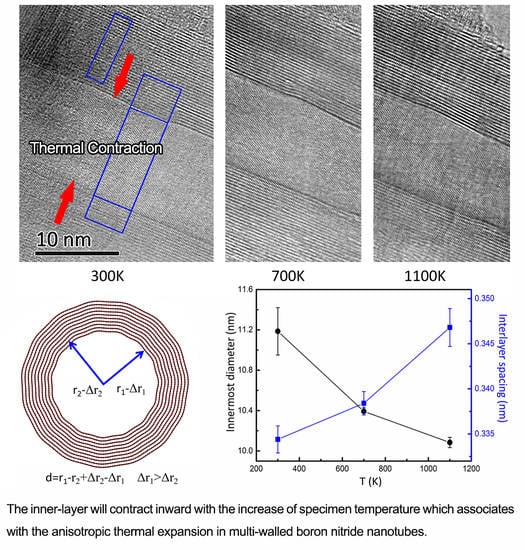

Direct Observation of Inner-Layer Inward Contractions of Multiwalled Boron Nitride Nanotubes upon in Situ Heating

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cavallaro, G.; Danilushkina, A.A.; Evtugyn, V.G.; Lazzara, G.; Milioto, S.; Parisi, F.; Rozhina, E.V.; Fakhrullin, R.F. Halloysite Nanotubes: Controlled Access and Release by Smart Gates. Nanomaterials 2017, 7, 199. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Chen, Y.; Leng, F.; Huang, L.; Wang, Z.; Tian, W. Recent Advances on Surface Modification of Halloysite Nanotubes for Multifunctional Applications. Appl. Sci. 2017, 7, 1215. [Google Scholar] [CrossRef]

- Makaremi, M.; Pasbakhsh, P.; Cavallaro, G.; Lazzara, G.; Aw, Y.K.; Lee, S.M.; Milioto, S. Effect of Morphology and Size of Halloysite Nanotubes on Functional Pectin Bionanocomposites for Food Packaging Applications. ACS Appl. Mater. Interfaces 2017, 9, 17476–17488. [Google Scholar] [CrossRef] [PubMed]

- Mceuen, P.L. Nanotechnology: Carbon-based electronics. Nature 1998, 393, 15–17. [Google Scholar] [CrossRef]

- Lu, W.; Lieber, C.M. Nanoelectronics from the bottom up. Nat. Mater. 2007, 6, 841–850. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Qin, S.; Savaikar, M.A.; Wang, J.; Hao, B.; Zhang, D.; Banyai, D.; Jaszczak, J.A.; Clark, K.W.; Idrobo, J.C.; et al. Room-temperature tunneling behavior of boron nitride nanotubes functionalized with gold quantum dots. Adv. Mater. 2013, 25, 4544–4548. [Google Scholar] [CrossRef] [PubMed]

- Anantram, M.P.; Léonard, F. Physics of carbon nanotube electronic devices. Rep. Prog. Phys. 2006, 69, 507–561. [Google Scholar] [CrossRef]

- Golberg, D.; Bando, Y.; Tang, C.C.; Zhi, C.Y. Boron Nitride Nanotubes. Adv. Mater. 2007, 19, 2413–2432. [Google Scholar] [CrossRef]

- Golberg, D.; Bando, Y.; Huang, Y.; Terao, T.; Mitome, M.; Tang, C.; Zhi, C. Boron Nitride Nanotubes and Nanosheets. ACS Nano 2010, 4, 2979–2993. [Google Scholar] [CrossRef] [PubMed]

- Xiang, C.; Chen, T.; Zhang, H.; Zou, Y.; Chu, H.; Zhang, H.; Xu, F.; Sun, L.; Tang, C. Growth of copper-benzene-1,3,5-tricarboxylate on boron nitride nanotubes and application of the composite in methane sensing. Appl. Surf. Sci. 2017, 424, 39–44. [Google Scholar] [CrossRef]

