Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles

Abstract

:1. Introduction

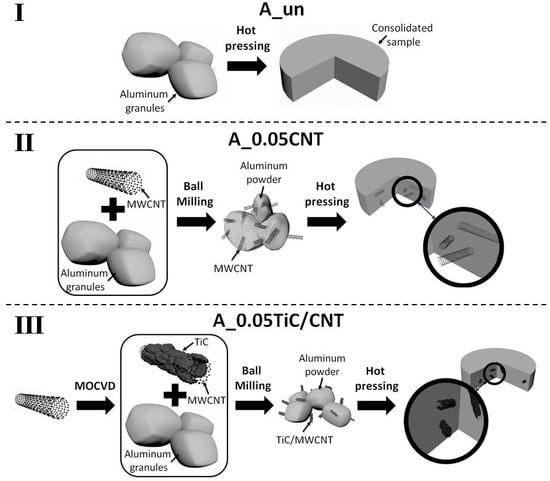

2. Materials and Methods

2.1. Materials Processing

2.2. Characterization Techniques

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shin, S.E.; Choi, H.J.; Hwang, J.Y.; Bae, D.H. Strengthening behavior of carbon/metal nanocomposites. Sci. Rep. 2015, 5, 16114. [Google Scholar] [CrossRef] [PubMed]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Shin, S.E.; Ko, Y.J.; Bae, D.H. Mechanical and thermal properties of nanocarbon-reinforced aluminum matrix composites at elevated temperatures. Compos. B Eng. 2016, 106, 66–73. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Cheng, H.M. Carbon nanotubes: Controlled growth and application. Mater. Today 2013, 16, 19–28. [Google Scholar] [CrossRef]

- Agarwal, A.; Bakshi, S.R.; Lahiri, D. Carbon Nanotubes: Reinforced Metal. Matrix Composites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Uriza-Vega, E.; Carreño-Gallardo, C.; López-Meléndez, C.; Cuadros-Lugo, E.; Pérez-Bustamante, R.; Ledezma-Sillas, E.; Herrera-Ramirez, J.M. Mechanical Behavior of Multiwalled Carbon Nanotube Reinforced 7075 Aluminum Alloy Composites Prepared by Mechanical Milling and Hot Extrusion. Mater. Res. 2019, 22, e20180652. [Google Scholar] [CrossRef]

- Esawi, A.; Morsi, K.; Sayed, A.; Tacher, M.; Lanka, S. The influence of carbon nanotube (CNT) morphology and diameter on the processing and properties of CNT-reinforced aluminium composites. Compos. Part A 2011, 42, 234–243. [Google Scholar] [CrossRef]

- Esawi, A.; Morsi, K.; Sayed, A.; Tacher, M.; Lanka, S. Effect of carbon nanotube (CNT) content on the mechanical properties of CNT-reinforced aluminium composites. Compos. Sci. Technol. 2010, 70, 2237–2241. [Google Scholar] [CrossRef]

- Dujardin, E.; Ebbesen, T.W.; Hiura, H.; Tanigaki, K. Capillarity and wetting of carbon nanotubes. Science 1994, 265, 1850–1852. [Google Scholar] [CrossRef] [PubMed]

- So, K.P.; Lee, I.H.; Duong, D.L.; Kim, T.H.; Lim, S.C.; An, K.H.; Lee, Y.H. Improving the wettability of aluminum on carbon nanotubes. Acta Mater. 2011, 59, 3313–3320. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Agarwal, A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon 2011, 49, 533–544. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Imai, H.; Umeda, J.; Takahashi, M.; Kondoh, K. Solid-state interfacial reaction and load transfer efficiency in carbon nanotubes (CNTs)-reinforced aluminum matrix composites. Carbon 2017, 114, 198–208. [Google Scholar] [CrossRef]

