Alignment of Boron Nitride Nanofibers in Epoxy Composite Films for Thermal Conductivity and Dielectric Breakdown Strength Improvement

Abstract

:1. Introduction

2. Experimental

2.1. Material

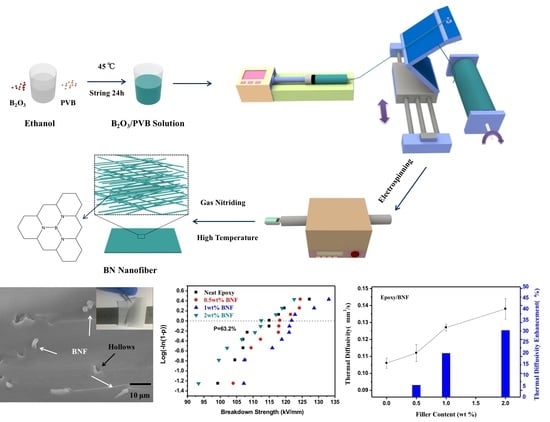

2.2. Preparation of BNNF

2.3. Preparation of Epoxy-based Nanocomposites Film

2.4. Characterization

3. Results and Discussion

3.1. X-ray Diffraction, SEM and TEM Analysis (BNNF)

3.2. SEM and Optical Microscope Analysis of BNNF/Epoxy Composites

3.3. Dielectric and Thermal Properties

3.4. Thermal Conductivity

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huang, X.; Zhi, C.; Jiang, P.; Golberg, D.; Bando, Y.; Tanaka, T. Polyhedral oligosilsesquioxane-modified boron nitride nanotube based epoxy nanocomposites: An ideal dielectric material with high thermal conductivity. Adv. Funct. Mater. 2013, 23, 1824–1831. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, Y.; Wang, H.; Yang, M.; Shao, Y.; Chen, X.; Tanaka, T. Sandwiched epoxy-alumina composites with synergistically enhanced thermal conductivity and breakdown strength. J. Mater. Sci. 2017, 52, 4299–4308. [Google Scholar] [CrossRef]

- Wu, G.; Cheng, Y.; Yang, Z.; Jia, Z.; Wu, H.; Yang, L.; Li, H.; Guo, P.; Lv, H. Design of Carbon Sphere/Magnetic Quantum Dots with Tunable Phase Compositions and Boost Dielectric Loss Behavior. Chem. Eng. J. 2018, 333, 519–528. [Google Scholar] [CrossRef]

- Hou, Z.-L.; Song, W.-L.; Wang, P.; Meziani, M.J.; Kong, C.Y.; Anderson, A.; Maimaiti, H.; LeCroy, G.E.; Qian, H.; Sun, Y.-P. Flexible Graphene-Graphene Composites of Superior Thermal and Electrical Transport Properties. ACS Appl. Mater. Interf. 2014, 6, 15026–15032. [Google Scholar] [CrossRef] [PubMed]

- Veca, L.M.; Meziani, M.J.; Wang, W.; Wang, X.; Lu, F.; Zhang, P.; Lin, Y.; Fee, R.; Connell, J.W.; Sun, Y.-P. Carbon Nanosheets for Highly Thermal Conductive Polymeric Nanocomposites. Adv. Mater. 2009, 21, 2088–2092. [Google Scholar] [CrossRef]

- Huang, Y.; Min, D.; Li, S.; Wang, X.; Lin, S. Dielectric relaxation and carrier transport in epoxy resin and its microcomposite. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3083–3091. [Google Scholar] [CrossRef]

- Huang, Y.; Min, D.; Li, S.; Li, Z.; Xie, D.; Wang, X.; Lin, S. Surface flashover performance of epoxy resin microcomposites improved by electron beam irradiation. Appl. Surf. Sci. 2017, 406, 39–45. [Google Scholar] [CrossRef]

- Song, W.-L.; Wang, P.; Cao, L.; Anderson, A.; Meziani, M.J.; Farr, A.J.; Sun, Y.-P. Polymer/Boron Nitride Nanocomposite Materials for Superior Thermal Transport Performance. Angew. Chem. Int. Ed. 2012, 51, 6498–6501. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Cheng, Y.; Yang, M.; Huang, J.; Cao, D.; Chen, S.; Xie, Q.; Lou, F.; Wu, H. Dielectric properties and thermal conductivity of epoxy composites using core/shell structured Si/SiO2/Polydopamine. Compos. Part B Eng. 2018, 140, 83–90. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, Y.; Shao, Y.; Xie, Q.; Wu, G. Thermal conductivity and electric breakdown strength properties of epoxy/alumina/boron nitride nanosheets composites. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; pp. 355–358. [Google Scholar] [CrossRef]

