1. Introduction

Wide-band-gap materials (WBGMs) are expected to replace silicon for power electronic applications. Properties such as their much higher breakdown field, thermal conductivity, or energy band-gap imply possibly huge benefits in commercial power devices [

1]. SiC power devices are already established, with a

$11.5 billion market in 2014, and III–V semiconductors such as GaN are reaching a similar level of prevalence [

2]. Synthetic diamond has lagged behind despite having the best intrinsic properties among the WBGMs [

3,

4]. Over recent years, the progress of microwave plasma-enhanced chemical vapour deposition (MPCVD) diamond for power electronic applications has resulted in the fabrication of a Schottky diode with extremely good rectification behavior and a high current density, about 10

3 A·cm

−2 at 6 V; a very low reverse current density, 10

–9 A·cm

–2, up to the maximum voltage |

Vmax| = 1000 V; and the highest Baliga’s power figure of merit (FOM) reported up to now (244 MW·cm

–2) [

5]. However, crystalline quality or electrical contacts are still issues that need to be improved in order to attain competitive diamond commercial devices. Moreover, the difficulties in obtaining high-quality diamond substrates and the reduced dimensions of those commercially available have blurred their industrial prospects.

In Si, SiC, and III–V materials, epitaxial lateral overgrowth (ELO) has shown very good results in terms of defect reduction over large areas as well as great advantages for electronic devices, such as power efficiency, performance enhancement, product miniaturisation, cost reduction, and modular design for improved time to market [

6,

7,

8,

9,

10]. Such benefits are also expected from its implementation in diamond [

11,

12,

13]. However, the lateral growth of diamond usually leads to a high density of defects. The conditions to reach selective boron-doped diamond lateral growth were recently obtained for {001}-oriented patterned substrates. Such growth conditions, that is, the use of low methane concentrations [

14], resulted in a low growth rate (<12 nm·min

–1) that justified further optimisation of the process. In fact, homoepitaxial boron-doped layers overgrown on both (001)- and (111)-oriented substrates usually contain lattice-related defects. Alegre et al. showed a direct relationship between the boron doping level and the dislocation density that depended on the plane of growth and on the methane concentration [

15]. Whatever their origin, these defects have an undesirable impact on the resulting diamond-based devices and should be avoided. The optimisation of both growth rates and boron doping levels is thus one of the required technological steps toward commercial electronic devices based on three-dimensional (3D) diamond architectures.

2. Materials and Methods

The effect of the growth orientation and doping level on the dislocation generation was studied by transmission electron microscopy (TEM), with the aim to determine the best conditions for diamond selective growth. Four (100)-oriented high-pressure, high-temperature (HPHT) diamond substrates were patterned into 1 µm high mesa-shaped disks (see

Figure 1) by inductively coupled plasma reactive ion etching (ICP-RIE), in order to make different growth orientations available in the same sample under exactly the same growth conditions. Growth was performed by MPCVD in a home-made NIRIM-type reactor [

16]. Sample 1 was a multi-layered sample formed by a stack of 13 doped/undoped bilayers. Doped layers were grown with 0.25% CH

4/H

2 (molar) and 10,700 ppm B

2H

6/CH

4 over 2 min. Undoped layers were grown for 60 min using 0.1% of methane in hydrogen. The pressure and plasma power were kept at 4.4 kPa and 300 W, respectively. Sample 2 was a boron-doped sample grown at 4% CH

4/H

2 and 1200 ppm B

2H

6/CH

4 for 10 min. Sample 3 was also a doped-layer sample in which the methane concentration was reduced to 0.5%. Diborane in hydrogen (6000 ppm) was used for doping, and the growth time was 10 min. Finally, sample 4 was a multi-layered sample formed by a stack of 11 doped/undoped bilayers. Doped layers were grown with 0.5% CH

4/H

2 and 14,000 ppm B

2H

6/CH

4 over 11 min, and undoped layers were grown over 12 min using 0.75% of methane in hydrogen and a 0.32% O

2/H

2 ratio.

The TEM study was performed on electron-transparent lamellas extracted from these samples by a focused ion beam (FIB) in a dual-beam FEI Quanta 200 3D microscope. The TEM studies were carried out in a field-emission JEOL 2010F and in a thermo-ionic filament-emission Philips CM200, both working at a 200 kV accelerating voltage.

3. Results

Figure 2a shows a bright-field (BF) TEM micrograph of sample 1 oriented along the [011] pole. A black dashed line marks the initial shape of the substrate, and doped layers are noted by smooth darker contrasts. The doped layers, with a boron content estimation of ~10

19 atm·cm

–3, are better seen in the magnified region of the inset. The sample was free of dislocation, and the promotion of the lateral growth is also clear, with a much larger thickness along the lateral side (a few micrometers) than along the vertical side (barely 100 nm). This was the result of a 12 nm/min growth rate along the <111> direction and of only 1 nm/min along <100>.

Figure 2b,c shows two weak-beam (WB) TEM micrographs of sample 2 oriented along the (011) pole, recorded under two beam conditions using the

and

reflections, respectively. White dashed lines mark the initial shape of the patterned substrate in both micrographs. This sample consisted of boron-doped layer overgrowth with 4% CH

4/H

2, and a boron content was estimated at 10

21 atm·cm

–3. These growth conditions resulted in a lateral growth rate of 38 nm/min, 3 times faster than for sample 1, and a [001]-oriented growth rate of 35 nm/min. A high density of dislocations was observed on the region grown laterally, that is, along the <111> direction. In contrast, the rest of the cross-sectional view, corresponding to growth along the <100> direction, appeared free of defects. Because the growth rates were very similar along both orientations, this situation established a different behaviour in the dislocation generation depending on the plane of growth. Burgers vectors of the threading dislocations were identified using the invisibility criterion [

17], resulting in the majority of dislocations with a vector

almost homogeneously distributed over the layer and only a few others, marked with arrows, with Burgers vector

. The density of dislocations, defined as the sum of dislocation lengths per volume [

17], was calculated for each growth orientation of this sample, resulting in 4 × 10

10 cm

–2 in the <111> growth sector and none for the <100> sector.