- Ci, L.J.; Ryu, Z.Y.; Jin-Phillipp, N.Y.; Ruhle, M. Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum. Acta Mater. 2006, 54, 5367–5375. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, X.; Cen, X.; Chen, B.; Wang, X.; Song, M.; Ni, S.; Yi, J.; Shen, T.; Du, Y. Enhanced mechanical properties of aluminum based composites reinforced by chemically oxidized carbon nanotubes. Carbon 2018, 139, 459–471. [Google Scholar] [CrossRef]

- Liu, X.; Li, J.; Liu, E.; Li, Q.; He, C.; Shi, C.; Zhao, N. Effectively reinforced load transfer and fracture elongation by forming Al4C3 for in-situ synthesizing carbon nanotube reinforced Al matrix composites. Mater. Sci. Eng. A 2018, 718, 182–189. [Google Scholar] [CrossRef]

- Yu, Z.; Tan, Z.; Xu, R.; Ji, G.; Fan, G.; Xiong, D.-B.; Guo, Q.; Li, Z.; Zhang, D. Enhanced load transfer by designing mechanical interfacial bonding in carbon nanotube reinforced aluminum composites. Carbon 2019, 146, 155–161. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.; Pan, B.; Pan, D.; Liu, L.; Hou, X.; Chu, M.; Kondoh, K.; Zhao, M. Regulation of interface between carbon nanotubes-aluminum and its strengthening effect in CNTs reinforced aluminum matrix nanocomposites. Carbon 2019, 155, 686–696. [Google Scholar] [CrossRef]

- Nie, J.; Jia, C.; Shi, N.; Zhang, Y.-F.; Li, Y.; Jia, X. Aluminum matrix composites reinforced by molybdenum-coated carbon nanotubes. Int. J. Miner. Metall. Mater. 2011, 18, 695–702. [Google Scholar] [CrossRef]

- Kremlev, K.V.; Ob’edkov, A.M.; Semenov, N.M.; Kaverin, B.S.; Ketkov, S.Y.; Vilkov, I.V.; Andreev, P.V.; Gusev, S.A.; Aborkin, A.V. Synthesis of hybrid materials based on multiwalled carbon nanotubes decorated with WC1–x nanocoatings of various morphologies. Tech. Phys. Lett. 2019, 45, 348–351. [Google Scholar] [CrossRef]

- Kremlev, K.V.; Ob”edkov, A.M.; Semenov, N.M.; Kaverina, B.S.; Ketkov, S.Y.; Gusev, S.A.; Yunin, P.A.; Elkin, A.I.; Aborkin, A.V. The gas-phase synthesis of a new functional hybrid material on the basis of multiwalled carbon nanotubes decorated with faceted aluminum nanocrystals. Tech. Phys. Lett. 2018, 44, 865–868. [Google Scholar] [CrossRef]

- Boscarino, S.; Filice, S.; Sciuto, A.; Libertino, S.; Scuderi, M.; Galati, C.; Scalese, S. Investigation of ZnO-decorated CNTs for UV light detection applications. Nanomaterials 2019, 9, 1099. [Google Scholar] [CrossRef] [PubMed]

- Zang, J.B.; Lu, J.; Wang, Y.H.; Zhang, J.H.; Cheng, X.Z.; Huang, H. Fabrication of core-shell structured MWCNT–Ti (TiC) using a one-pot reaction from a mixture of TiCl3, TiH2, and MWCNTs. Carbon 2010, 48, 3802–3806. [Google Scholar] [CrossRef]

- Saba, F.; Haddad-Sabzevar, M.; Sajjadi, S.A.; Zhang, F. The effect of TiC:CNT mixing ratio and CNT content on the mechanical and tribological behaviors of TiC modified CNT-reinforced Al-matrix nanocomposites. Powder Technol. 2018, 331, 107–120. [Google Scholar] [CrossRef]

- Saba, F.; Zhang, F.; Sajjadi, S.A.; Haddad-Sabzevar, M.; Li, P. Pulsed current field assisted surface modification of carbon nanotubes with nanocrystalline titanium carbide. Carbon 2016, 101, 261–271. [Google Scholar] [CrossRef]