- Wang, Z.B.; Iizuka, T.; Kozako, M.; Ohki, Y.; Tanaka, T. Development of epoxy/BN composites with high thermal conductivity and sufficient dielectric breakdown strength Part I. Sample preparations and thermal conductivity. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1963–1972. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Yao, Y.; Chen, C.Y.; Moon, K.; Wang, H.; Wong, C.P. The use of polyimide-modified aluminum nitride fillers in AlN@PI/Epoxy composites with enhanced thermal conductivity for electronic encapsulation. Sci. Rep. 2014, 4, 4779. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Lv, Z.; Wu, Y.; Guo, Y.; Tian, L.; Qiu, H.; Li, W.; Zhang, Q. Dielectric thermally conductive boron nitride/polyimide composites with outstanding thermal stabilities via in situ polymerization-electrospinning-hot press method. Compos. Part A Appl. Sci. Manuf. 2017, 94, 209–216. [Google Scholar] [CrossRef]

- Pan, C.; Zhang, J.; Kou, K.; Zhang, Y.; Wu, G. Investigation of the through-plane thermal conductivity of polymer composites with in-plane oriented hexagonal boron nitride. Int. J. Heat Mass Transf. 2018, 120, 1–8. [Google Scholar] [CrossRef]

- Meziani, M.J.; Song, W.-L.; Wang, P.; Lu, F.; Hou, Z.; Anderson, A.; Maimaiti, H.; Sun, Y.-P. Boron Nitride Nanomaterials for Thermal Management Applications. ChemPhysChem 2015, 16, 1339–1346. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Huang, X.; Zhu, Y.; Jiang, P. Cellulose Nanofiber Supported 3D Interconnected BN Nanosheets for Epoxy Nanocomposites with Ultrahigh Thermal Management Capability. Adv. Funct. Mater. 2017, 27, 1604754. [Google Scholar] [CrossRef]

- Nika, D.L.; Balandin, A.A. Phonons and thermal transport in graphene and graphene-based materials. Rep. Prog. Phys. Phys. Soc. 2017, 80, 036502. [Google Scholar] [CrossRef] [PubMed]

- Saadah, M.; Hernandez, E.; Balandin, A. Thermal Management of Concentrated Multi-Junction Solar Cells with Graphene-Enhanced Thermal Interface Materials. Appl. Sci. 2017, 7, 589. [Google Scholar] [CrossRef]

- Shahil, K.M.F.; Balandin, A.A. Thermal properties of graphene and multilayer graphene: Applications in thermal interface materials. Solid State Commun. 2012, 152, 1331–1340. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.A.; Sun, S.; Zheng, D.; Wang, H.; Tian, H.; Yang, H.; Bai, X.; Li, J. Direct Observation of Inner-Layer Inward Contractions of Multiwalled Boron Nitride Nanotubes upon in Situ Heating. Nanomaterials 2018, 8, 86. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.-H.; Yang, S.-T.; Wang, X.; Wang, H.; Liu, Y.; Luo, P.G.; Liu, Y.; Sun, Y.-P. Carbon Nanoparticles Trapped in vivo—Similar to Carbon Nanotubes in Time-Dependent Biodistribution. ACS Appl. Mater. Interfaces 2014, 6, 14672–14678. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Mortimer, M.; Chang, C.H.; Holden, P. Alginic Acid-Aided Dispersion of Carbon Nanotubes, Graphene, and Boron Nitride Nanomaterials for Microbial Toxicity Testing. Nanomaterials 2018, 8, 76. [Google Scholar] [CrossRef] [PubMed]

- Zhi, C.; Bando, Y.; Terao, T.; Tang, C.; Kuwahara, H.; Golberg, D. Boron Nanotube–Polymer Composites: Towards Thermoconductive, Electrically Insulating Polymeric Composites with Boron Nitride Nanotubes as Fillers. Adv. Funct. Mater. 2009, 19, 1857–1862. [Google Scholar] [CrossRef]

