Dry-Coated Graphite onto Sandpaper for Triboelectric Nanogenerator as an Active Power Source for Portable Electronics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Sandpaper-Based Electrode

2.2. Fabrication of Triboelectric Nanogenerator (TENG)

2.3. Characterization and Electrical Measurement

2.4. Comsol Simulation

3. Results and Discussion

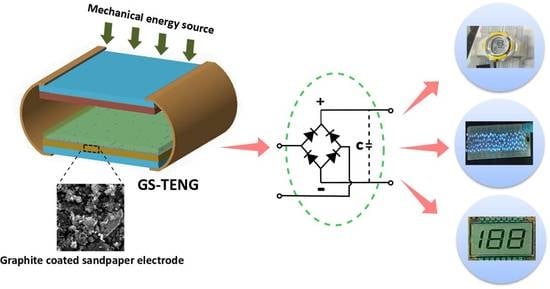

3.1. Characterizations of the Graphite-Coated Sandpaper-Based Triboelectric Nanogenerator (GS-TENG)

3.2. Working Principle of TENG

3.3. Performance of GS-TENG

3.4. Application of GS-TENG for Energy Harvesting and Self-Powered Devices

4. Conclusion

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pu, X.; Li, L.; Song, H.; Du, C.; Zhao, Z.; Jiang, C.; Cao, G.; Hu, W.; Wang, Z.L. A Self-Charging Power Unit by Integration of a Textile Triboelectric Nanogenerator and a Flexible Lithium-Ion Battery for Wearable Electronics. Adv. Mater. 2015, 27, 2472–2478. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.M.; Yi, F.; Zi, Y.L.; Lin, J.; Wang, X.F.; Xu, Y.L.; Wang, Z.L. Sustainably powering wearable electronics solely by biomechanical energy. Nat. Commun. 2016, 7, 12744. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trung, T.Q.; Lee, N.-E. Flexible and Stretchable Physical Sensor Integrated Platforms for Wearable Human-Activity Monitoringand Personal Healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef] [PubMed]

- Jayathilaka, W.A.D.M.; Qi, K.; Qin, Y.; Chinnappan, A.; Serrano-García, W.; Baskar, C.; Wang, H.; He, J.; Cui, S.; Thomas, S.W.; et al. Significance of Nanomaterials in Wearables: A Review on Wearable Actuators and Sensors. Adv. Mater. 2019, 31, 1805921. [Google Scholar] [CrossRef] [PubMed]

- Hou, H.; Xu, Q.; Pang, Y.; Li, L.; Wang, J.; Zhang, C.; Sun, C. Efficient Storing Energy Harvested by Triboelectric Nanogenerators Using a Safe and Durable All-Solid-State Sodium-Ion Battery. Adv. Sci. 2017, 4, 1700072. [Google Scholar] [CrossRef] [PubMed]

- Zhao, T.; Ye, Y.; Lao, C.-Y.; Divitini, G.; Coxon, P.R.; Peng, X.; He, X.; Kim, H.-K.; Xi, K.; Ducati, C.; et al. A Praline-Like Flexible Interlayer with Highly Mounted Polysulfide Anchors for Lithium–Sulfur Batteries. Small 2017, 13, 1700357. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, G.; Yang, W.; Jing, Q.; Bai, P.; Yang, Y.; Hou, T.-C.; Wang, Z.L. Harmonic-Resonator-Based Triboelectric Nanogenerator as a Sustainable Power Source and a Self-Powered Active Vibration Sensor. Adv. Mater. 2013, 25, 6094–6099. [Google Scholar] [CrossRef]

- Zhang, X.-S.; Han, M.-D.; Wang, R.-X.; Zhu, F.-Y.; Li, Z.-H.; Wang, W.; Zhang, H.-X. Frequency-Multiplication High-Output Triboelectric Nanogenerator for Sustainably Powering Biomedical Microsystems. Nano Lett. 2013, 13, 1168–1172. [Google Scholar] [CrossRef]

- Shankaregowda, S.A.; Nanjegowda, C.B.; Cheng, X.L.; Shi, M.Y.; Liu, Z.F.; Zhang, H.X. A Flexible and Transparent Graphene-Based Triboelectric Nanogenerator. IEEE Trans. Nanotechnol. 2016, 15, 435–441. [Google Scholar] [CrossRef]