- Dhungana, K.B.; Pati, R. Boron nitride nanotubes for spintronics. Sensors 2014, 14, 17655–17685. [Google Scholar] [CrossRef] [PubMed]

- Farmanzadeh, D.; Ghazanfary, S. Interaction of vitamins B3 and C and their radicals with (5, 0) single-walled boron nitride nanotube for use as biosensor or in drug delivery. J. Chem. Sci. 2013, 125, 1595–1606. [Google Scholar] [CrossRef]

- Chen, X.; Wu, P.; Rousseas, M.; Okawa, D.; Gartner, Z.; Zettl, A.; Bertozzi, C.R. Boron Nitride Nanotubes Are Noncytotoxic and Can Be Functionalized for Interaction with Proteins and Cells. J. Am. Chem. Soc. 2009, 131, 890–891. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Paxton, W.F.; Baughman, R.H.; Huang, T.J.; Stoddart, J.F.; Weiss, P.S. Molecular, Supramolecular, and Macromolecular Motors and Artificial Muscles. MRS Bull. 2011, 34, 671–681. [Google Scholar] [CrossRef]

- Ramachandramoorthy, R.; Bernal, R.; Espinosa, H.D. Pushing the envelope of in situ transmission electron microscopy. ACS Nano 2015, 9, 4675–4685. [Google Scholar] [CrossRef] [PubMed]

- Golberg, D.; Bai, X.D.; Mitome, M.; Tang, C.C.; Zhi, C.Y.; Bando, Y. Structural peculiarities of in situ deformation of a multi-walled BN nanotube inside a high-resolution analytical transmission electron microscope. Acta Mater. 2007, 55, 1293–1298. [Google Scholar] [CrossRef]

- Zhi, C.; Bando, Y.; Tan, C.; Golberg, D. Effective precursor for high yield synthesis of pure BN nanotubes. Solid State Commun. 2005, 135, 67–70. [Google Scholar] [CrossRef]

- Maniwa, Y.; Fujiwara, R.; Kira, H.; Tou, H.; Nishibori, E.; Takata, M.; Sakata, M.; Fujiwara, A.; Zhao, X.; Iijima, S.; et al. Multiwalled carbon nanotubes grown in hydrogen atmosphere: An X-ray diffraction study. Phys. Rev. B 2001, 64, 073105. [Google Scholar] [CrossRef]

- Lavin, J.G.; Subramoney, S.; Ruoff, R.S.; Berber, S.; Tománek, D. Scrolls and nested tubes in multiwall carbon nanotubes. Carbon 2002, 40, 1123–1130. [Google Scholar] [CrossRef]

- Cao, G.; Chen, X.; Kysar, J.W. Apparent thermal contraction of single-walled carbon nanotubes. Phys. Rev. B 2005, 72, 235404. [Google Scholar] [CrossRef]

- Bandow, S. Radial Thermal Expansion of Purified Multiwall Carbon Nanotubes Measured by X-ray Diffraction. Jpn. J. Appl. Phys. 1997, 36, L1403–L1405. [Google Scholar] [CrossRef]

- Yates, B.; Overy, M.J.; Pirgon, O. The anisotropic thermal expansion of boron nitride. Philos. Mag. 2006, 32, 847–857. [Google Scholar] [CrossRef]

- Tohei, T.; Lee, H.-S.; Ikuhara, Y. First Principles Calculation of Thermal Expansion of Carbon and Boron Nitrides Based on Quasi-Harmonic Approximation. Mater. Trans. 2015, 56, 1452–1456. [Google Scholar] [CrossRef]

- Park, S.T.; Flannigan, D.J.; Zewail, A.H. 4D electron microscopy visualization of anisotropic atomic motions in carbon nanotubes. J. Am. Chem. Soc. 2012, 134, 9146–9149. [Google Scholar] [CrossRef] [PubMed]