- Chopra, N.G.; Luyken, R.J.; Cherrey, K.; Crespi, V.H.; Cohen, M.L.; Louie, S.G.; Zettl, A. Boron nitride nanotubes. Science 1995, 269, 966. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, P.; Khandaker, M.U.; Amin, Y.M. Synthesis of boron nitride nanotubes by Argon supported Thermal Chemical Vapor Deposition. Phys. E Low-Dimens. Syst. Nanostruct. 2015, 67, 33–37. [Google Scholar] [CrossRef]

- Kalay, S.; Yilmaz, Z.; Sen, O.; Emanet, M.; Kazanc, E.; Çulha, M. Synthesis of boron nitride nanotubes and their applications. Beilstein J. Nanotechnol. 2015, 6, 84–102. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Jiang, P. Core–Shell Structured High-k Polymer Nanocomposites for Energy Storage and Dielectric Applications. Adv. Mater. 2015, 27, 546. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Qu, S.; Cheng, Y.; Zheng, C.; Chen, S.; Wu, H. Facile synthesis of Co3O4, spheres and their unexpected high specific discharge capacity for Lithium-ion batteries. Appl. Surf. Sci. 2017, 416, 338–343. [Google Scholar] [CrossRef]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun Nanofiber: Emerging Reinforcing Filler in Polymer Matrix Composite Materials. Prog. Polym. Sci. 2017, 75. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Cao, D.; Lu, X.; Han, X.; Niu, C. Epitaxial Growth of Urchin-Like CoSe2 Nanorods from Electrospun Co-Embedded Porous Carbon Nanofibers and Their Superior Lithium Storage Properties. Part. Part. Syst. Charact. 2017, 34, 1700185. [Google Scholar] [CrossRef]

- Ko, F.; Gogotsi, Y.; Ali, A.; Naguib, N.; Ye, H.; Yang, G.L.; Li, C.; Willis, P. Electrospinning of Continuous Carbon Nanotube-Filled Nanofiber Yarns. Adv. Mater. 2003, 15, 1161–1165. [Google Scholar] [CrossRef]

- Ren, L.; Pashayi, K.; Fard, H.R.; Hotha, P.S.; Tasciuc, T.B.; Ozisik, T.R. Engineering the coefficient of thermal expansion and thermal conductivity of polymers filled with high aspect ratio silica nanofibers. Compos. Part B Eng. 2014, 66, 228–234. [Google Scholar] [CrossRef]

- Jae-Kon, L.; Jin-Gon, K. Generalized Self-Consistent Model for Predicting Thermal Conductivity of Composites with Aligned Short Fibers. Mater. Trans. 2010, 51, 2039–2044. [Google Scholar] [CrossRef]

- Hu, P.; Wang, J.; Shen, Y.; Guan, Y.; Lin, Y.; Nan, C. Highly enhanced energy density induced by hetero-interface in sandwich-structured polymer nanocomposites. J. Mater. Chem. A 2013, 1, 12321–12326. [Google Scholar] [CrossRef]

- Rana, D.; Sauvant, V.; Halary, J.L. Molecular analysis of yielding in pure and antiplasticized epoxy-amine thermosets. J. Mater. Sci. 2002, 37, 5267–5274. [Google Scholar] [CrossRef]

- Feng, A.; Jia, Z.; Yu, Q.; Zhang, H.; Wu, G. Preparation and Characterization of Carbon Nanotubes/Carbon Fiber/Phenolic Composites on Mechanical and Thermal Conductivity Properties. NANO 2018. [Google Scholar] [CrossRef]

- Rana, D.; Mounach, H.; Halary, J.L.; Monnerie, L. Differences in mechanical behavior between alternating and random styrene-methyl methacrylate copolymers. J. Mater. Sci. 2005, 40, 943–953. [Google Scholar] [CrossRef]

- Feng, A.; Wu, G.; Pan, C.; Wang, Y. Synthesis, preparation and mechanical property of wood fiber-reinforced poly(vinyl chloride) composites. J. Nanosci. Nanotechnol. 2017, 17, 3859–3863. [Google Scholar] [CrossRef]

- Feng, A.; Wu, G.; Pan, C.; Wang, Y. The Behavior of Acid Treating Carbon Fiber and the Mechanical Proper ties and Thermal Conductivity of Phenolic Resin Matrix Composites. J. Nanosci. Nanotechnol. 2017, 17, 3786–3791. [Google Scholar] [CrossRef]