- Petrović, M.; Chellappan, V.; Ramakrishna, S. Perovskites: Solar cells & engineering applications—Materials and device developments. Sol. Energy 2015, 122, 678–699. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef] [PubMed]

- Song, W.-Z.; Wang, X.-X.; Qiu, H.-J.; Liu, Q.; Zhang, J.; Fan, Z.; Yu, M.; Ramakrishna, S.; Hu, H.; Long, Y.-Z. Sliding non-contact inductive nanogenerator. Nano Energy 2019, 63, 103878. [Google Scholar] [CrossRef]

- Wang, X.; Song, W.-Z.; You, M.-H.; Zhang, J.; Yu, M.; Fan, Z.; Ramakrishna, S.; Long, Y.-Z. Bionic Single-Electrode Electronic Skin Unit Based on Piezoelectric Nanogenerator. ACS Nano 2018, 12, 8588–8596. [Google Scholar] [CrossRef] [PubMed]

- Ye, Q.; Wu, Y.; Qi, Y.; Shi, L.; Huang, S.; Zhang, L.; Li, M.; Li, W.; Zeng, X.; Wo, H.; et al. Effects of liquid metal particles on performance of triboelectric nanogenerator with electrospun polyacrylonitrile fiber films. Nano Energy 2019, 61, 381–388. [Google Scholar] [CrossRef]

- Bai, P.; Zhu, G.; Jing, Q.; Yang, J.; Chen, J.; Su, Y.; Ma, J.; Zhang, G.; Wang, Z.L. Membrane-Based Self-Powered Triboelectric Sensors for Pressure Change Detection and Its Uses in Security Surveillance and Healthcare Monitoring. Adv. Funct. Mater. 2014, 24, 5807–5813. [Google Scholar] [CrossRef]

- Zhai, S.; Karahan, H.E.; Wei, L.; Qian, Q.; Harris, A.T.; Minett, A.I.; Ramakrishna, S.; Ng, A.K.; Chen, Y. Textile energy storage: Structural design concepts, material selection and future perspectives. Energy Storage Mater. 2016, 3, 123–139. [Google Scholar] [CrossRef]

- Pu, X.; Guo, H.; Tang, Q.; Chen, J.; Feng, L.; Liu, G.; Wang, X.; Xi, Y.; Hu, C.; Wang, Z.L. Rotation sensing and gesture control of a robot joint via triboelectric quantization sensor. Nano Energy 2018, 54, 453–460. [Google Scholar] [CrossRef]

- Bai, P.; Zhu, G.; Liu, Y.; Chen, J.; Jing, Q.; Yang, W.; Ma, J.; Zhang, G.; Wang, Z.L. Cylindrical Rotating Triboelectric Nanogenerator. ACS Nano 2013, 7, 6361–6366. [Google Scholar] [CrossRef]

- Zhang, C.; Tang, W.; Pang, Y.; Han, C.; Wang, Z.L. Active Micro-Actuators for Optical Modulation Based on a Planar Sliding Triboelectric Nanogenerator. Adv. Mater. 2015, 27, 719–726. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef]

- Chandrasekhar, A.; Alluri, N.R.; Sudhakaran, M.S.P.; Mok, Y.S.; Kim, S.-J. A smart mobile pouch as a biomechanical energy harvester towards self-powered smart wireless power transfer applications. Nanoscale 2017, 9, 9818–9824. [Google Scholar] [CrossRef] [PubMed]

- Mahmud, M.A.P.; Huda, N.; Farjana, S.H.; Asadnia, M.; Lang, C. Recent Advances in Nanogenerator-Driven Self-Powered Implantable Biomedical Devices. Adv. Energy Mater. 2018, 8. [Google Scholar] [CrossRef]

- Deng, B.; Hsu, P.-C.; Chen, G.; Chandrashekar, B.N.; Liao, L.; Ayitimuda, Z.; Wu, J.; Guo, Y.; Lin, L.; Zhou, Y.; et al. Roll-to-Roll Encapsulation of Metal Nanowires between Graphene and Plastic Substrate for High-Performance Flexible Transparent Electrodes. Nano Lett. 2015, 15, 4206–4213. [Google Scholar] [CrossRef] [PubMed]