- Saba, F.; Sajjadi, S.A.; Haddad-Sabzevar, M.; Zhang, F. Formation mechanism of nano titanium carbide on multi-walled carbon nanotube and influence of the nanocarbides on the loadbearing contribution of the nanotubes inner-walls in aluminum matrix composites. Carbon 2017, 115, 720–729. [Google Scholar] [CrossRef]

- Hirsch, J. Aluminium in innovative light-weight car design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef]

- Obiedkov, A.M.; Kaverin, B.S.; Egorov, V.A.; Semenov, N.M.; Ketkov, S.Y.; Domrachev, G.A.; Kremlev, K.V.; Gusev, S.A.; Perevezentsev, V.N.; Moskvichev, A.N.; et al. Macroscopic cylinders on the basis of radial-oriented multi-wall carbon nanotubes. Lett. Mater. 2012, 2, 152–156. [Google Scholar] [CrossRef]

- Kremlev, K.V.; Ob’’edkov, A.M.; Ketkov, S.Y.; Kaverin, B.S.; Semenov, N.M.; Gusev, S.A.; Tatarskii, D.A.; Yunin, P.A. Pyrolytic deposition of nanostructured titanium carbide coatings on the surface of multiwalled carbon nanotubes. Tech. Phys. Lett. 2016, 42, 517–519. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Kallip, K.; Leparoux, M.; AlOgab, K.A.; Clerc, S.; Deguilhem, G.; Arroyo, Y.; Kwon, H. Investigation of different carbon nanotube reinforcements for fabricating bulk AlMg5 matrix nanocomposites. J. Alloy. Compd. 2015, 646, 710–718. [Google Scholar] [CrossRef]

- Rhee, S.K. Wetting of ceramics by liquid aluminum. J. Am. Ceram. Soc. 1970, 53, 386–389. [Google Scholar] [CrossRef]

- Landry, K.; Kalogeropoulou, S.; Eustathopoulos, N. Wettability of carbon by aluminum and aluminum alloys. Mater. Sci. Eng. A 1998, 254, 99–111. [Google Scholar] [CrossRef]

- Deng, C.F.; Wang, D.Z.; Zhang, X.X.; Li, A.B. Processing and properties of carbon nanotubes reinforced aluminum composites. Mater. Sci. Eng. A 2007, 444, 138–145. [Google Scholar] [CrossRef]

- Perez-Bustamante, R.; Estrada-Guel, I.; Antunez-Flores, W.; Miki-Yoshida, M.; Ferreira, P.J. Martinez-Sanchez, R. Novel Al-matrix nanocomposites reinforced with multi-walled carbon nanotubes. J. Alloy. Compd. 2008, 450, 323–326. [Google Scholar] [CrossRef]

- Kwon, H.; Estili, M.; Takagi, K.; Miyazaki, T.; Kawasaki, A. Combination of hot extrusion and spark plasma sintering for producing carbon nanotube reinforced aluminum matrix composites. Carbon 2009, 47, 570–577. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Jia, L.; Li, S.; Umeda, J.; Takahashi, M.; Kondoh, K. Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater. 2017, 140, 317–325. [Google Scholar] [CrossRef]

- Bradbury, C.R.; Gomon, J.-K.; Kollo, L.; Kwon, H.; Leparoux, M. Hardness of Multi Wall Carbon Nanotubes reinforced aluminium matrix composites. J. Alloy. Compd. 2014, 585, 362–367. [Google Scholar] [CrossRef]

- Poirier, D.; Gauvin, R.; Drew, R.A.L. Structural characterization of a mechanically milled carbon nanotube/aluminum mixture. Compos. Part A 2009, 40, 1482–1489. [Google Scholar] [CrossRef]

- Delhaes, P.; Couzi, M.; Trinquecoste, M.; Dentzer, J.; Hamidou, H.; Vix-Guterl, C. A comparison between Raman spectroscopy and surface characterizations of multiwall carbon nanotubes. Carbon 2006, 44, 3005–3013. [Google Scholar] [CrossRef]