- Qiu, Y.; Yu, J.; Rafique, J.; Yin, J.; Bai, X.; Wang, E. Large-Scale Production of Aligned Long Boron Nitride Nanofibers by Multijet/Multicollector Electrospinning. J. Phys. Chem. C 2009, 113, 11228–11234. [Google Scholar] [CrossRef]

- Coleburn, N.L.; Forbes, J.W. Irreversible Transformation of Hexagonal Boron Nitride by Shock Compression. J. Chem. Phys. 1968, 48, 555–559. [Google Scholar] [CrossRef]

- Renteria, J.; Legedza, S.; Salgado, R.; Balandin, M.P.; Ramirez, S.; Saadah, M.; Kargar, F.; Balandin, A.A. Magnetically-functionalized self-aligning graphene fillers for high-efficiency thermal management applications. Mater. Des. 2015, 88, 214–221. [Google Scholar] [CrossRef]

- Lazzara, G.; Cavallaro, G.; Panchal, A.; Fakhrullin, R.; Stavitskaya, A.; Vinokurov, V.; Lvov, Y. An assembly of organic-inorganic composites using halloysite clay nanotubes. Curr. Opin. Colloid Interface Sci. 2018, 35. [Google Scholar] [CrossRef]

- Lee, J.W.; Park, S.J.; Kim, Y.H. Improvement of Interfacial Adhesion of Incorporated Halloysite-Nanotubes in Fiber-Reinforced Epoxy-Based Composites. Appl. Sci. 2017, 7, 441. [Google Scholar] [CrossRef]

- Cavallaro, G.; Danilushkina, A.A.; Evtugyn, V.G.; Lazzara, G.; Milioto, S.; Parisi, F.; Parisi, E.V.; Fakhrullin, R.F. Halloysite Nanotubes: Controlled Access and Release by Smart Gates. Nanomaterials 2017, 7, 199. [Google Scholar] [CrossRef] [PubMed]

- Peña-Parás, L.; Sánchez-Fernández, J.; Martínez, C.; Ontiveros, J.A.; Saldívar, K.I.; Urbina, L.M.; Arias, M.J.; García-Pineda, P.; Castaños, B. Evaluation of Anti-Wear Properties of Metalworking Fluids Enhanced with Halloysite Nanotubes. Appl. Sci. 2017, 7, 1019. [Google Scholar] [CrossRef]

- Qu, S.; Yu, Y.; Lin, K.; Liu, P.; Zheng, C.; Wang, L.; Xu, T.; Wang, Z.; Wu, H. Easy hydrothermal synthesis of multi-shelled La2O3 hollow spheres for lithium-ion batteries. J. Mater. Sci. Mater. Electron. 2018, 29, 1232–1237. [Google Scholar] [CrossRef]

- Wu, G.; Wu, H.; Wang, K.; Zheng, C.; Wang, Y.; Feng, A. Facile synthesis and application of multi-shelled SnO2 hollow spheres in lithium ion battery. RSC Adv. 2016, 6, 58069–58076. [Google Scholar] [CrossRef]

- Shi, C.; Zhu, J.; Shen, X.; Chen, F.; Ning, F.; Zhang, H.; Long, Y.; Ning, X.; Zhao, J. Flexible inorganic membranes used as a high thermal safety separator for the lithium-ion battery. RSC Adv. 2018, 8, 4072–4077. [Google Scholar] [CrossRef]

- Wu, H.; Wu, G.; Ren, Y.; Yang, L.; Wang, L.; Li, X. Co2+/Co3+ ratio dependence of electromagnetic wave absorption in hierarchical NiCo2O4-CoNiO2 hybrids. J. Mater. Chem. C 2015, 3, 7677–7690. [Google Scholar] [CrossRef]

- Feng, A.; Jia, Z.; Zhao, Y.; Lv, H. Development of Fe/Fe3O4@C composite with excellent electromagnetic absorption performance. J. Alloys Compd. 2018, 745, 547–554. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Wu, X.; Luo, C.; Wang, Q.; Li, J.; Hu, L. Conducting polymer coated metal-organic framework nanoparticles: Facile synthesis and enhanced electromagnetic absorption properties. Synth. Met. 2017, 228, 18–24. [Google Scholar] [CrossRef]

- Ren, X.; Liu, L.; Li, Y.; Dai, Q.; Zhang, M.; Jing, X. Facile Preparation of Gadolinium(III) Chelates Functionalized Carbon Quantum Dots-based Contrast Agent for Magnetic Resonance/Fluorescence Multimodal Imaging. J. Mater. Chem. B 2014, 2, 5541–5549. [Google Scholar] [CrossRef]