- Chandrashekar, B.N.; Deng, B.; Smitha, A.S.; Chen, Y.; Tan, C.; Zhang, H.; Peng, H.; Liu, Z. Roll-to-Roll Green Transfer of CVD Graphene onto Plastic for a Transparent and Flexible Triboelectric Nanogenerator. Adv. Mater. 2015, 27, 5210–5216. [Google Scholar] [CrossRef]

- Huang, Q.; Zhang, K.; Yang, Y.; Ren, J.; Sun, R.; Huang, F.; Wang, X. Highly smooth, stable and reflective Ag-paper electrode enabled by silver mirror reaction for organic optoelectronics. Chem. Eng. J. 2019, 370, 1048–1056. [Google Scholar] [CrossRef]

- Guo, H.; Yeh, M.-H.; Zi, Y.; Wen, Z.; Chen, J.; Liu, G.; Hu, C.; Wang, Z.L. Ultralight Cut-Paper-Based Self-Charging Power Unit for Self-Powered Portable Electronic and Medical Systems. ACS Nano 2017, 11, 4475–4482. [Google Scholar] [CrossRef]

- He, X.; Zi, Y.; Yu, H.; Zhang, S.L.; Wang, J.; Ding, W.; Zou, H.; Zhang, W.; Lu, C.; Wang, Z.L. An ultrathin paper-based self-powered system for portable electronics and wireless human-machine interaction. Nano Energy 2017, 39, 328–336. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Cui, K.; Ge, S.; Cheng, X.; Yan, M.; Yu, J.; Liu, H. Flexible Electronics Based on Micro/Nanostructured Paper. Adv. Mater. 2018, 30, 1801588. [Google Scholar] [CrossRef]

- Yang, W.; Cao, R.; Zhang, X.; Li, H.; Li, C. Air-Permeable and Washable Paper–Based Triboelectric Nanogenerator Based on Highly Flexible and Robust Paper Electrodes. Adv. Mater. Technol. 2018, 3, 1800178. [Google Scholar] [CrossRef]

- Wang, X.; Hu, H.; Shen, Y.; Zhou, X.; Zheng, Z. Stretchable Conductors with Ultrahigh Tensile Strain and Stable Metallic Conductance Enabled by Prestrained Polyelectrolyte Nanoplatforms. Adv. Mater. 2011, 23, 3090–3094. [Google Scholar] [CrossRef]

- Yang, P.-K.; Lin, Z.-H.; Pradel, K.C.; Lin, L.; Li, X.; Wen, X.; He, J.-H.; Wang, Z.L. Paper-Based Origami Triboelectric Nanogenerators and Self-Powered Pressure Sensors. ACS Nano 2015, 9, 901–907. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.-S.; Su, M.; Brugger, J.; Kim, B. Penciling a triboelectric nanogenerator on paper for autonomous power MEMS applications. Nano Energy 2017, 33, 393–401. [Google Scholar] [CrossRef]

- Kim, D.; Lee, H.M.; Choi, Y.-K. Large-sized sandpaper coated with solution-processed aluminum for a triboelectric nanogenerator with reliable durability. Rsc Adv. 2017, 7, 137–144. [Google Scholar] [CrossRef]

- Rasel, M.S.U.; Park, J.-Y. A sandpaper assisted micro-structured polydimethylsiloxane fabrication for human skin based triboelectric energy harvesting application. Appl. Energy 2017, 206, 150–158. [Google Scholar] [CrossRef]

- Zhang, X.-W.; Li, G.-Z.; Wang, G.-G.; Tian, J.-L.; Liu, Y.-L.; Ye, D.-M.; Liu, Z.; Zhang, H.-Y.; Han, J.-C. High-Performance Triboelectric Nanogenerator with Double-Surface Shape-Complementary Microstructures Prepared by Using Simple Sandpaper Templates. ACS Sustain. Chem. Eng. 2018, 6, 2283–2291. [Google Scholar] [CrossRef]

- Tribocharging and the Triboelectric Series. Encycl. Inorg. Bioinorg. Chem. 2011, 1–9. [CrossRef]