- Stein, J.; Lenczowski, B.; Anglaret, E.; Fréty, N. Influence of the concentration and nature of carbon nanotubes on the mechanical properties of AA5083 aluminium alloy matrix composites. Carbon 2014, 77, 44–52. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Khor’kov, K.S.; Ob’edkov, A.M.; Kremlev, K.V.; Izobello, A.Y.; Volochko, A.T.; Alymov, M.I. Evolution of Multiwalled Carbon Nanotubes and Related Nanostructures during the Formation of Alumomatrix Composite Materials. Tech. Phys. Lett. 2019, 45, 20–23. [Google Scholar] [CrossRef]

- Kwon, H.; Park, D.H.; Silvain, J.F.; Kawasaki, A. Investigation of carbon nanotube reinforced aluminum matrix composite materials. Compos. Sci. Technol. 2010, 70, 546–550. [Google Scholar] [CrossRef]

- Kallip, K.; Babu, N.K.; AlOgab, K.A.; Kollo, L.; Maeder, X.; Arroyo, Y.; Leparoux, M. Microstructure and mechanical properties of near net shaped aluminium/alumina nanocomposites fabricated by powder metallurgy. J. Alloy. Compd. 2017, 714, 133–143. [Google Scholar] [CrossRef]

- Balog, M.; Hu, T.; Krizik, P.; Riglos, M.V.C.; Saller, B.D.; Yang, H.; Schoenung, J.M.; Lavernia, E.J. On the thermal stability of ultrafine-grained Al stabilized by in-situ amorphous Al2O3 network. Mat. Sci. Eng. A 2015, 648, 61–71. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Akhmadeev, N.A.; Kobelev, N.P.; Mulyukov, R.R.; Soifer, Y.M.; Valiev, R.Z. The effect of heat treatment on the elastic and dissipative properties of copper with the submicrocrystalline structure. Acta Metall. Mater. 1993, 41, 1041–1046. [Google Scholar] [CrossRef]

| Ref. Name | Reinforcement | Process Control Agent |

|---|---|---|

| A_un (unmilled) | – | – |

| A_0.05CNT | 0.05 wt % MWCNTs | 0.2 wt % |

| A_0.05TiC/CNT | 0.05 wt % TiC/MWCNTs | 0.2 wt % |

| Ref. Name | Powder | Bulk | ||||

|---|---|---|---|---|---|---|

| Microhardness (GPa) | Elastic Modulus (GPa) | Relative Density (%) | Microhardness (GPa) | Elastic Modulus (GPa) | Oxygen Content (wt %) | |

| A_un (unmilled) | – | – | 98.19 | 0.68 | 72.3 | 0.05 |

| A_0.05CNT | 2.08 | 75.6 | 98.83 | 1.03 | 86.8 | 0.15 |

| A_0.05TiC/CNT | 2.06 | 71.1 | 97.34 | 1.09 | 96.7 | 0.12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aborkin, A.; Khorkov, K.; Prusov, E.; Ob’edkov, A.; Kremlev, K.; Perezhogin, I.; Alymov, M. Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles. Nanomaterials 2019, 9, 1596. https://doi.org/10.3390/nano9111596

Aborkin A, Khorkov K, Prusov E, Ob’edkov A, Kremlev K, Perezhogin I, Alymov M. Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles. Nanomaterials. 2019; 9(11):1596. https://doi.org/10.3390/nano9111596

Chicago/Turabian StyleAborkin, Artemiy, Kirill Khorkov, Evgeny Prusov, Anatoly Ob’edkov, Kirill Kremlev, Igor Perezhogin, and Michail Alymov. 2019. "Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles" Nanomaterials 9, no. 11: 1596. https://doi.org/10.3390/nano9111596

APA StyleAborkin, A., Khorkov, K., Prusov, E., Ob’edkov, A., Kremlev, K., Perezhogin, I., & Alymov, M. (2019). Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles. Nanomaterials, 9(11), 1596. https://doi.org/10.3390/nano9111596