- Cao, G.; Sun, S.; Li, Z.; Tian, H.; Yang, H.; Li, J. Clocking the anisotropic lattice dynamics of multi-walled carbon nanotubes by four-dimensional ultrafast transmission electron microscopy. Sci. Rep. 2015, 5, 8404. [Google Scholar] [CrossRef] [PubMed]

- Kiang, C.H.; Endo, M.; Ajayan, P.M.; Dresselhaus, G.; Dresselhaus, M.S. Size Effects in Carbon Nanotubes. Phys. Rev. Lett. 1998, 81, 1869–1872. [Google Scholar] [CrossRef]

- Salehi-Khojin, A.; Jalili, N. Buckling of boron nitride nanotube reinforced piezoelectric polymeric composites subject to combined electro-thermo-mechanical loadings. Compos. Sci. Technol. 2008, 68, 1489–1501. [Google Scholar] [CrossRef]

- Thomas, S.; Ajith, K.M.; Chandra, S.; Valsakumar, M.C. Temperature dependent structural properties and bending rigidity of pristine and defective hexagonal boron nitride. J. Phys. Condens. Matter Inst. Phys. J. 2015, 27, 315302. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Xu, F.; Sun, L.-T. In situ investigation of the mechanical properties of nanomaterials by transmission electron microscopy. Acta Mech. Sin. 2012, 28, 1513–1527. [Google Scholar] [CrossRef]

- Mashreghi, A. Thermal expansion/contraction of boron nitride nanotubes in axial, radial and circumferential directions. Comput. Mater. Sci. 2012, 65, 356–364. [Google Scholar] [CrossRef]

- Kwon, Y.K.; Berber, S.; Tomanek, D. Thermal contraction of carbon fullerenes and nanotubes. Phys. Rev. Lett. 2004, 92, 015901. [Google Scholar] [CrossRef] [PubMed]

- He, X.Q.; Eisenberger, M.; Liew, K.M. The effect of van der Waals interaction modeling on the vibration characteristics of multiwalled carbon nanotubes. J. Appl. Phys. 2006, 100, 124317. [Google Scholar] [CrossRef]

- Wang, C.Y.; Ru, C.Q.; Mioduchowski, A. Free vibration of multiwall carbon nanotubes. J. Appl. Phys. 2005, 97, 114323. [Google Scholar] [CrossRef]

- Cao, G.; Chen, X.; Kysar, J.W. Thermal vibration and apparent thermal contraction of single-walled carbon nanotubes. J. Mech. Phys. Solids 2006, 54, 1206–1236. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Li, Z.-A.; Sun, S.; Zheng, D.; Wang, H.; Tian, H.; Yang, H.; Bai, X.; Li, J. Direct Observation of Inner-Layer Inward Contractions of Multiwalled Boron Nitride Nanotubes upon in Situ Heating. Nanomaterials 2018, 8, 86. https://doi.org/10.3390/nano8020086

Li Z, Li Z-A, Sun S, Zheng D, Wang H, Tian H, Yang H, Bai X, Li J. Direct Observation of Inner-Layer Inward Contractions of Multiwalled Boron Nitride Nanotubes upon in Situ Heating. Nanomaterials. 2018; 8(2):86. https://doi.org/10.3390/nano8020086

Chicago/Turabian StyleLi, Zhongwen, Zi-An Li, Shuaishuai Sun, Dingguo Zheng, Hong Wang, Huanfang Tian, Huaixin Yang, Xuedong Bai, and Jianqi Li. 2018. "Direct Observation of Inner-Layer Inward Contractions of Multiwalled Boron Nitride Nanotubes upon in Situ Heating" Nanomaterials 8, no. 2: 86. https://doi.org/10.3390/nano8020086

APA StyleLi, Z., Li, Z. -A., Sun, S., Zheng, D., Wang, H., Tian, H., Yang, H., Bai, X., & Li, J. (2018). Direct Observation of Inner-Layer Inward Contractions of Multiwalled Boron Nitride Nanotubes upon in Situ Heating. Nanomaterials, 8(2), 86. https://doi.org/10.3390/nano8020086