- Wu, H.; Wu, G.; Wang, L. Peculiar porous α-Fe2O3, γ-Fe2O3 and Fe3O4 nanospheres: Facile synthesis and electromagnetic properties. Powder Technol. 2015, 269, 443–451. [Google Scholar] [CrossRef]

- Ren, X.Y.; Yuan, X.X.; Wang, Y.P.; Liu, C.C.; Qin, L.; Guo, L.P.; Liu, L.H. Facile preparation of Gd3+ doped carbon quantum dots: Photoluminescence materials with magnetic resonance response as magnetic resonance/fluorescence bimodal probes. Opt. Mater. 2016, 57, 56–62. [Google Scholar] [CrossRef]

- Wu, H.; Wu, G.; Ren, Y.; Li, X.; Wang, L. Multishelled metal oxide hollow spheres: Easy synthesis and formation mechanism. Chem. A Eur. J. 2016, 22, 8864–8871. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, L.E. Mechanical Properties of Polymers and Composites; Marcel Dekker: New York, NY, USA, 1974; Volume 2. [Google Scholar]

- Terao, T.; Zhi, C.; Bando, Y.; Mitome, M.; Tang, C.; Golberg, D. Alignment of Boron Nitride Nanotubes in Polymeric Composite Films for Thermal Conductivity Improvement. J. Phys. Chem. C 2010, 114, 4340–4344. [Google Scholar] [CrossRef]

- Song, W.L.; Wang, W.; Veca, L.M.; Kong, C.Y.; Cao, M.S.; Wang, P.; Meziani, M.J.; Qian, H.; LeCroy, G.E.; Cao, L.; et al. Polymer/carbon nanocomposites for enhanced thermal transport properties-carbon nanotubes versus graphene sheets as nanoscale fillers. J. Mater. Chem. 2012, 22, 17133–17139. [Google Scholar] [CrossRef]

| Samples | (W/mk) | Nielsen (W/mk) | α (cm2/s) | DBS (kV/mm) | β | Thickness (μm) | Deviation (μm) |

|---|---|---|---|---|---|---|---|

| Pure Epoxy | 0.162 | 0.162 | 0.106 | 115.8 | 14.74 | 112 | ±8 |

| 0.5 wt% | 0.17 | 0.181 | 0.112 | 118.8 | 20.95 | 108 | ±3 |

| 1 wt% | 0.185 | 0.194 | 0.127 | 122.8 | 19.67 | 112 | ±7 |

| 2 wt% | 0.205 | 0.227 | 0.138 | 113.5 | 15.05 | 115 | ±3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Liu, J.; Cheng, Y.; Chen, S.; Yang, M.; Huang, J.; Wang, H.; Wu, G.; Wu, H. Alignment of Boron Nitride Nanofibers in Epoxy Composite Films for Thermal Conductivity and Dielectric Breakdown Strength Improvement. Nanomaterials 2018, 8, 242. https://doi.org/10.3390/nano8040242

Wang Z, Liu J, Cheng Y, Chen S, Yang M, Huang J, Wang H, Wu G, Wu H. Alignment of Boron Nitride Nanofibers in Epoxy Composite Films for Thermal Conductivity and Dielectric Breakdown Strength Improvement. Nanomaterials. 2018; 8(4):242. https://doi.org/10.3390/nano8040242

Chicago/Turabian StyleWang, Zhengdong, Jingya Liu, Yonghong Cheng, Siyu Chen, Mengmeng Yang, Jialiang Huang, Hongkang Wang, Guanglei Wu, and Hongjing Wu. 2018. "Alignment of Boron Nitride Nanofibers in Epoxy Composite Films for Thermal Conductivity and Dielectric Breakdown Strength Improvement" Nanomaterials 8, no. 4: 242. https://doi.org/10.3390/nano8040242

APA StyleWang, Z., Liu, J., Cheng, Y., Chen, S., Yang, M., Huang, J., Wang, H., Wu, G., & Wu, H. (2018). Alignment of Boron Nitride Nanofibers in Epoxy Composite Films for Thermal Conductivity and Dielectric Breakdown Strength Improvement. Nanomaterials, 8(4), 242. https://doi.org/10.3390/nano8040242