; Munioz-Camuniez, L.E.; Dotor, M.L.; Postigo, P.A. Optical absorption enhancement in a hybrid system photonic crystal–thin substrate for photovoltaic applications. Opt. Express 2012, 20, A452–A464. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Raman, A.; Fan, S. Fundamental limit of light trapping in grating structures. Opt. Express 2010, 18, A366–A380. [Google Scholar] [CrossRef] [PubMed]

- Simonsen, I. Optics of surface disordered systems. Eur. Phys. J. Spec. Top. 2010, 181, 1–103. [Google Scholar] [CrossRef]

- Fahr, S.; Kirchartz, T.; Rockstuhl, C.; Lederer, F. Approaching the Lambertian limit in randomly textured thin-film solar cells. Opt. Express 2011, 19, A865–A874. [Google Scholar] [CrossRef] [PubMed]

- Jäger, K.; Fischer, M.; Van Swaaij, R.; Zeman, M. A scattering model for nano-textured interfaces and its application in opto-electrical simulations of thin-film silicon solar cells. J. Appl. Phys. 2012, 111, 083108. [Google Scholar] [CrossRef]

- Xia, Y.; Whitesides, G.M. Soft lithography. Annu. Rev. Mater. Sci. 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Baquedano, E.; Martinez, R.V.; Llorens, J.M.; Postigo, P.A. Fabrication of Silicon Nanobelts and Nanopillars by Soft Lithography for Hydrophobic and Hydrophilic Photonic Surfaces. Nanomaterials 2017, 7, 109. [Google Scholar] [CrossRef] [PubMed]

- Macleod, H.A. Thin-Film Optical Filters, 3rd ed.; CRC Press Taylor & Francis: London, UK, 2001; ISBN 978-0-75-030688-1. [Google Scholar]

- Park, K.C.; Choi, H.J.; Chang, C.H.; Cohen, R.E.; McKinley, G.H.; Barbastathis, G. Nanotextured silica surfaces with robust superhydrophobicity and omnidirectional broadband supertransmissivity. ACS Nano 2012, 6, 3789–3799. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.M.; Choi, H.J.; Yu, J.S.; Lee, Y.T. Design of highly transparent glasses with broadband antireflective subwavelength structures. Opt. Express 2010, 18, 13063–13071. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.A.; Tsai, M.L.; Wei, W.R.; Lai, K.Y.; He, J.H. Packaging glass with a hierarchically nanostructured surface: A universal method to achieve self-cleaning omnidirectional solar cells. ACS Nano 2015, 10, 549–555. [Google Scholar] [CrossRef] [PubMed]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Zeitouny, J.; Katz, E.A.; Dollet, A.; Vossier, A. Band Gap Engineering of Multi-Junction Solar Cells: Effects of Series Resistances and Solar Concentration. Sci. Rep. 2017, 7, 1766. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Hsu, C.M.; Yu, Z.; Fan, S.; Cui, Y. Nanodome solar cells with efficient light management and self-cleaning. Nano Lett. 2009, 10, 1979–1984. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baquedano, E.; Torné, L.; Caño, P.; Postigo, P.A. Increased Efficiency of Solar Cells Protected by Hydrophobic and Hydrophilic Anti-Reflecting Nanostructured Glasses. Nanomaterials 2017, 7, 437. https://doi.org/10.3390/nano7120437

Baquedano E, Torné L, Caño P, Postigo PA. Increased Efficiency of Solar Cells Protected by Hydrophobic and Hydrophilic Anti-Reflecting Nanostructured Glasses. Nanomaterials. 2017; 7(12):437. https://doi.org/10.3390/nano7120437

Chicago/Turabian StyleBaquedano, Estela, Lorena Torné, Pablo Caño, and Pablo A. Postigo. 2017. "Increased Efficiency of Solar Cells Protected by Hydrophobic and Hydrophilic Anti-Reflecting Nanostructured Glasses" Nanomaterials 7, no. 12: 437. https://doi.org/10.3390/nano7120437

APA StyleBaquedano, E., Torné, L., Caño, P., & Postigo, P. A. (2017). Increased Efficiency of Solar Cells Protected by Hydrophobic and Hydrophilic Anti-Reflecting Nanostructured Glasses. Nanomaterials, 7(12), 437. https://doi.org/10.3390/nano7120437