Figure 3a,b shows WB micrographs of sample 3 oriented in the (011) pole, recorded using the

and

reflections, respectively. This sample was grown with a similar boron content, estimated at 3 × 10

21 atm·cm

–3, but with a lower methane/hydrogen ratio than for sample 2. The use of a lower methane concentration implied a higher growth selectivity, because, for this sample, the growth rates were 42 and 23 nm/min along the <111> and <100> directions, respectively. However, also in this case, micrographs showed the laterally grown region to contain many defects. In contrast, 001-oriented growth appeared free of dislocations. The dislocation distribution along the lateral growth layer also seemed different to that of sample 2. It was clearly inhomogenously distributed, and only dislocations with

Burgers vectors were obtained. The density of dislocations estimated in this sample was zero again for the <100> orientation and was relatively high, 25 × 10

10 cm

–2, in the <111> growth sector.

Figure 3c shows a dark-field (DF) micrograph of sample 4 in the (001) pole, recorded under two beam conditions using the

reflection. This sample was multi-layered and grown with a boron content similar to those of samples 2 and 3, estimated at 2.3 × 10

21 atm·cm

–3. The methane/hydrogen molar ratio remained at 0.5% for the doped samples (the same as for sample 3) but was increased to 0.75% for the undoped sample. This sample also showed the laterally grown region to be defective. Nevertheless, the distribution of these defects was clearer, and the observations showed that dislocations were generated in the doped layers. This is even more apparent in the more highly magnified region of the inset, where white arrows show some of these dislocations. These dislocations are revealed as white points, indicating that they lay into the growing plane. Their behaviour corresponded to that previously reported by Alegre et al. [

15], where, first, the boron proximity effect generated dislocations into the growing plane, and, second, interaction with other dopants favoured their bending to thread across the epitaxial layer structure. Their Burgers vectors were

and

, of the same vector family as that for sample 3.

4. Discussion

From this study, it seems evident that selective lateral growth can only be achieved using low methane concentrations. The use of CH

4/H

2 concentrations equal to or higher than 0.5% resulted in the generation of threading dislocations. Such dislocations could be

and/or

. Alegre et al. [

15] reported a critical boron level (CBL) in diamond samples depending on the CH

4/H

2 molar ratio and on the growth directions. They argued that substitutional boron atoms too close to each other (proximity effect) generate local stress on the diamond lattice. Such local stress results in the displacement of a carbon atom and the subsequent generation of a threading dislocation. This local stress can also block the dislocations, and this may explain why two different families of Burgers vectors were observed. During growth,

perfect dislocations are generated. It is energetically favourable for such dislocations to be dissociated into two

partial Shockley dislocations. When the boron concentration is too high, the stress generated by boron atoms blocks the dislocations and prevents their dissociation. This tentatively explains why, at high doping levels, only perfect dislocations with a

Burgers vector were observed.

More evident in the micrographs (

Figure 3c), this local stress also explains the behaviour observed for sample 4, for which dislocations were clearly generated in the doped layers. In this sample, the doping level was estimated at 2.3 × 10

21 atm·cm

–3. For similar growth conditions, the calculated CBLs were 6.5 × 10

20 and 3.2 × 10

21 atm·cm

–3 for the <111> and <100> growth directions, respectively. Sample 4 was thus below the CBL for the <100> direction and above this value for the <111> orientation. A similar situation took place for samples 2 and 3, in good correspondence with the literature.

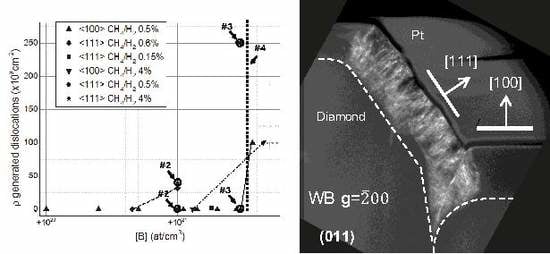

Figure 4 shows the density of dislocations as a function of the boron doping level of p

+ layers reported in the work of Alegre [

15] and complemented by the present results. In the values extracted from the literature, each orientation, marked by stars or circles depending on whether they correspond to the <111> or <100> growth direction, respectively, was obtained from the study of a different sample. Here, the dislocation density generated along two different growth orientations was measured on the same sample, that is, under exactly the same growth conditions. Our results thus allow the appropriate growth parameters for good crystal quality in both planar and lateral growth to be limited somewhat more.

The present study shows that it is possible for growth along the <100> orientation with CH4/H2 of 0.5% without dislocations when boron concentration values are less than or equal to 3 × 1021 [B] atm·cm–3. However, as doping increased up to 4 × 1021 [B] atm·cm–3, the dislocation density increased quickly. Nevertheless, under the same growth conditions, samples grown along the <111> orientations were already shown to be full of defects at doping values of 3 × 1021 [B] atm·cm–3. Thus, for such growth orientations, the doping level should be reduced. Indeed, we note that, even at the low methane content of CH4/H2 of 0.15%, for growth along the <111> orientation, dislocations were observed. However, the dislocation density was much smaller even if the boron concentration was as high as ~1021 atm·cm–3.