- Tang, W.; Jiang, T.; Fan, F.R.; Yu, A.F.; Zhang, C.; Cao, X.; Wang, Z.L. Liquid-Metal Electrode for High-Performance Triboelectric Nanogenerator at an Instantaneous Energy Conversion Efficiency of 70.6%. Adv. Funct. Mater. 2015, 25, 3718–3725. [Google Scholar] [CrossRef]

- Fowkes, F.M.; McCarthy, D.C.; Mostafa, M.A. Contact angles and the equilibrium spreading pressures of liquids on hydrophobic solids. J. Colloid Interface Sci. 1980, 78, 200–206. [Google Scholar] [CrossRef]

- Li, W.; Chen, T.; Xu, W. On impedance matching and maximum power transfer. Electr. Power Syst. Res. 2010, 80, 1082–1088. [Google Scholar] [CrossRef]

- Zhu, G.; Lin, Z.-H.; Jing, Q.; Bai, P.; Pan, C.; Yang, Y.; Zhou, Y.; Wang, Z.L. Toward Large-Scale Energy Harvesting by a Nanoparticle-Enhanced Triboelectric Nanogenerator. Nano Lett. 2013, 13, 847–853. [Google Scholar] [CrossRef]

- Shankaregowda, S.A.; Ahmed, R.F.S.M.; Nanjegowda, C.B.; Wang, J.; Guan, S.R.; Puttaswamy, M.; Amini, A.; Zhang, Y.; Kong, D.; Sannathammegowda, K.; et al. Single-electrode triboelectric nanogenerator based on economical graphite coated paper for harvesting waste environmental energy. Nano Energy 2019, 66, 104141. [Google Scholar] [CrossRef]

- Nanjegowda, C.B.; Shankaregowda, S.A.; Wu, Y.; Cai, N.; Li, Y.; Huang, Z.; Wang, W.; Shi, R.; Wang, J.; Liu, S.; et al. A universal stamping method of graphene transfer for conducting flexible and transparent polymers. Sci. Rep. 2019, 9, 3999. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ankanahalli Shankaregowda, S.; Sagade Muktar Ahmed, R.F.; Liu, Y.; Bananakere Nanjegowda, C.; Cheng, X.; Shivanna, S.; Ramakrishna, S.; Yu, Z.; Zhang, X.; Sannathammegowda, K. Dry-Coated Graphite onto Sandpaper for Triboelectric Nanogenerator as an Active Power Source for Portable Electronics. Nanomaterials 2019, 9, 1585. https://doi.org/10.3390/nano9111585

Ankanahalli Shankaregowda S, Sagade Muktar Ahmed RF, Liu Y, Bananakere Nanjegowda C, Cheng X, Shivanna S, Ramakrishna S, Yu Z, Zhang X, Sannathammegowda K. Dry-Coated Graphite onto Sandpaper for Triboelectric Nanogenerator as an Active Power Source for Portable Electronics. Nanomaterials. 2019; 9(11):1585. https://doi.org/10.3390/nano9111585

Chicago/Turabian StyleAnkanahalli Shankaregowda, Smitha, Rumana Farheen Sagade Muktar Ahmed, Yu Liu, Chandrashekar Bananakere Nanjegowda, Xing Cheng, Srikantaswamy Shivanna, Seeram Ramakrishna, Zhenfei Yu, Xiang Zhang, and Krishnaveni Sannathammegowda. 2019. "Dry-Coated Graphite onto Sandpaper for Triboelectric Nanogenerator as an Active Power Source for Portable Electronics" Nanomaterials 9, no. 11: 1585. https://doi.org/10.3390/nano9111585

APA StyleAnkanahalli Shankaregowda, S., Sagade Muktar Ahmed, R. F., Liu, Y., Bananakere Nanjegowda, C., Cheng, X., Shivanna, S., Ramakrishna, S., Yu, Z., Zhang, X., & Sannathammegowda, K. (2019). Dry-Coated Graphite onto Sandpaper for Triboelectric Nanogenerator as an Active Power Source for Portable Electronics. Nanomaterials, 9(11), 1585. https://doi.org/10.3390/nano9111585